Novel dynamic physical shielding purifier, production method and special fixture

A dynamic physics, special fixture technology, applied in chemical instruments and methods, household appliances, separation methods, etc., can solve the problems of reducing the purification rate of the purifier, low purification rate, large wind resistance, etc., to reduce wind resistance, high purification rate, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

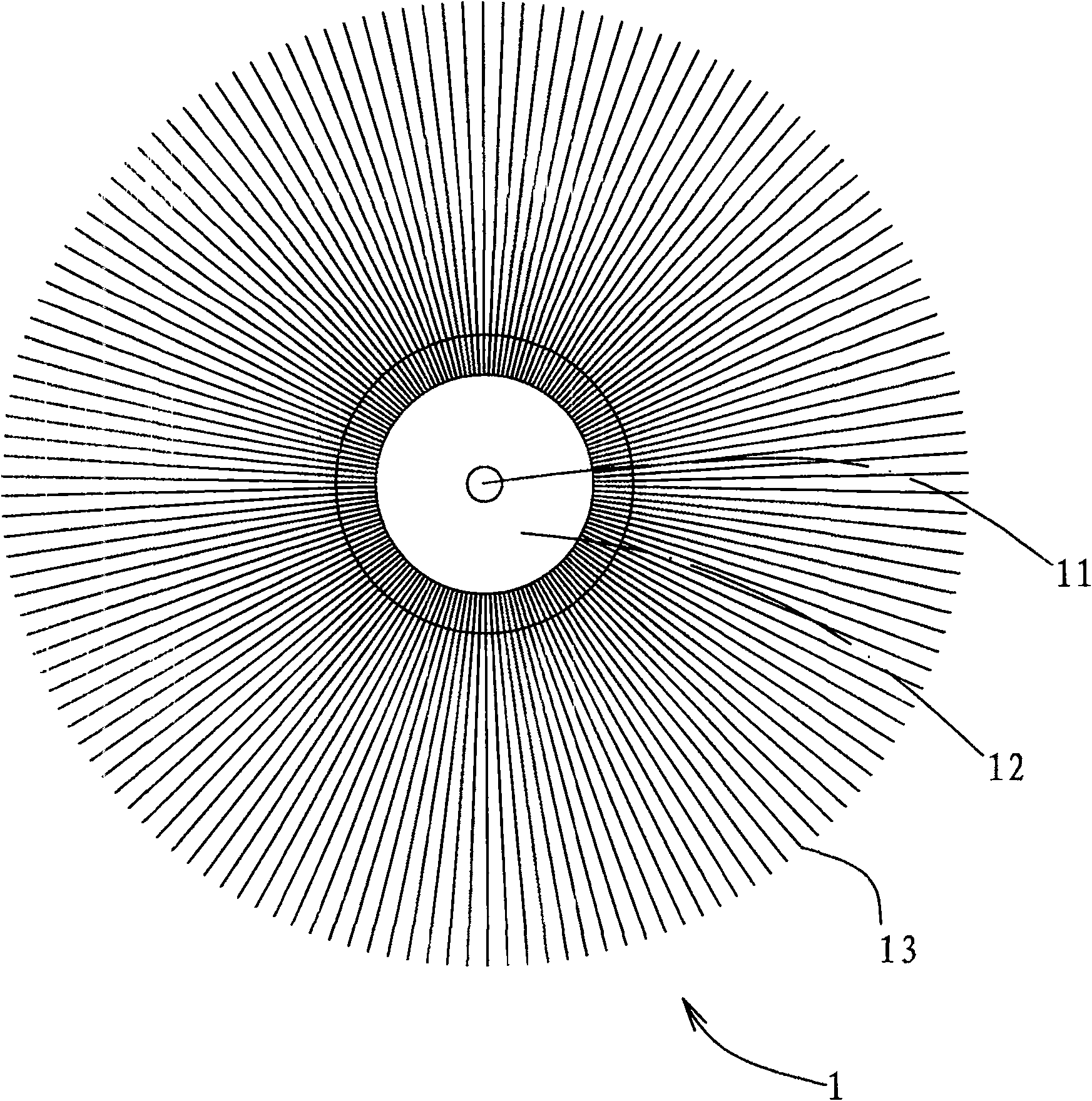

[0037] See figure 1 , which is a dynamic physical shielding purifier 1, including a central disc 12 with a shaft hole 11, the central disc 12 can be stamped from a stainless steel plate with a thickness of 1-3 mm, and the circumference of the central disc 12 can be provided with a circle , to enhance the strength of the central disk 12. On the front side of the central disk 12, 150 metal spokes 13 with a diameter of 1 mm and arranged radially are welded by laser welding.

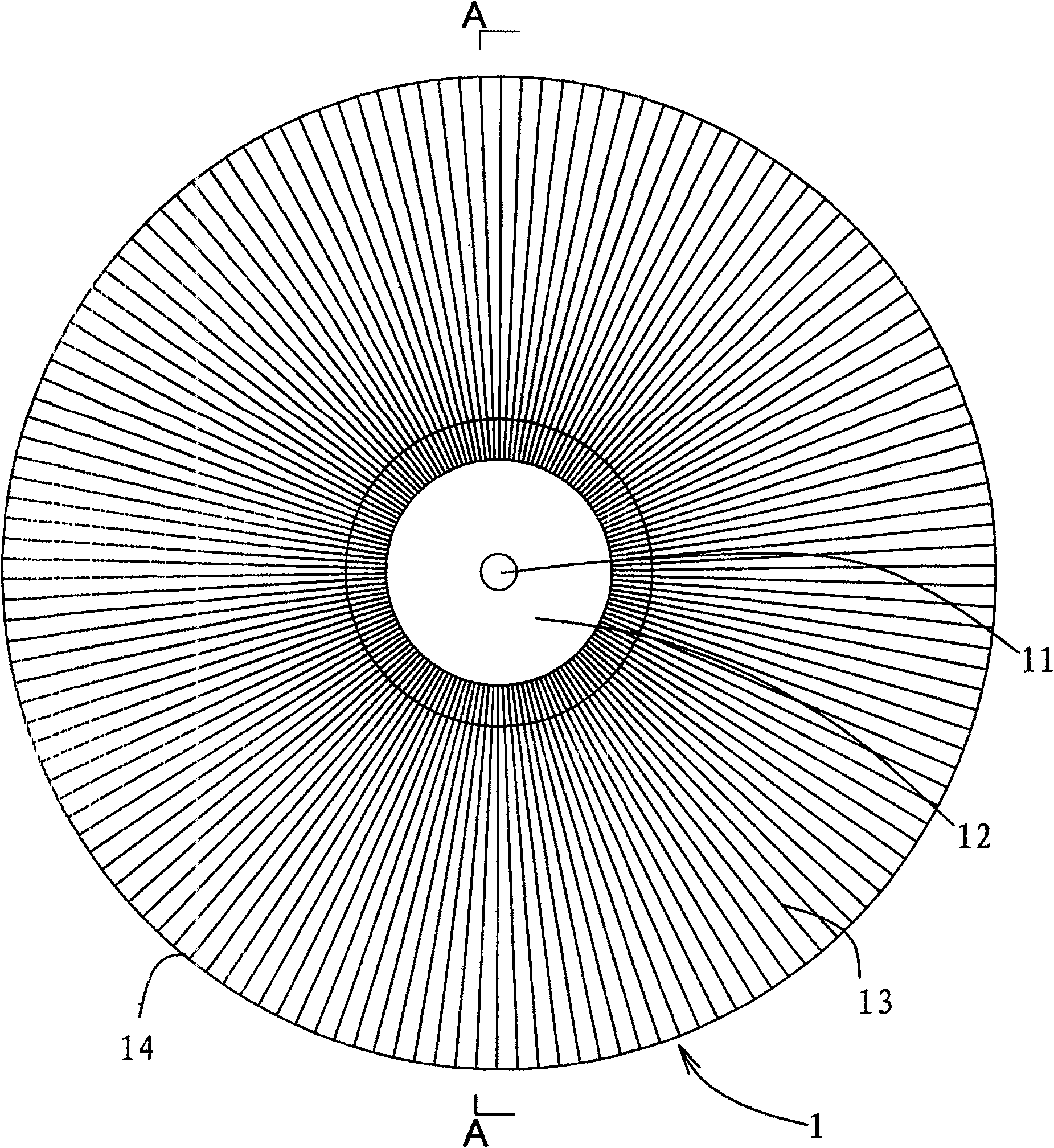

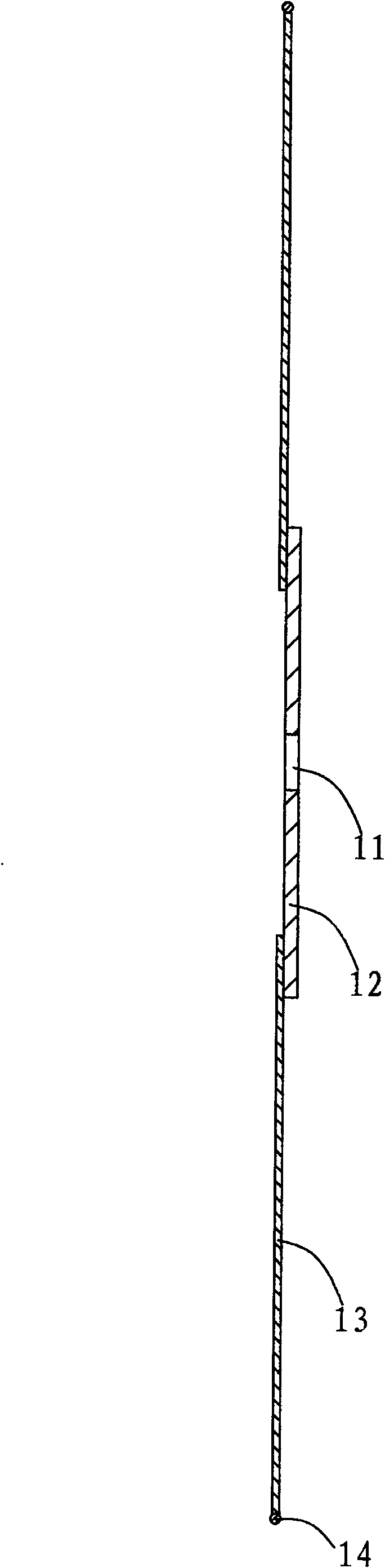

[0038] See figure 2 with image 3 , figure 2 It is a schematic plan view of the second embodiment of the present invention. image 3 yes figure 2 Schematic diagram of the A-A cross-sectional structure. This embodiment and figure 1 Compared with the shown embodiment, its general structure is the same, and the difference is that the purifier 1 also includes a fixed ring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com