High-efficiency energy-saving absorption device of industrial volatilizable organic pollutant

An organic pollutant, high-efficiency and energy-saving technology, applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of high operating costs, waste of the environment, and high energy consumption, and achieve reduced equipment operating costs and reduced electrical energy Consumption, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

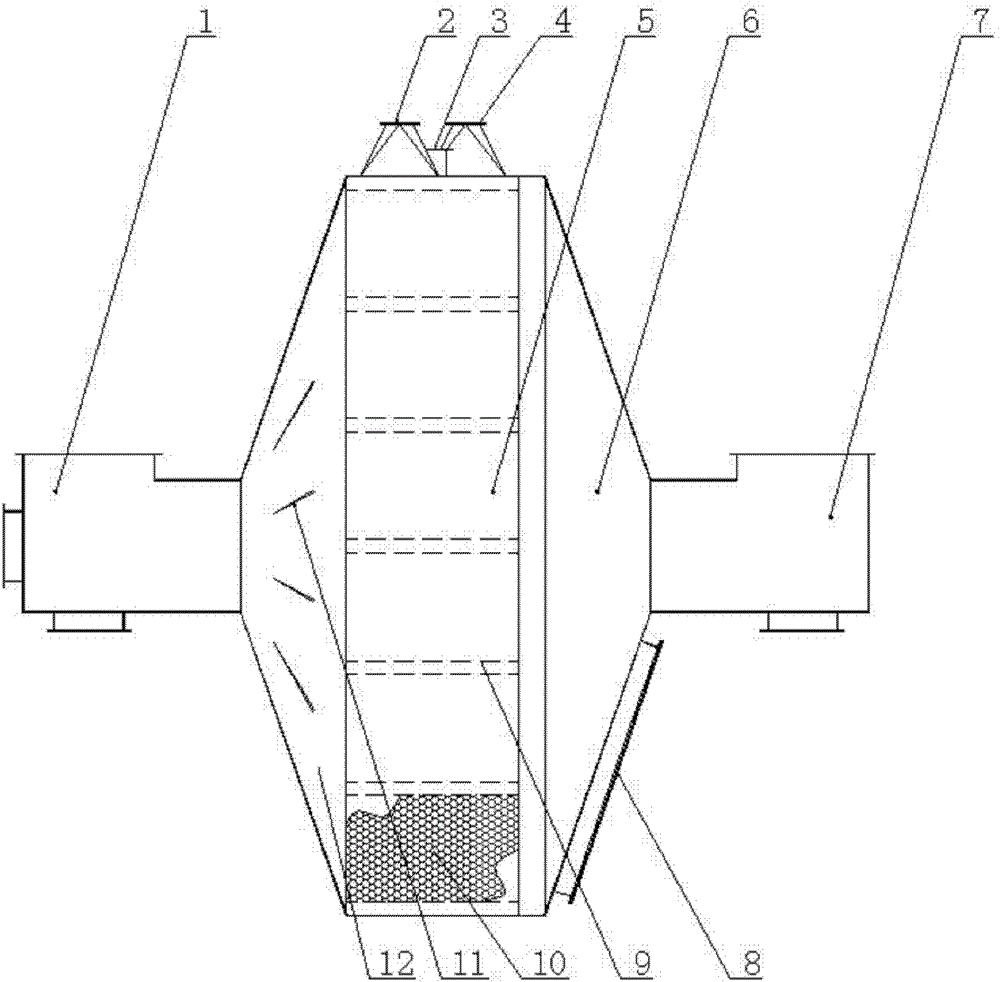

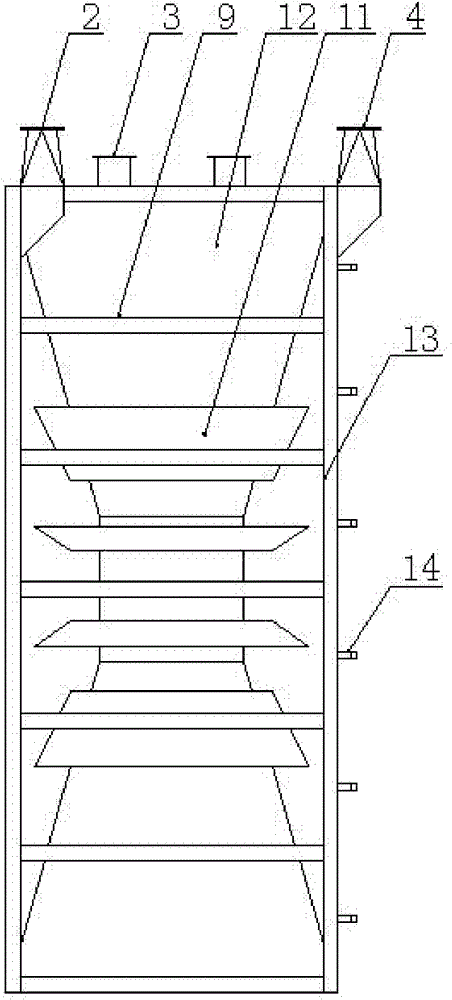

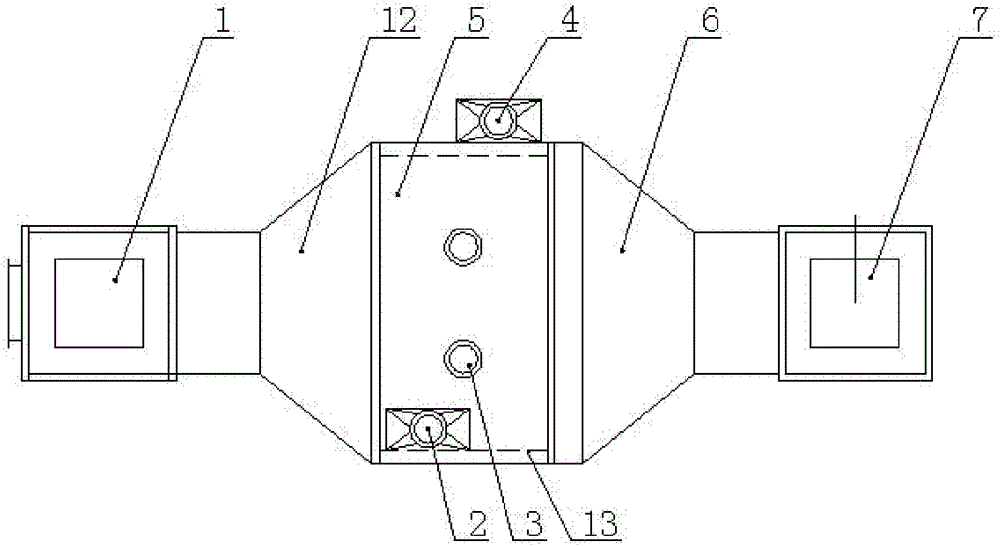

[0019] A high-efficiency energy-saving adsorption device for industrial volatile organic pollutants, comprising an air inlet flaring part 12, an activated carbon bed body 5, and an air outlet constricting part 6, the small-diameter end of the air inlet flaring part is connected to the air inlet pipe 1, the inlet The air duct can be respectively connected to the waste gas source of industrial volatile organic pollutants and the qualified hot gas source treated by the combustion catalytic bed through the tee and the valve. Connect the adsorption fan and the desorption fan. A manhole 8 is opened at the lower part of the air outlet constriction. The manhole is equipped with a refueling door. The upper part of the activated carbon bed is equipped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com