Construction technique for rebuilding prestressing force system after built prestressing force system destroyed in reinforced concrete structure

A construction technology and prestressing technology, which is applied in the processing of building materials, construction, building maintenance, etc., can solve problems that affect engineering excellence, increase self-weight load, and affect the appearance of the surface, so as not to affect the appearance quality and increase The effect of shortening the load and construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

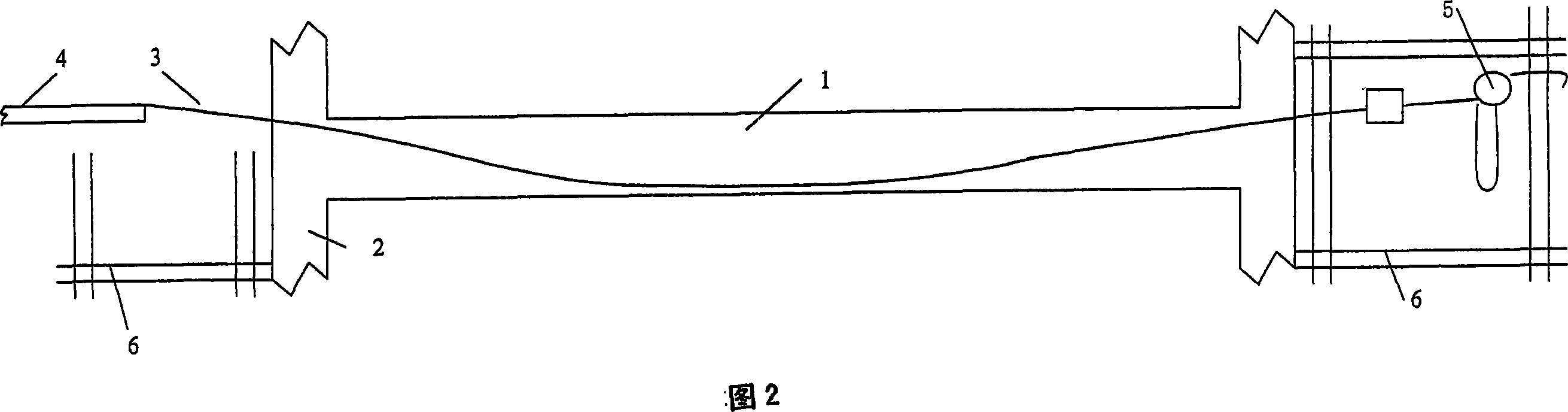

[0019] In Fig. 2, 1 is a frame beam, 2 is a column head, 3 is a steel bar, 4 is a new steel strand, 5 is a chain block, and 6 is an operating platform.

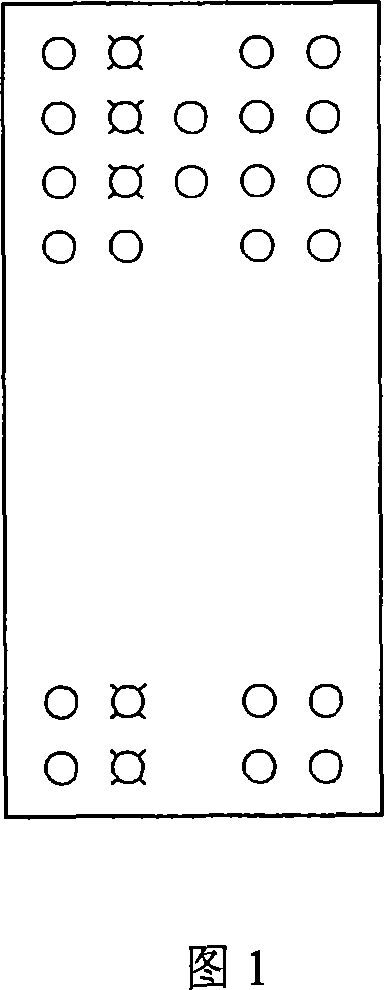

[0020] Referring to Figure 1, The 5 anchors 7 were cut off by wrong construction, of which the upper 3 are tension end anchors (clip type), and the lower 2 are fixed end anchors (P-type extrusion anchors). Because the design is that the tension end and fixed end anchorages in the same beam are arranged in a staggered manner, and one end is tensioned and anchored separately. "○" is a normal anchor 8.

[0021] Referring to Fig. 1 and Fig. 2, the partially damaged original prestressed steel strand anchors 7 are all removed. The new prestressed steel strand 4 with the same specification and strength as the original prestressed steel strand is stripped of the surface plastic sheath. Prepare a steel bar 3 who...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com