Chlorobenzene catalytic degradation method by absorption-low temperature plasma and preparation method of adsorptive catalyst thereof

A low-temperature plasma and plasma technology, applied in catalyst activation/preparation, physical/chemical process catalysts, separation methods, etc., can solve the problem of lack of selectivity of pollutants, and achieve improved CO2 selectivity, low energy consumption, and reduced energy consumption. The effect of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

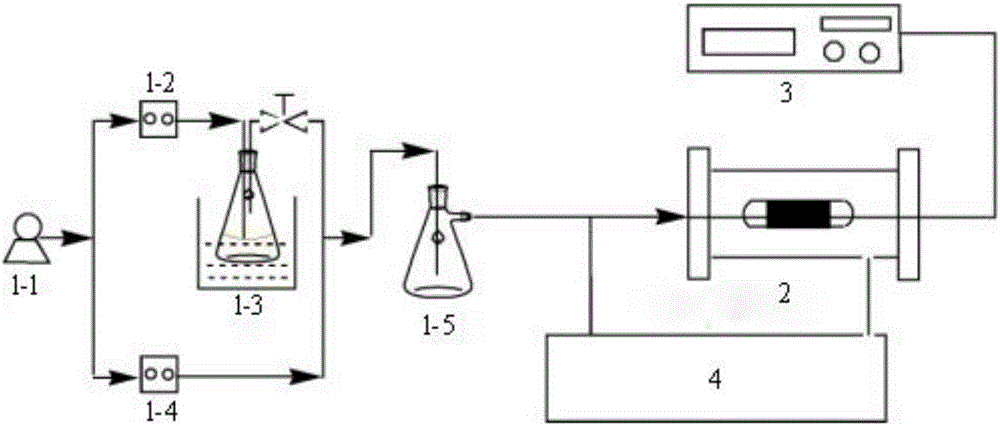

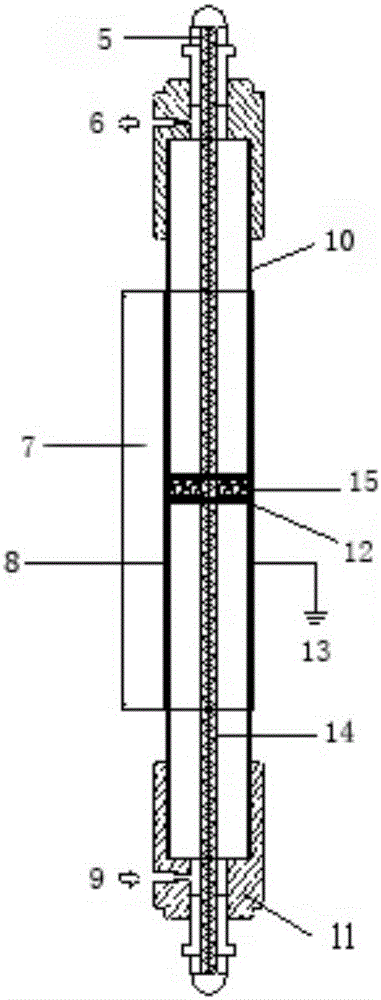

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: the preparation of Ag / AC catalyst (Ⅰ)

[0043] (1) Carrier pretreatment: Activated carbon is washed with water before use to remove inorganic impurities on the surface, then washed with 0.1-0.2mol / L nitric acid, then washed with water until neutral, and dried at 110°C for 12 hours for use.

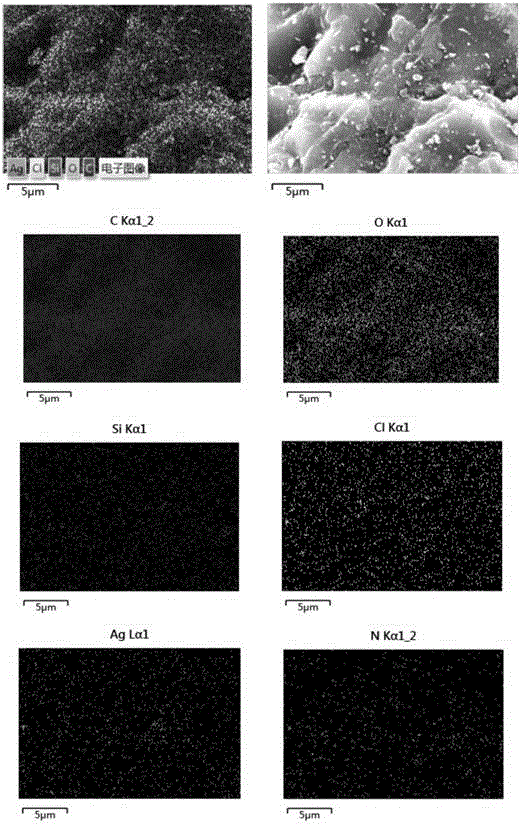

[0044] (2) Catalyst preparation: take 0.1574g of silver nitrate, dissolve it in 100mL of distilled water, add 9.8426g of pretreated activated carbon under stirring, stir at 55°C for 5 hours, let it stand for 2.5 hours, dry at 110°C for 12h, and put it in a nitrogen atmosphere Heating to 450°C at a heating rate of 3°C / min and keeping the temperature constant for 2h, cooling, washing with water and drying to obtain the 8g Ag / AC catalyst (I). The EDS layered images, SEM images, and EDS spectra of the Ag / AC catalyst are shown in Figure 7 , XRD diagram see Figure 8 .

Embodiment 2

[0045] Embodiment 2: the preparation of Ag / AC catalyst (Ⅱ)

[0046] (1) Carrier pretreatment: Activated carbon was washed with water before use to remove inorganic impurities on the surface, then washed with 0.1mol / L nitric acid, then washed with water until neutral, and dried at 105°C for 11 hours before use.

[0047] (2) Catalyst preparation: Take 0.1574g of silver nitrate, dissolve it with 100mL of distilled water, add 9.8426g of pretreated activated carbon under stirring, stir at 50°C for 4h, let it stand for 2h, dry at 105°C for 13h, and dry it at 105°C for 13h. Heating rate of ℃ / min to 450 ℃ and constant temperature for 2.5h, cooling, washing and drying to obtain 8g Ag / AC catalyst (Ⅱ)

Embodiment 3

[0048] Embodiment 3: Ag / AC catalyst adsorption performance test

[0049] The adsorption performance of the catalyst is one of the keys of the adsorption-plasma catalytic system, so the adsorption performance of the Ag / AC adsorption catalyst prepared in Example 1 was tested. Set the flow rate of the chlorobenzene stream to 2L / min, and the intake concentration to 180mg / m 3 , the amount of catalyst is 0.3g, from the breakthrough curve of activated carbon, it can be concluded that the breakthrough time of Ag / AC is 35min, and the Ag in Ag / AC may be expressed as Ag + It exists in the form and can form a strong π complex bond with chlorobenzene. The results show that the catalyst with AC as the carrier has a good adsorption effect of chlorobenzene, which has obvious advantages in the later stage of NTP treatment.

[0050] Test of p-Chlorobenzene Removal Efficiency of Ag / AC Catalyst

[0051] (1) The flow velocity of the chlorobenzene airflow is set to be 2L / min, and the intake conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com