Environment-friendly high-performance antiwear agent

A high-performance, environmentally friendly technology, used in additives, petroleum industry, lubricating compositions, etc., can solve problems such as electrochemical corrosion of alloy bearings, clogging of filter systems, catalyst poisoning, etc., to achieve good corrosion resistance, good oil solubility, The effect of excellent extreme pressure performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The environment-friendly high-performance anti-wear agent, in parts by weight, its preparation raw materials include: 100 parts of sulfonated graphene, 10 parts of terpineyl acetate, 5 parts of nano-molybdenum disulfide, 15 parts of sodium tetradecylbenzenesulfonate, 60 parts of D70 solvent naphtha. The sulfonation degree of the sulfonated graphene is 1%, and the particle diameter of the nano molybdenum disulfide is 80nm.

[0065] The preparation method of the environment-friendly high-performance antiwear agent is as follows: 100 parts by weight of sulfonated graphene, 10 parts by weight of terpineol acetate, 5 parts by weight of nano-molybdenum disulfide, 15 parts by weight of sodium tetradecylbenzenesulfonate, 60 parts by weight of D70 solvent oil were mixed in a reaction kettle, stirred for 30 minutes, and obtained.

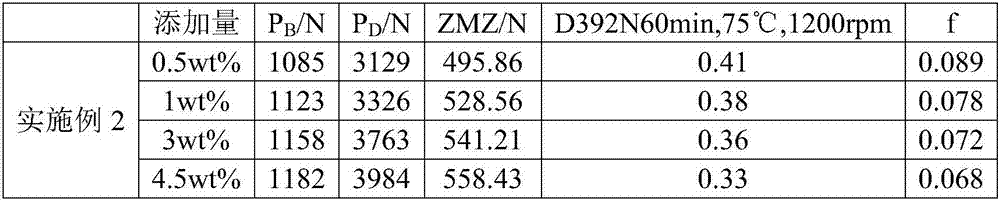

Embodiment 2

[0067] The environment-friendly high-performance anti-wear agent, in parts by weight, its preparation raw materials include: 100 parts of sulfonated graphene, 10 parts of terpineyl acetate, 5 parts of nano-molybdenum disulfide, 15 parts of sodium tetradecylbenzenesulfonate, 60 parts of D70 solvent naphtha. The sulfonation degree of the sulfonated graphene is 3%, and the particle diameter of the nano molybdenum disulfide is 80nm.

[0068] The preparation method of the environment-friendly high-performance antiwear agent is as follows: 100 parts by weight of sulfonated graphene, 10 parts by weight of terpineol acetate, 5 parts by weight of nano-molybdenum disulfide, 15 parts by weight of sodium tetradecylbenzenesulfonate, 60 parts by weight of D70 solvent oil were mixed in a reaction kettle, stirred for 30 minutes, and obtained.

Embodiment 3

[0070] The environment-friendly high-performance anti-wear agent, in parts by weight, its preparation raw materials include: 100 parts of sulfonated graphene, 10 parts of terpineyl acetate, 5 parts of nano-molybdenum disulfide, 15 parts of sodium tetradecylbenzenesulfonate, 60 parts of D70 solvent naphtha. The sulfonation degree of the sulfonated graphene is 5%, and the particle diameter of the nano molybdenum disulfide is 80nm.

[0071] The preparation method of the environment-friendly high-performance antiwear agent is as follows: 100 parts by weight of sulfonated graphene, 10 parts by weight of terpineol acetate, 5 parts by weight of nano-molybdenum disulfide, 15 parts by weight of sodium tetradecylbenzenesulfonate, 60 parts by weight of D70 solvent oil were mixed in a reaction kettle, stirred for 30 minutes, and obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com