Treatment method for realizing leachate pollutant zero-discharge and recycling

A treatment method and technology for pollutants, applied in water/sewage treatment, chemical instruments and methods, heating water/sewage treatment, etc., can solve the problems of air secondary pollution, non-implementation, secondary pollution, etc., and achieve volume reduction, The effect of low equipment cost and processing cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

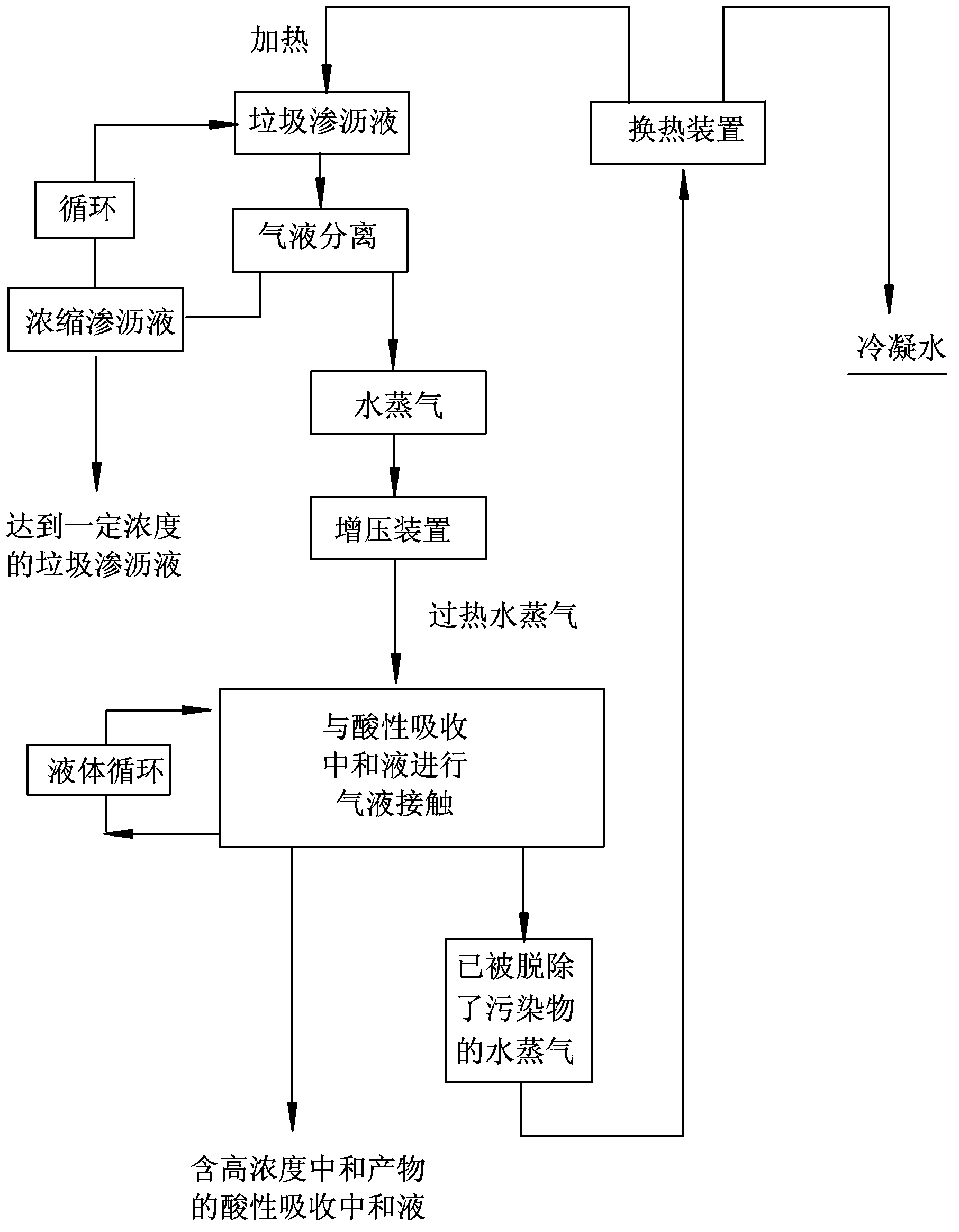

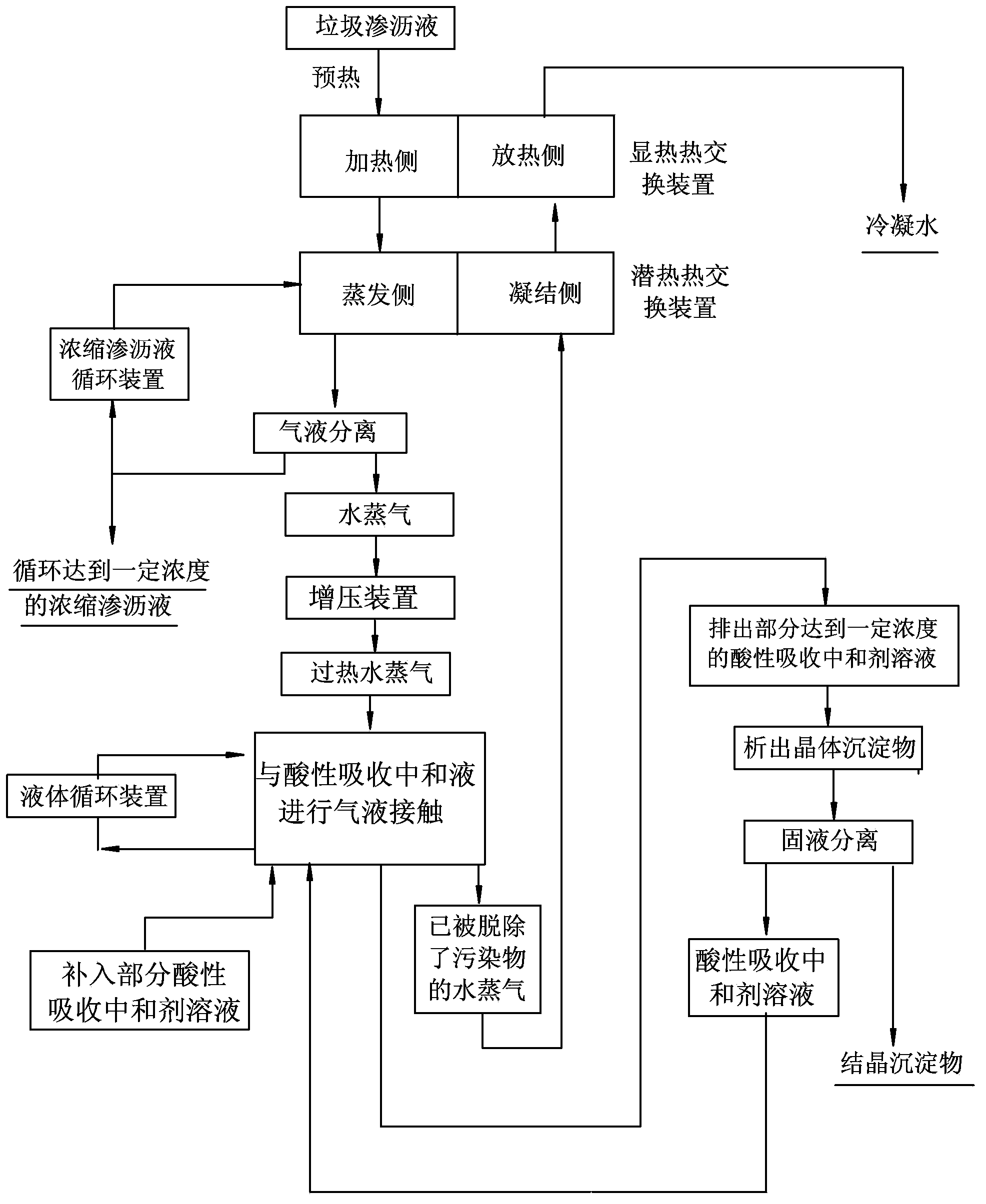

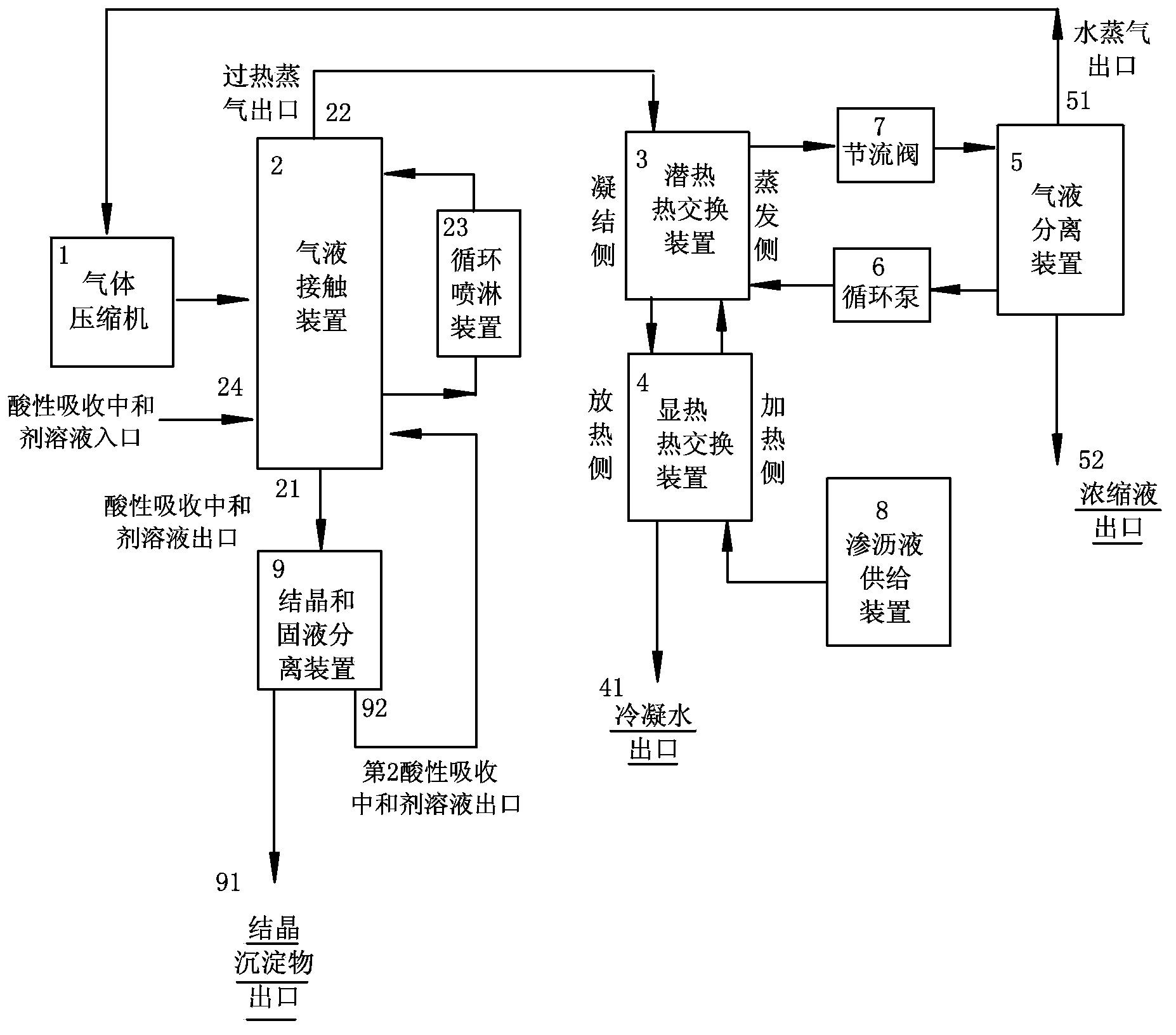

[0039] figure 2 It is the process flow chart of this embodiment, image 3 It is a schematic diagram of the device structure used in the implementation of this embodiment.

[0040] This example is for the treatment of landfill leachate containing low-boiling point gaseous alkaline pollutants.

[0041] The sensible heat exchange device 4 is used to preheat the leachate, and then the latent heat exchange device 3 is used to heat the leachate to generate steam. The process is:

[0042] The leachate pumped by the leachate supply device 8 is heated by the heating side of the sensible heat exchange device 4 and the evaporation side of the latent heat exchange device 3, and then enters the gas-liquid separation device 5 through the throttle valve 7;

[0043] The separated water vapor containing low-boiling point gaseous basic pollutants is output from the water vapor outlet 51 of the gas-liquid separation device 5, passes through the gas compressor 1 to generate superheated steam, ...

Embodiment 2

[0074] Normal pressure operation, acid absorption neutralizer solution is nitric acid aqueous solution, PH=0.2, total dissolved matter concentration 51%, relevant data and purification effect are as follows:

[0075]

[0076]

[0077] The purification effect meets the national standard GB1689-2008 special emission limit and agricultural recycling standard.

Embodiment 3

[0079] Normal pressure operation, the acidic absorption neutralizer solution is a high-boiling organic solvent containing nitric acid aqueous solution, PH=0.3, and the total dissolved matter concentration is 52%. The relevant data and purification effect are as follows:

[0080]

[0081] The purification effect meets the national standard GB1689-2008 special discharge limit and industrial reuse water standard.

[0082] The "total dissolved matter" described in the above-mentioned embodiments 2-3 refers to all dissolved matter in the acidic absorption neutralizing agent solution, including acidic absorption neutralizing agent and absorption of gaseous basic pollutants generated in superheated steam. Volatile soluble salts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com