Blue-ray curing formula and textile digital functional finishing method utilizing same

A technology of textiles and blue light, which is applied in the direction of textiles and papermaking, application, dyeing, etc., and can solve problems such as complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] For a circular polyester-cotton fabric (cotton / polyester: 60 / 40, warp and weft yarn density 45tex×45tex) with a diameter of 10cm and a weight of 3g, the blue light curing formula of the present invention is used for digital functional finishing, and benzotriazole is used as Anti-ultraviolet finishing agent, the dosage of benzotriazole to fabric is 1% (owf), namely 0.03g.

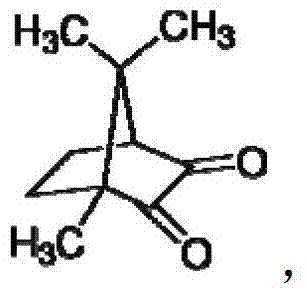

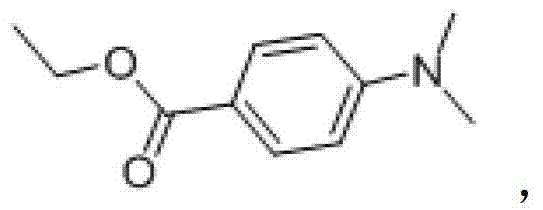

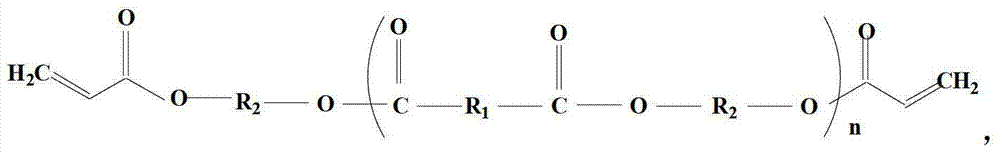

[0065] ⑴ Accurately weigh 0.01g CQ and 0.01g EDB, add 0.8g TPGDA, ultrasonically disperse until the solids are fully dissolved, add 1.2g PEA, continue ultrasonically disperse, and wait until the reaction solution is fully mixed to obtain a transparent and clear oily liquid that is the blue light curing reaction liquid.

[0066] (2) Dilute 2g of the blue-light curing reaction solution with 10g of acetone to obtain the diluted solution, pipette 3mL of the diluted solution, and then add 0.03g of benzotriazole anti-ultraviolet finishing agent to obtain the blue-light curing and finishing solution, the ben...

Embodiment 2

[0069] Concrete scheme is with embodiment 1, and difference is:

[0070] ⑴ Accurately weigh 0.01g CQ and 0.01g EDB, add 0.8g IBOMA, ultrasonically disperse until the solids are fully dissolved, add 1.2g PEA, continue ultrasonically disperse, and wait until the reaction solution is fully mixed to obtain a transparent and clear oily liquid that is the blue light curing reaction liquid.

Embodiment 3

[0072] Concrete scheme is with embodiment 1, and difference is:

[0073] ⑴ Accurately weigh 0.01g CQ and 0.01g EDB, add 0.4g TPGDA, ultrasonically disperse until the solid is fully dissolved, add 1.6g aliphatic PUA, continue ultrasonically disperse, and wait until the reaction solution is fully mixed to obtain a transparent and clear oily liquid that is blue light curing The reaction solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com