Method for synthesizing ultrathin molybdenum disulfide nanocrystals

A nanocrystalline and molybdenum sulfide technology, which is applied in the direction of molybdenum sulfide, nanotechnology, nanotechnology, etc., can solve the problems of poor crystallization of molybdenum disulfide, unfavorable popularization and use, and low yield, and achieve good crystallization, excellent oil solubility, and dispersibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

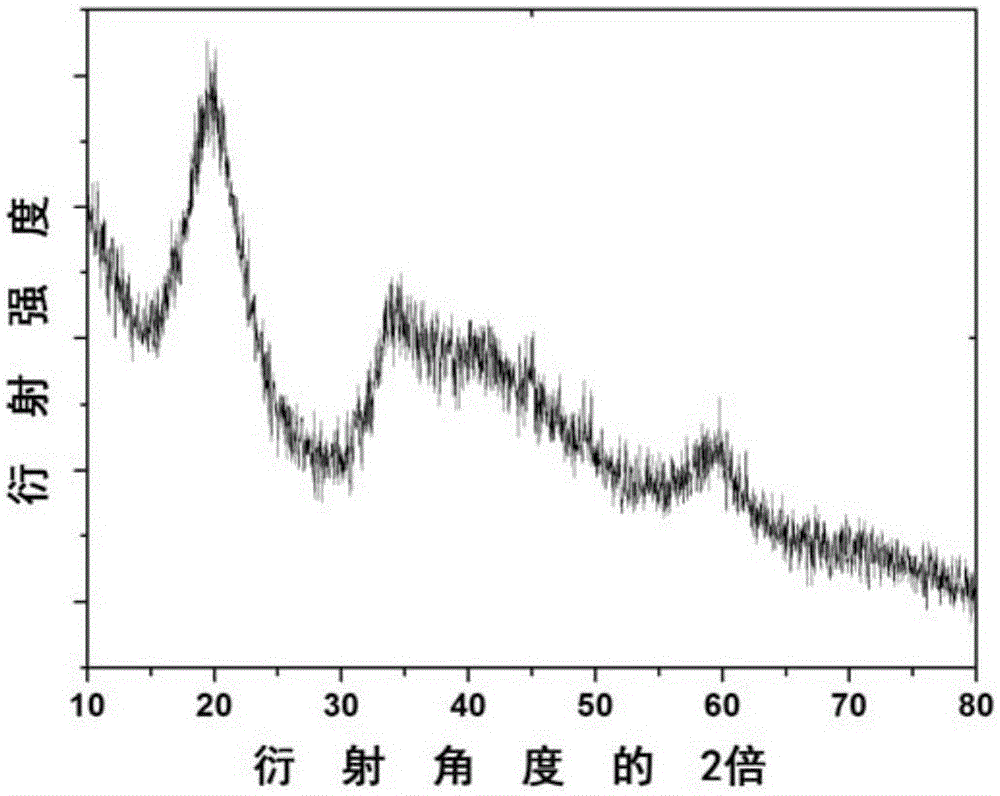

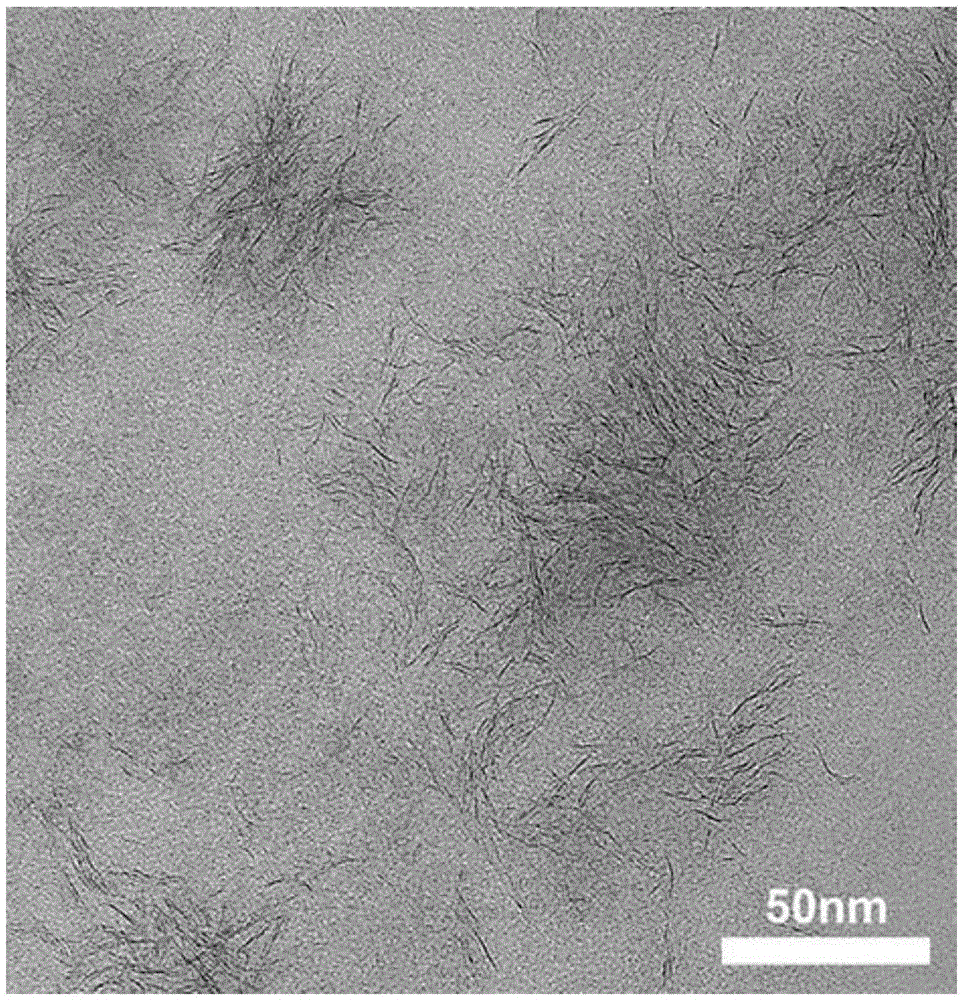

[0022] Get 10ml of oleylamine and 1ml of oleic acid and heat to 160°C, put ammonium molybdate and thiourea with a molar ratio of 1:10 and a total mass of 0.1g, react for 30 minutes, and pour out the mixed solvent of oleylamine and oleic acid. The obtained precipitate was washed with ethanol and dried at 40 °C to obtain ultrathin molybdenum disulfide nanocrystals with few atomic layers. The obtained products were all characterized by XRD and transmission electron microscopy. Its powder X-ray diffraction spectrum is attached figure 1 shown. Its transmission electron microscope photo is attached figure 2 shown, where the synthesized MoS 2 Most MoS is 1-5 atomic layers 2 Nanocrystalline.

Embodiment 2

[0024] Get 10ml of oleylamine and 1g of sodium oleate and heat to 300°C, put in the ammonium molybdate and thiourea that the molar ratio is 1:5 and the total mass is 20g, react for 120 minutes, pour out the oleylamine and wash the resulting precipitate with ethanol , and dried at 40 °C to obtain ultra-thin molybdenum disulfide nanocrystals with a few atomic layers. The obtained products were all characterized by XRD and transmission electron microscopy.

Embodiment 3

[0026] Get 10ml of octadecylamine and 5ml of oleic acid and heat to 240°C, put ammonium molybdate and thiourea with a molar ratio of 5:2 and a total mass of 5g, react for 60 minutes, and pour out the mixed solvent of oleylamine and oleic acid. The obtained precipitate was washed with ethanol and dried at 40 °C to obtain ultrathin molybdenum disulfide nanocrystals with few atomic layers. The obtained products were all characterized by XRD and transmission electron microscopy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com