Novel vertical anaerobic reactor

An anaerobic reactor, vertical technology, used in anaerobic digestion treatment, chemical instruments and methods, water treatment parameter control, etc. Material requirements and other issues to achieve the effect of reducing hydraulic retention time, reducing tank volume, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

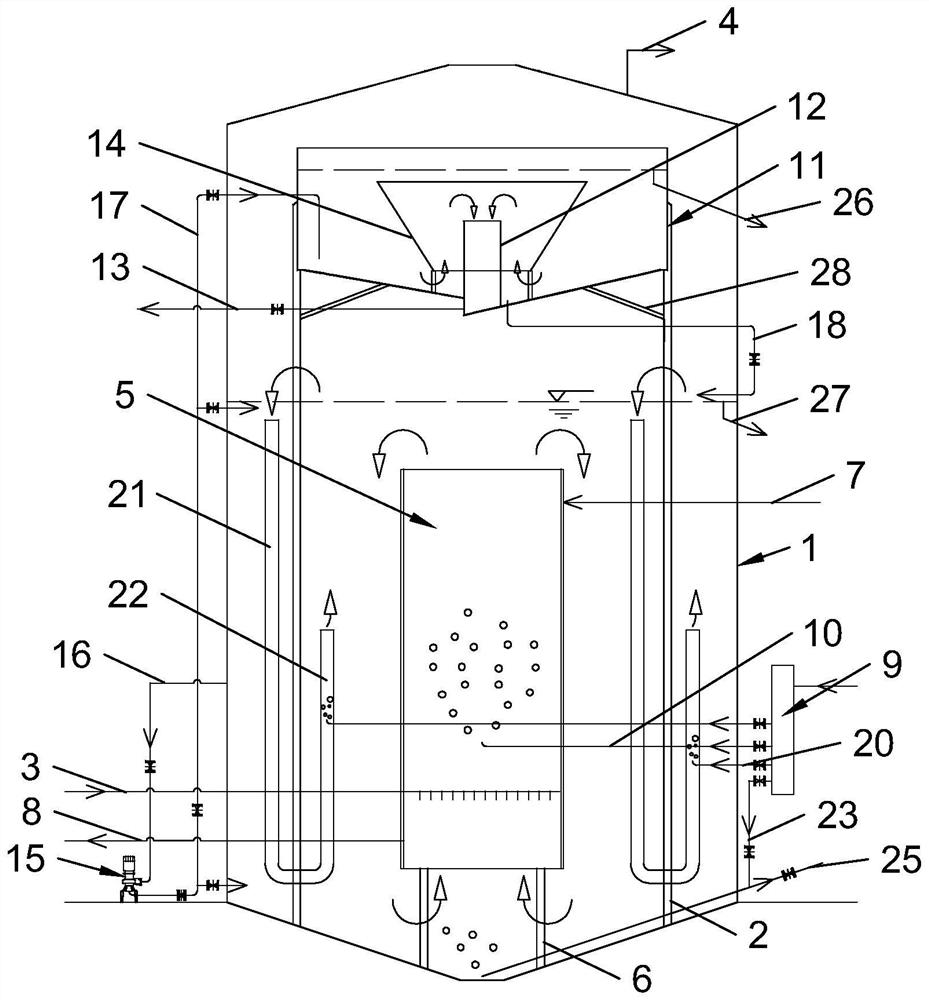

[0030] The present invention will be further described with reference to the accompanying drawings.

[0031] This embodiment discloses a novel vertical anaerobic reactor, such as figure 1 As shown, it includes a tank body 1, a material circulation stirring assembly arranged in the tank body 1, and a biogas slurry separator, and the biogas slurry separator is located above the material circulation stirring assembly, and the biogas slurry separator is fixed on the tank through the first bracket 2 Inside the body 1 and located on the upper part of the tank body 1; wherein, the bottom of the tank body 1 is in an inverted conical shape; the top of the tank body 1 is also in a conical shape, and the bottom of the tank body 1 is in an inverted conical shape, which is conducive to the accumulation of heavy substances. The top of the tank 1 is conical, which is conducive to the accumulation of steam; the tank 1 is provided with a feed pipe 3, and the top of the tank 1 is also provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com