Apparatus for recovering ethanol in organic exhaust gas from tipping paper printing

A technology for recycling water and waste gas, which is applied in steam condensation, dispersed particle filtration, and dispersed particle separation, etc. It can solve the problems of waste gas emission and environmental pollution, achieve high recovery efficiency, improve pollution, and shorten desorption time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

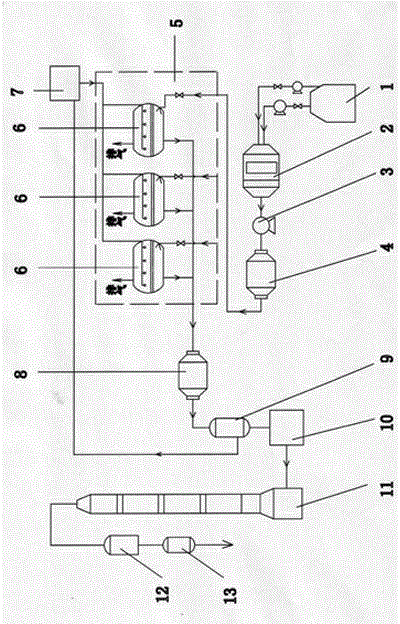

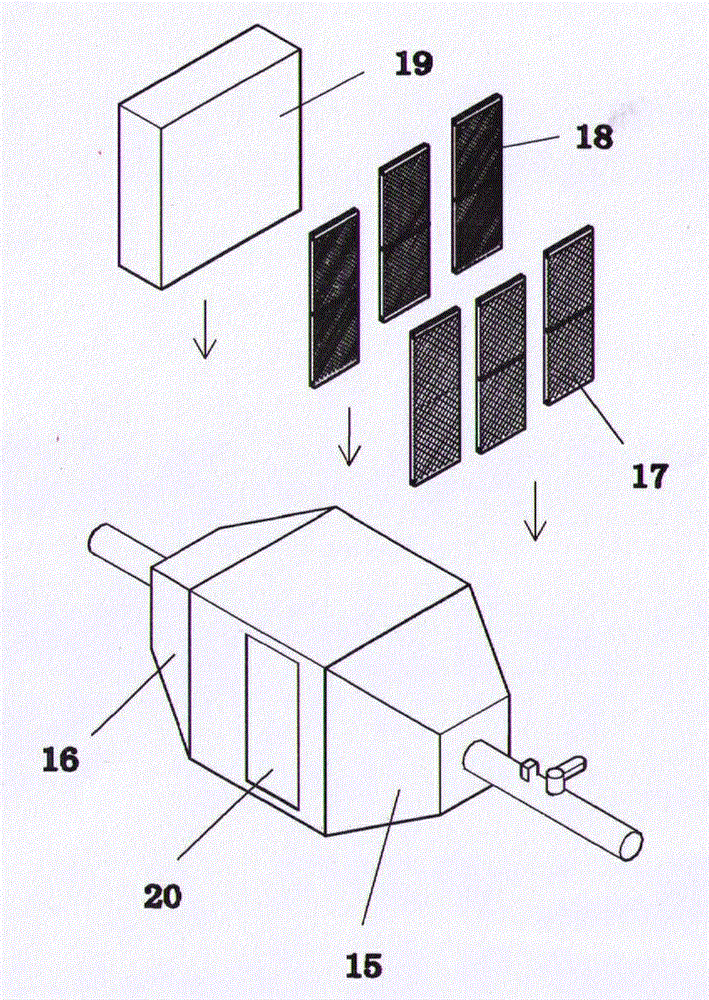

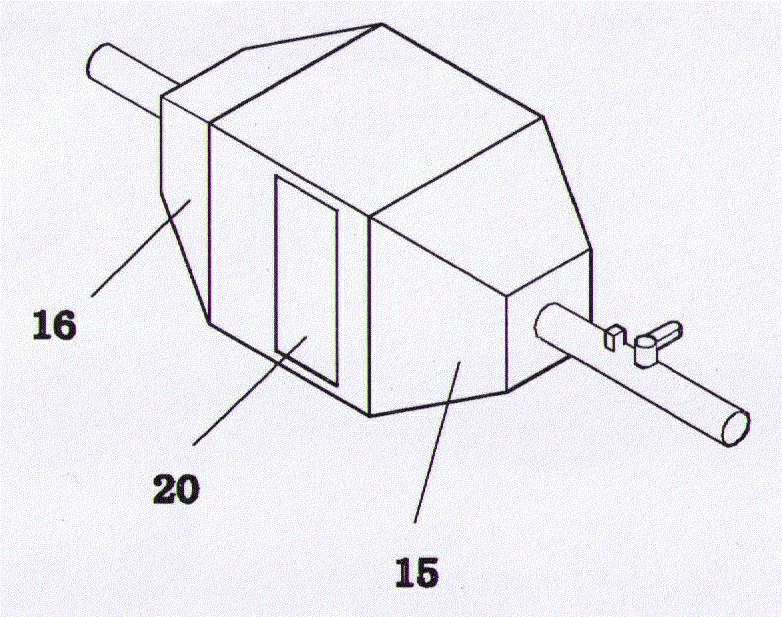

[0026] Embodiment 1: A device for recovering ethanol in waste gas from tipping paper printing, including a filter 2 connected in sequence, a fan 3, a secondary surface cooler 4, an adsorber assembly 5, a desorber condenser 8, and gas-liquid separation Device 10, liquid storage tank 11 and rectifying tower 12. The exhaust gas collection room 1 installed on the printing press is connected to the air inlet of the filter 2 through a pipeline, and a flow regulating valve is installed on the outlet pipe of the filter 2, and the two ends of the filter 2 are funnel-shaped front wind cover 15 and Rear wind cover 16 is connected by the rectangular two-way box body that is positioned at the middle, and the primary sieve 17 of 80 mesh screens is installed on the side of the air inlet in the box; Stage sieve 18; There is a certain distance in the middle of the two-stage filter sieve, and a sealed door 20 is provided on the side wall of the rectangular box corresponding to the distance.

...

Embodiment 2

[0030]Embodiment 2: A device for recovering ethanol in tipping paper printing waste gas. The difference from Embodiment 1 is that the horizontal adsorber with the following structure is adopted: the horizontal adsorber 6 includes an adsorption tank body 21 that is cylindrical as a whole , the adsorption core 22 that is made up of activated carbon granules in the middle and lower part of the adsorption tank body 21, the steam pipe 25 above the adsorption tank body 22, the waste gas inlet pipe 23 positioned at one end of the adsorption tank body 21, and the exhaust gas inlet pipe 23 positioned at the adsorption tank body 21 top Exhaust pipe 26, solution collecting pipe 27 of the bottom, gas diffuser is installed on the described waste gas inlet pipe 23, and gas high-speed nozzle is installed on the gas diffuser, described steam pipe 25 is U-shaped and is arranged on it. A plurality of steam injection holes 28; the end cover 29 at one end of the adsorption tank body 21 is movably ...

Embodiment 3

[0031] Embodiment 3: A device for recovering ethanol in waste gas from tipping paper printing. The difference from Embodiment 2 is that a primary condensation is provided at one end of the secondary screen 18 in the filter 2 box body and close to the rear windshield 16. Device 19.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com