Ultraviolet cured offset printing ink

An offset printing ink and ultraviolet light technology, applied in the field of printing ink, can solve the problems affecting the printing quality of high-end packaging products, difficult to adjust the ink properties, difficult to adapt to the printing process, etc., to achieve bright and sticky appearance, excellent physical performance indicators, Excellent ink properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: 45Kg epoxy resin ink prepolymer, 2Kg 2, or 4-isopropyl thioxanthone, 3Kg p-dimethylaminobenzoic acid ethyl ester, 0.5Kg p-hydroxybenzoic acid under room temperature condition Ether and 8Kg of tripropylene glycol diacrylate are mixed evenly in a container, and then 12Kg of titanium dioxide pigment with a fineness of ≤20um and 2.5Kg of calcium carbonate with a fineness of ≤20um are added in turn, and fully stirred to make the above materials fully mixed evenly.

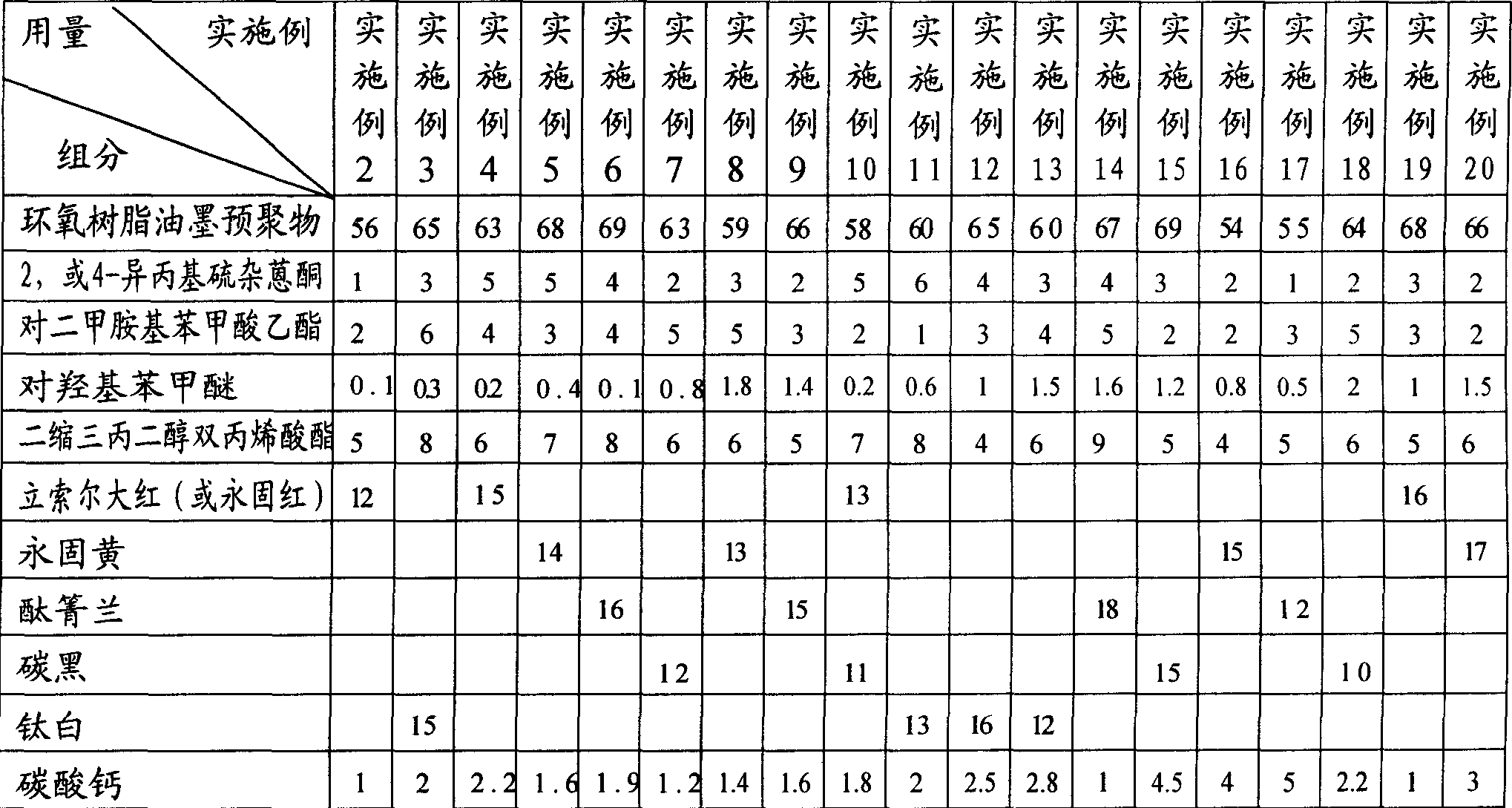

[0026] The difference between other embodiments and embodiment 1 is shown in the table below:

[0027] Unit: (Kg)

[0028]

[0029] The fineness of solid materials such as pigments and additives in the above embodiments is ≤20um.

[0030] After measurement, the fluidity of the UV-curable offset printing ink prepared in the above examples is: 20-35mm / room temperature, viscosity: 100-300pa.s / 30°C, drying time: 150-800s / room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com