A multi-station series dynamic nitrogen adsorption specific surface meter and specific surface measurement method

A technology of nitrogen adsorption and surface meter, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of lower test accuracy, poor specific surface test accuracy, unfavorable automatic control, etc., achieve shortened desorption time, improve test accuracy, The effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

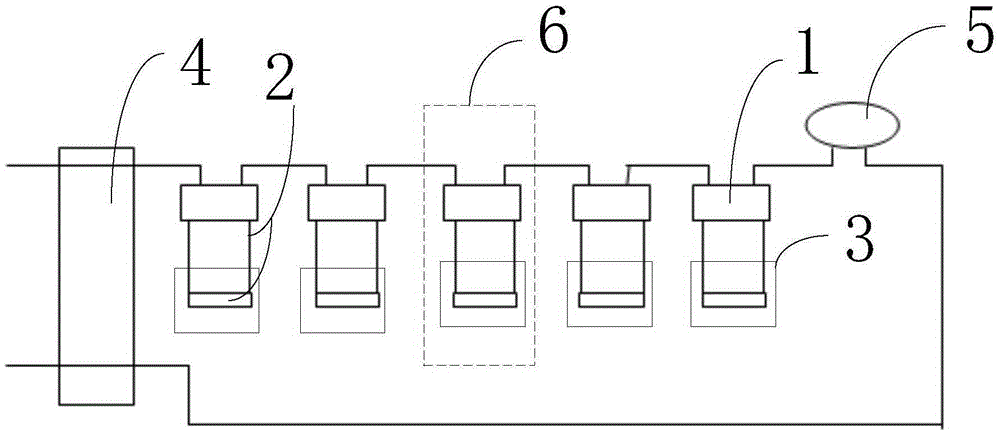

[0036] A multi-station series dynamic nitrogen adsorption specific surface meter, comprising a plurality of four-way solenoid valves 1, a plurality of U-shaped sample tubes 2, a plurality of liquid nitrogen cups 3, a thermal conductivity pool 4 and a quantitative nitrogen gas pipeline 5;

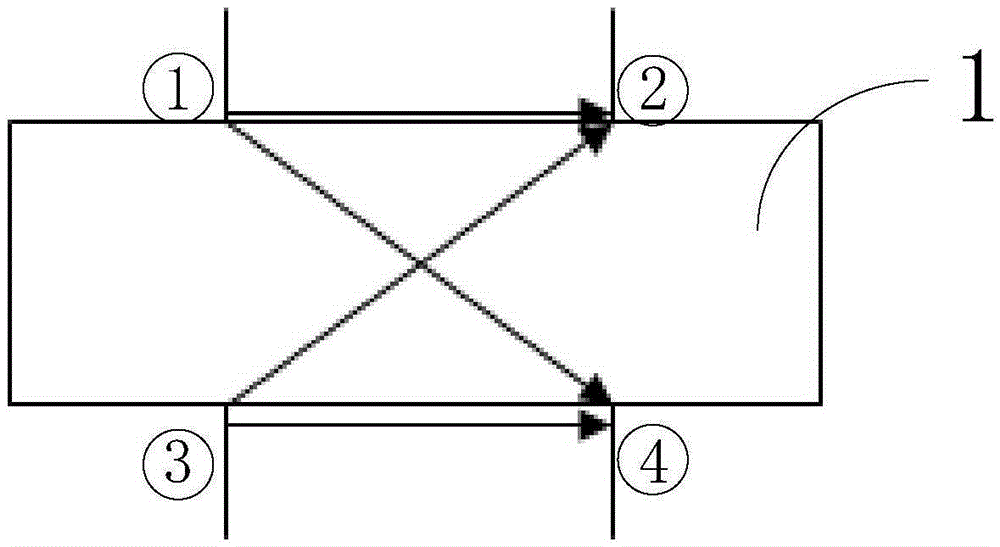

[0037] Each four-way solenoid valve 1 forms an adsorption unit 6 with a sample tube 2 and a liquid nitrogen cup 3 respectively, and the third connection port and the fourth connection port of the four-way solenoid valve 1 are respectively connected to the two connection ends of the sample tube 2 , the bottom transverse edge of the sample tube 2 is immersed in the liquid nitrogen cup 3;

[0038] A plurality of adsorption units 6 are connected in series, the first connection port of the four-way solenoid valve 1 in the adsorption unit 6 at the head end communicates with the reference wall port of the thermal conductivity pool 4, and the four-way solenoid valve in the adsorption unit 6 at the ta...

Embodiment 2

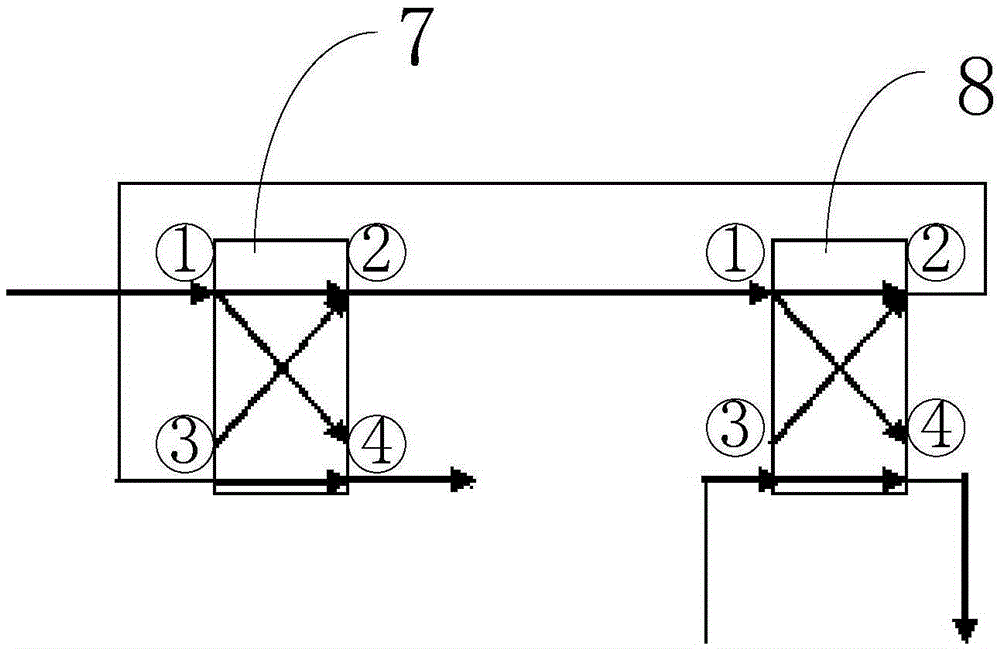

[0042] The difference between embodiment 2 and embodiment 1 is that: the pipeline 5 for adding quantitative nitrogen gas is a gas path formed by a combination of double four-way valves.

[0043] Described double four-way valve comprises the first four-way valve 7 and the second four-way valve 8, and the second connecting port of the first four-way valve 7 communicates with the first connecting port of the second four-way valve 8, and the first four-way valve The first connection port of the one-way valve 7 is used for taking in nitrogen from the outside, the fourth connection port of the first four-way valve 7 is used for discharging gas to the outside, and the second connection port of the second four-way valve 8 is connected to the first four-way valve. The third connection port of the valve 7 is connected, and the third connection port of the second four-way valve 8 is connected in series with the fourth connection port of the second four-way valve 8 in the test gas circuit,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com