Catalytic adsorption-desorption isomerization method

A technology of isomerization and reaction, applied in the field of reversible isomerization reaction, which can solve the problem that the conversion rate of specific components cannot be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028]The preparation of the catalyst can be carried out according to the conventional method. The hydrogen type zeolite is mixed with the binder and then molded. The molding is preferably extruded, then dried and calcined. The firing temperature is 400-600°C. To support platinum group metals, impregnate the catalyst containing molecular sieves with a solution containing platinum group metal compounds, preferably chloroplatinic acid, dry and calcinate to obtain a catalyst containing platinum group metals.

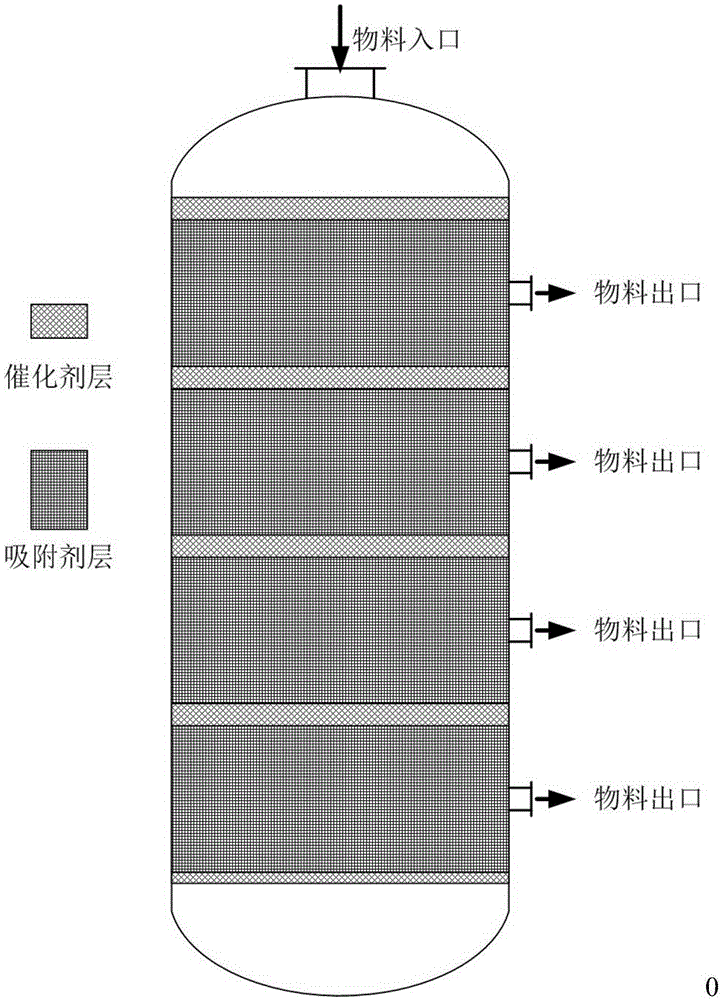

[0029] In a preferred solution of the present invention, the catalyst is mixed with an adsorbent, or the two are placed in layers at intervals. The mass ratio of the catalyst to the adsorbent is preferably 1:1-30, more preferably 1:4-20.

[0030] The adsorbent is sodium ZSM-5 or Silicalite-1 zeolite. The silica / alumina molar ratio of the sodium ZSM-5 zeolite is preferably 300-700.

[0031] The adsorbent preferably contains a binder, and the binder is preferably kaolinite...

example 1

[0040] Take the hydrogen-type ZSM-5 zeolite with a silica / alumina molar ratio of 25, use alumina as a binder, extrude into strips with an outer diameter of 1 mm, cut into particles with a length of 2 to 3 mm, and roast at 500 ° C to prepare the catalyst A, wherein the HZSM-5 zeolite content is 70% by mass.

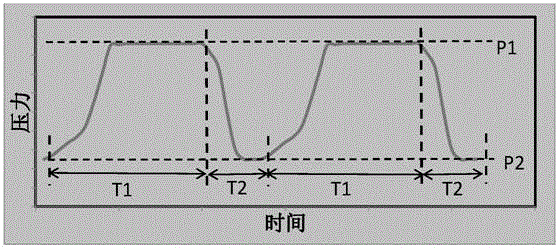

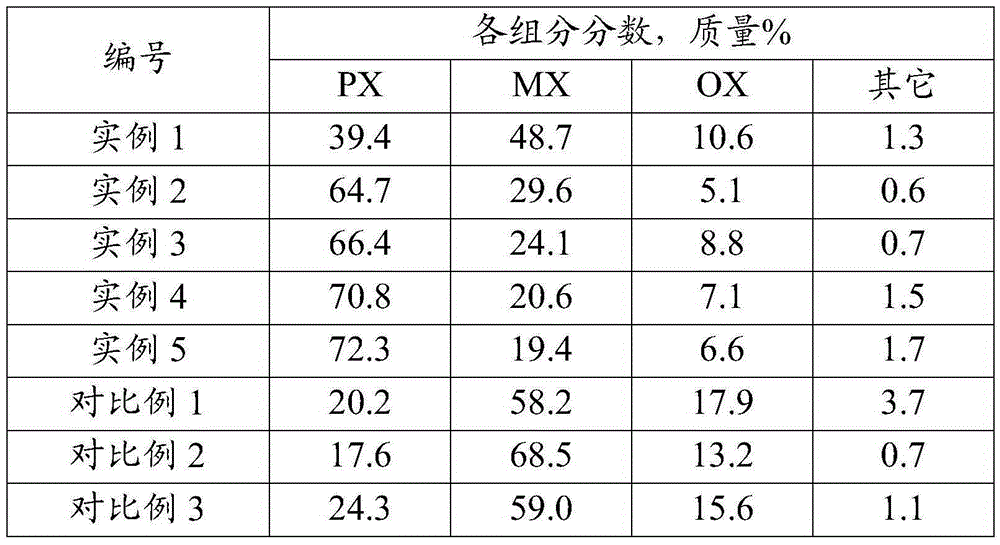

[0041] A cylindrical reactor with an inner diameter of 30mm and a height of 120mm was filled with 50g of catalyst A, replaced with nitrogen and then heated to 210°C. Using m-xylene (MX) with a purity greater than 99% by mass as the raw material, it enters the reactor through preheating and vaporization. The mass flow rate of the feed is 2.5g / min, and the feed time is 41s. In the state of feeding and not discharging for 69s, open the outlet of the reactor, release and collect the reaction product, reduce the pressure of the reactor to 0.1MPa, and discharge the material for 10s. Then re-feed m-xylene into the reactor at a flow rate of 2.5 g / min, repeat the above steps and c...

example 2

[0043] Take NaZSM-5 zeolite with a silica / alumina molar ratio of 600, use kaolin as a binder, and roll into balls to obtain small balls with a particle size of 0.6-1.0 mm. After roasting at 500 ° C, the adsorbent B is prepared. Among them, the content of NaZSM-5 zeolite is 92% by mass.

[0044] Get 45g adsorbent B and 5g catalyst A and mix homogeneously, fill in the used reactor of example 1. After replacing with nitrogen, the temperature was raised to 220°C. Using m-xylene (MX) with a purity greater than 99% by mass as the raw material, it enters the reactor through preheating vaporization, the feed mass flow rate is 5g / min, and the feed time is 39s. In the state of 71s that the material is not discharged, the outlet of the reactor is opened, the reaction product is discharged and collected, the pressure of the reactor is reduced to 0.1MPa, and the discharge time is 10s. Then feed the reaction raw materials into the reactor again at a flow rate of 5 g / min, repeat the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com