Vertical Anaerobic Reactor

An anaerobic reactor, vertical technology, used in anaerobic digestion treatment, chemical instruments and methods, biological water/sewage treatment, etc. The requirements of chemical materials, etc., can reduce the construction cost, reduce the hydraulic retention time, and reduce the volume of the tank.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

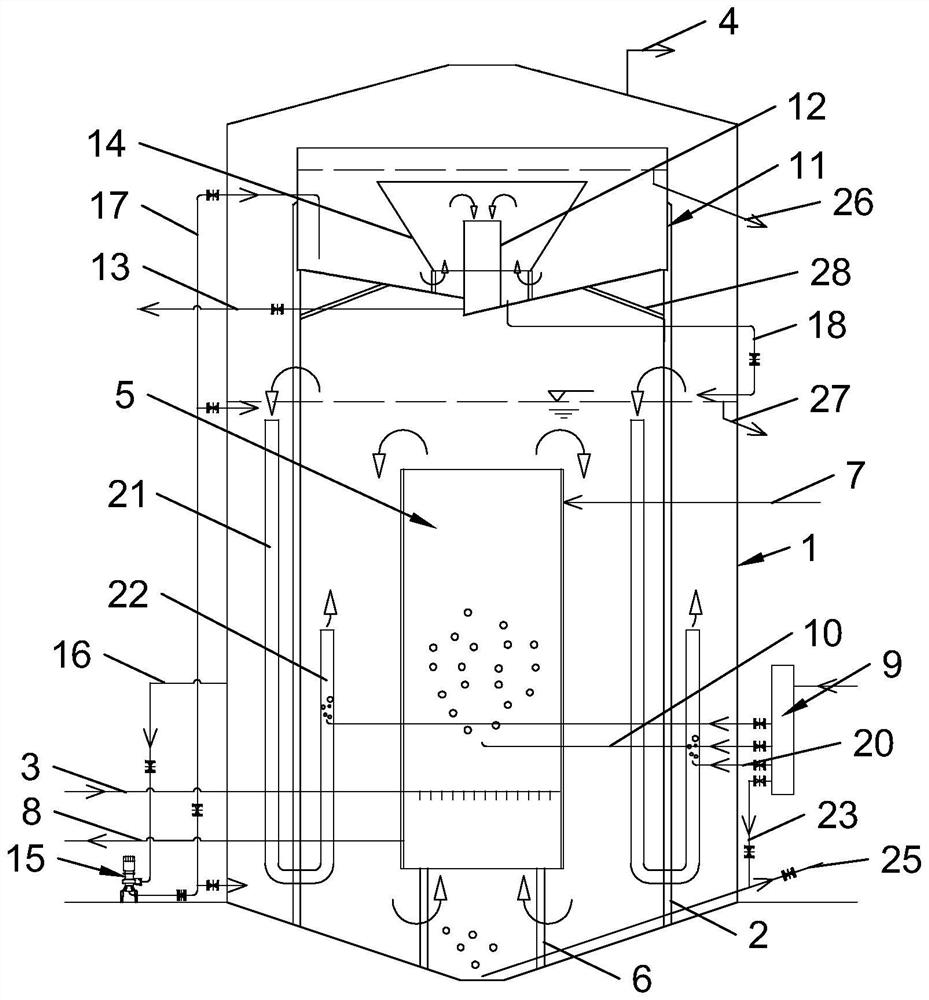

[0030] The present invention will be further described with reference to the accompanying drawings.

[0031] This embodiment discloses a novel vertical anaerobic reactor, such as figure 1 As shown, it includes a tank body 1, a material circulation stirring assembly arranged in the tank body 1, and a biogas slurry separator, and the biogas slurry separator is located above the material circulation stirring assembly, and the biogas slurry separator is fixed on the tank through the first bracket 2 Inside the body 1 and located on the upper part of the tank body 1; wherein, the bottom of the tank body 1 is in an inverted conical shape; the top of the tank body 1 is also in a conical shape, and the bottom of the tank body 1 is in an inverted conical shape, which is conducive to the accumulation of heavy substances. The top of the tank 1 is conical, which is conducive to the accumulation of steam; the tank 1 is provided with a feed pipe 3, and the top of the tank 1 is also provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com