Fatty polyol dimer and its prepn process and application in foamed polyurethane plastic

A technology of dimerization of fatty acid methyl ester and dimerization of fatty acid, applied in the field of organic polymer compounds, can solve the problems of heat resistance, strength and tear resistance that cannot meet the requirements of technological development, and achieve good thermal insulation and good resistance. Thermal performance, good strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

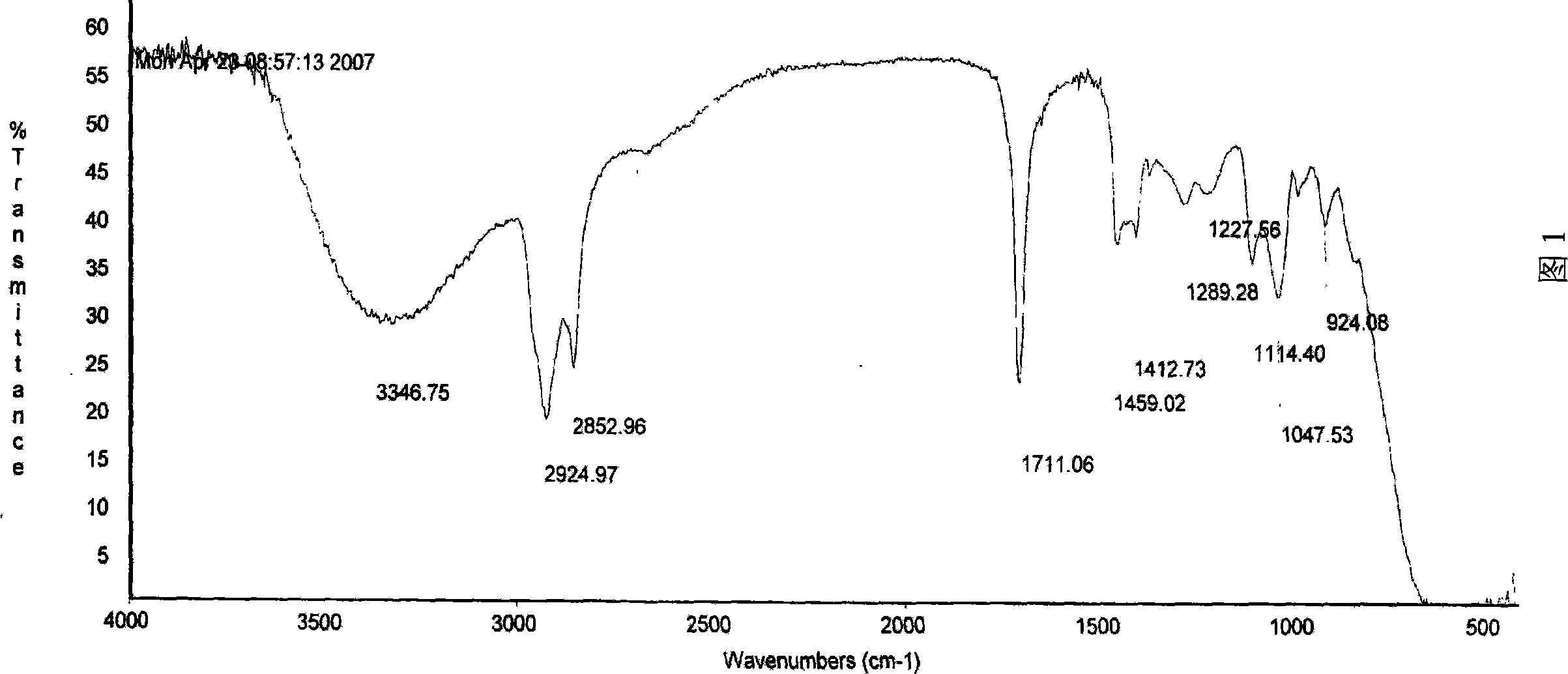

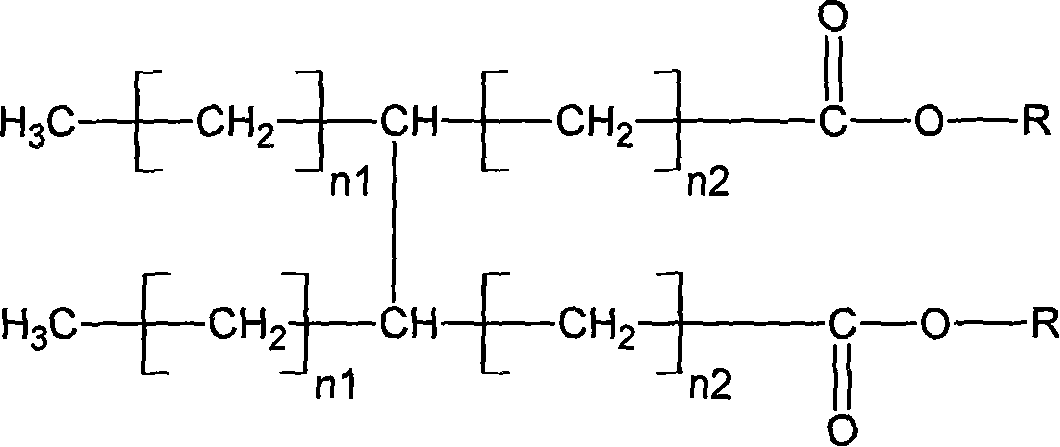

[0023] A dimer fatty acid polyol has the following chemical structural formula:

[0024]

[0025] Among them, n1=1~12;

[0026] n2=1~10;

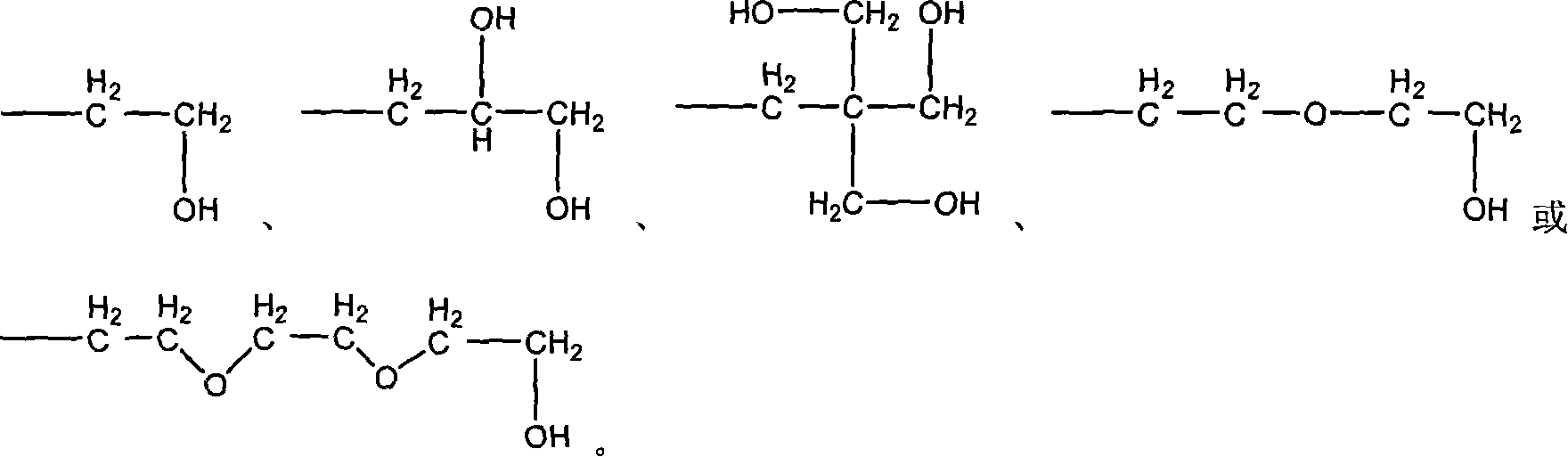

[0027] R =

[0028]

[0029] A method for preparing dimerized fatty acid polyols. The preparation steps are as follows: alcoholysis of fresh or discarded vegetable oils by conventional techniques to obtain fatty acid methyl esters, alcoholysis of oils and recovered oils:

[0030]

[0031] The fatty acid methyl ester obtained in the previous step is thermally polymerized through conventional techniques, and the fatty acid monoester with low boiling point is removed by distillation to obtain dimer fatty acid methyl ester (more than 95% in purity), and fatty acid thermal polymerization reaction:

[0032]

[0033]Add the dimerized fatty acid methyl ester to the polyol, wherein the mass ratio of the dimerized fatty acid methyl ester to the polyol is 1:1 to 4, and simultaneously add 0.1 to 3% zinc oxide of the dimerized fatt...

Embodiment 2

[0035] Preparation of dimerized fatty acid polyol: Add the obtained dimerized fatty acid methyl ester into ethylene glycol, glycerin, pentaerythritol, diethylene glycol, triethylene glycol, etc., take one or more of them and mix them. The amount is 1:1-4 parts by mass, while adding zinc oxide of 0.1-3% by mass of dimer fatty acid methyl ester, heating at 100-220°C for transesterification reaction, during the reaction process, the methanol generated by the reaction is continuously distilled out, 2 When no methanol is distilled after -5 hours, the reaction is stopped, and the excess alcohol in the reactant is recovered by distillation under reduced pressure at 100-200° C. / 10-30 mmHg to obtain a dimerized fatty acid polyol. Sampling analysis shows that the hydroxyl value is 350-600KOHmg / g; the viscosity (25°C) is 400-2000mpa.s.

Embodiment 3

[0037] The preparation of dimerized fatty acid polyol: add the obtained dimerized fatty acid methyl ester to ethylene glycol, the amount added is 1: 1 mass parts, add the zinc oxide of dimerized fatty acid methyl ester quality 0.1% at the same time, carry out heating at 170 ℃ During the transesterification reaction, the methanol produced by the reaction is continuously distilled out. When no methanol is distilled out after 2 hours, the reaction is stopped, and the excess alcohol in the reactant is recovered by distillation under reduced pressure at 100°C / 30mmHg to obtain dimer fatty acid Polyol. Sampling analysis shows that the hydroxyl value is 500KOHmg / g; the viscosity (25°C) is 2000mpa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com