Method for separating n-alkane from C5 to C6 alkane isomerized products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

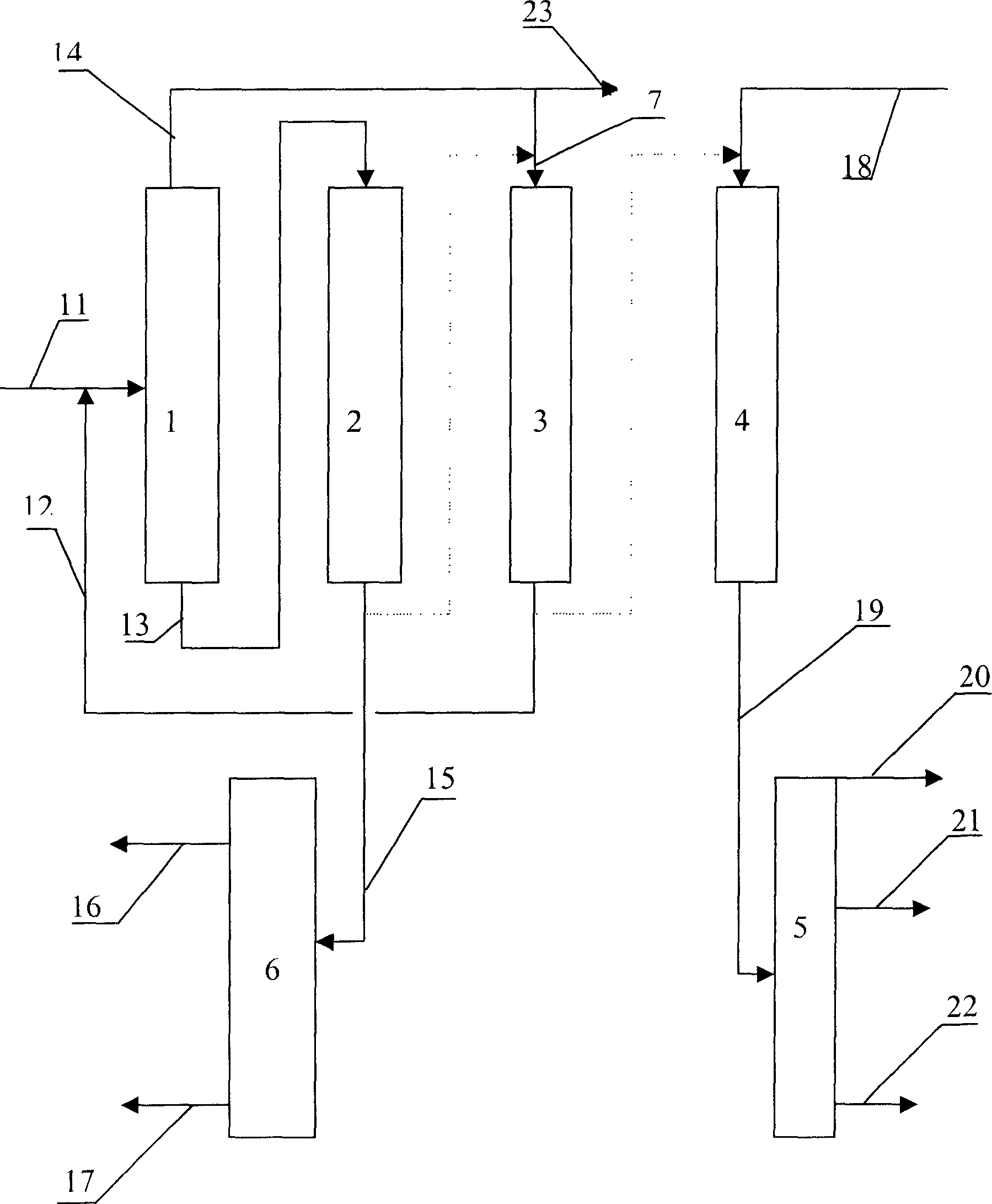

Method used

Image

Examples

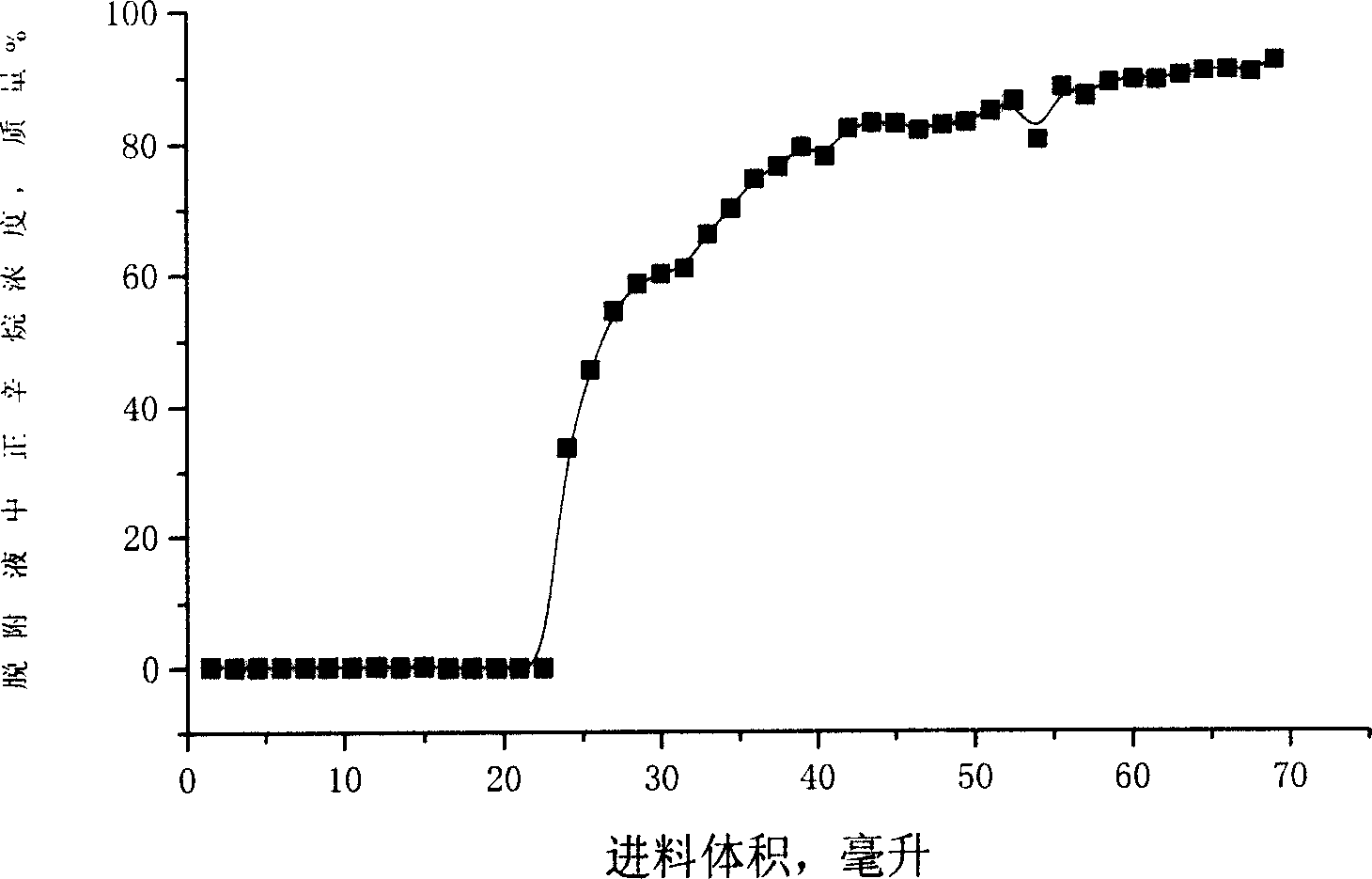

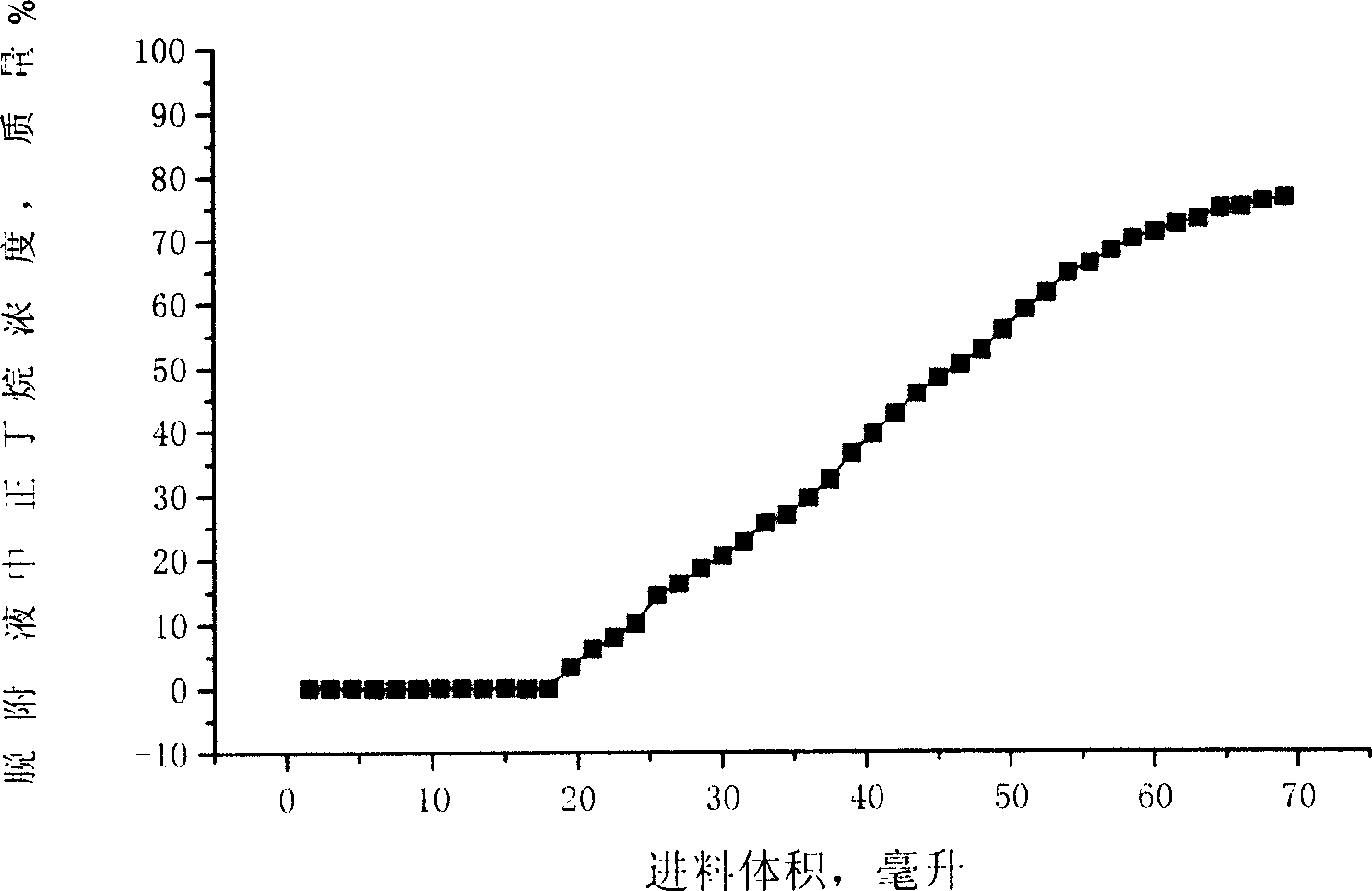

example 1

[0030] Weigh 50 grams (dry basis) of 5A molecular sieve (Nanjing Jinling Catalyst Factory) as an adsorbent and pack it into a φ10×250mm stainless steel adsorption column, and put the C 5 、C 6 The alkane isomerization product undergoes distillation de-pentanization, C before and after de-pentanization 5 、C 6 The composition of alkane isomerization products is shown in Table 1. Under the condition of 3.0MPa, 150℃ and liquid phase, the C after deisopentanization 5 、C 6 Alkane isomerization products according to 1.0 -1 The volume space velocity is passed into the adsorption column for adsorption and separation operation. After the adsorption is saturated, add the flushing agent isopentane at 1.0 -1 The volume space velocity is passed into the adsorption column to replace the adsorption material in the invalid volume of the adsorption column. After washing, use n-octane as the desorbent to desorb the n-alkanes adsorbed in the pores of the adsorbent, and when the volume space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com