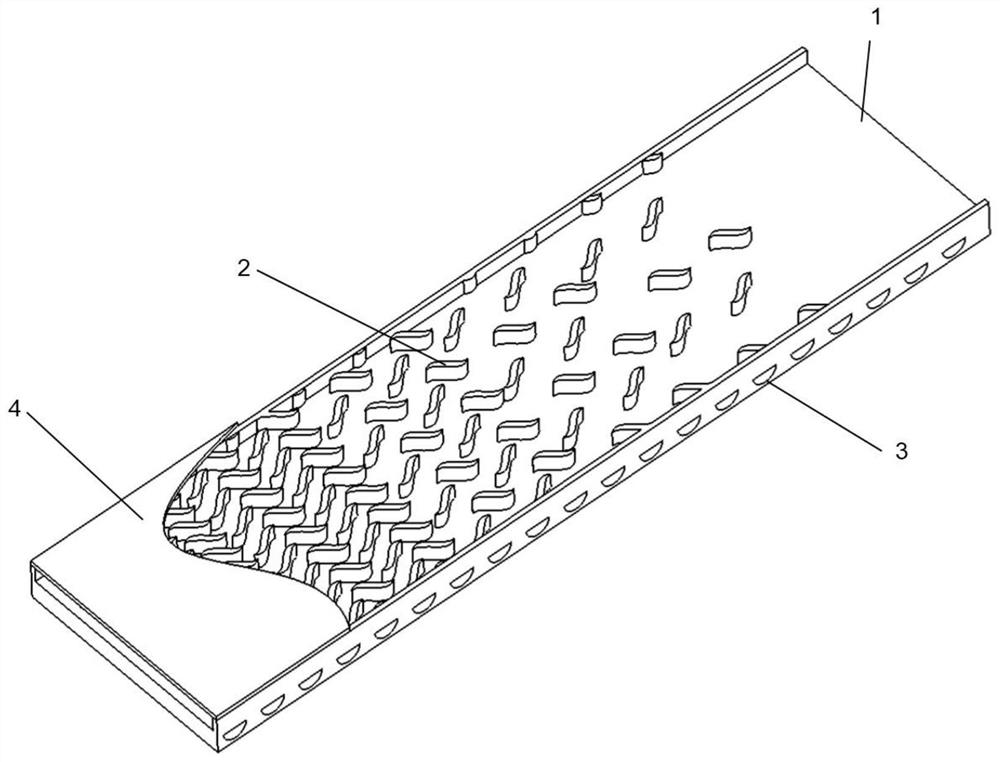

Self-adaptive non-uniform fin plate bundle for heat exchanger and design method of flow channel thereof

A finned plate, non-uniform technology, applied in the field of adaptive non-uniform finned plate bundle and its flow channel design for heat exchangers, to achieve the effects of ensuring service life, improving heat exchange capacity, and increasing heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to enable those skilled in the art to better understand the technical solution of the present invention, the specific implementation manners of the present invention will be clearly and completely described below according to the accompanying drawings.

[0039] In this embodiment, the heat exchanger required for LNG gasification is taken as an example for illustration.

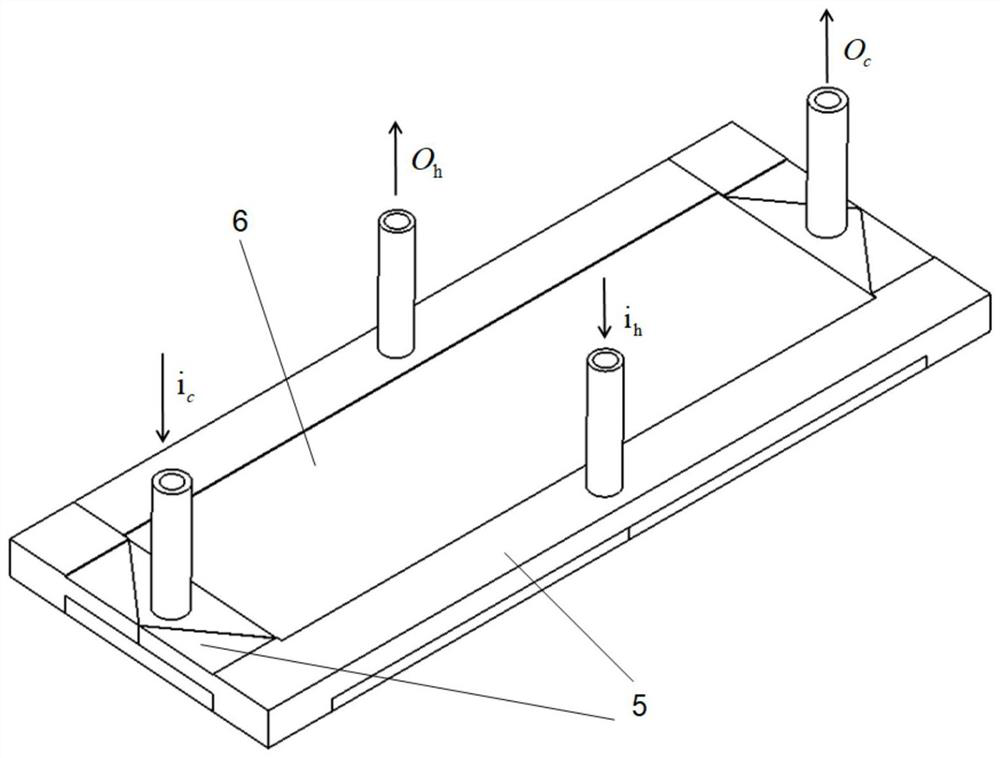

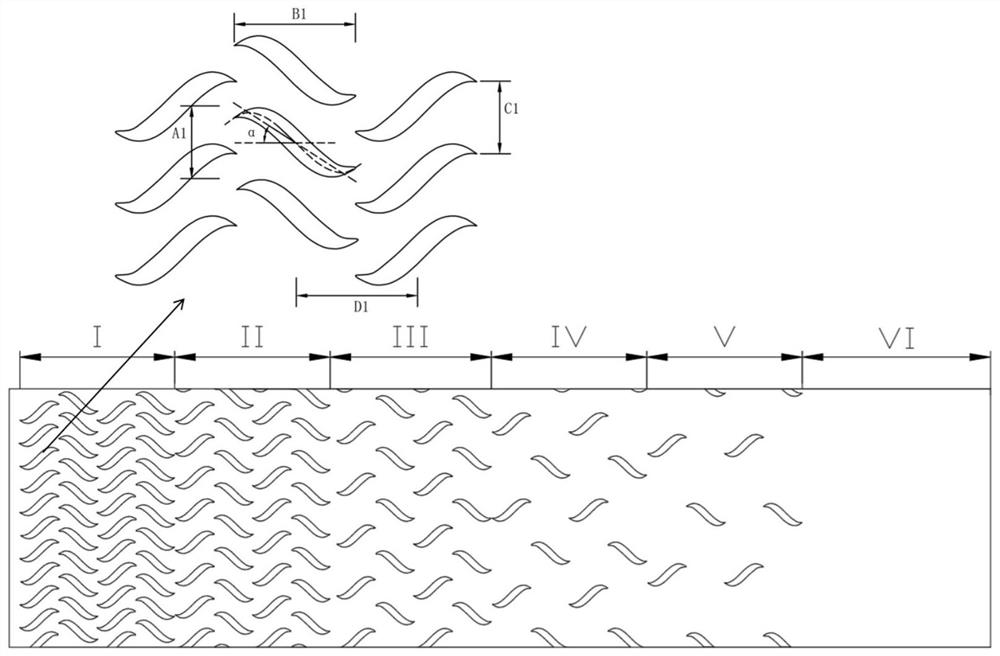

[0040] Such as image 3 , Figure 7 As shown, a heat exchanger with self-adaptive non-uniform finned plate bundle and its flow channel design method includes the following steps:

[0041] Step 1: According to the required pressure p, temperature t, and flow G of the cold fluid inlet and outlet channels, and because the LNG gasification process is carried out at sea, the required heat exchanger should be as compact as possible, so the fin type in the cold runner adopts snake shape structure;

[0042] Step 2: According to the hot and cold fluid flow G and keep the flow velocity v at 2~8m / s, us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com