Powder concentrator being convenient for fine powder collection

A technology of fine powder collection and powder classifier, which is applied in the direction of separating solids from solids with airflow, dispersing particle filtration, solid separation, etc., which can solve the problems of fine powder waste and dust raising, and achieve the effect of avoiding dust raising

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following is a further detailed description through specific implementations:

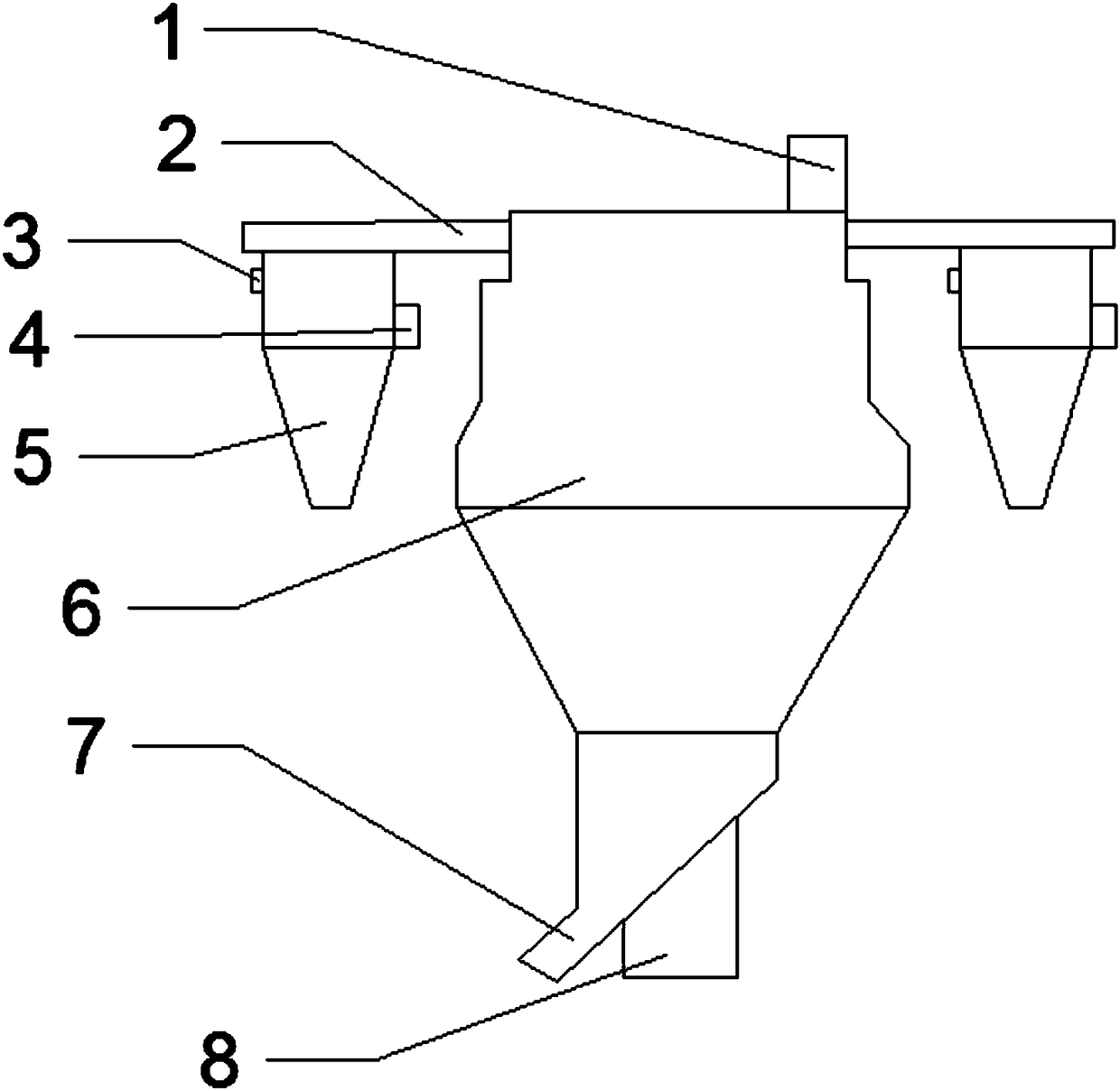

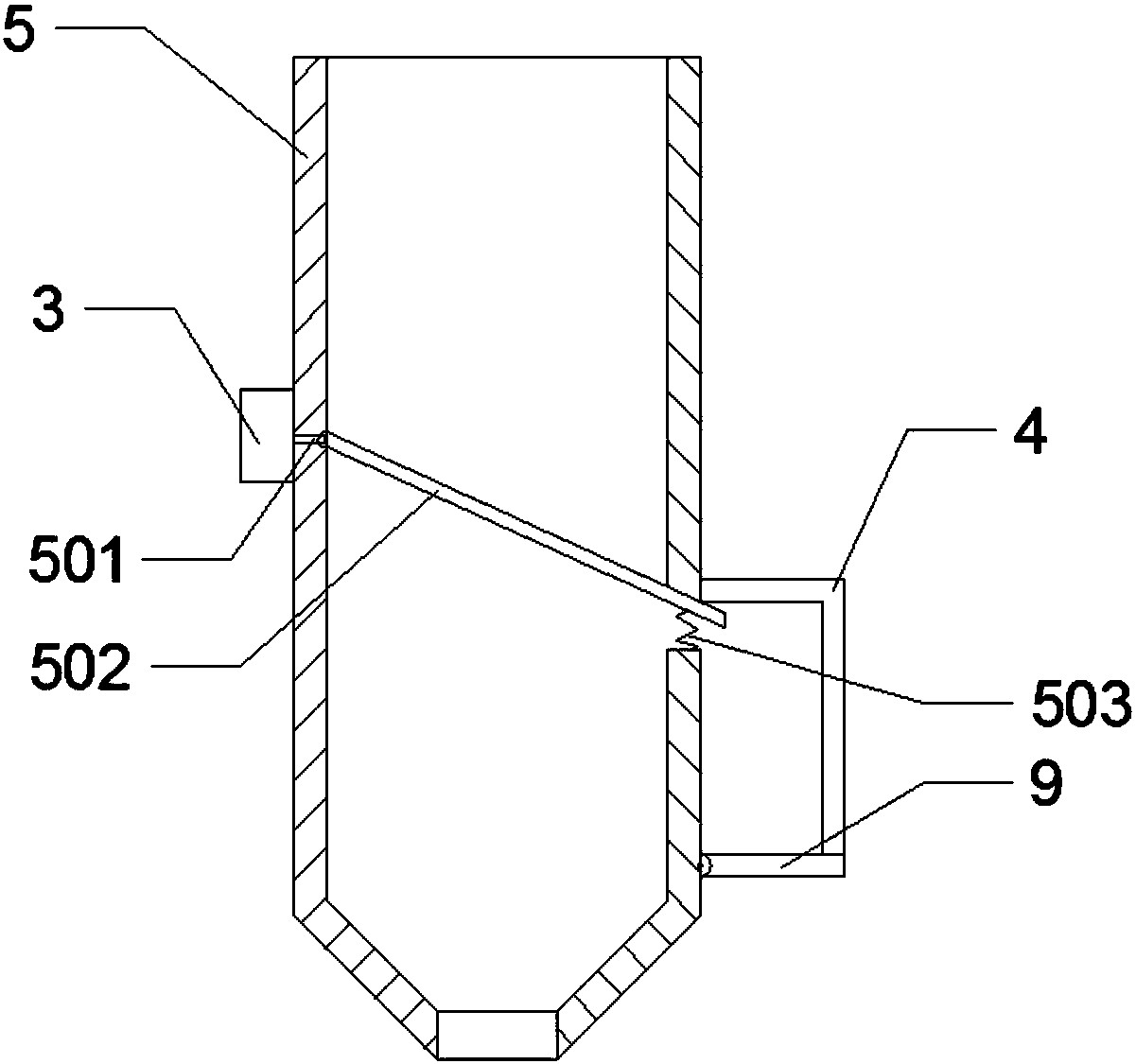

[0012] The reference signs in the drawings of the specification include: transmission device 1, ventilation pipe 2, vibration motor 3, collecting box 4, cyclone 5, output shaft 501, filter plate 502, spring 503, shell 6, coarse powder outlet 7 , Air inlet 8, sealing plate 9.

[0013] The embodiment is basically as attached figure 1 with figure 2 Shown:

[0014] A powder classifier that is convenient for fine powder collection includes a powder classifier body. The powder classifier body includes a transmission device 1, a feeding hopper, a casing 6, a rotor, and a cyclone tube 5. The rotor is located in the casing 6 and the transmission device 1 The output shaft 501 is connected, the shell 6 is connected with the hopper, the top two sides of the shell 6 are respectively connected with the ventilation pipe 2, the bottom end of the shell 6 is welded and connected with the coarse powder outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com