A slice tobacco processing method for improving the use value of raw materials by using a redrying production line

A technology of use value and processing method, which is applied in the fields of application, tobacco, and tobacco preparation, can solve the problems of uneven quality grades of stock tobacco, impact of formula and cigarette quality, unreasonable quality structure of tobacco leaf raw materials, etc., and achieve chemical The effect of coordination of ingredient content, improvement of sensory quality, and reduction of large film rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

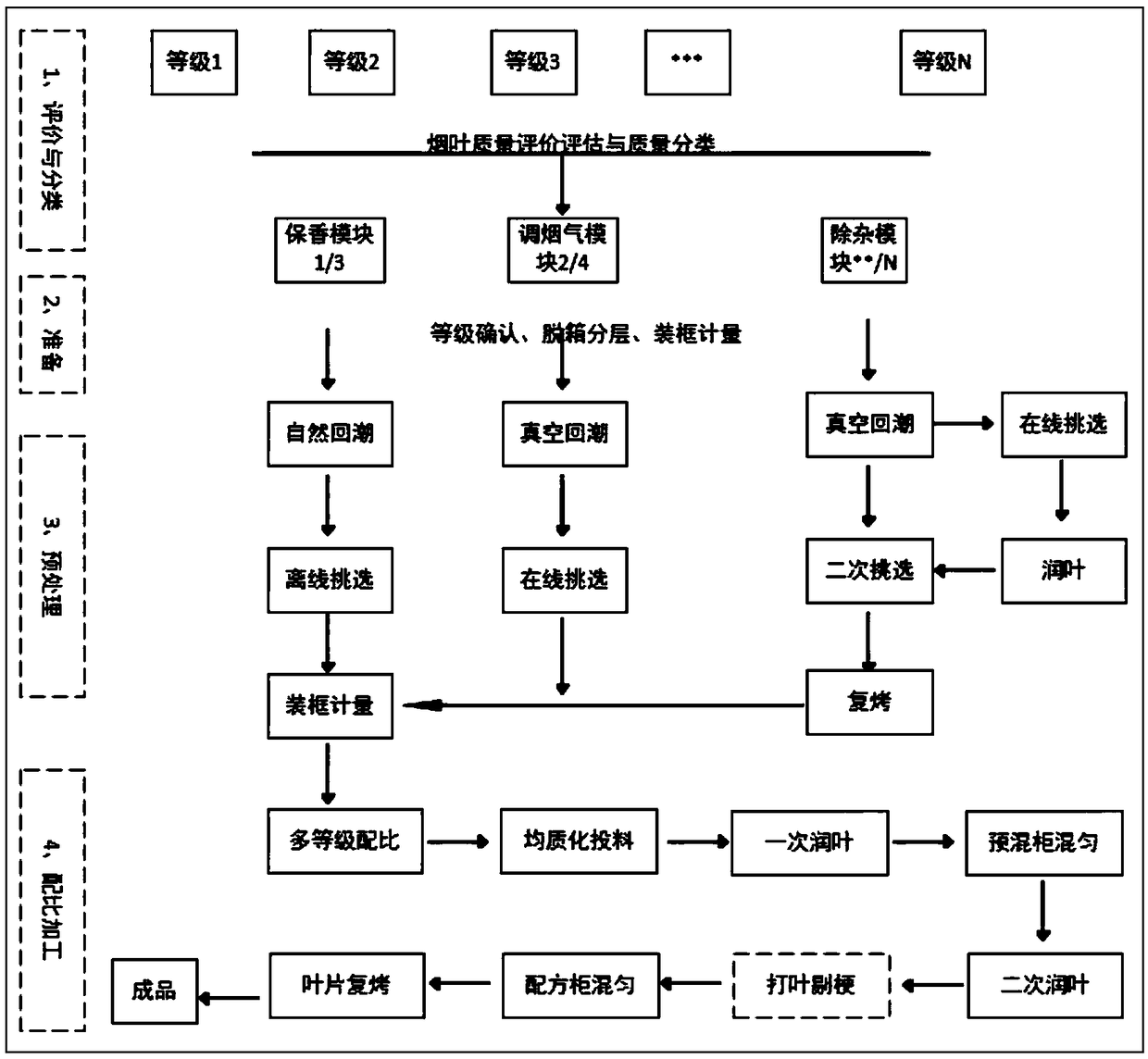

[0028] The technical solutions in the present invention will be clearly and completely described below in conjunction with the drawings and specific embodiments of the present invention.

[0029] A method for processing laminar tobacco using a redrying production line to increase the use value of raw materials, comprising the following steps:

[0030] The first step: quality assessment and evaluation of tobacco grades.

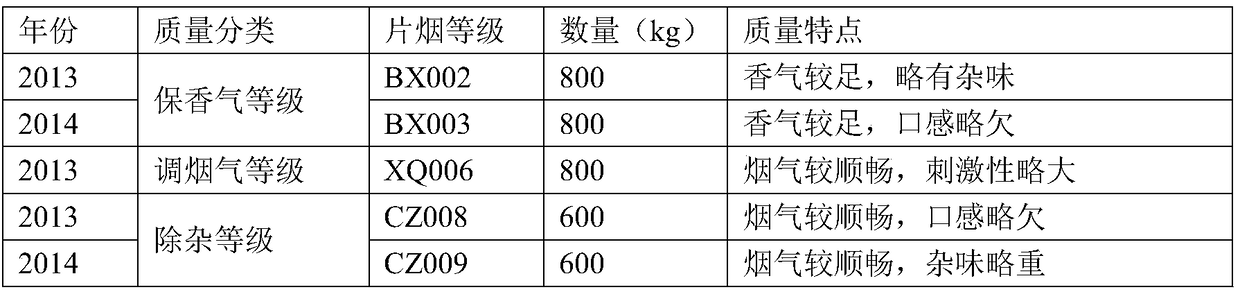

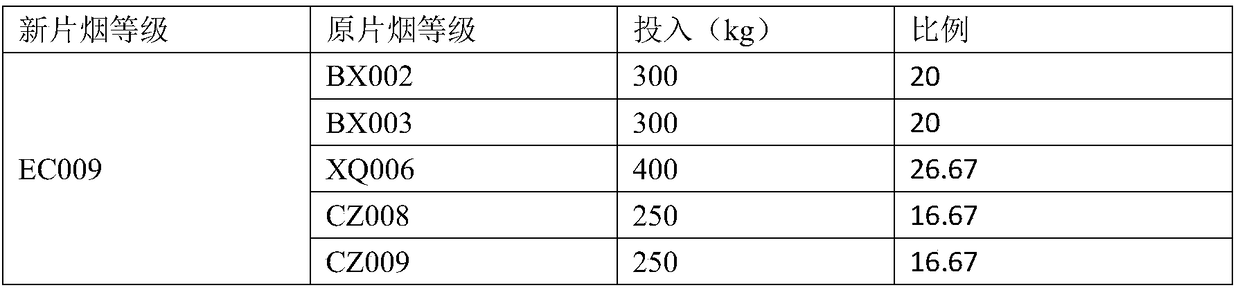

[0031] Evaluate the quality of the grades of tobacco that need to be processed, and divide them into three categories: aroma-preserving grades, smoke-adjusting grades, and impurity-removing grades, and determine the technical methods such as moisture regain and leaf selection for pretreatment.

[0032] The second step: raw material preparation stage.

[0033] Raw material preparation mainly includes tobacco grade confirmation, unboxing, layering, and framing. For the stock grade tobacco that needs to be processed, remove the cigarette case by case, manually ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com