Effective organic waste gas recovery device and process

A technology of organic waste gas and recovery device, applied in drying gas arrangement, dryer, gas treatment and other directions, can solve the problems of low organic waste gas treatment efficiency, short fragile life of membrane device, unstable membrane separation effect, etc. High efficiency, extended service life, and the effect of ensuring continuous processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

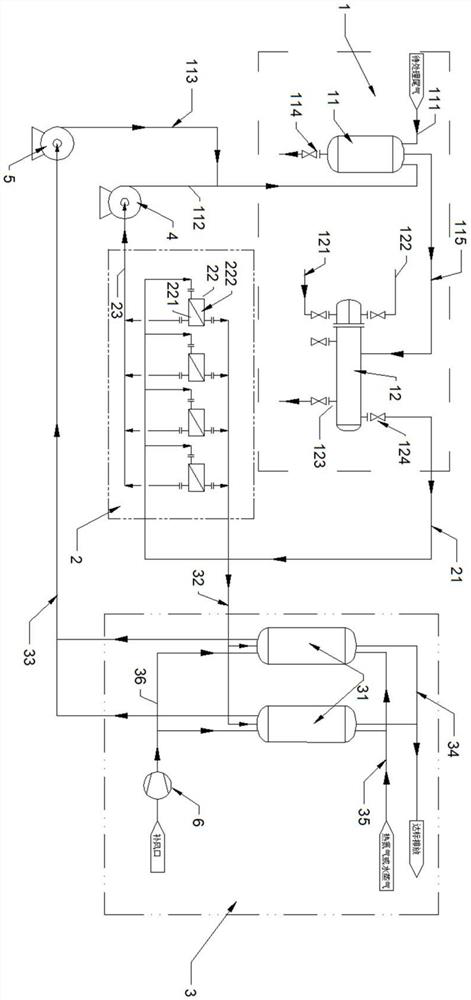

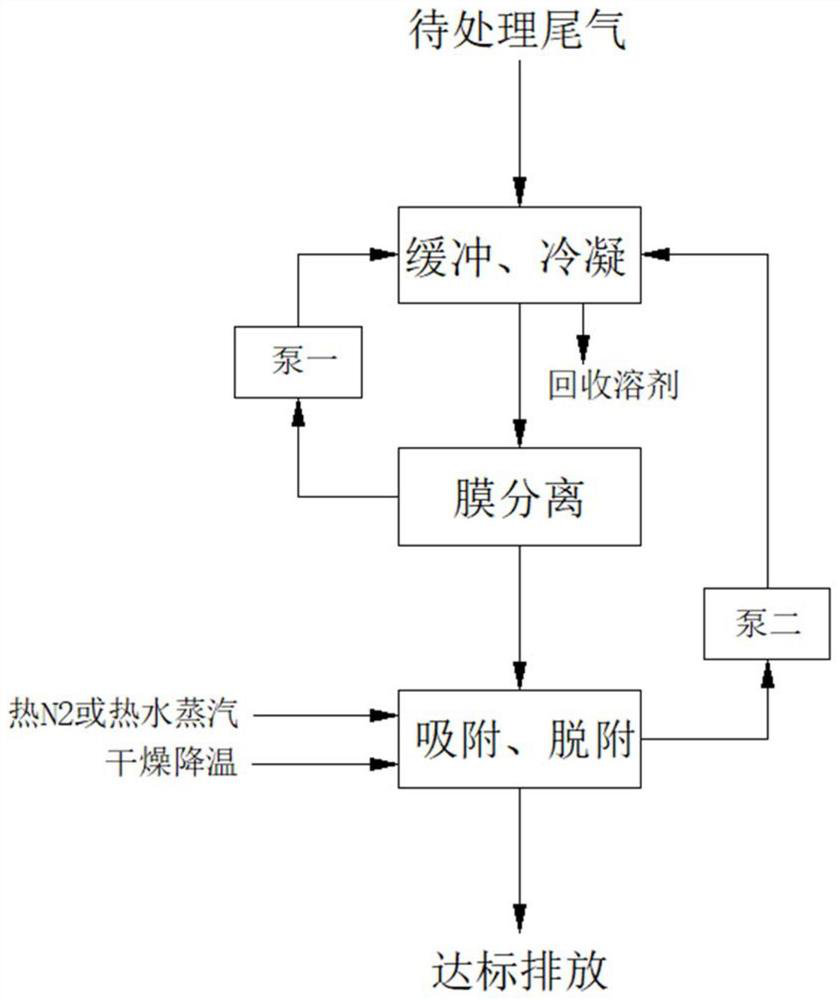

[0035] The invention discloses an organic waste gas recovery device, which can be applied to waste gas discharged from industries such as petrochemical industry, fine chemical industry, spray coating, adhesive production, medicine and pesticide manufacturing, such as figure 1 As shown, a high-efficiency organic waste gas recovery device includes a condensation system 1, a membrane separation system 2, an adsorption system 3, and a vacuum system. It is characterized in that the condensation system 1 is used to condense organic tail gas to form a liquid organic solvent; the membrane separation system 2 It is respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com