Patents

Literature

39results about "Fencing wire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

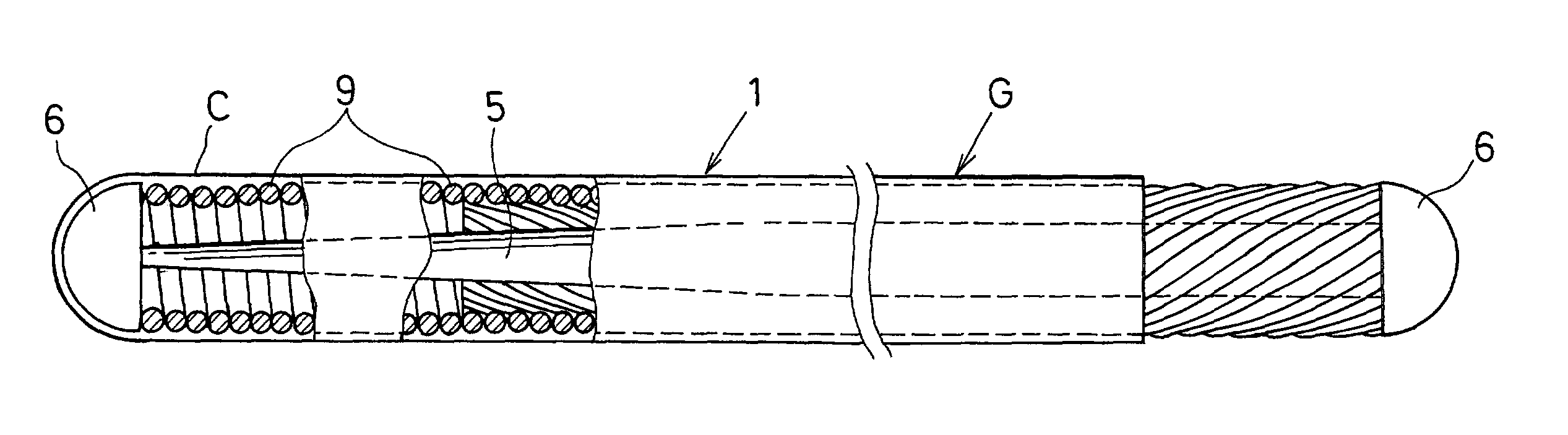

Wire-stranded hollow coil body, a medical equipment made therefrom and a method of making the same

InactiveUS7117703B2Improve rendering capabilitiesImprove straightnessStentsGuide wiresEngineeringMedical device

A wire-stranded hollow coil body (1) has a multitude of coil line elements (2) stranded along a predetermined circular line to form a flexible wire tube having a central axial hollow portion (3), the flexible wire tube is stranded under a strand-turn resistant load and heat treated to remove a residual stress upon formation so as to provide a high rotation-following capability and a high straightness. Further, a method provides a way to strand the coil line elements (2) under a strand-turn resistant load while heat treating the coil line elements (2).

Owner:ASAHI INTECC CO LTD

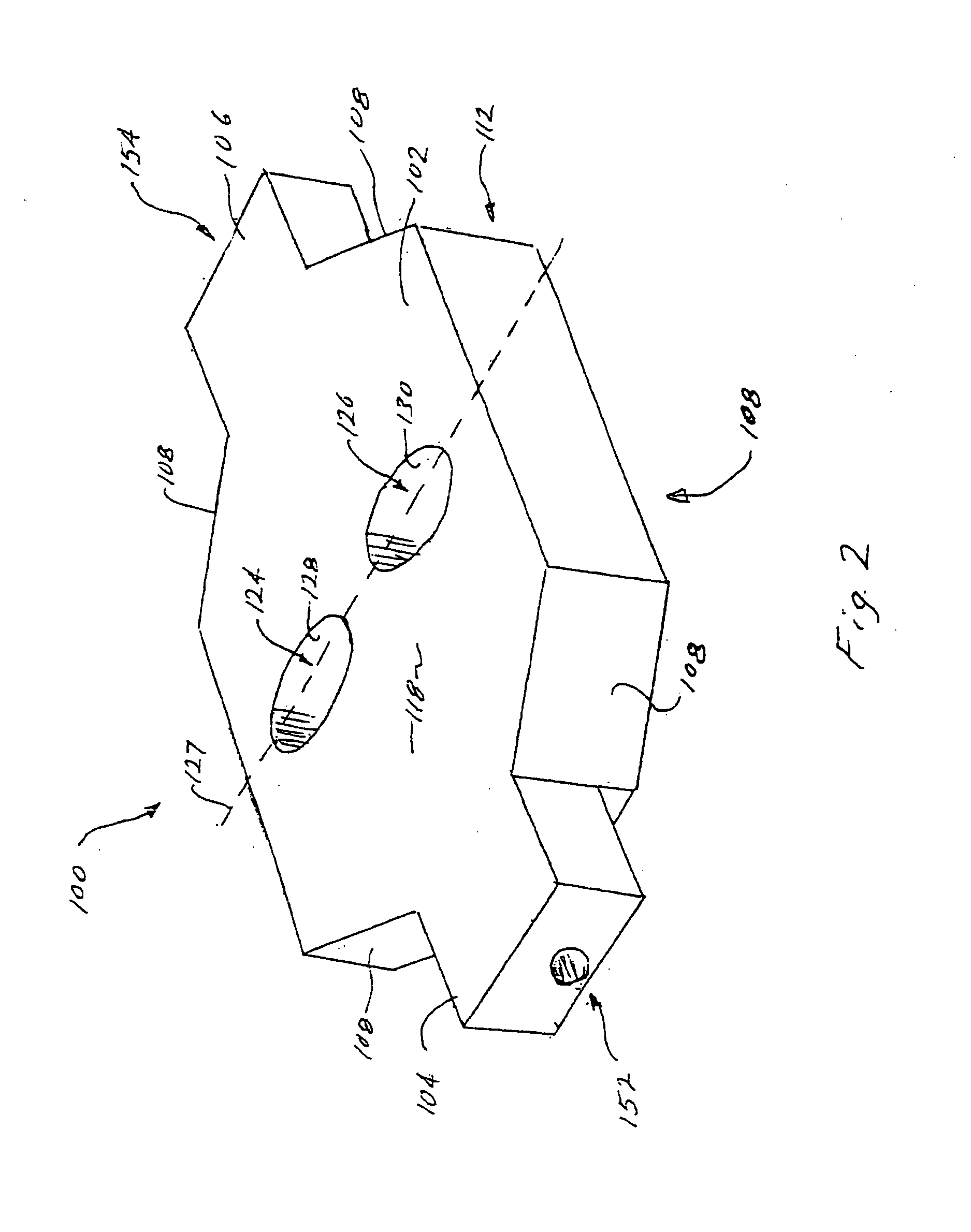

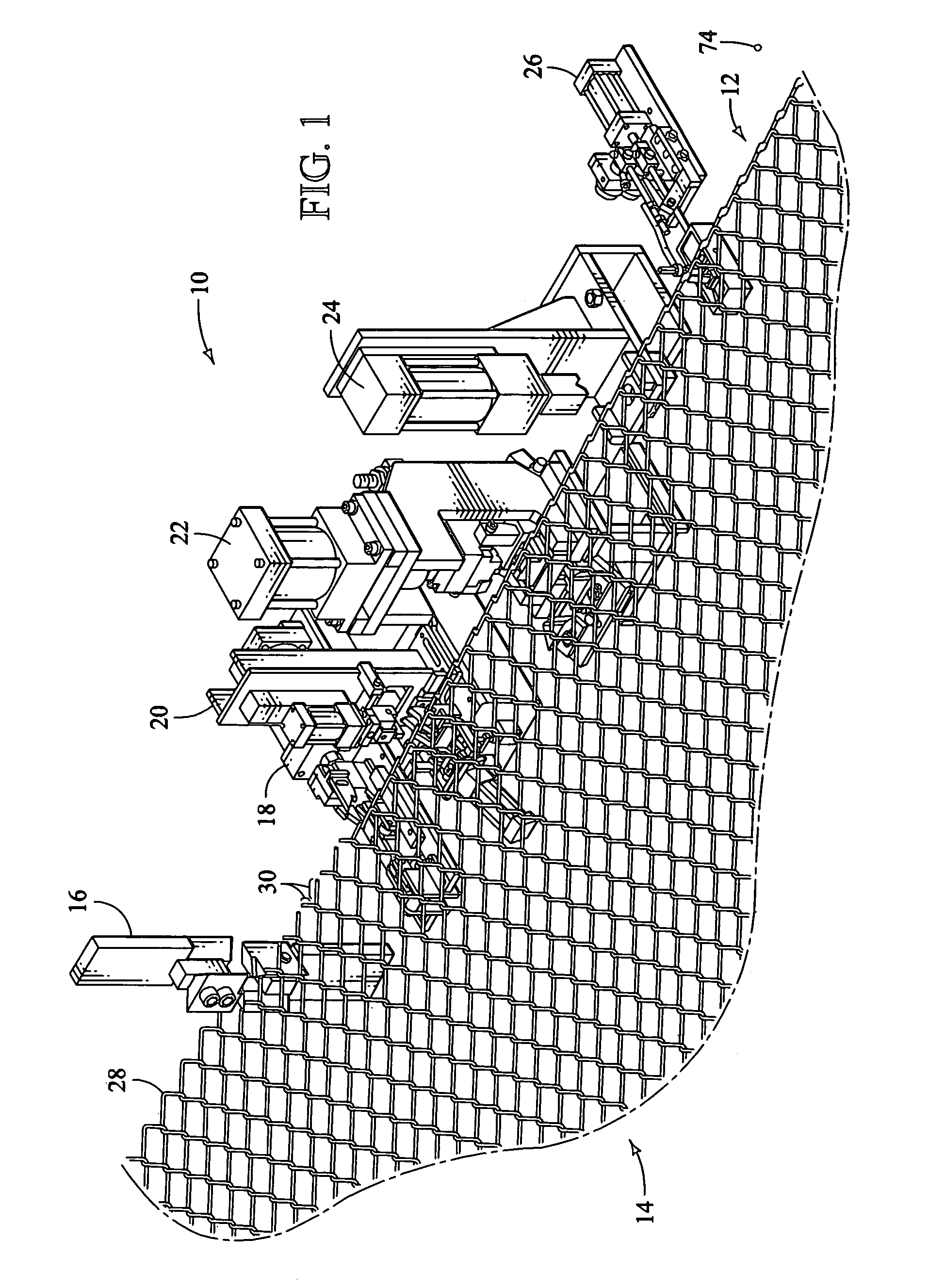

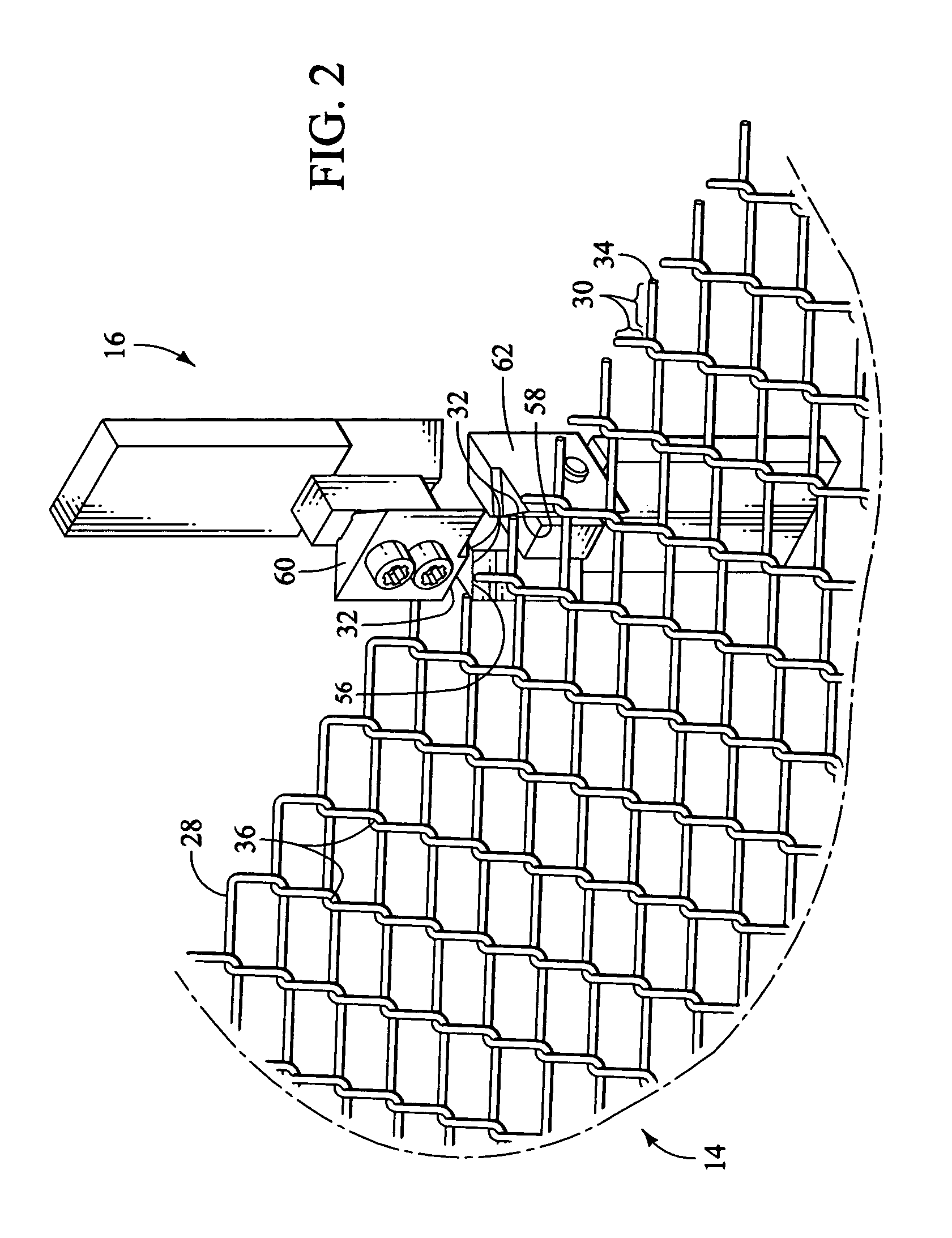

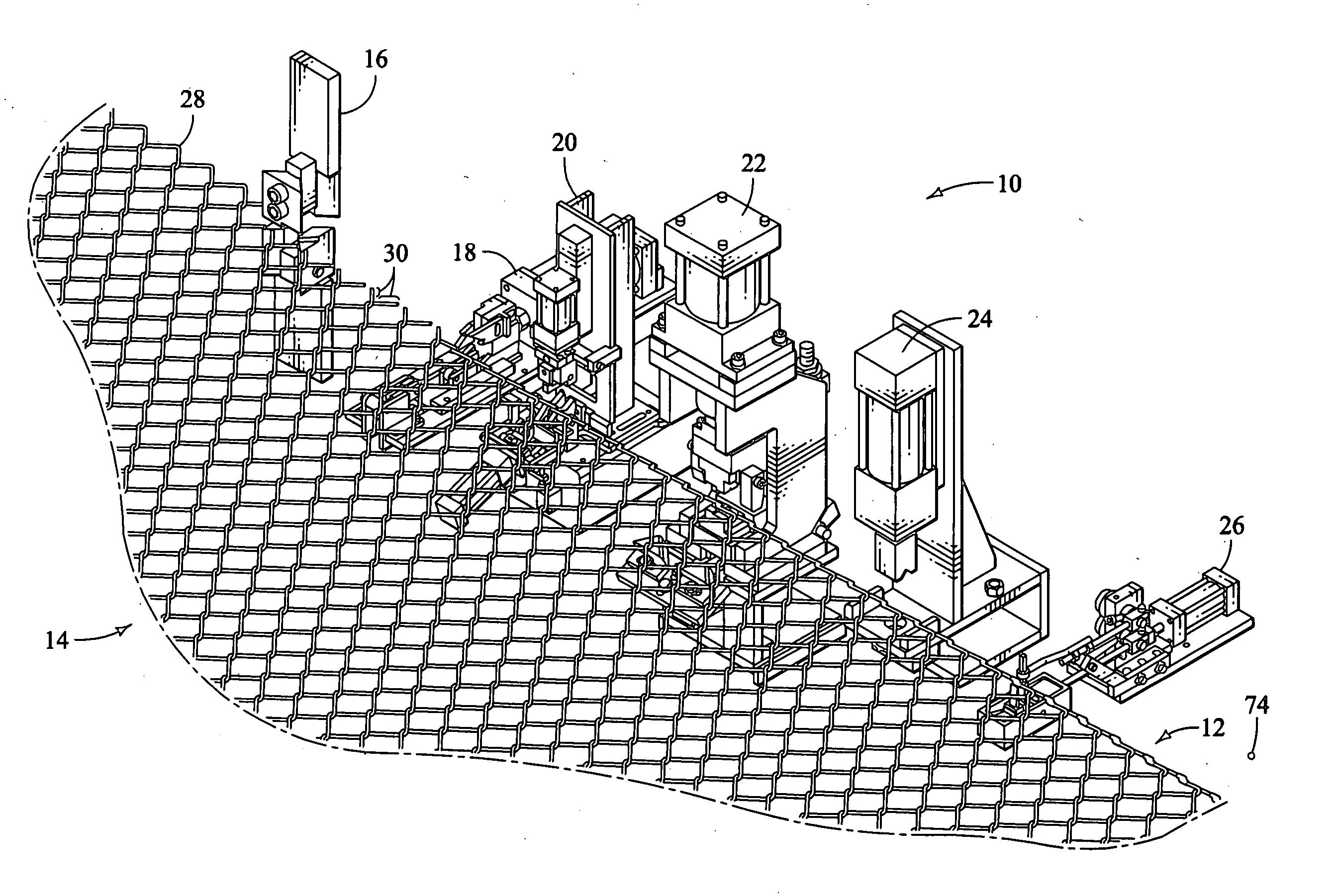

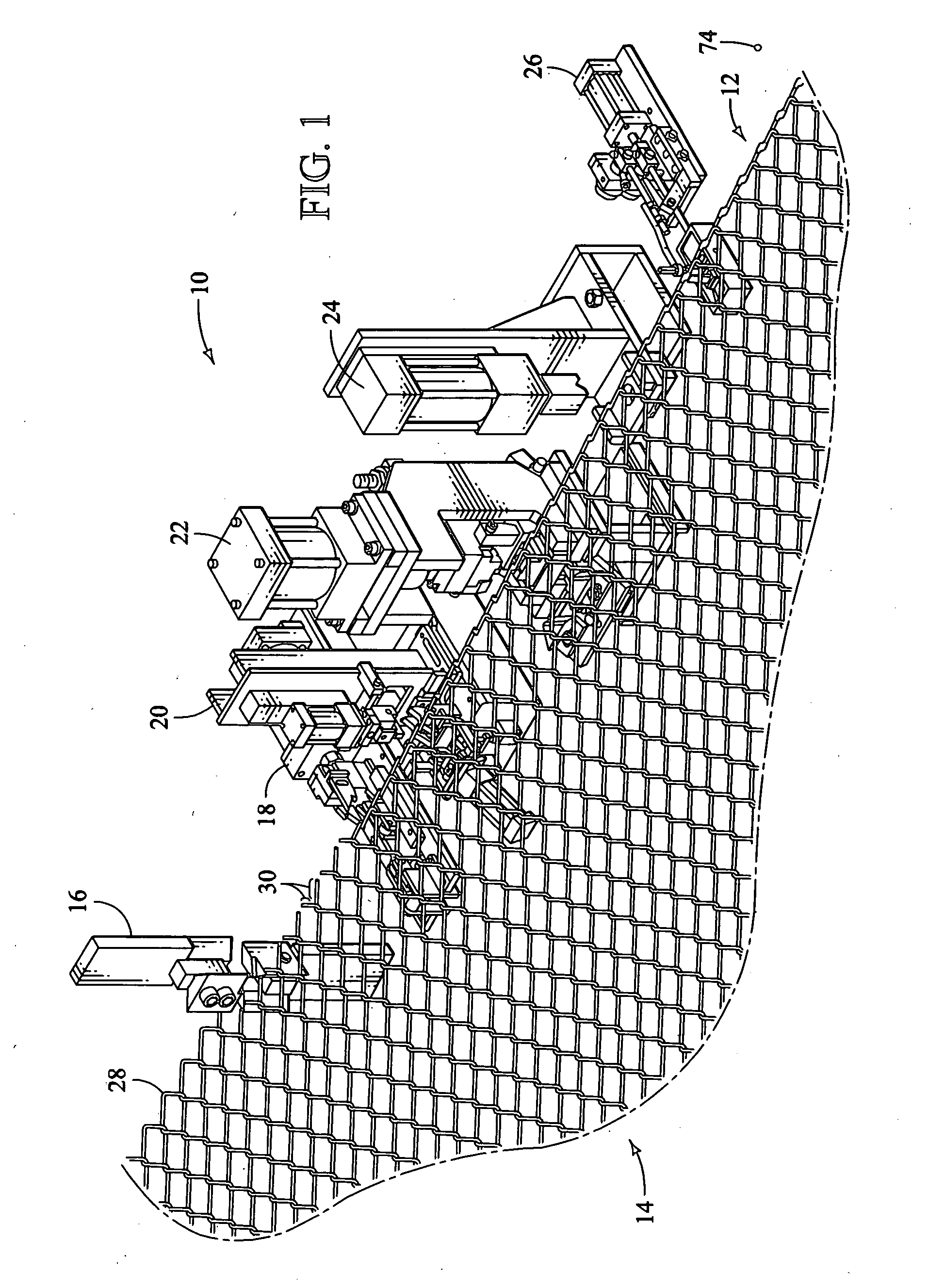

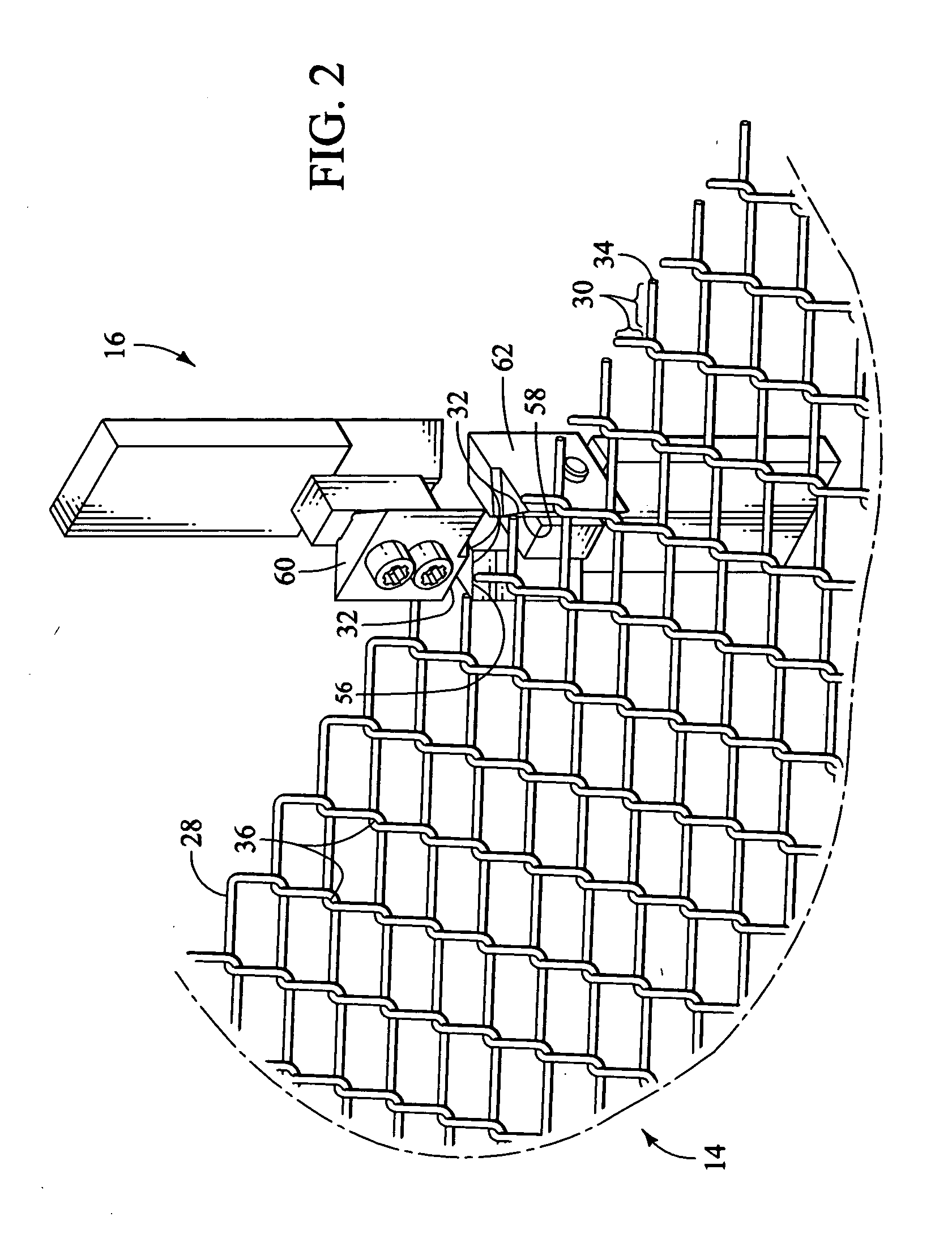

Fence apparatus and related methods

InactiveUS20060038165A1Improve shipping efficiencyImprove handling capacityFencingFencing wireEngineeringSurface plate

Owner:LARSEN CHARLES

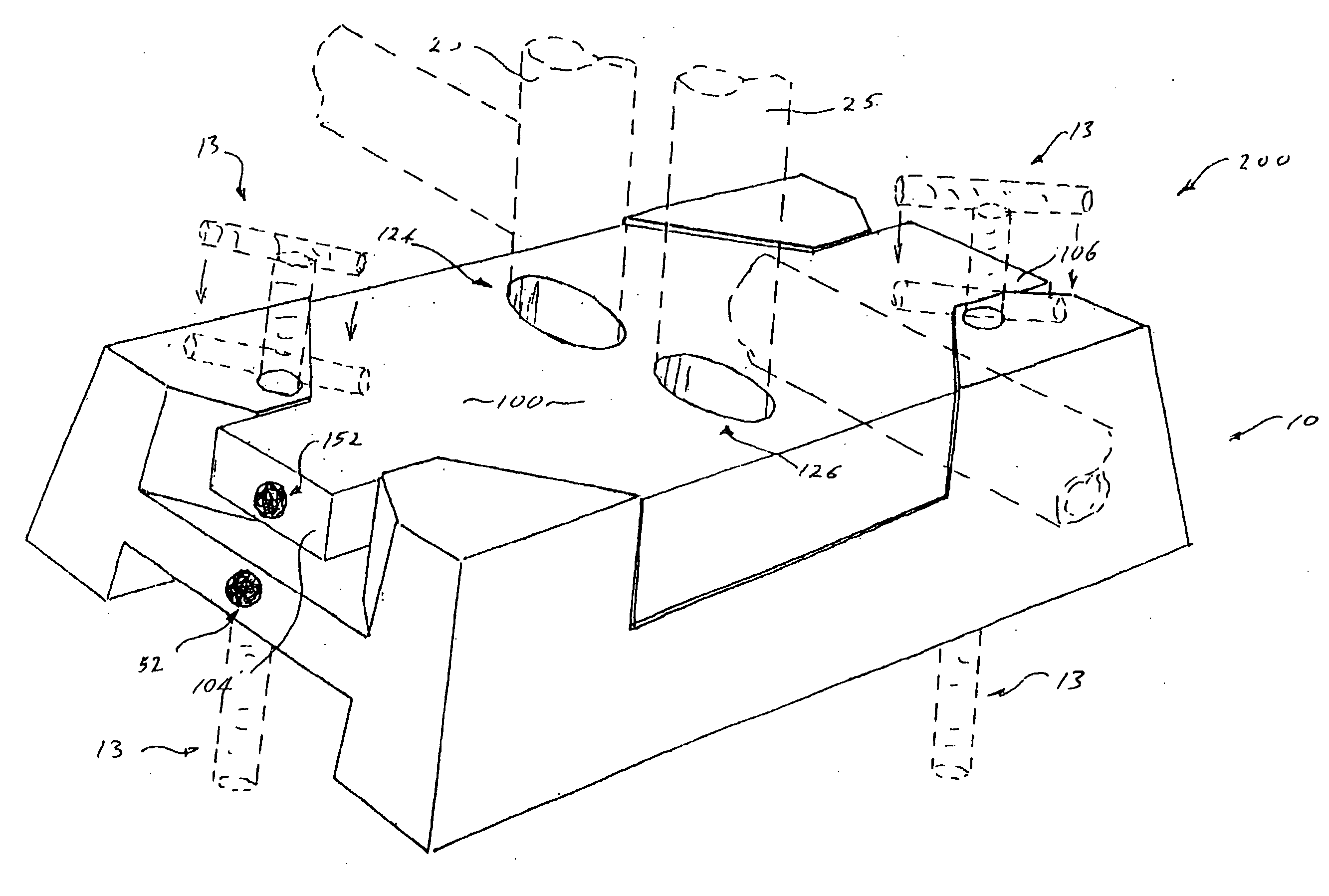

Two-part fence base

An anchor assembly for a temporary fence; said assembly comprising a base portion and a superposed insert portion; each said base portion and said superposed insert portion comprising a composite of a shell open at the underside, and a settable material filling said shell; and wherein respective pairs of formers integral to each said shell of said base portion and said superposed portion, define substantially vertical pairs of passages through said base portion and said superposed insert portion; said passages arranged so that when said base portion and said superposed insert portion are assembled together, respective pairs of said passages are in vertical alignment; said passages adapted for receiving therethrough respective ends of uprights of adjacent panels of said temporary fence; said ends passing through both said superposed insert portion and said base portion.

Owner:KELVINDALE PROD

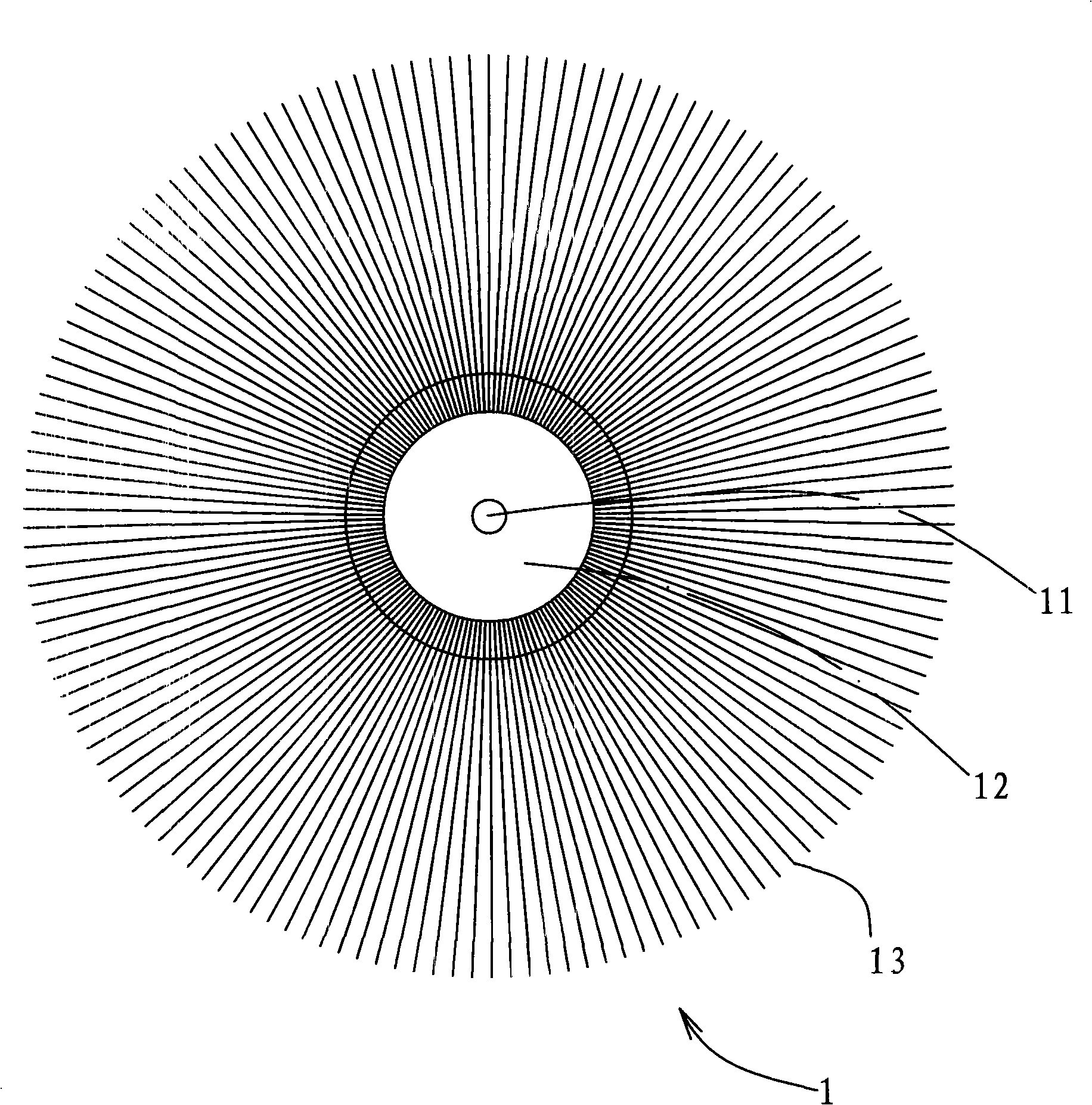

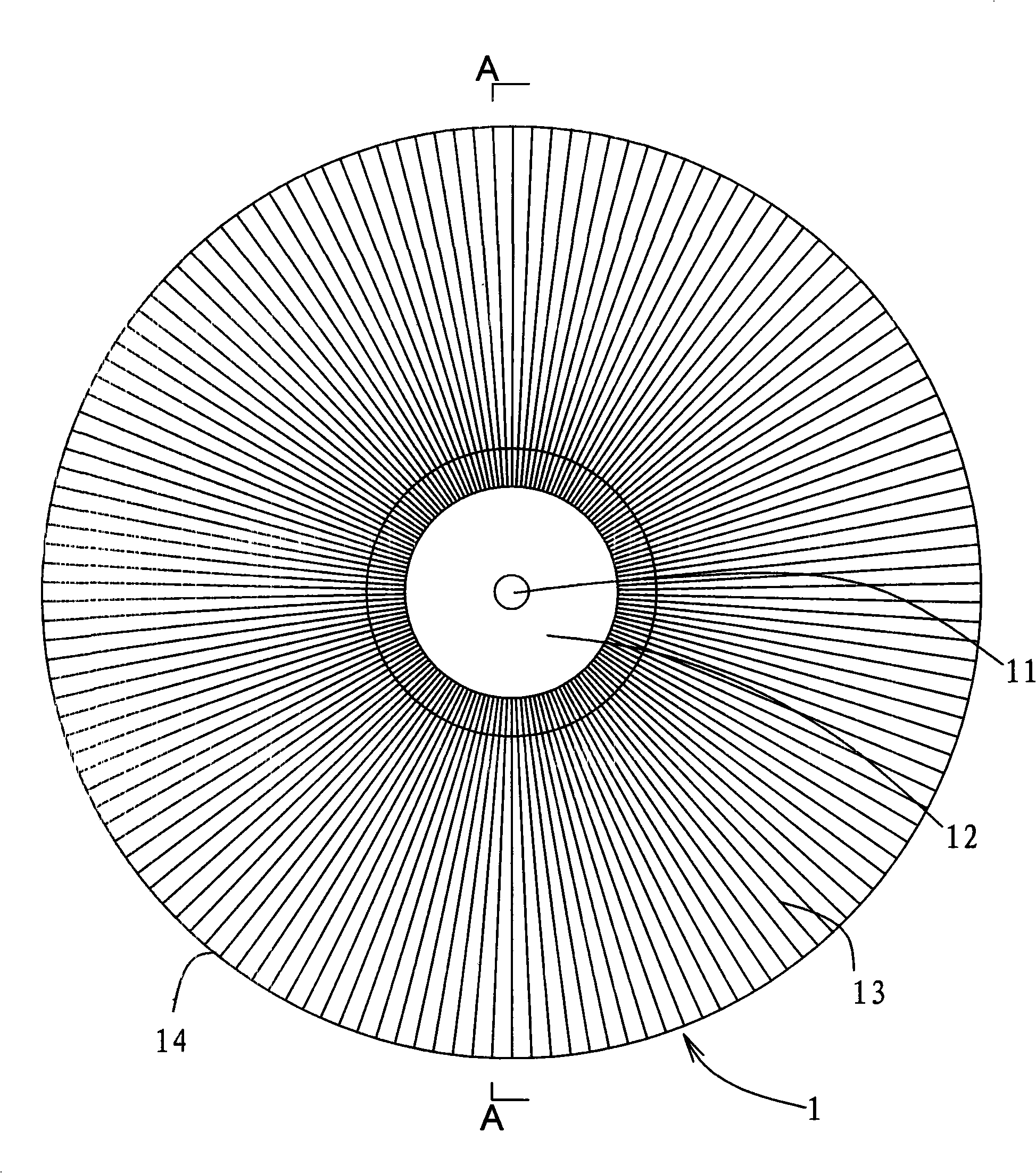

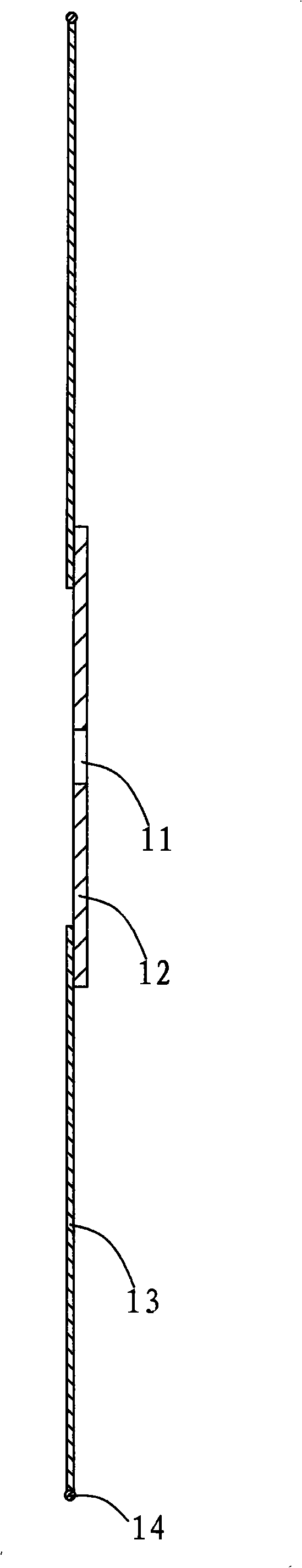

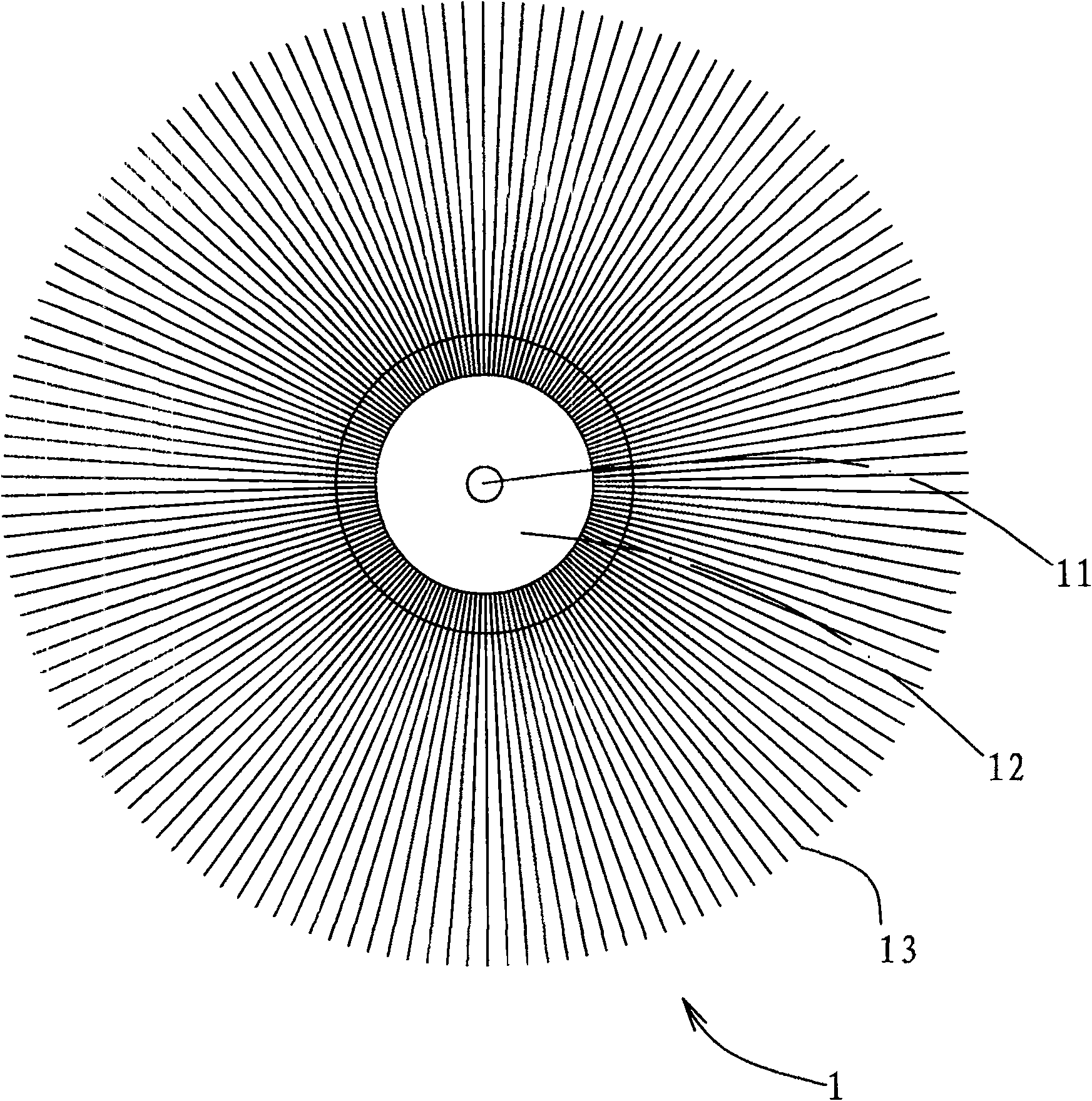

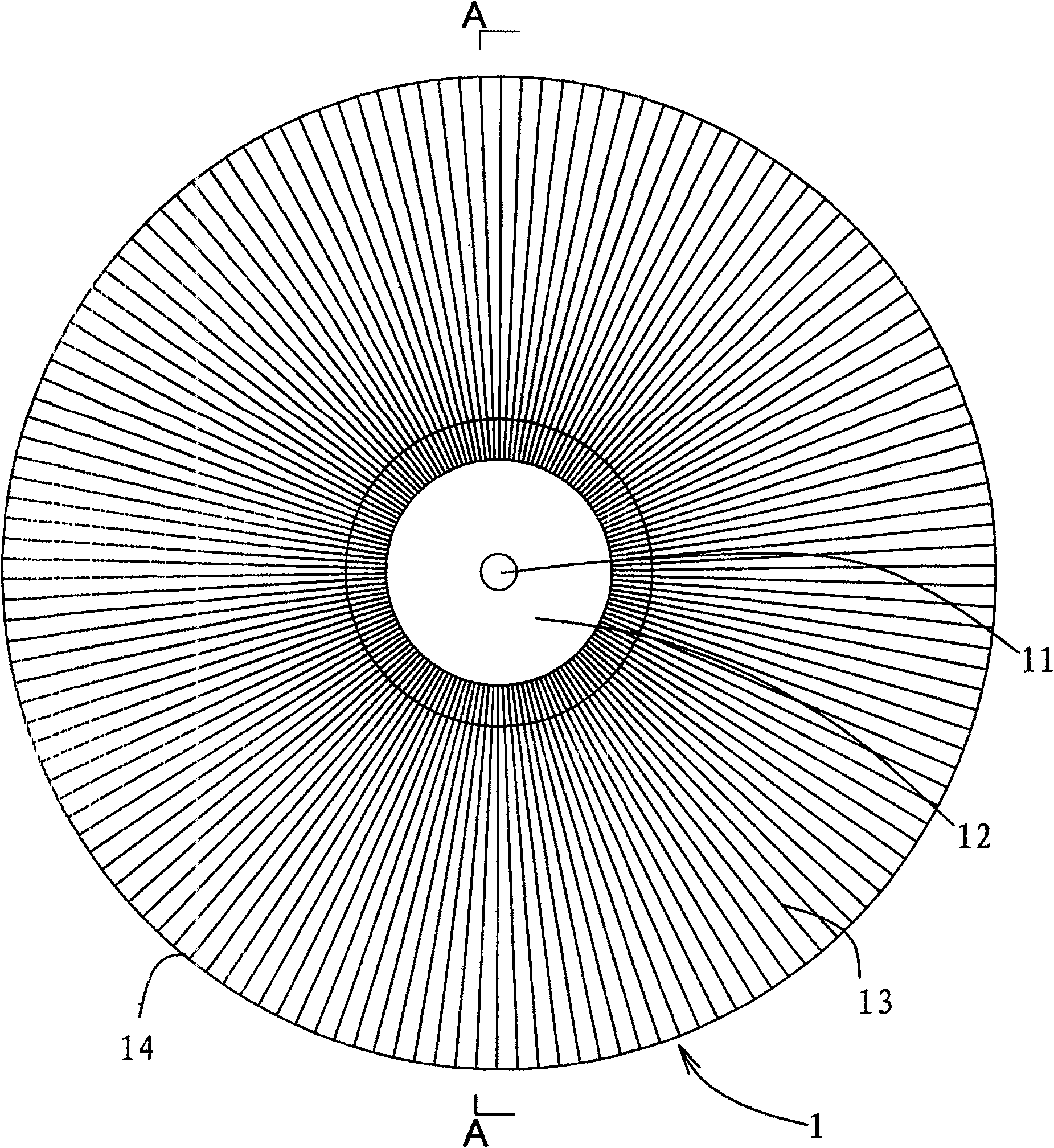

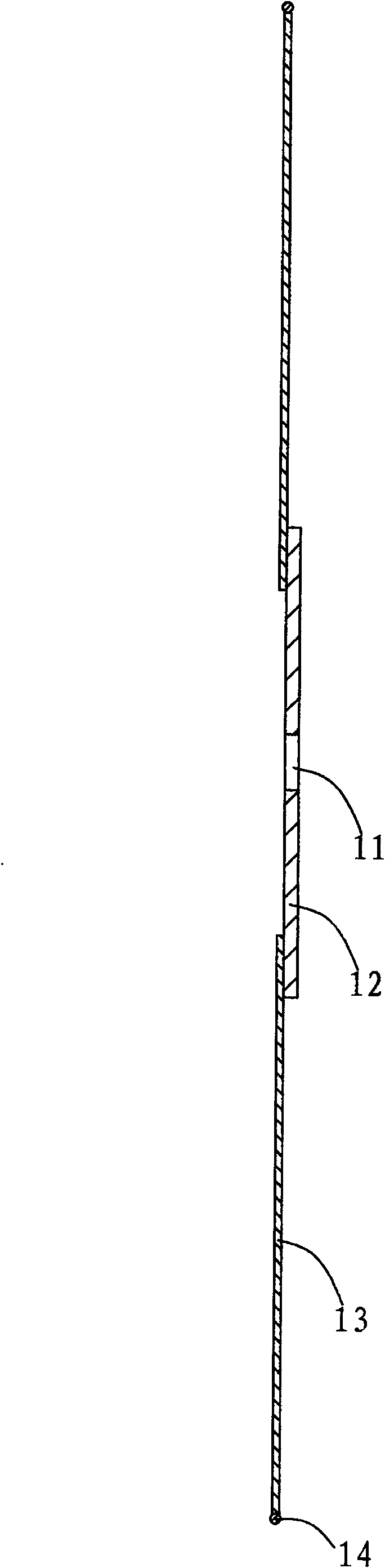

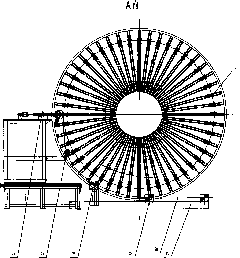

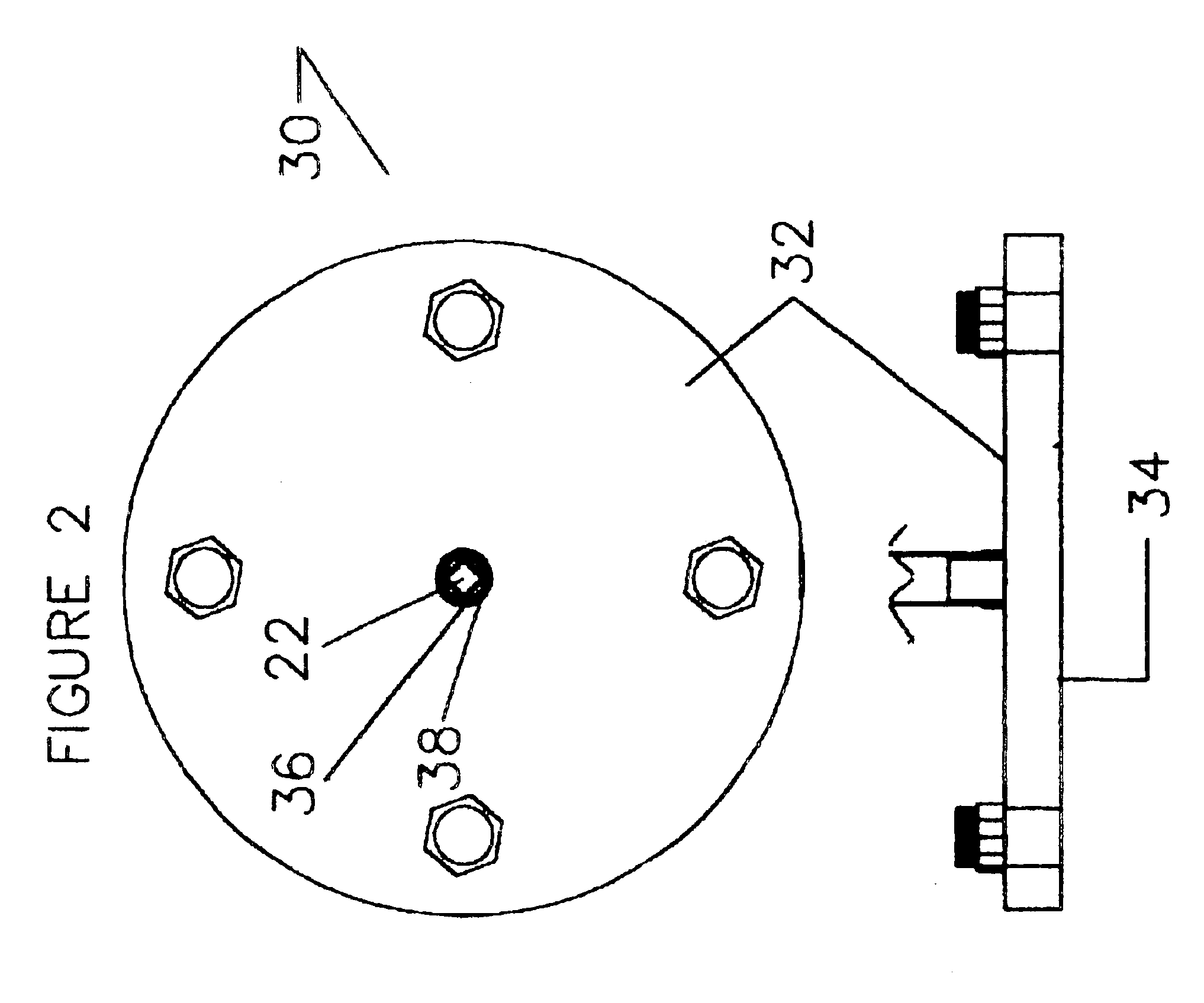

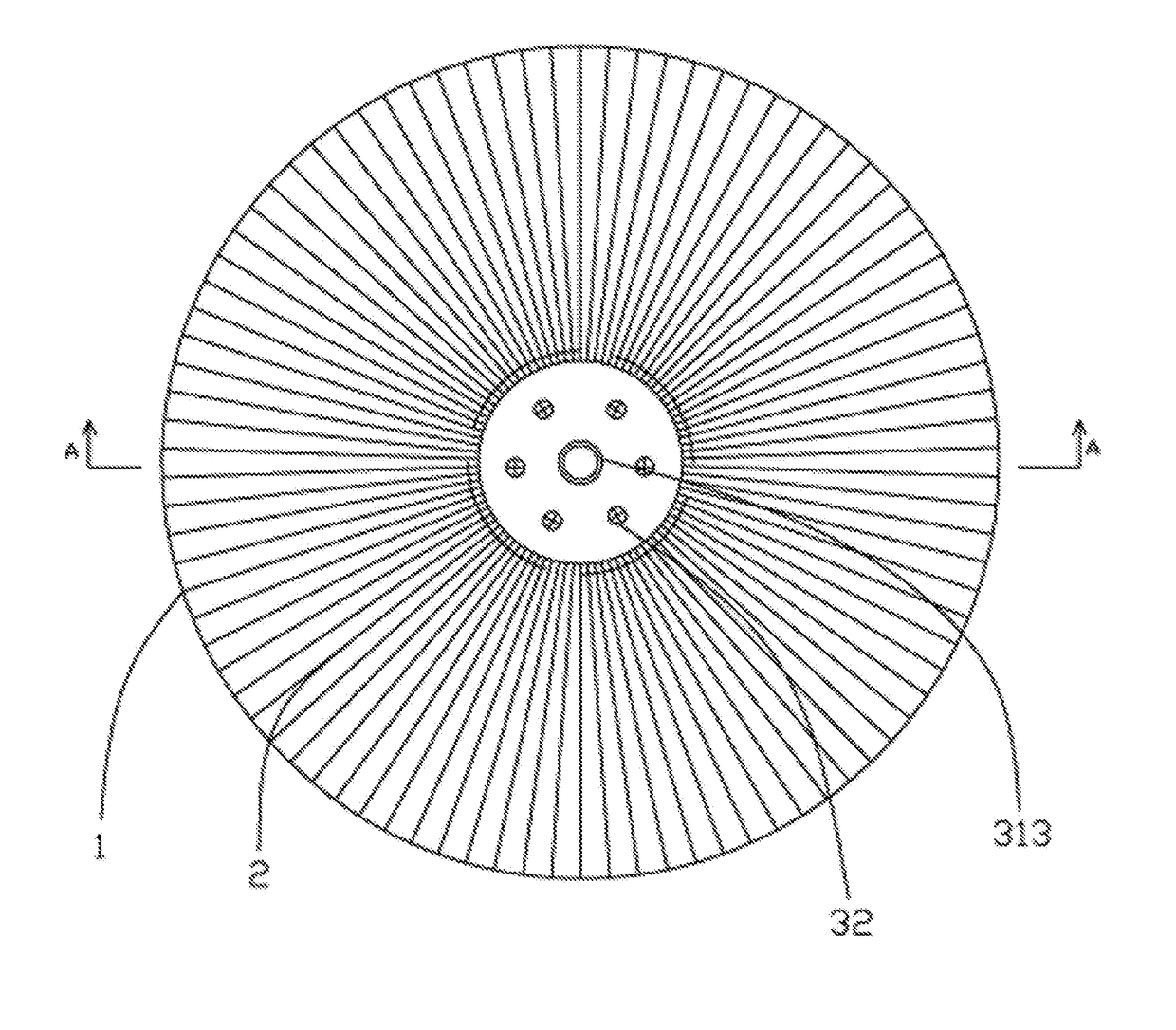

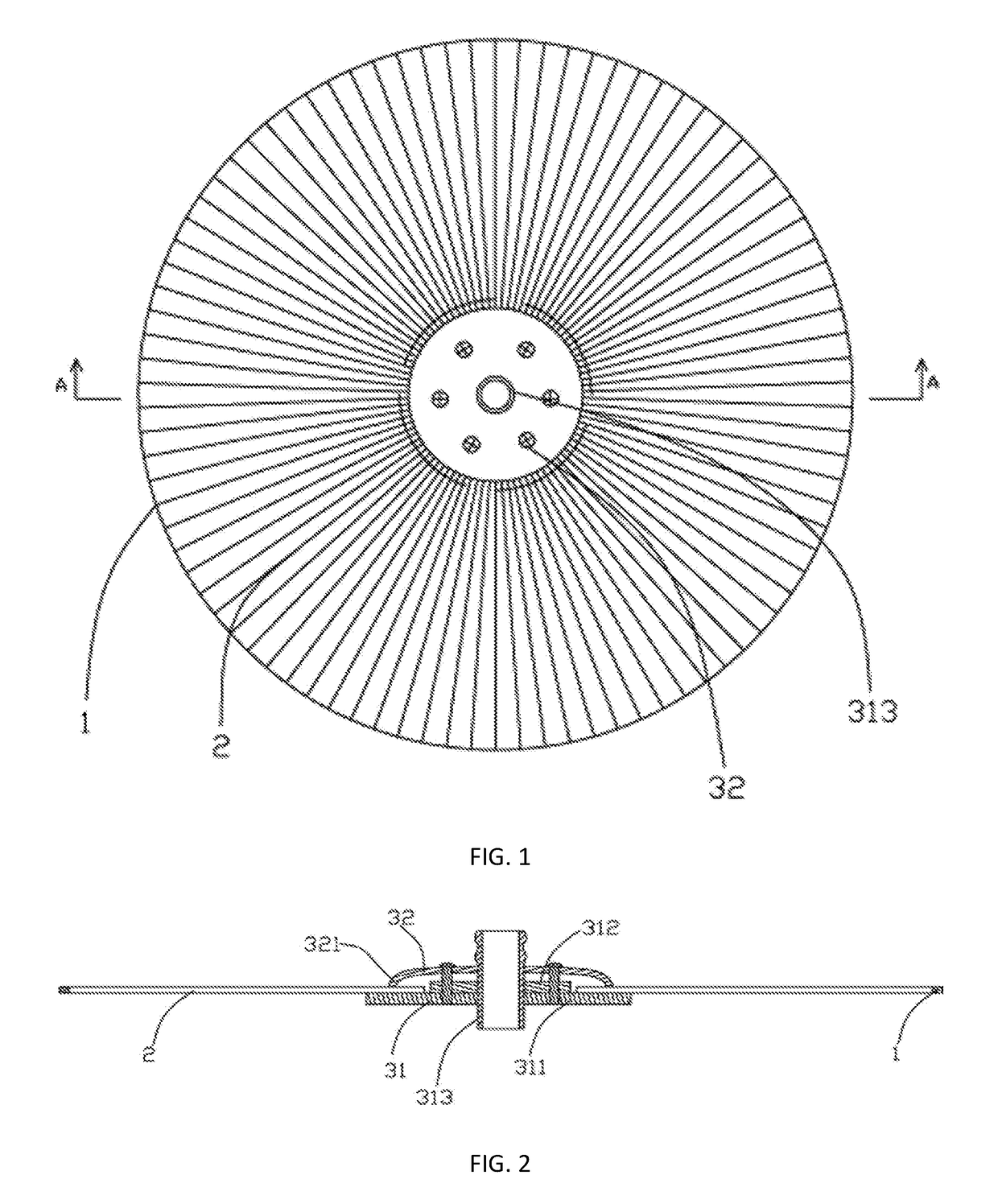

Novel dynamic physical shielding purifier, production method and special fixture

ActiveCN101288817AEasy maintenanceLow costDispersed particle separationFencing wireEngineeringMillimeter

The invention provides a novel dynamic physical screen purifier and a method and a special clamp used for fabricating the purifier at the same time; the purifier comprises a central disc and a plurality of round spokes which are arranged in a plane; one ends of the spokes are fixedly connected on the central disc in a radial radiation type; the product of the diameter millimetre number of the spoke and the number of the spokes are more than or equal to than 46 and less than or equal to 460; furthermore, the diameter of temperature spoke is not less than 0.3mm. The novel dynamic physical screen purifier has the advantages of simple structure, low fabrication cost and high purification rate.

Owner:深圳厨之道环保高科有限公司

Novel dynamic physical shielding purifier, production method and special fixture

ActiveCN100591405CEasy maintenanceLow costDispersed particle separationFencing wireEngineeringMillimeter

The invention provides a novel dynamic physical screen purifier and a method and a special clamp used for fabricating the purifier at the same time; the purifier comprises a central disc and a plurality of round spokes which are arranged in a plane; one ends of the spokes are fixedly connected on the central disc in a radial radiation type; the product of the diameter millimetre number of the spoke and the number of the spokes are more than or equal to than 46 and less than or equal to 460; furthermore, the diameter of temperature spoke is not less than 0.3mm. The novel dynamic physical screenpurifier has the advantages of simple structure, low fabrication cost and high purification rate.

Owner:深圳厨之道环保高科有限公司

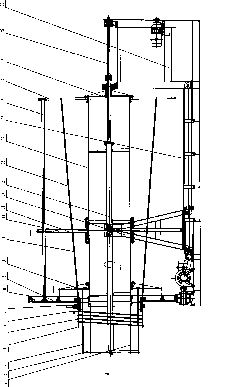

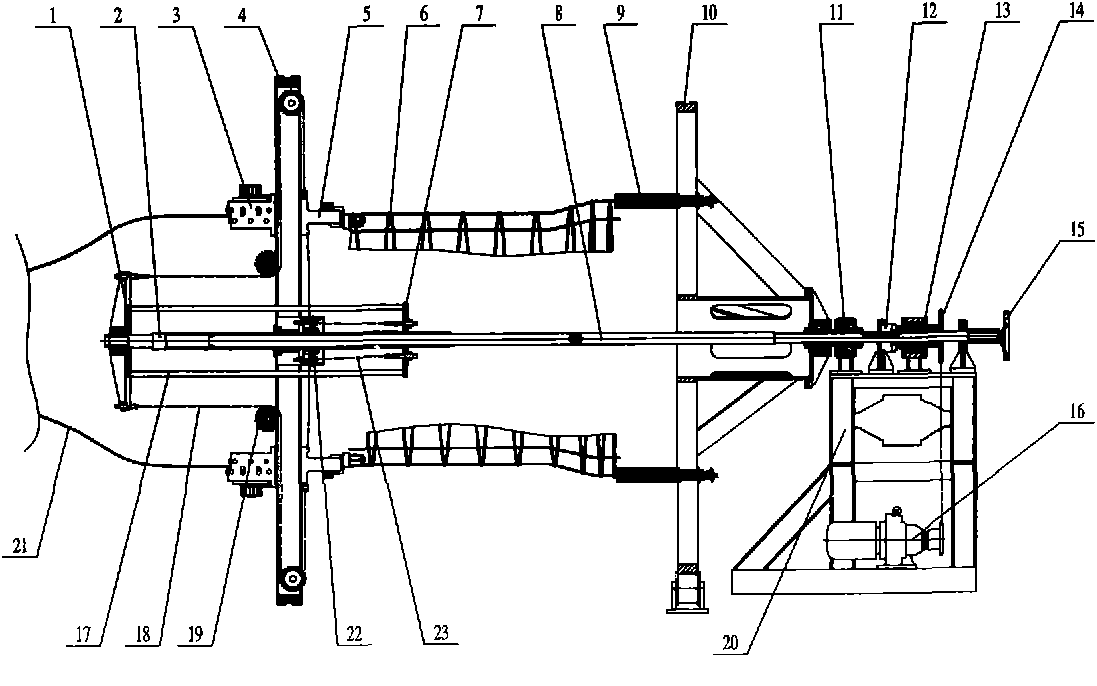

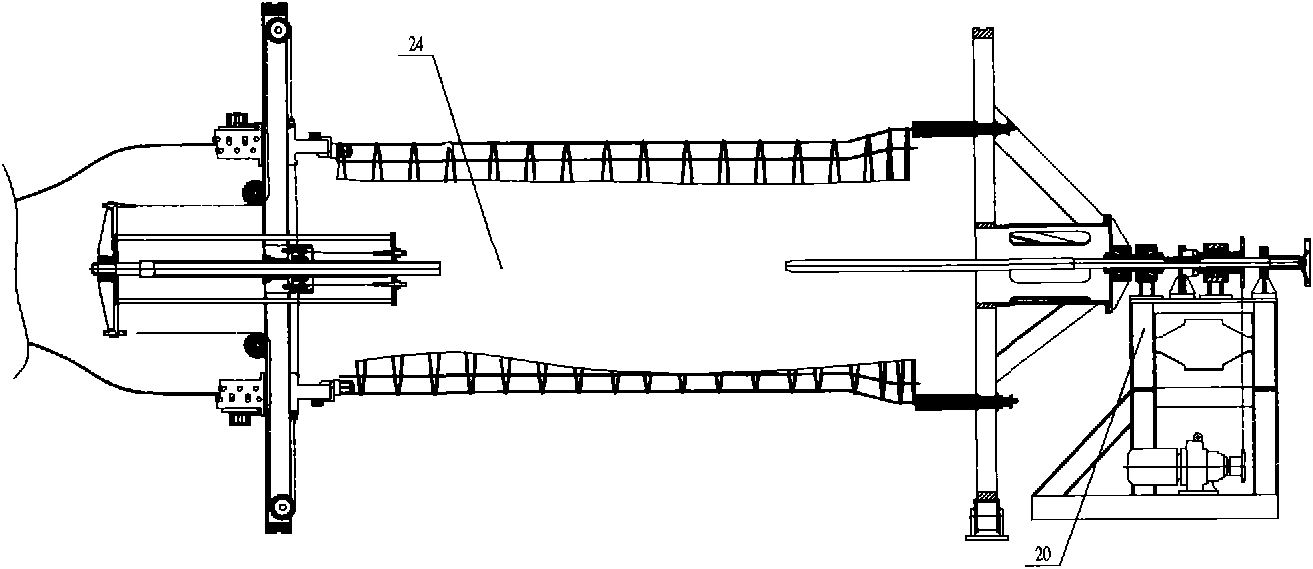

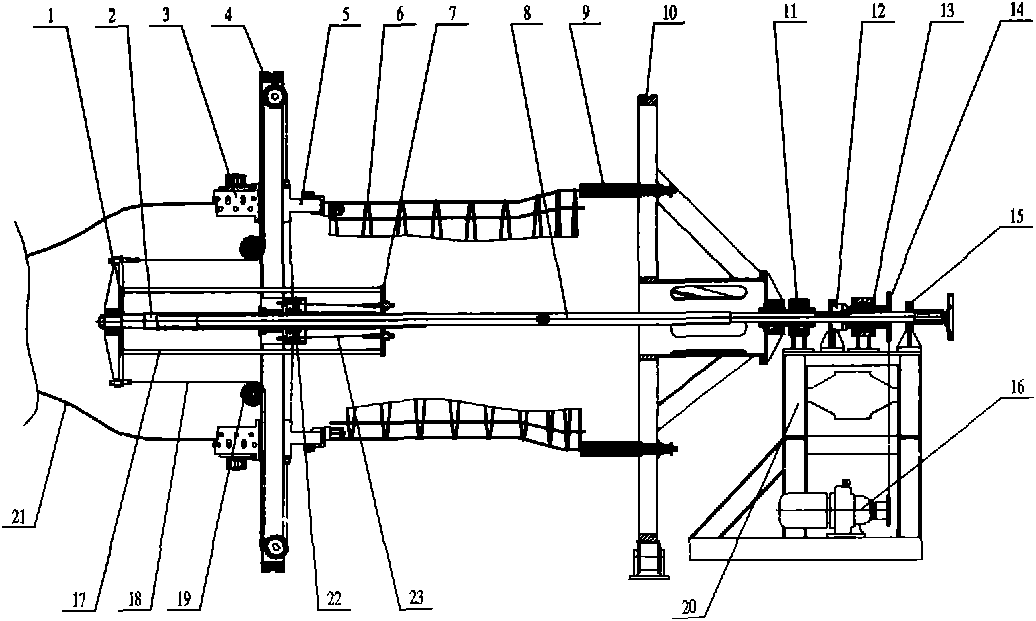

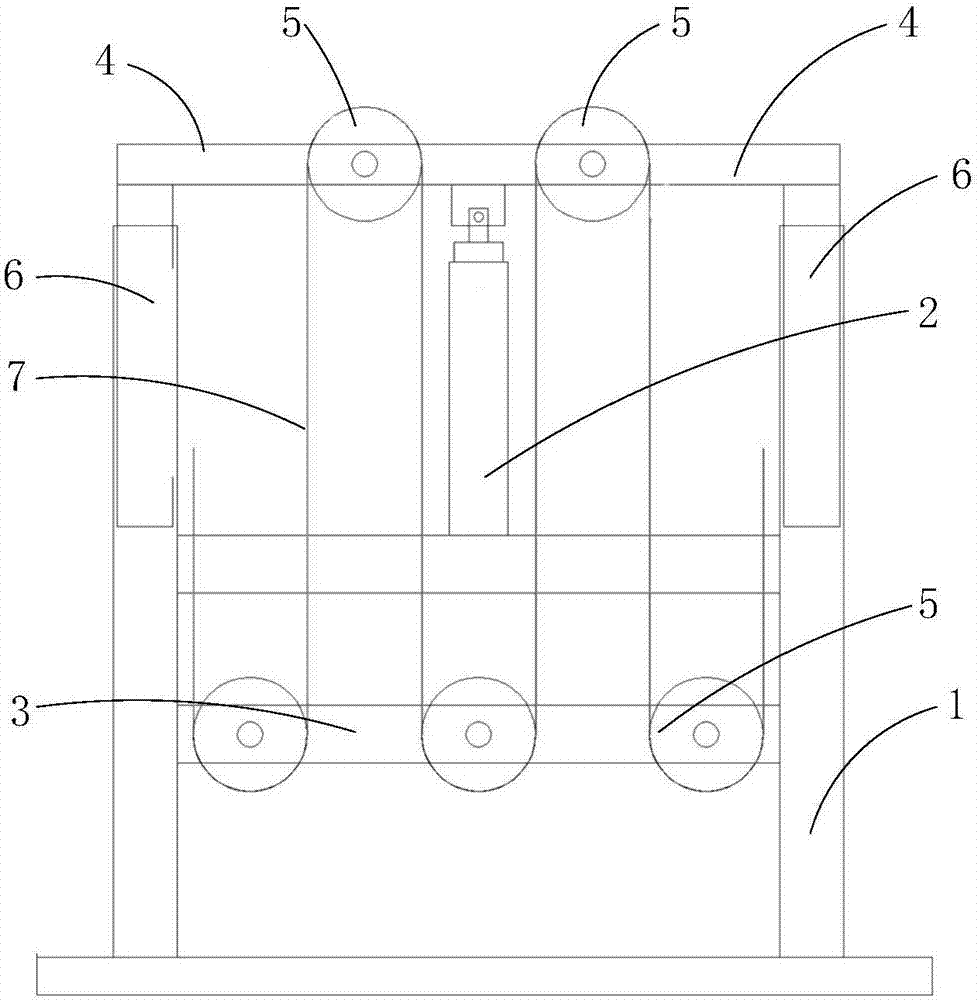

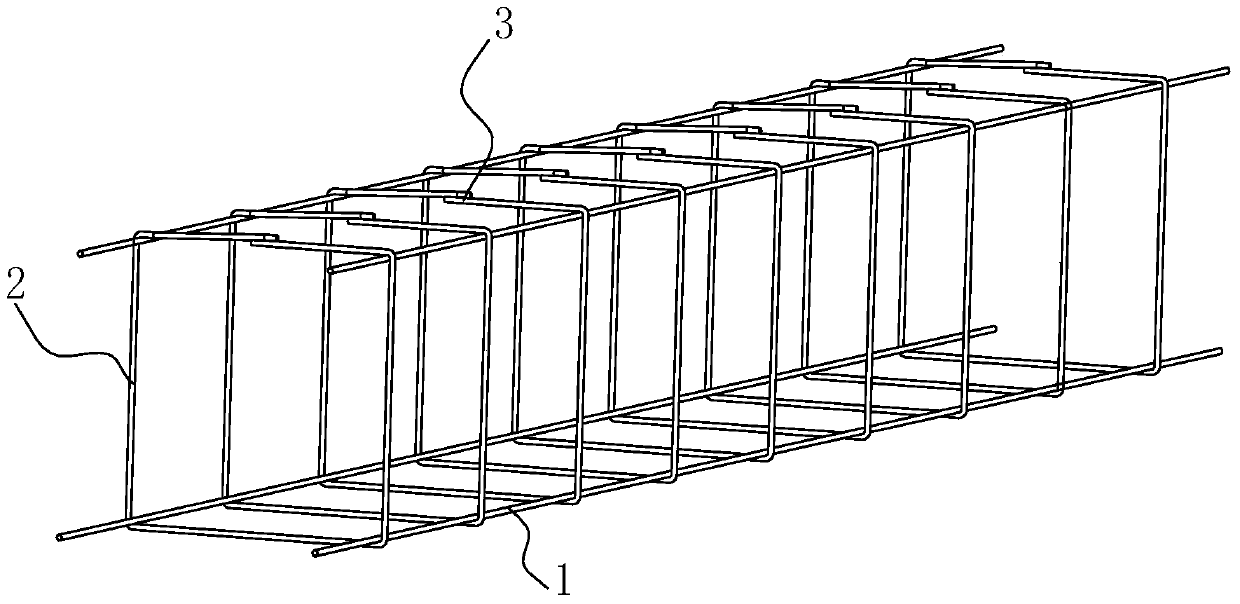

Double-reinforcement parallel-winding full-automatic reinforced concrete pipe reinforcement cage seam welder

The invention discloses a double-reinforcement parallel-winding full-automatic reinforced concrete pipe reinforcement cage seam welder, which relates to a seam welder. The seam welder can meet the requirement on double-reinforcement parallel winding, and can efficiently and accurately fabricate a stressless cage with a large caliber and a high reinforcement ratio. The double-reinforcement parallel-winding seam welder comprises a chassis, a main shaft, a reinforcement-pushing rod, a reinforcement-pushing shaft, a main faceplate, a flange plate, a rear faceplate, a reinforcement-pushing faceplate, a welding seat, a guide rod, a reinforcement-pushing trolley unit, a double-reinforcement guiding unit and a welding unit; the seam welder also comprises the double-reinforcement guiding unit, a reinforcement-threading unit and a reducing mechanism; the double-reinforcement guiding unit comprises a gradual guide roller group for a single reinforcement and a guide roller group for double-reinforcement combination; the reinforcement-threading unit comprises a reinforcement-threading tube with a longitudinal slot, a piece of reinforcement-pushing round steel, a reinforcement-pushing faceplate, the reinforcement-pushing trolley unit and a drive mechanism for driving the reinforcement-pushing faceplate to axially move; the reducing mechanism comprises the reinforcement-pushing rod-connecting flange plate, the reinforcement-pushing rod, the reinforcement-pushing shaft, a chain drive mechanism and a flange drive mechanism; and a welding electrode wheel is provided with a groove larger than the diameters of two circular reinforcements.

Owner:江苏中意建材机械有限公司

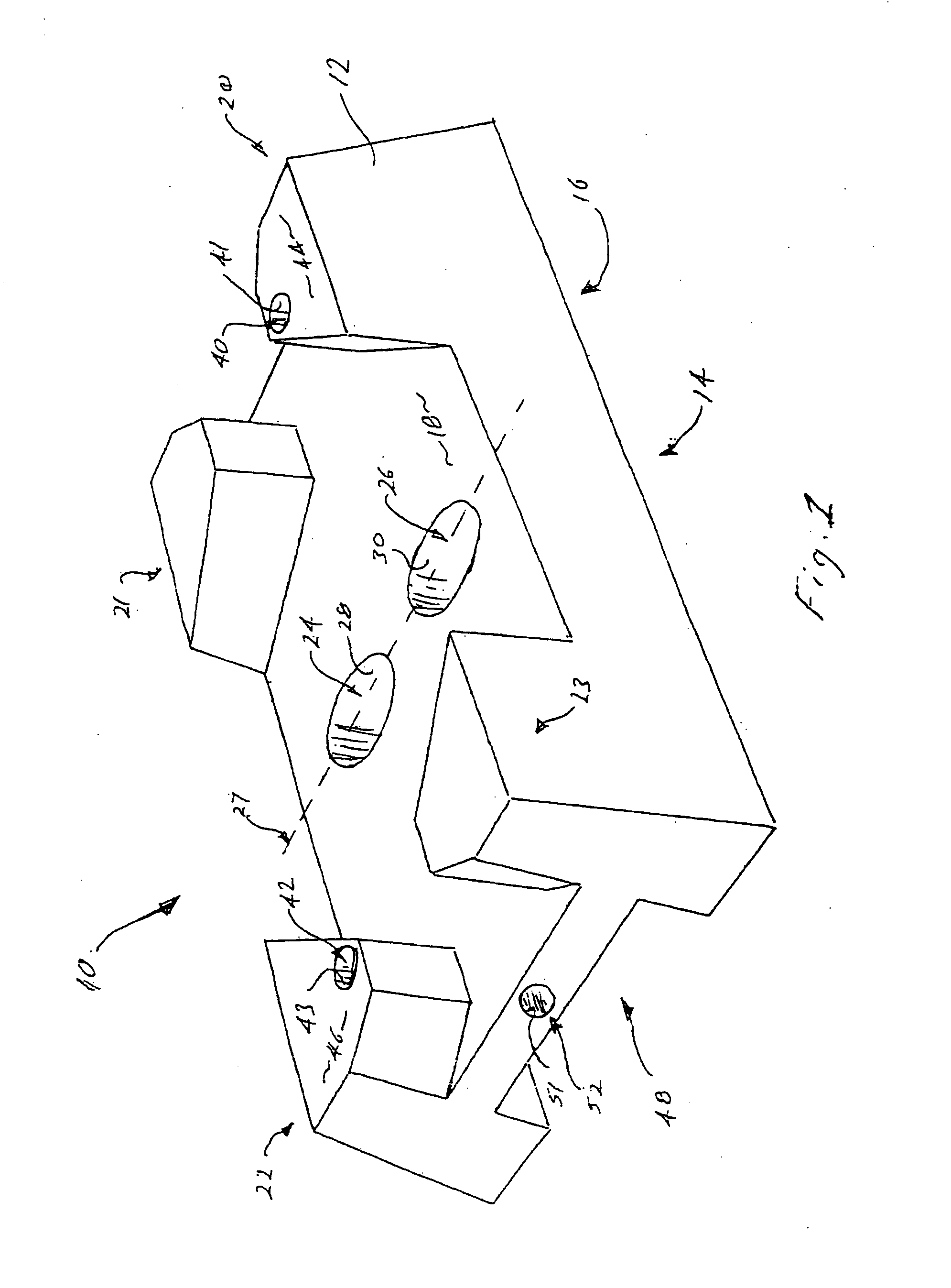

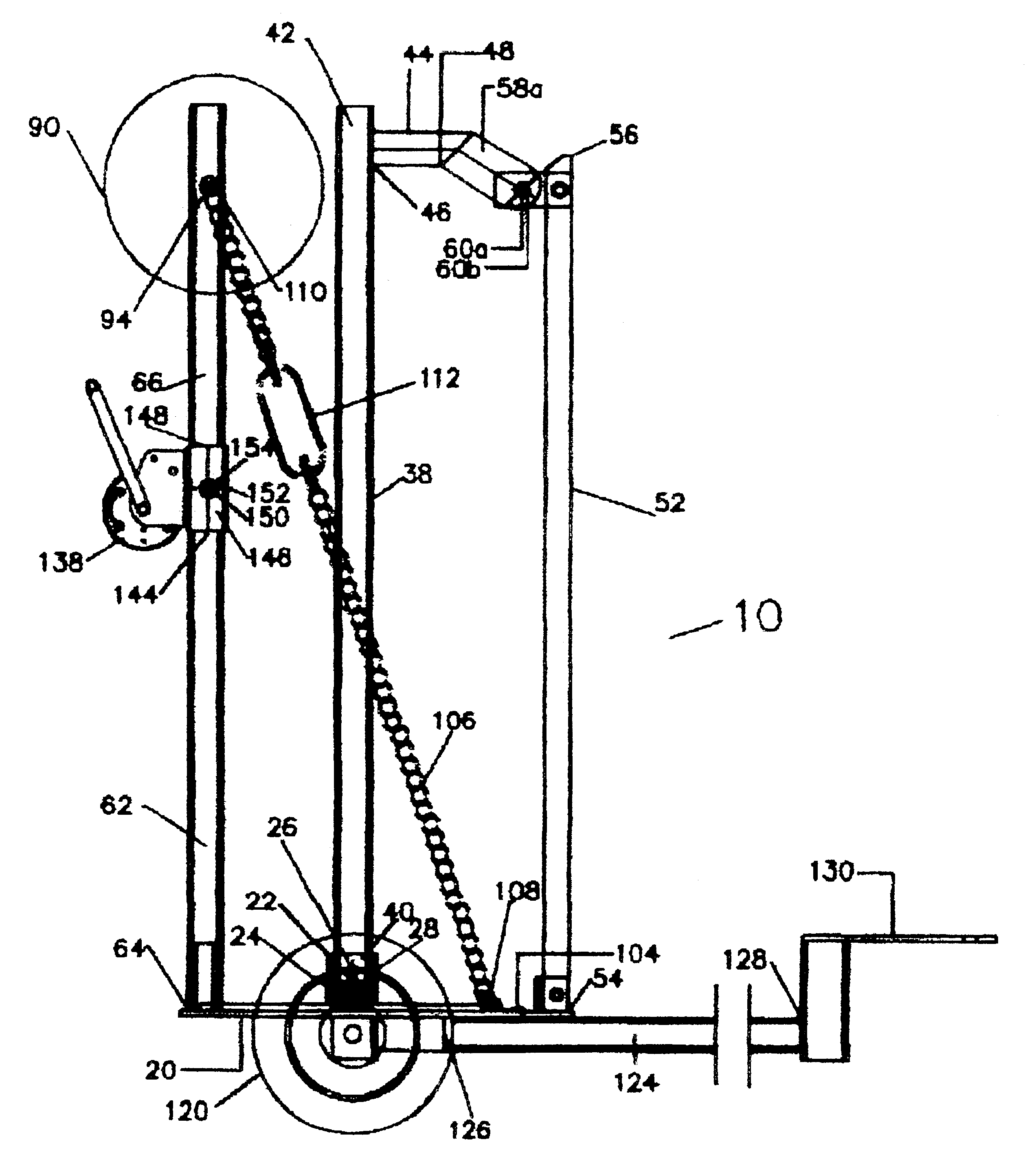

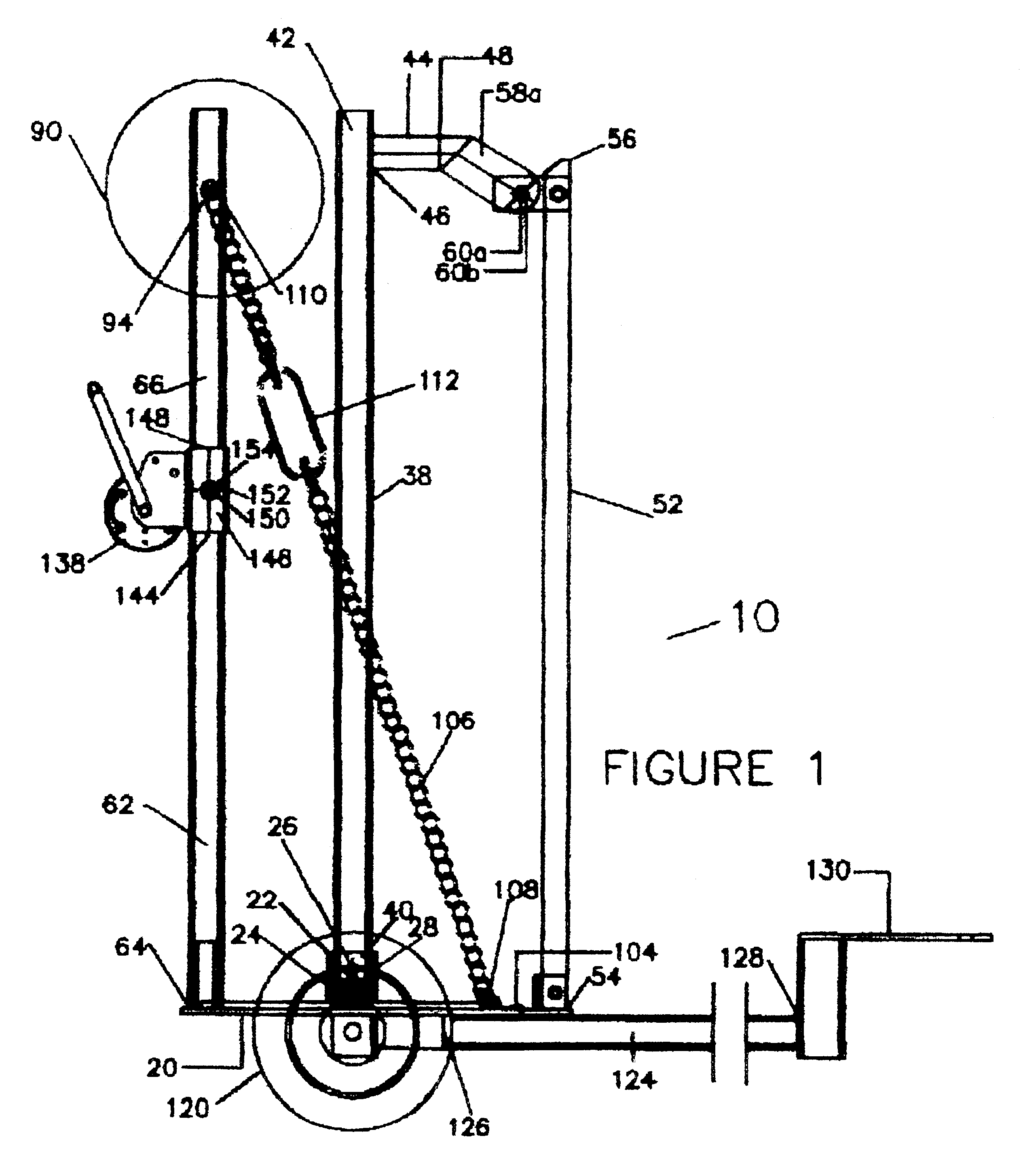

Fence dispensing apparatus

InactiveUS6860471B2Improve efficiencyExcessive wearFilament handlingFencingMobile vehicleEngineering

A fence dispensing apparatus for installing fencing wire along a line of fence posts. The fence dispensing apparatus permits easy setup along with efficient and safe operation. In addition to dispensing wire, the apparatus stretches unrolled wire using a winch and a wire interface. The fence dispensing apparatus essentially comprises a base member that sits on an axle and wheels. Moreover, the base member connects to a motor vehicle via a hitch receiver or a three-point tractor hookup. As the vehicle travels along a fence line, the apparatus dispenses wire from a vertically aligned spindle and / or from a horizontally aligned roller. The spindle disconnects from the base member, permitting it to be easily loaded with wire and set up for operation. Additionally, a spindle lock and spindle support act in concert to safely hold the loaded spindle in position. Furthermore, a wear plate between the loaded spindle and the base member protects the base member from excessive wear during operation. In addition to the spindle, a horizontally aligned roller dispenses wire. The horizontal roller includes a safety plate that protects against injury if the unrolled wire breaks and backlashes. Unrolled wire may be connected to a wire interface, permitting the unrolled wire to be associated to a cable without cutting the wire. Turning the apparatus' winch reels in the cable, stretching the unrolled wire.

Owner:ALBRITTON SANDERFORD FENCE CO

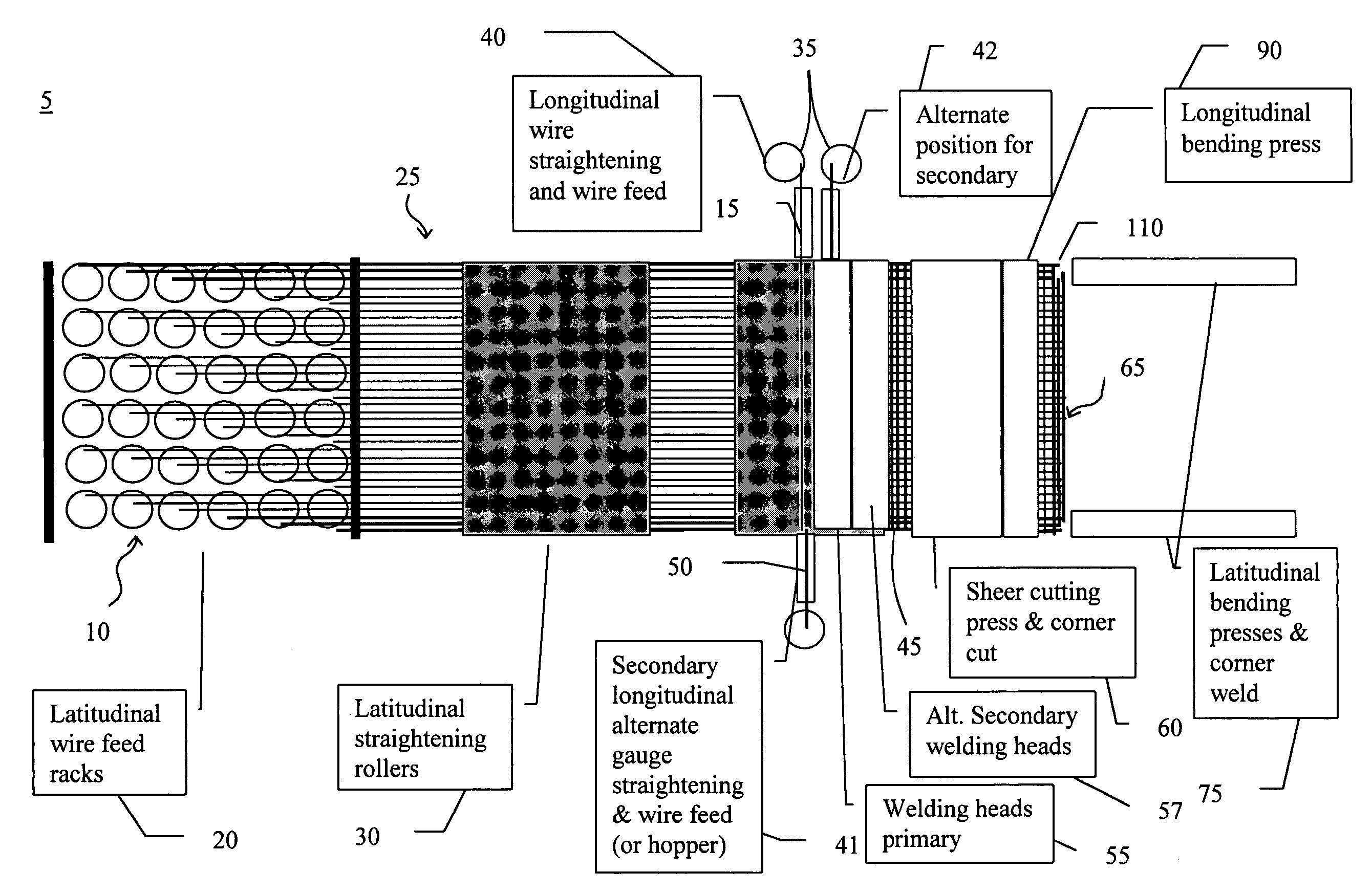

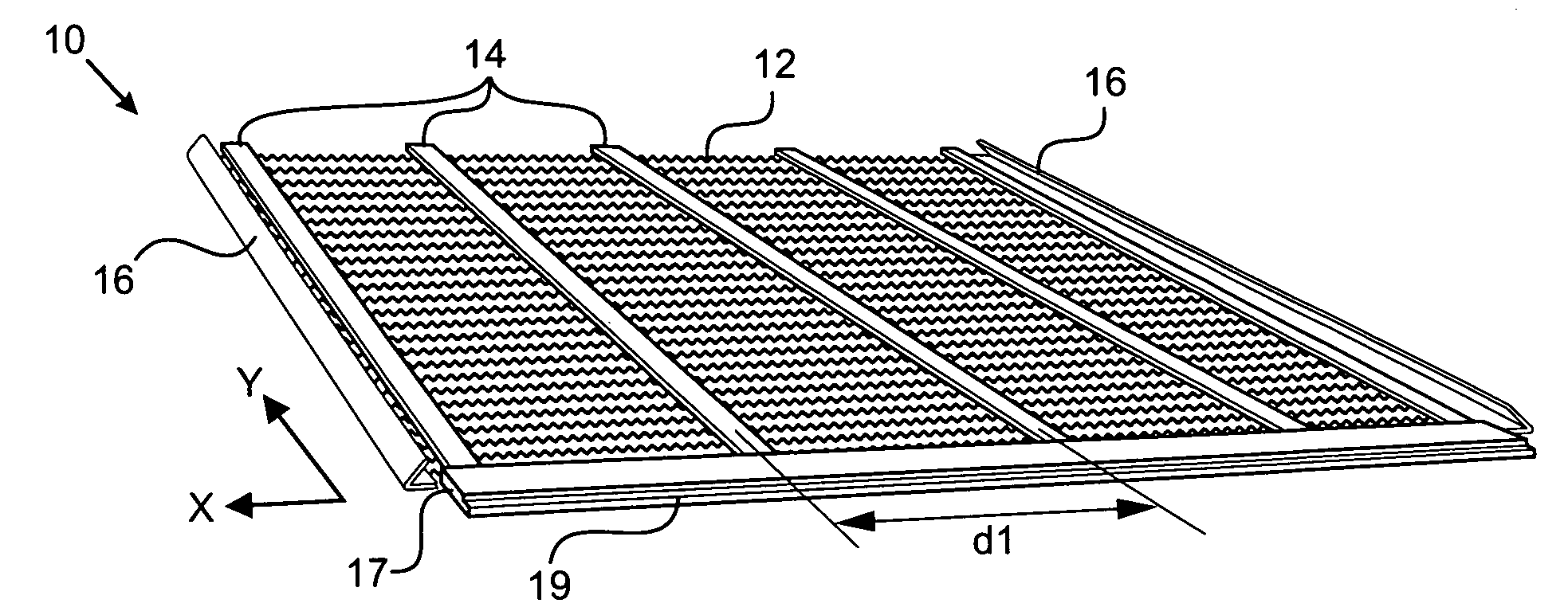

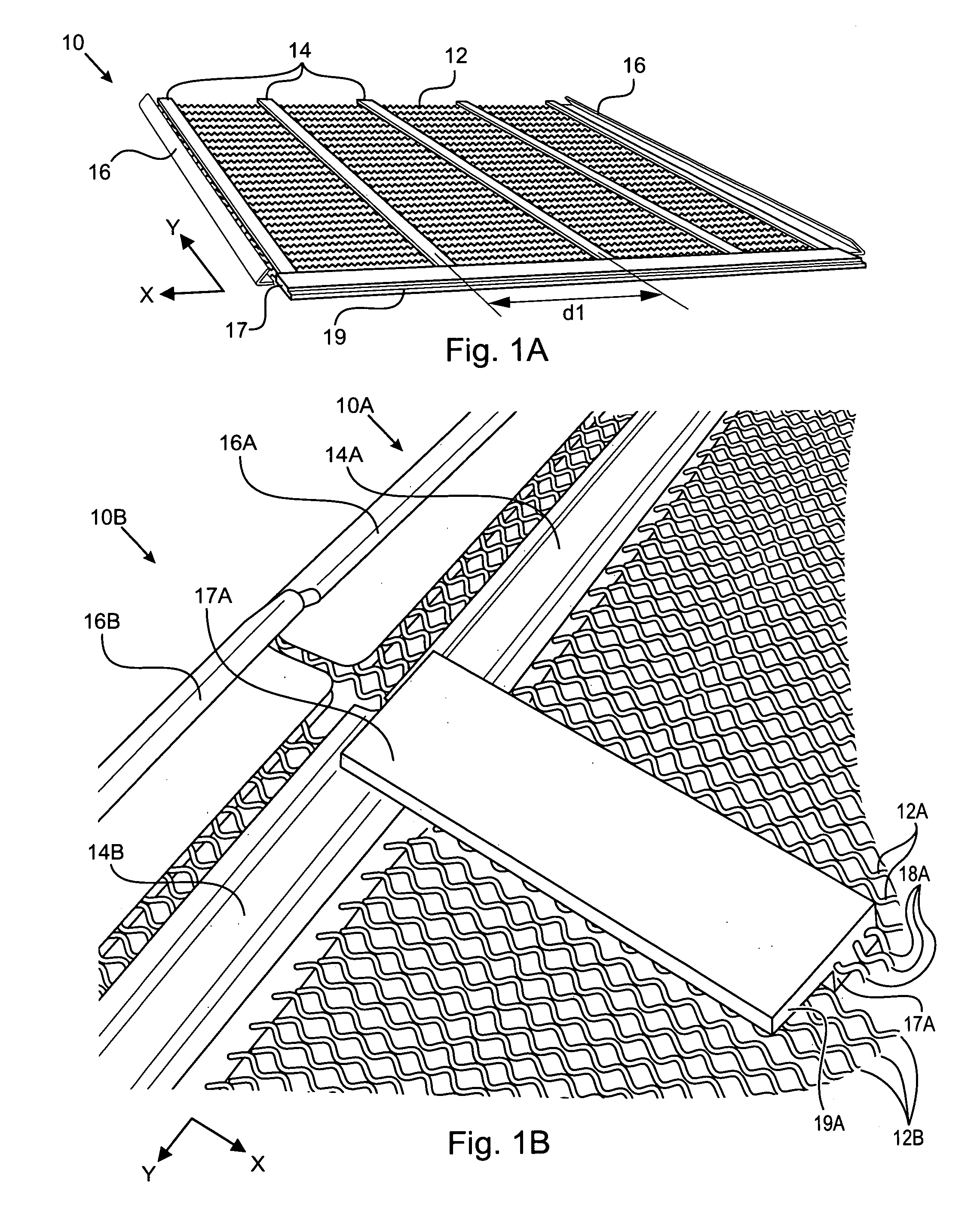

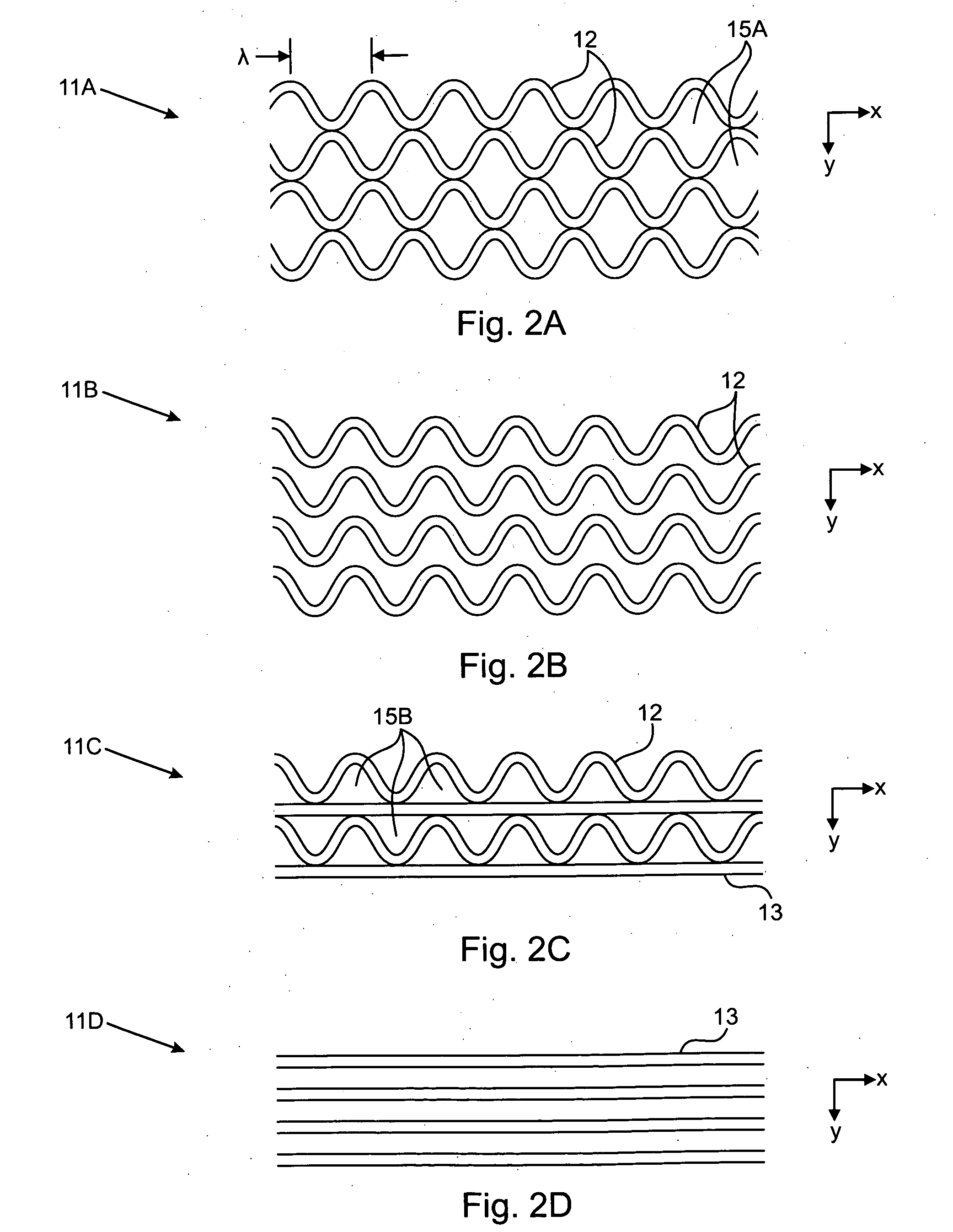

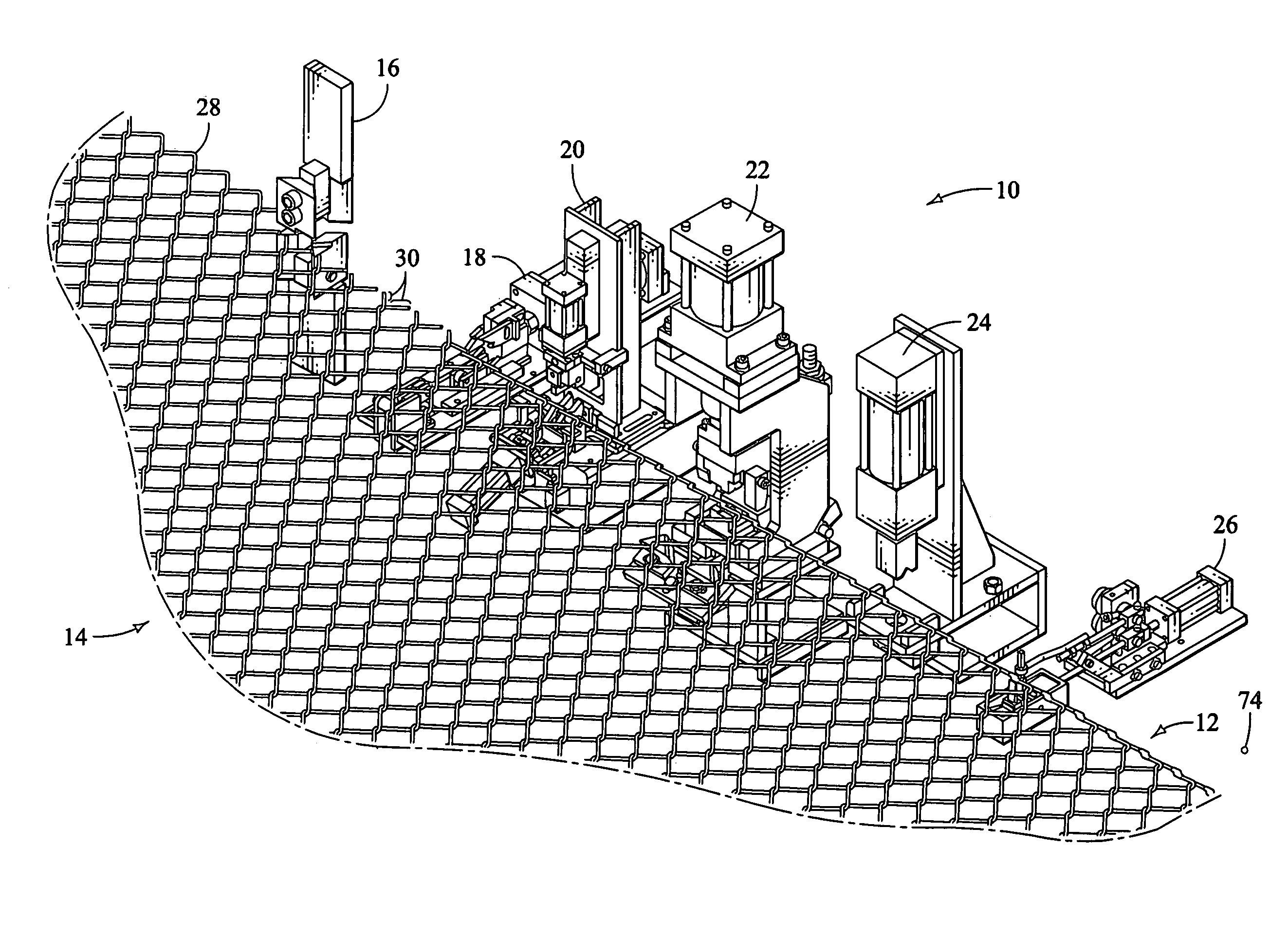

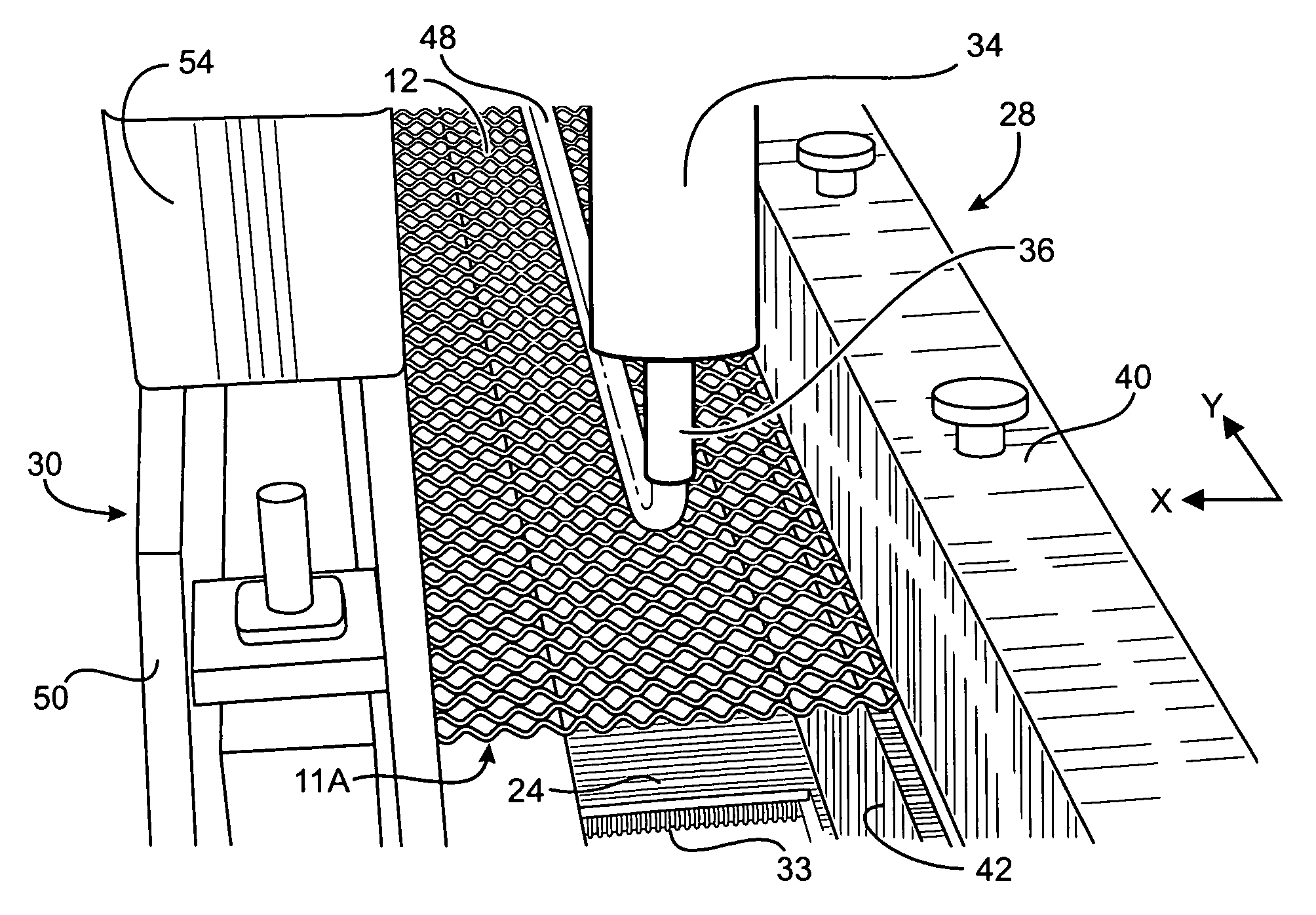

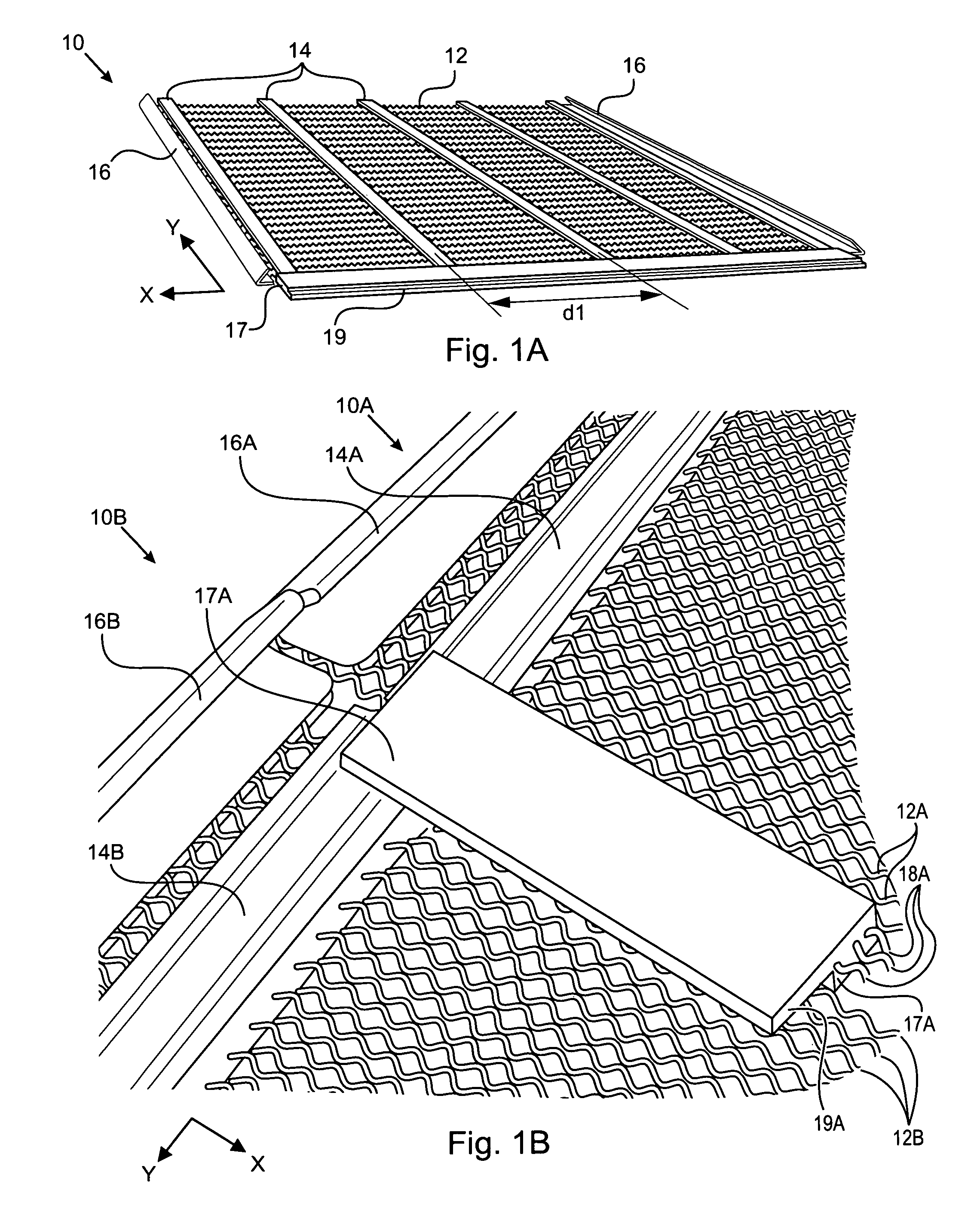

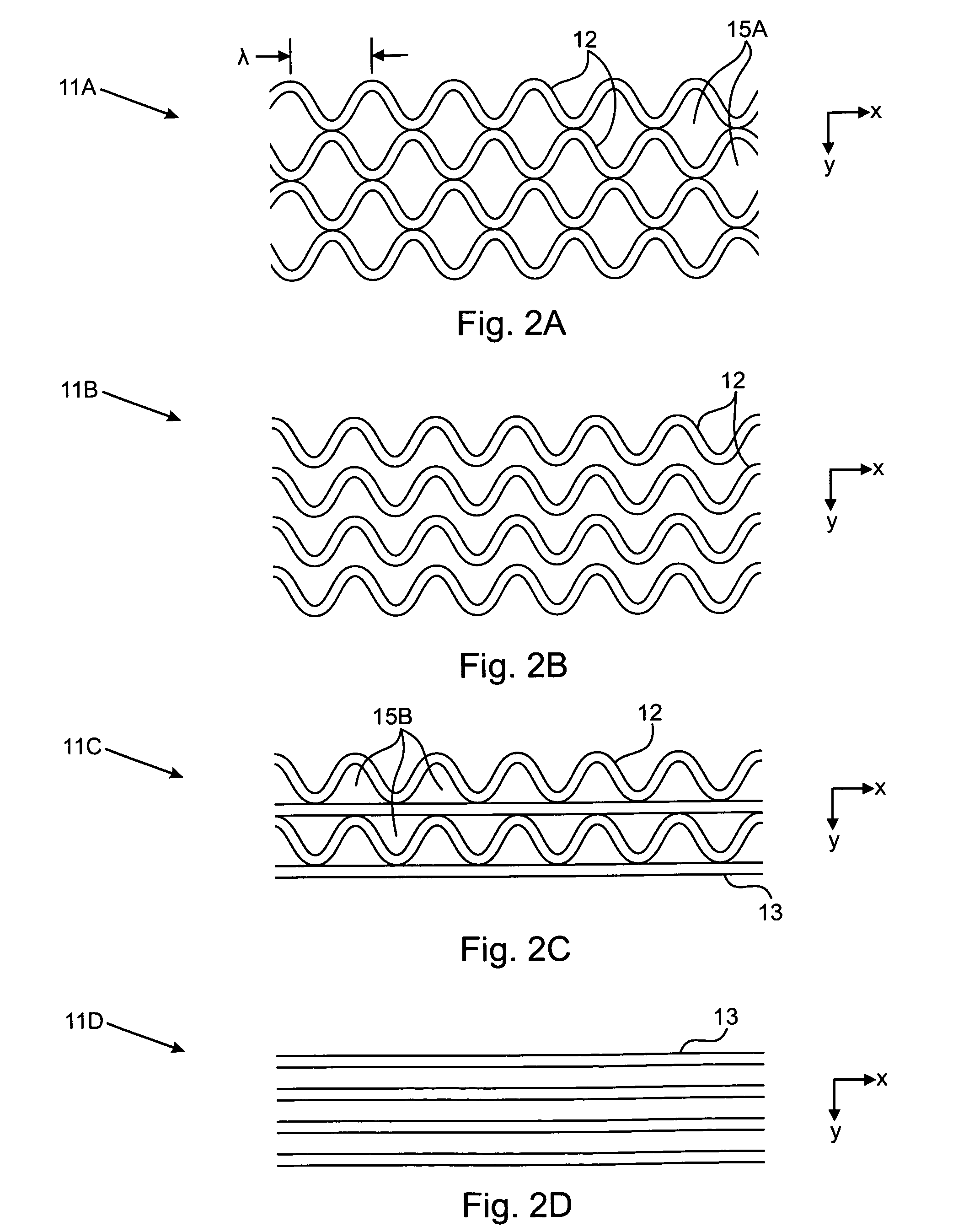

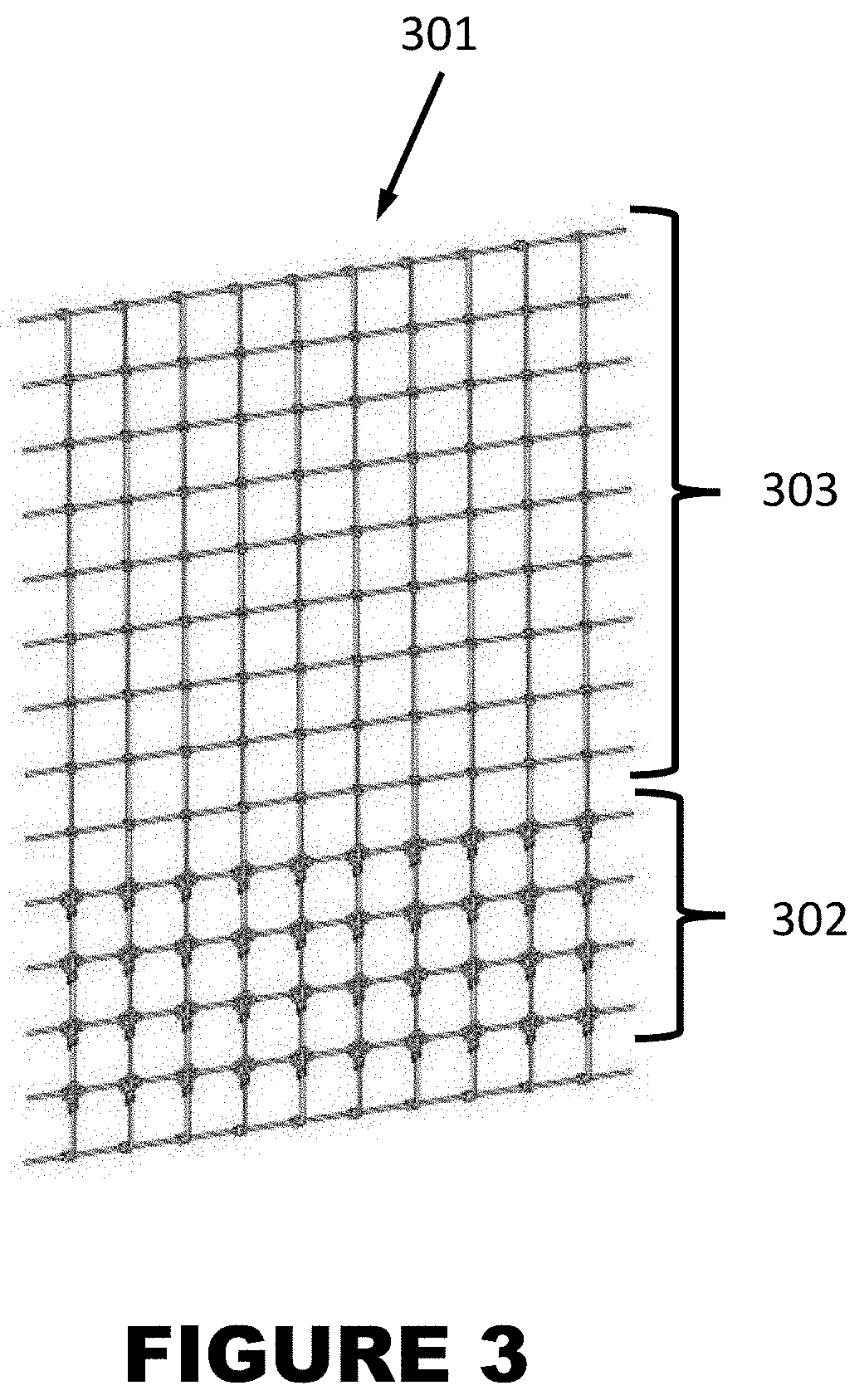

Apparatus and method for making wire screen

A method of making a screen with an apparatus, the screen including a plurality of wires arranged in a patterned configuration, the apparatus including an extruder and a mold, the method including (a) longitudinally aligning the plurality of wires in the apparatus in a first direction only and arranging the wires in the patterned configuration, (b) applying a first bead of molten material on the wires via the extruder, and (c) directly molding the first bead of molten material into a support member for the screen by closing the mold about the bead, wherein the support member at least partially encases at least one of the wires.

Owner:BUFFALO WIRE WORKS

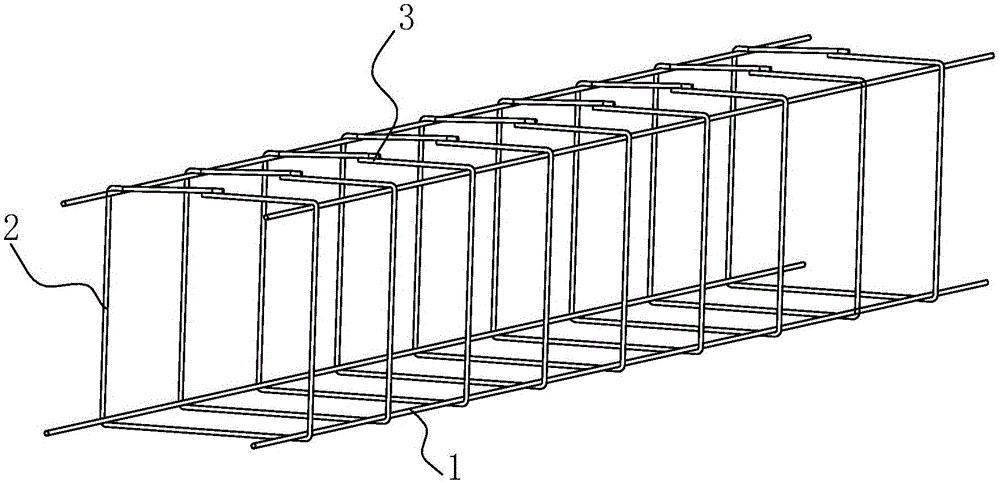

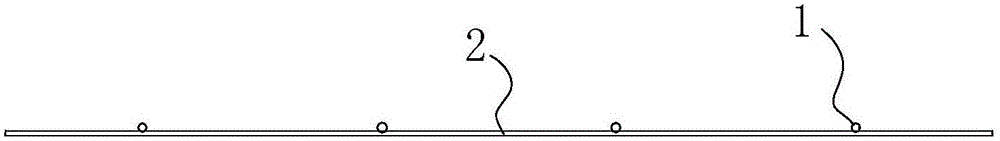

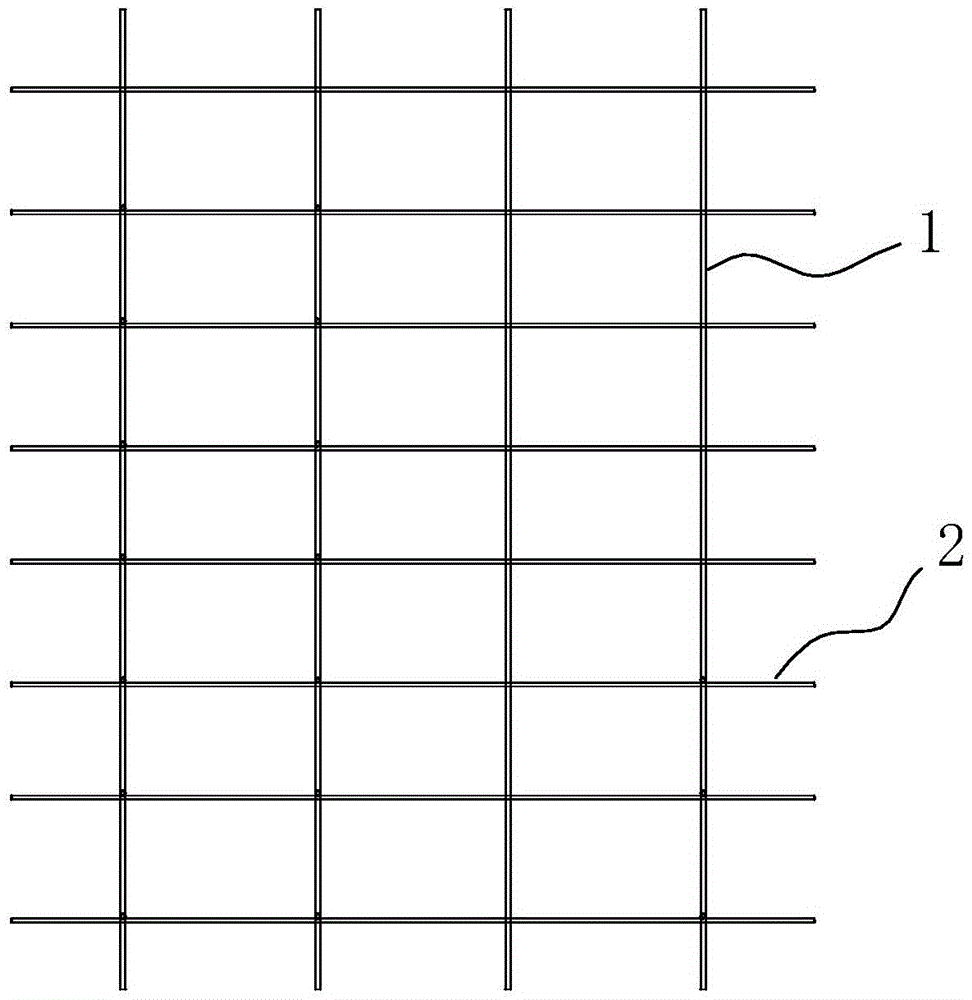

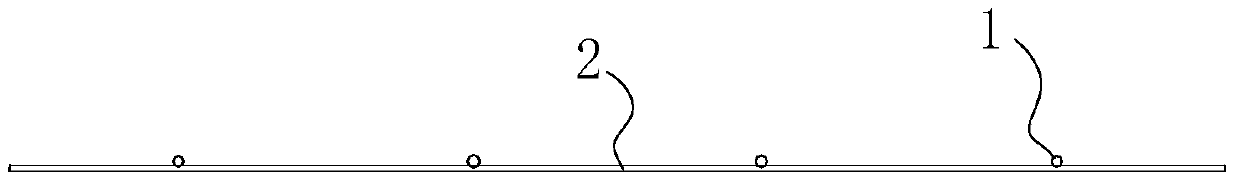

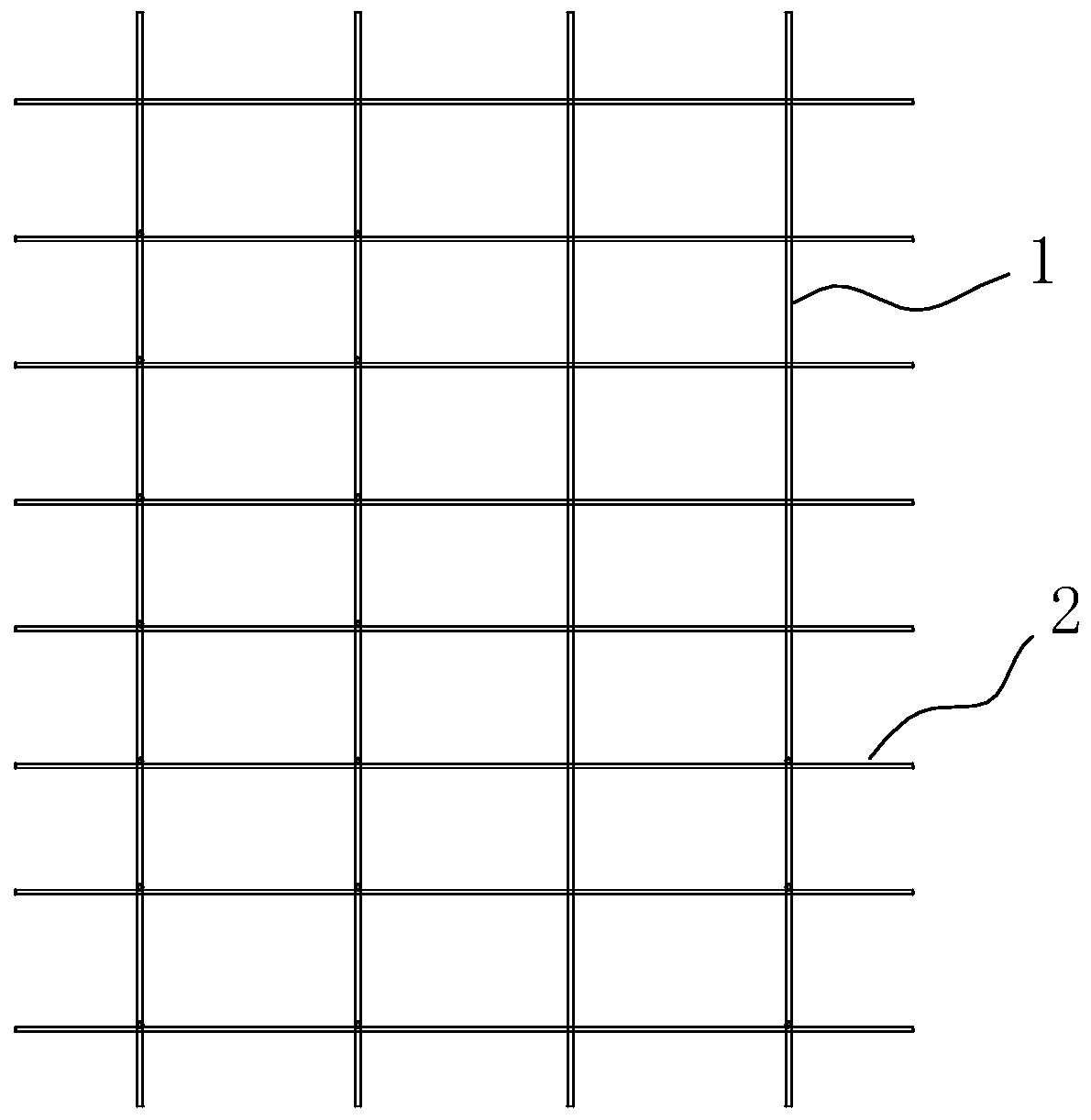

Machining method and equipment for steel bar keels

ActiveCN105057511AImprove processing efficiencyImprove reliabilityFencing wireWire networkKeelEngineering

The invention relates to a machining method and equipment for steel bar keels. The machining method includes the steps that a plurality of steel reinforced cages which are shaped like pillars overall are arranged in parallel and then connected into a whole; then the steel reinforced cages connected into a whole are cut into steel bar keels matched with prefabricated wall body modules in shape; or the steel reinforced cages connected into a whole are cut and then reassembled and connected into steel bar keels matched with the prefabricated wall body modules in shape. The machining method and equipment for steel bar keels have the beneficial effects that sheet-shaped steel bar nets are obtained through a net welding machine and then bent to obtain the cylindrical steel reinforced cages; continuous steel reinforced cages can be rapidly machined by connecting upper weft steel bars and lower weft steel bars through the cylindrical steel reinforced cages and then cut into needed steel bar keels or cut and then reconnected into steel bar keels. The machining method and equipment for steel bar keels resolve the bottleneck problem of low machining efficiency of steel bar keels in the process of prefabricating of the wall body modules. Feeding is carried out through a steel bar coil sold in the market, then finished steel bar keel products can be rapidly machined through a set of equipment, and wide application of the prefabricated wall body modules is facilitated.

Owner:赵光林

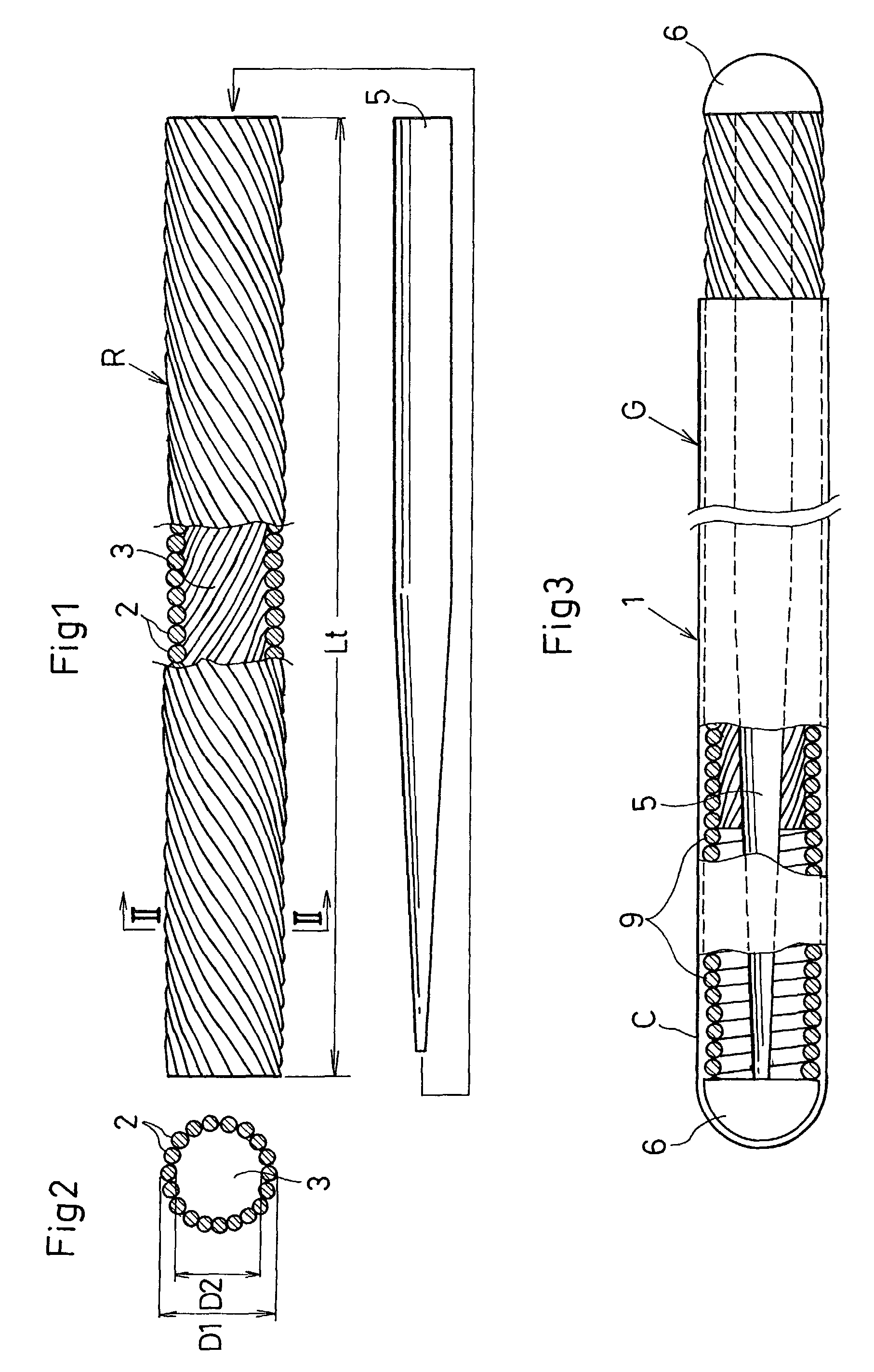

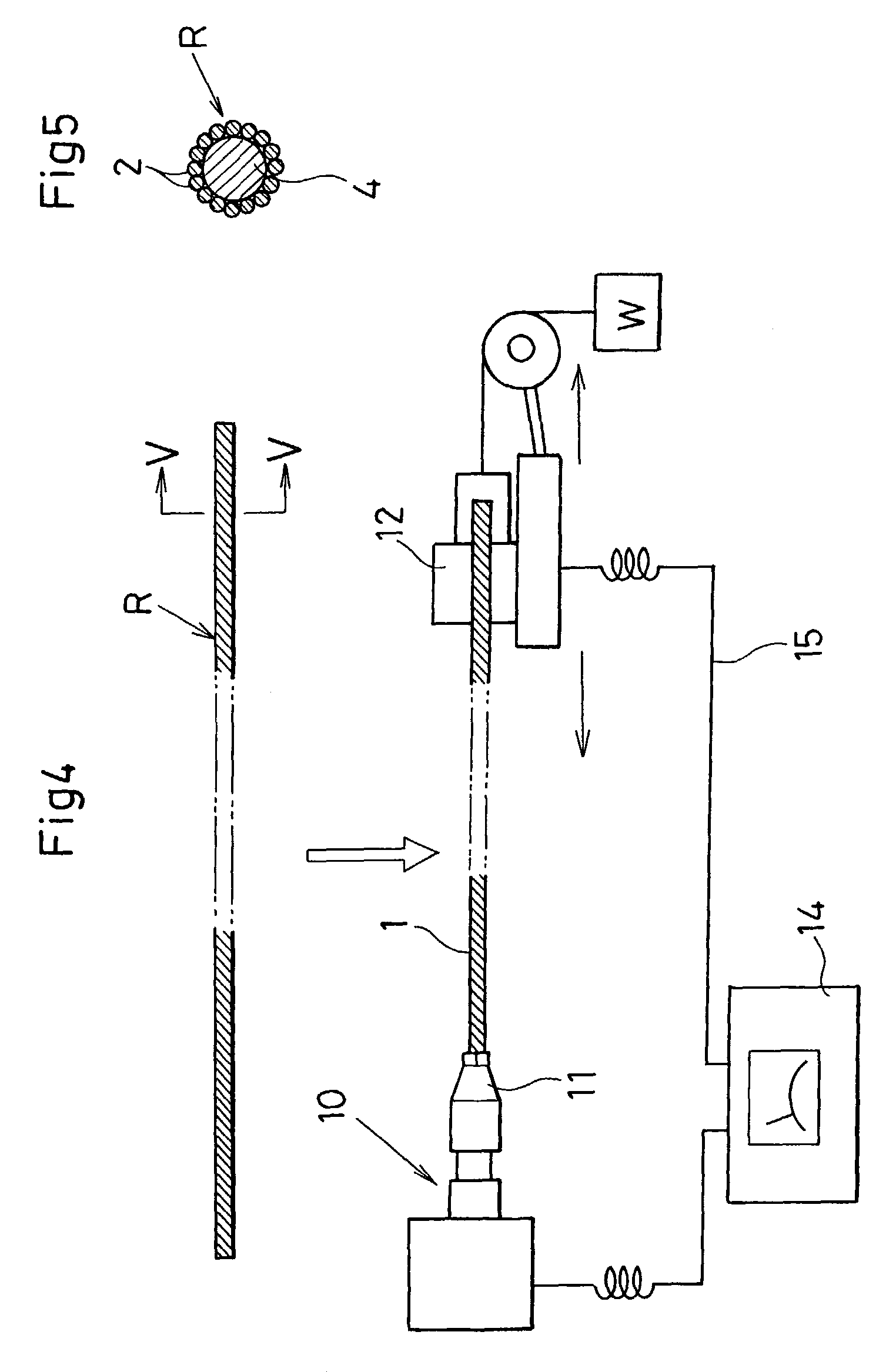

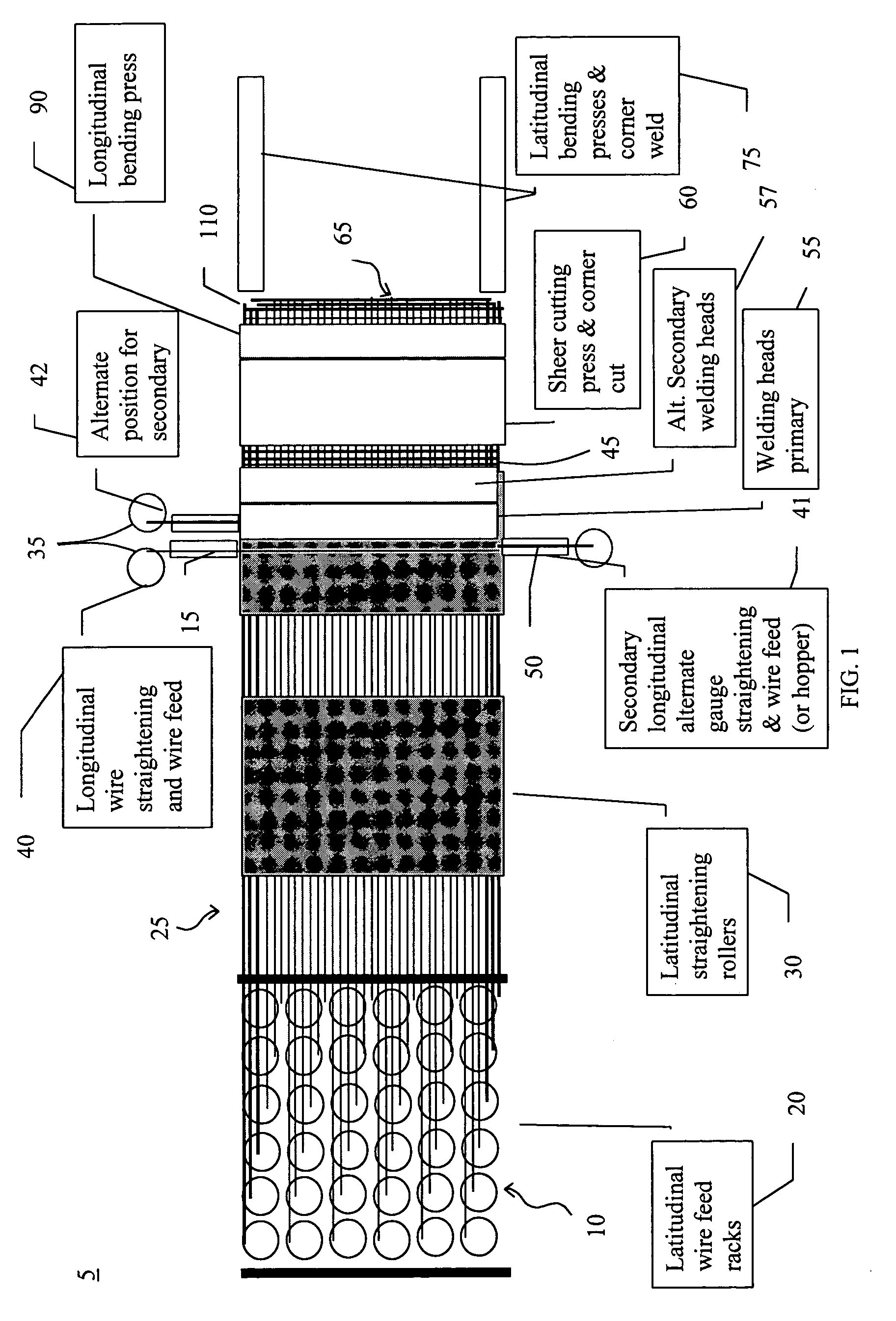

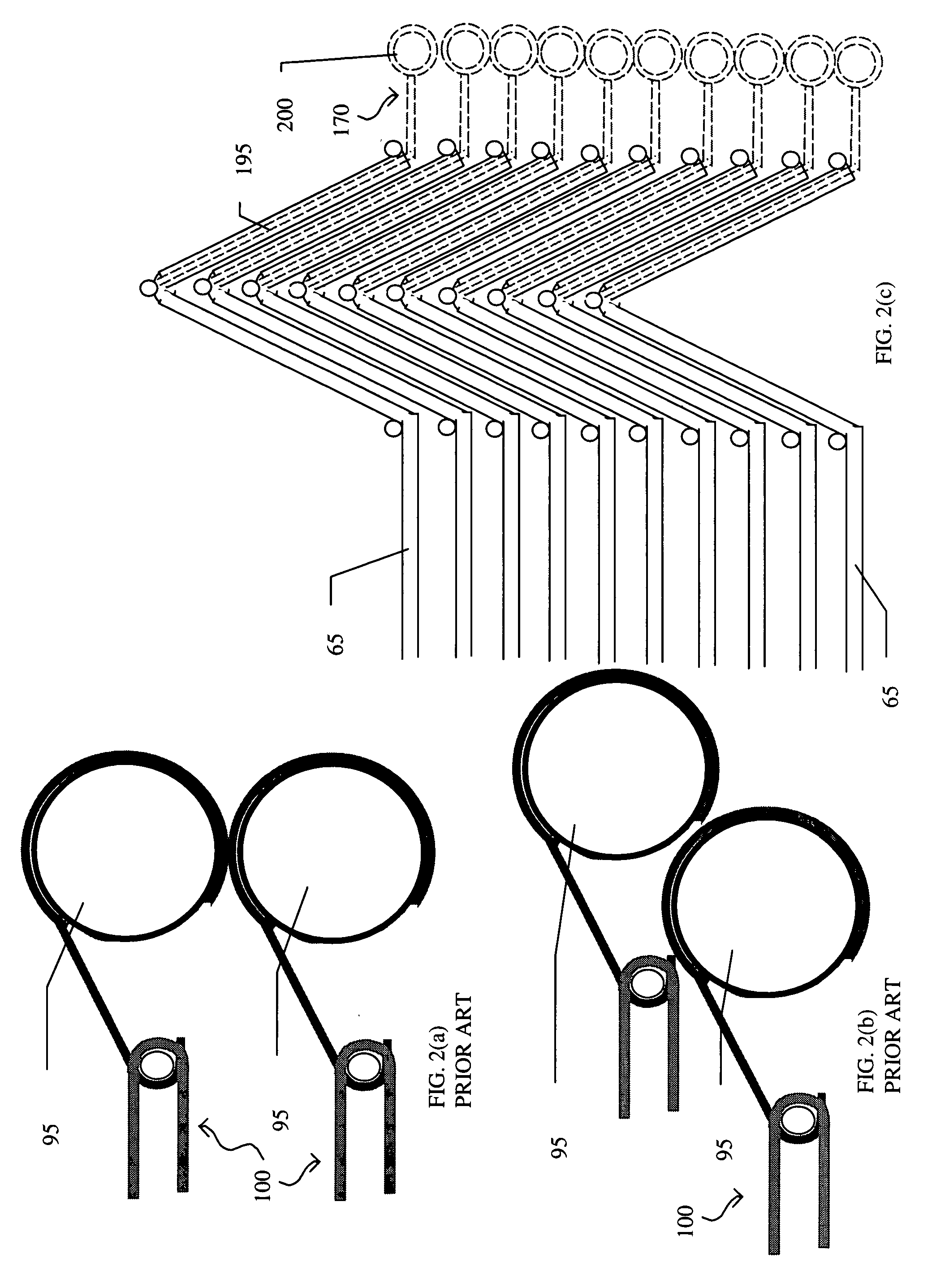

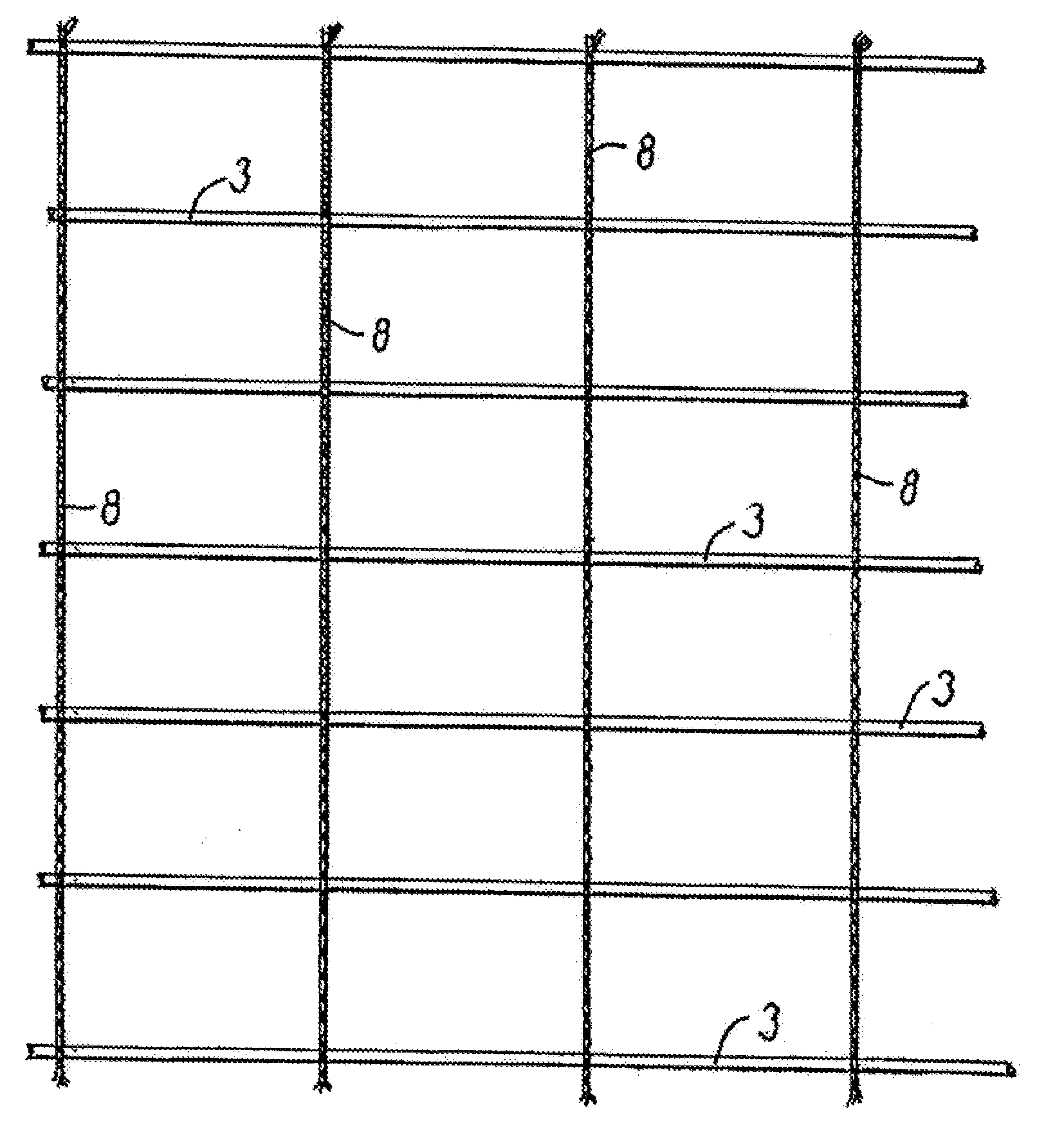

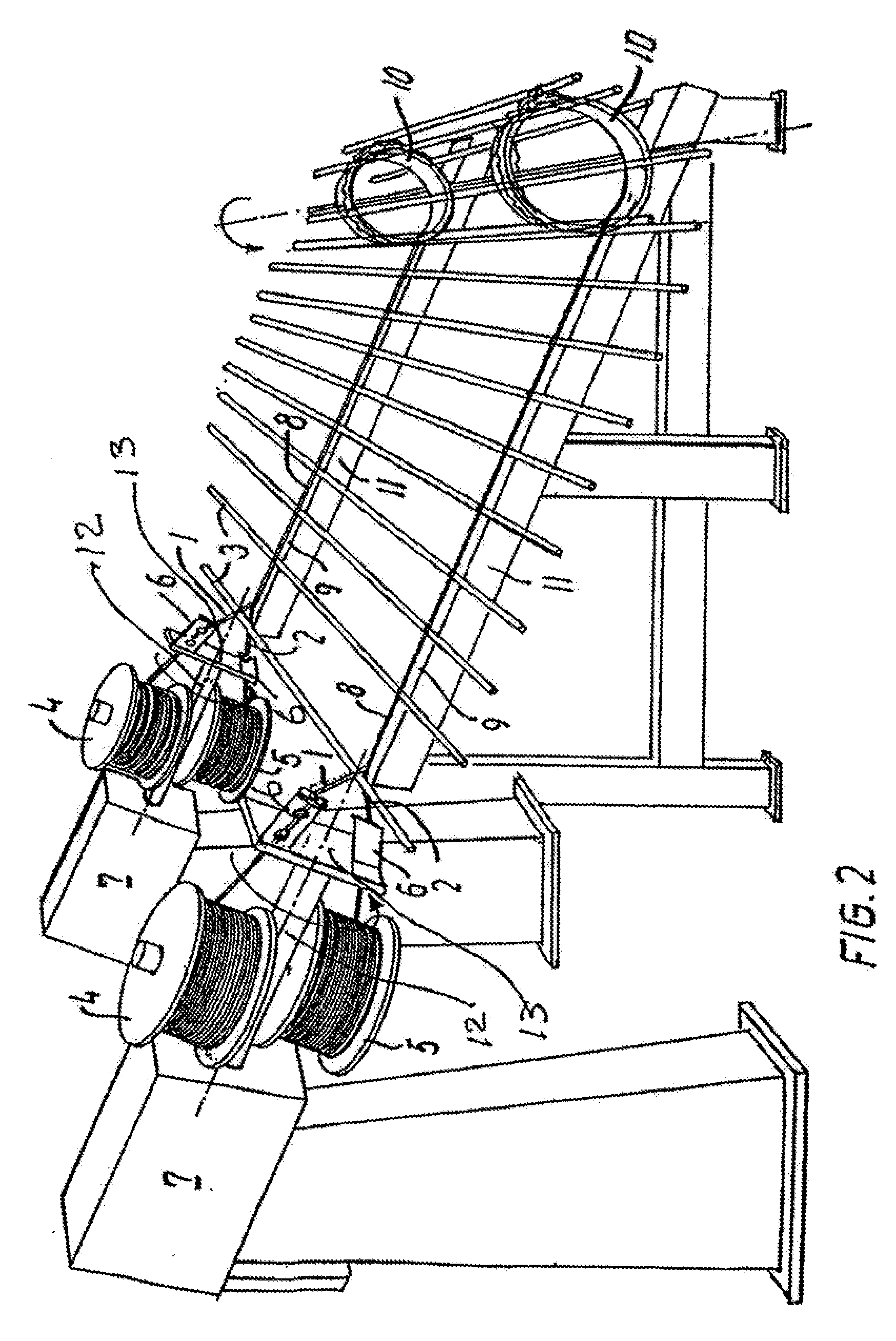

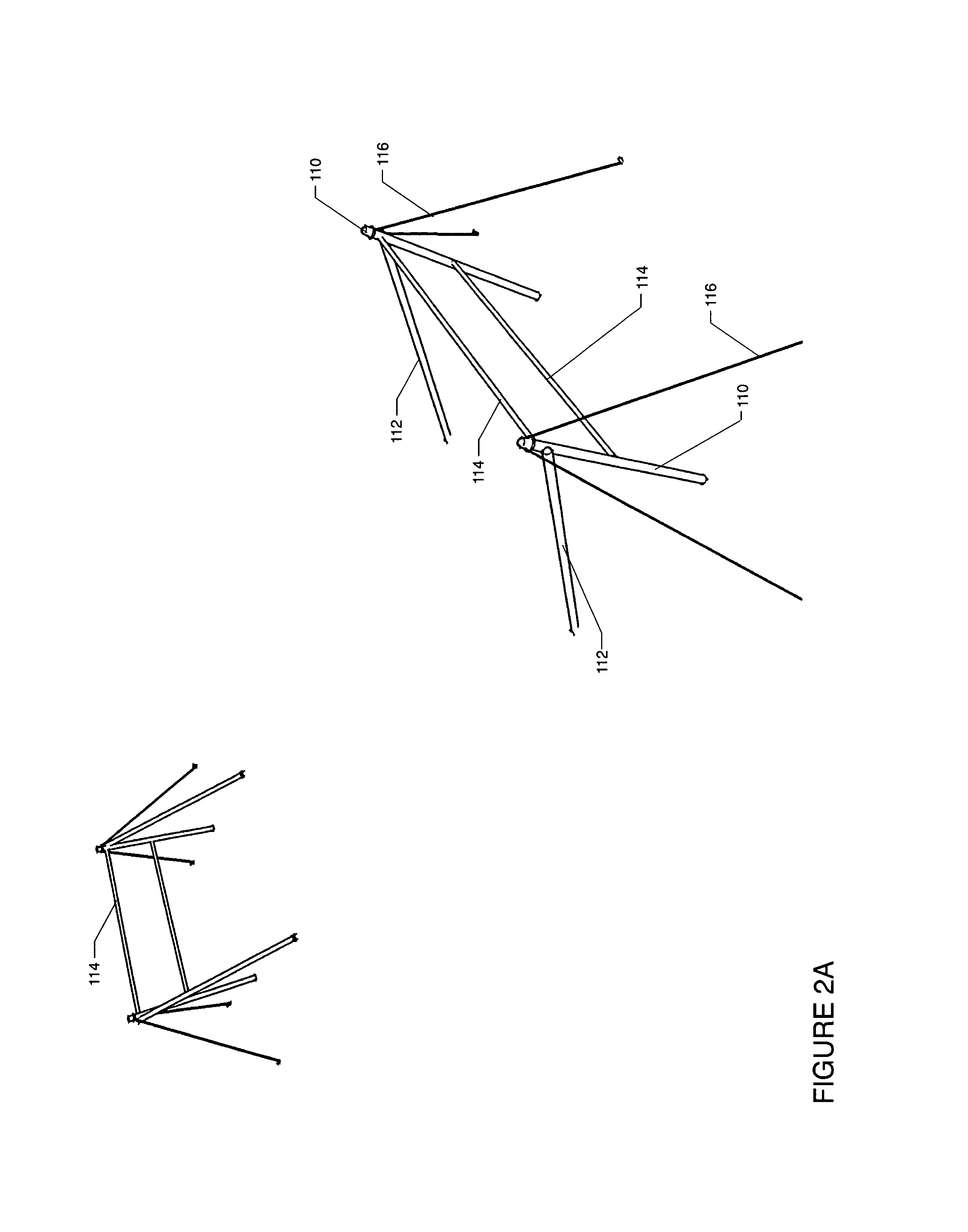

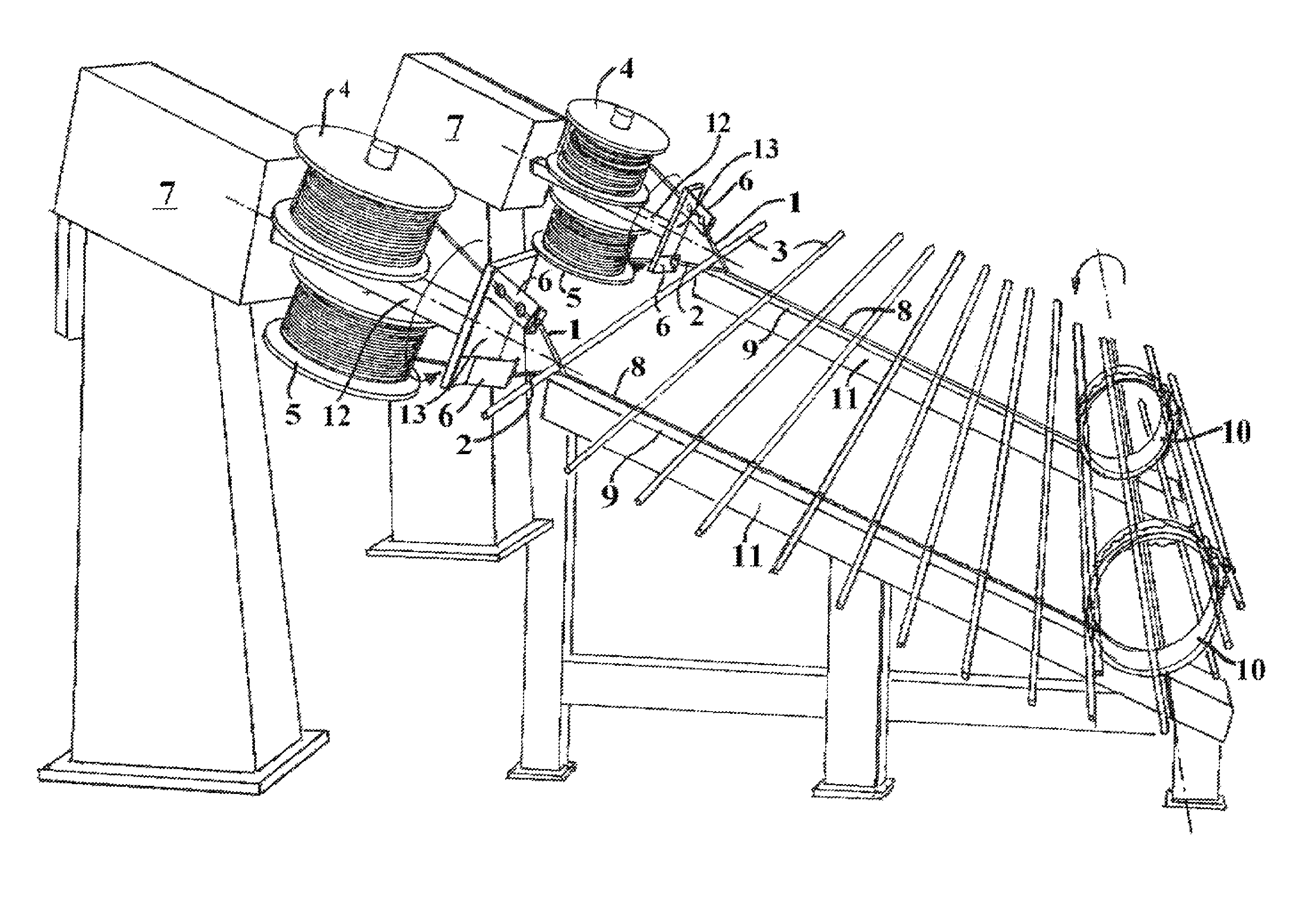

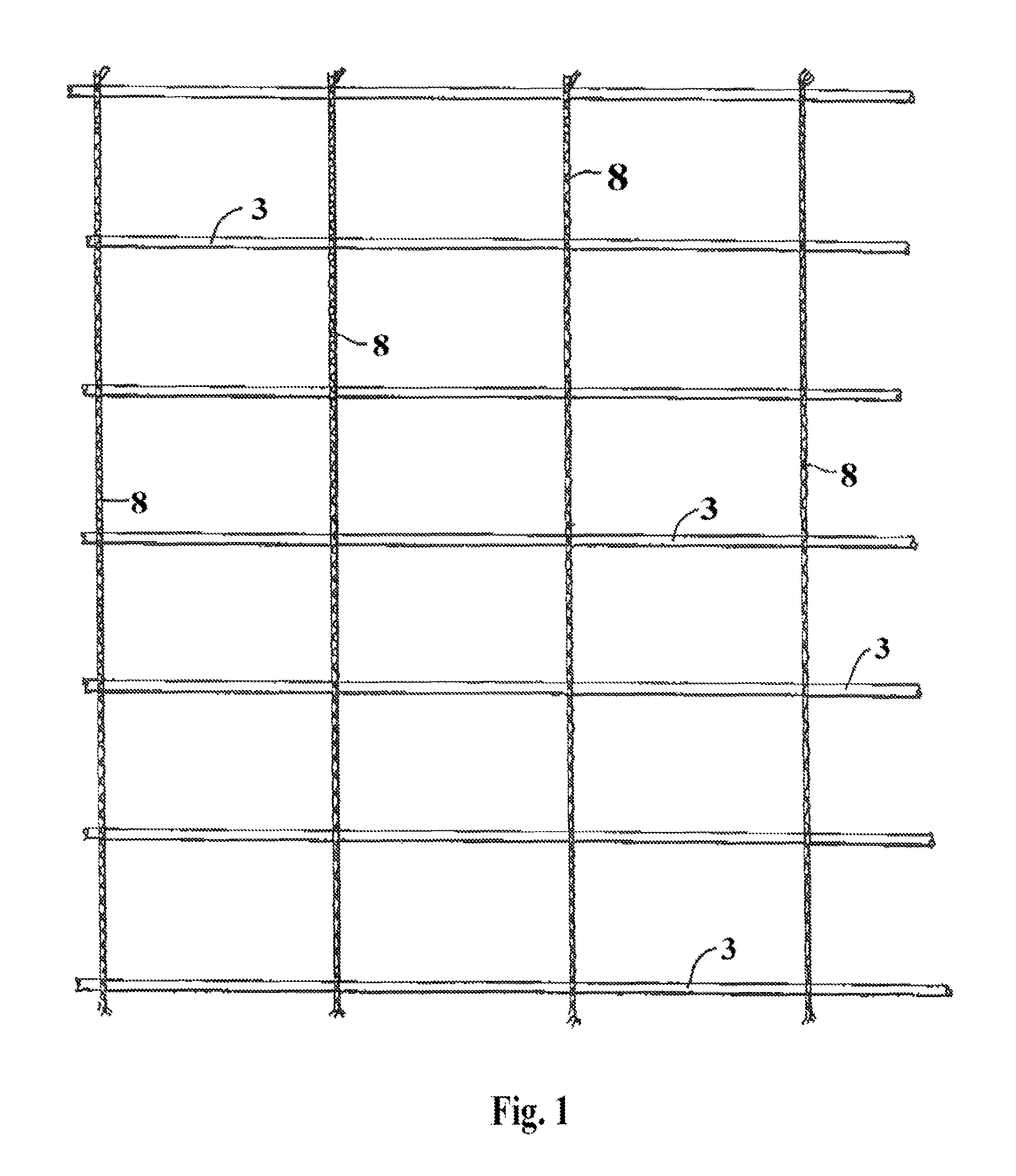

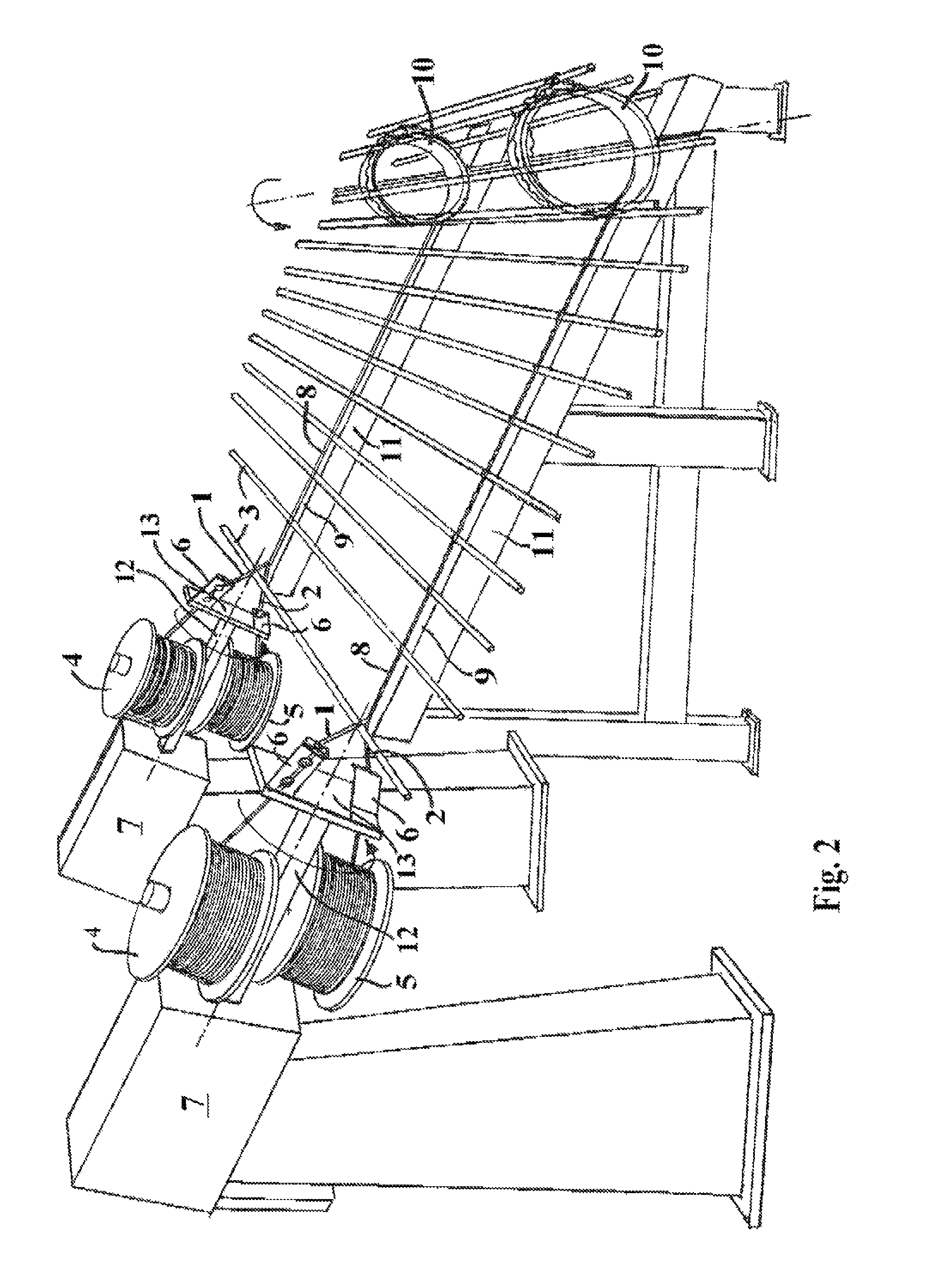

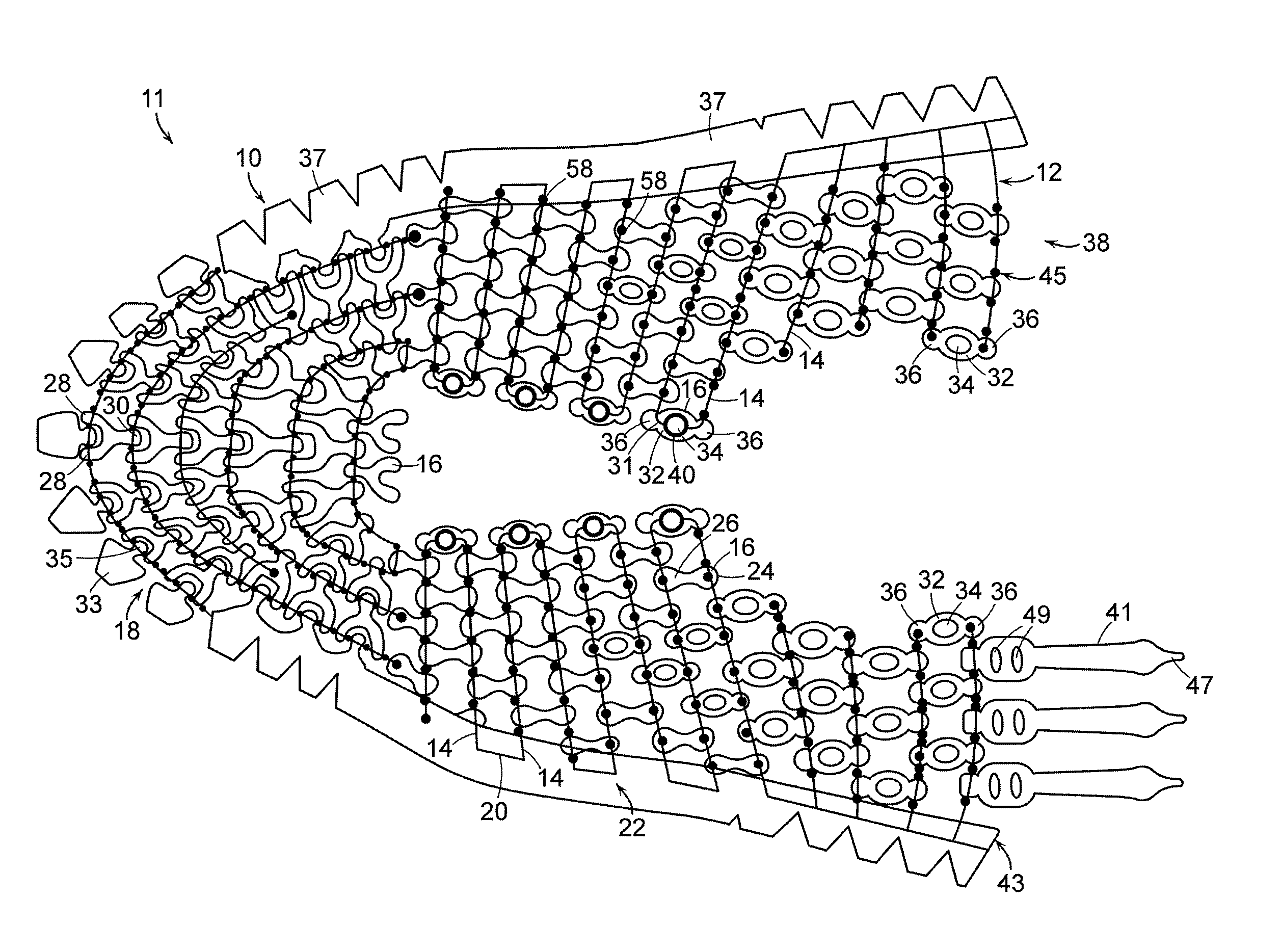

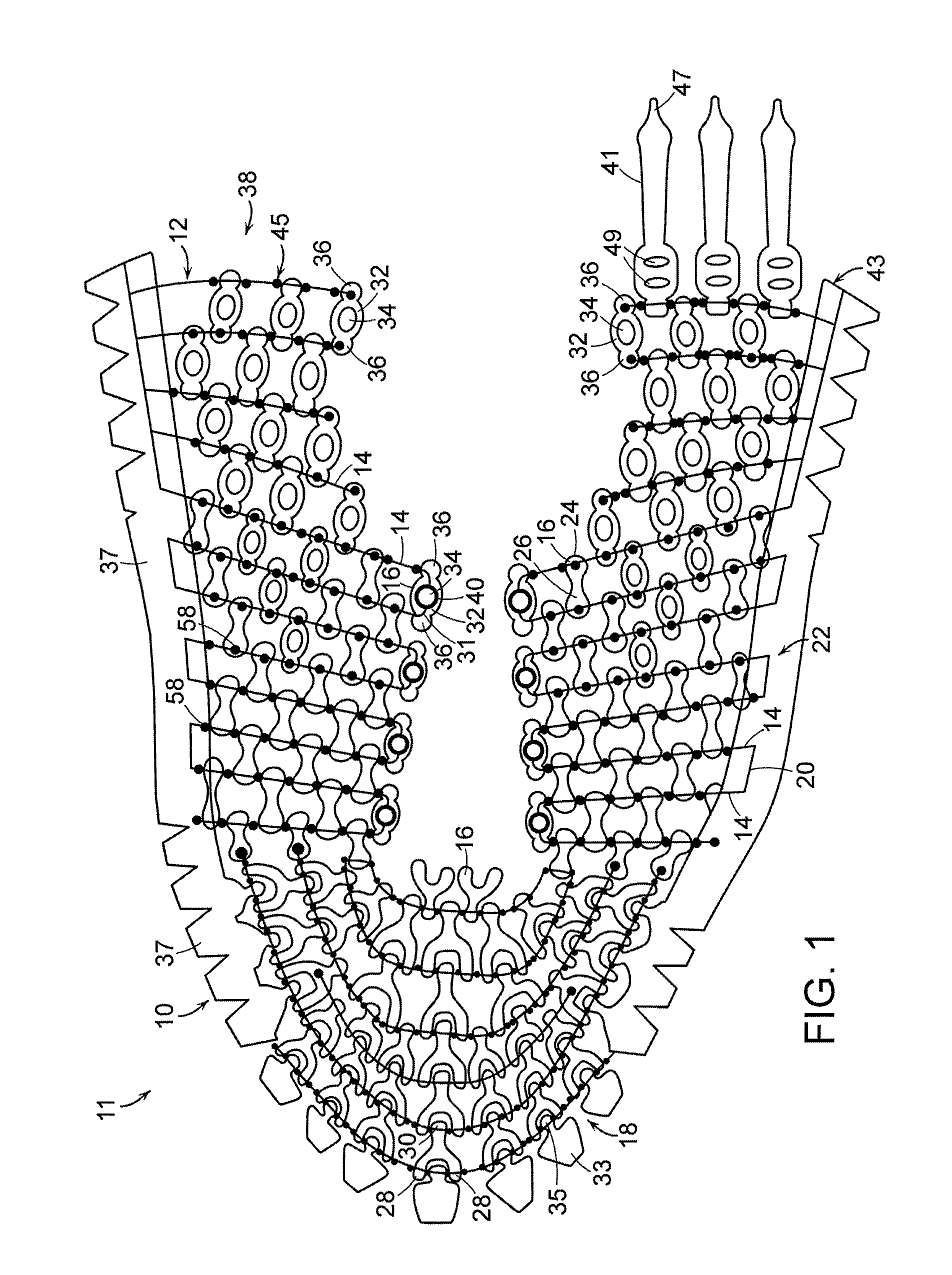

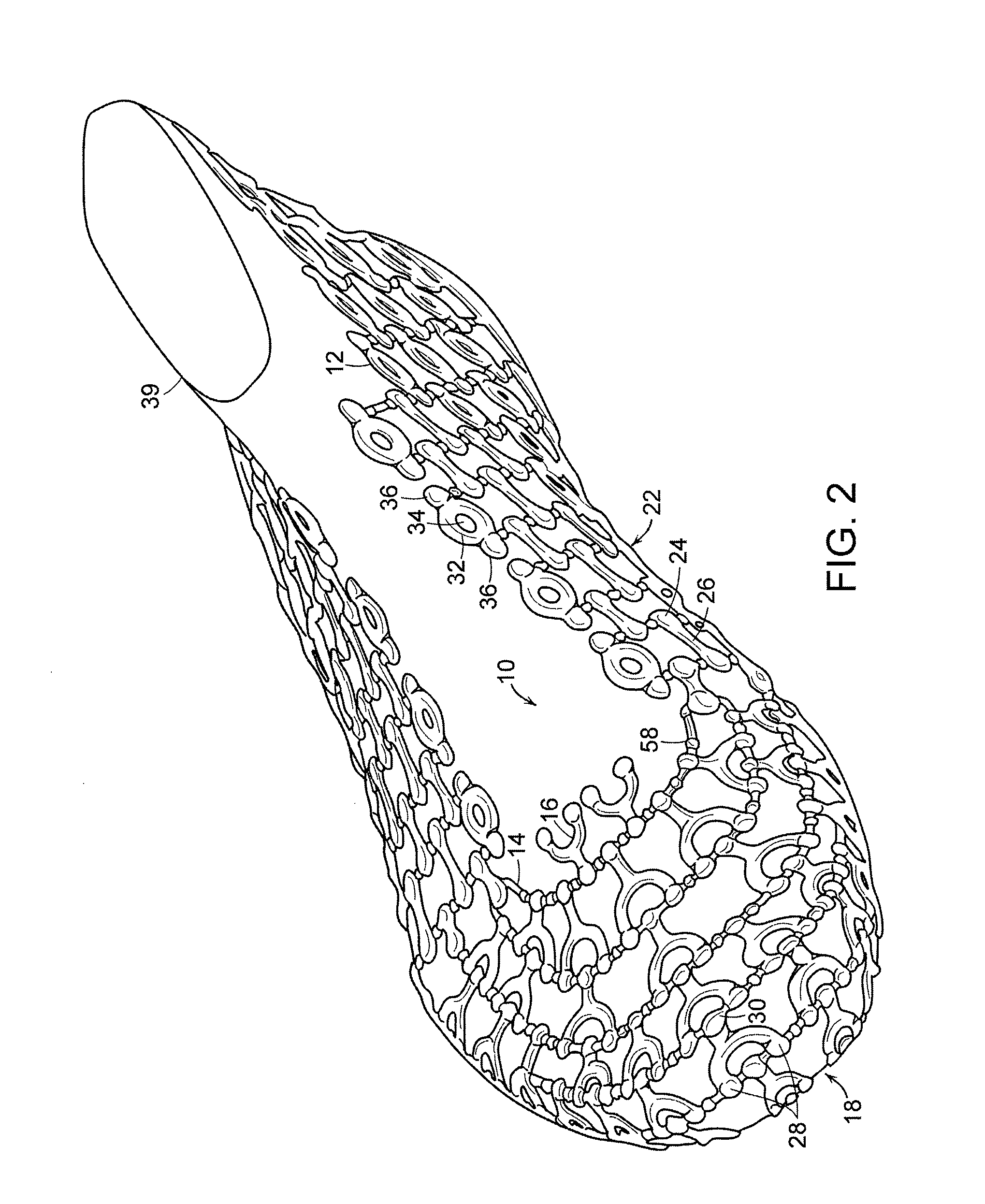

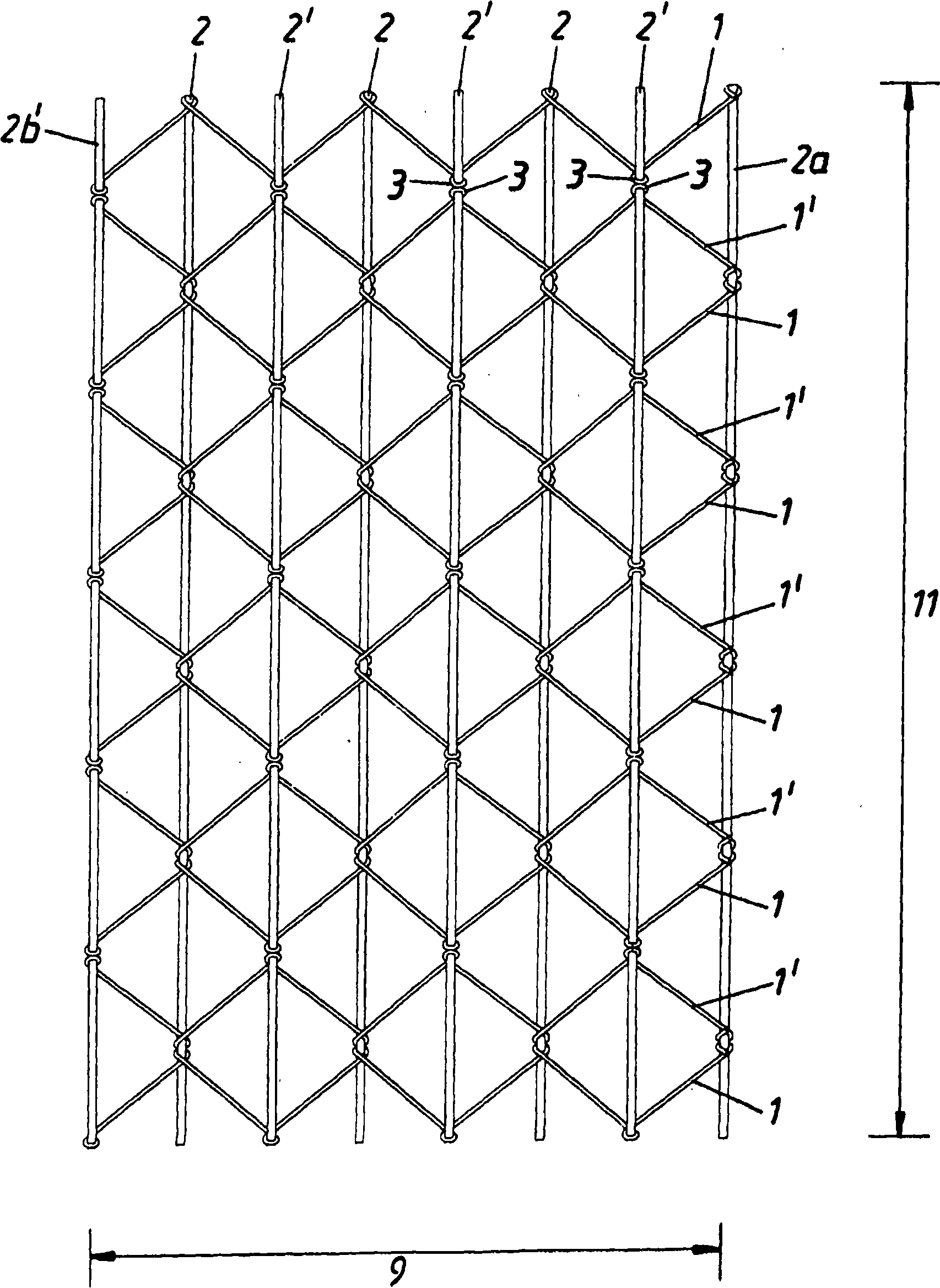

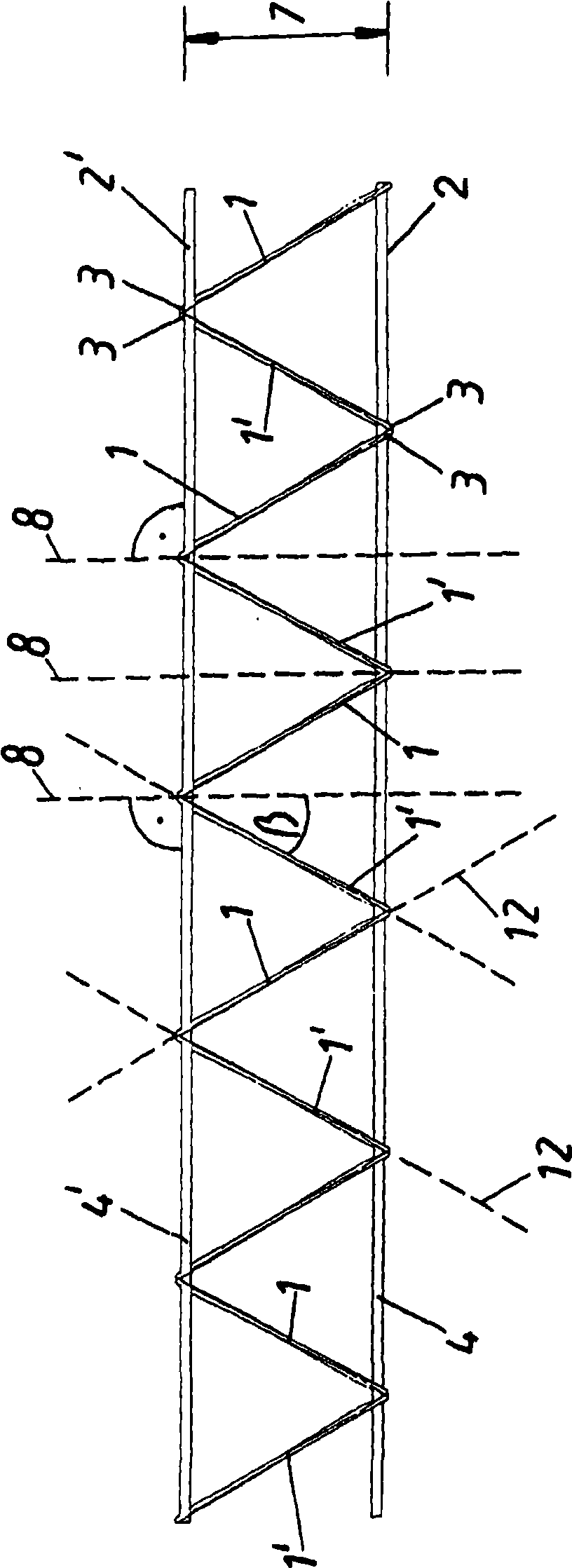

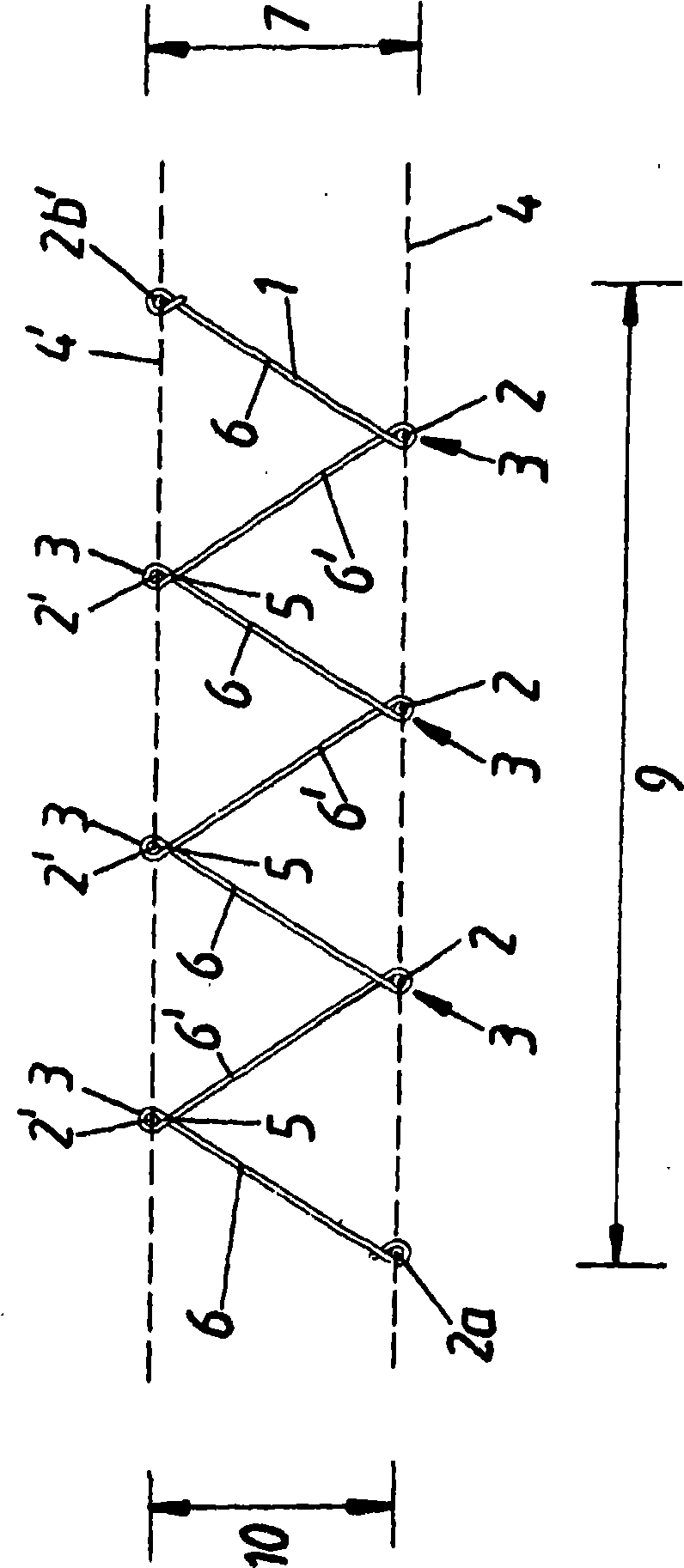

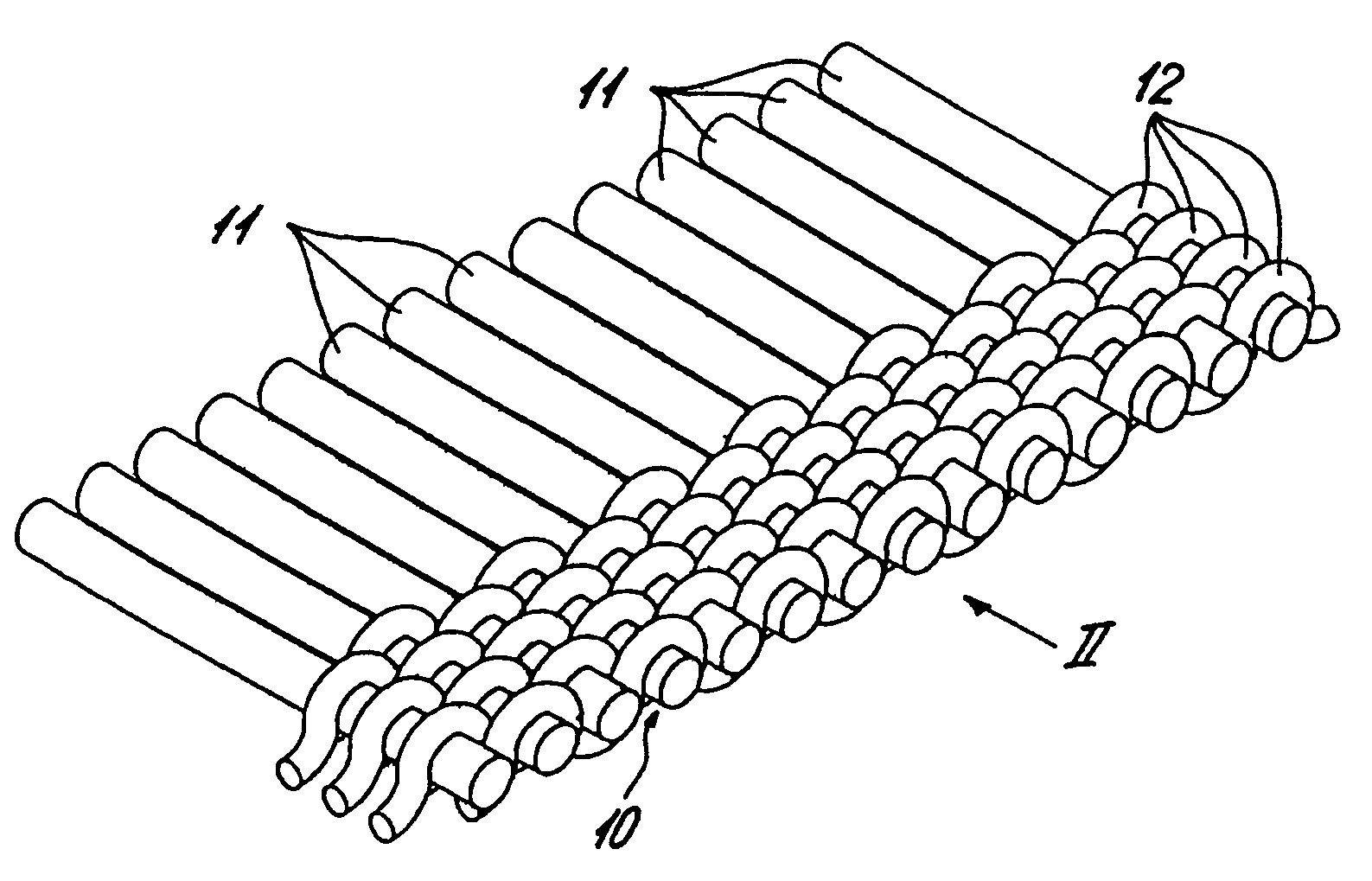

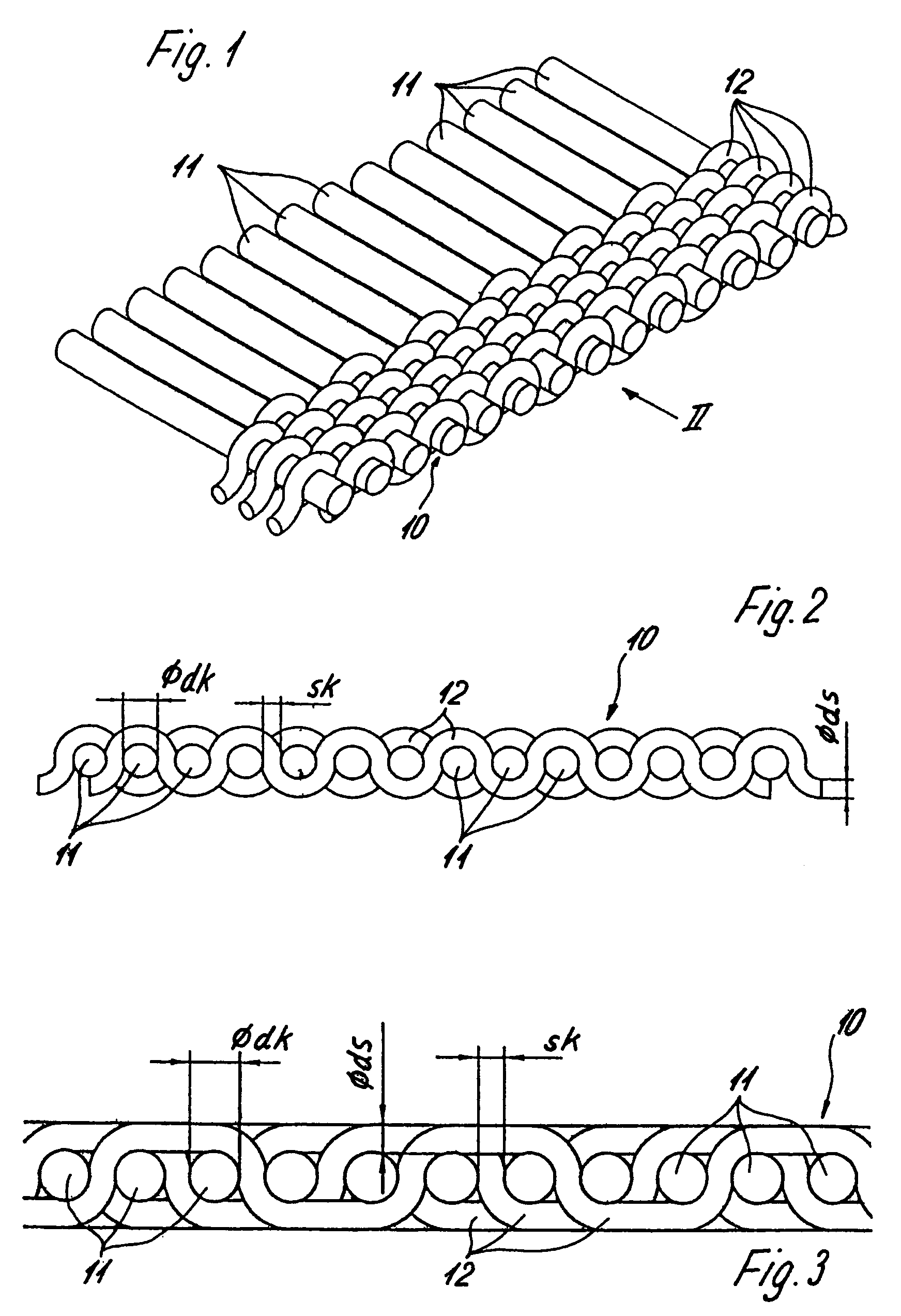

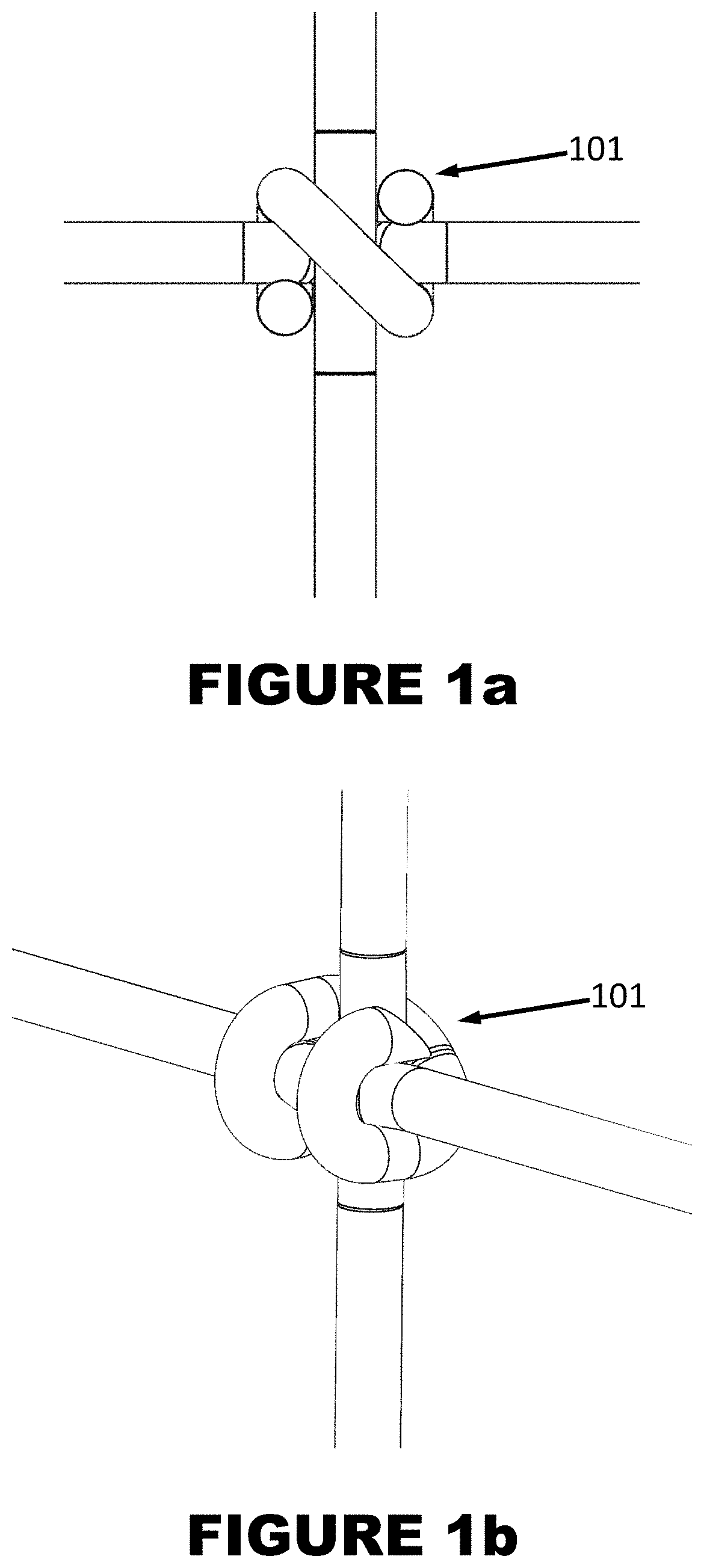

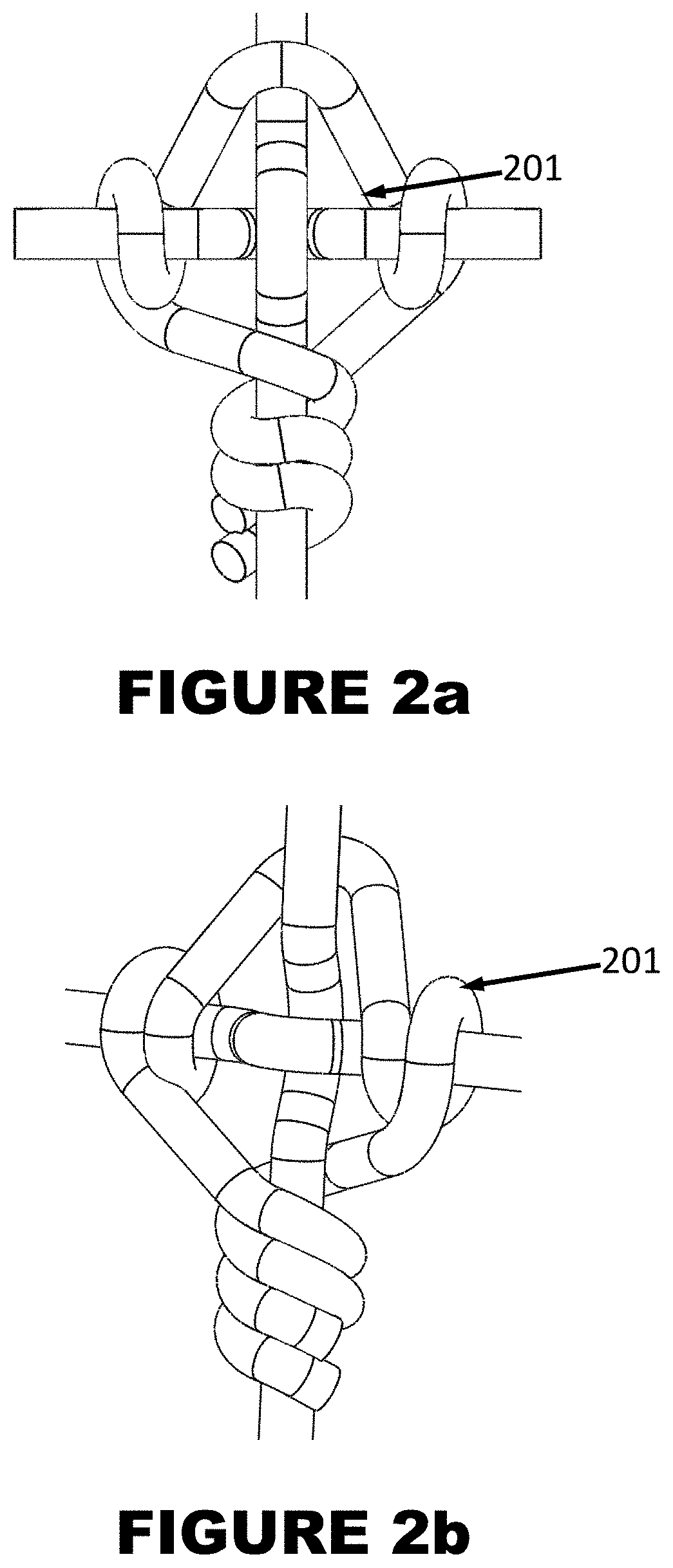

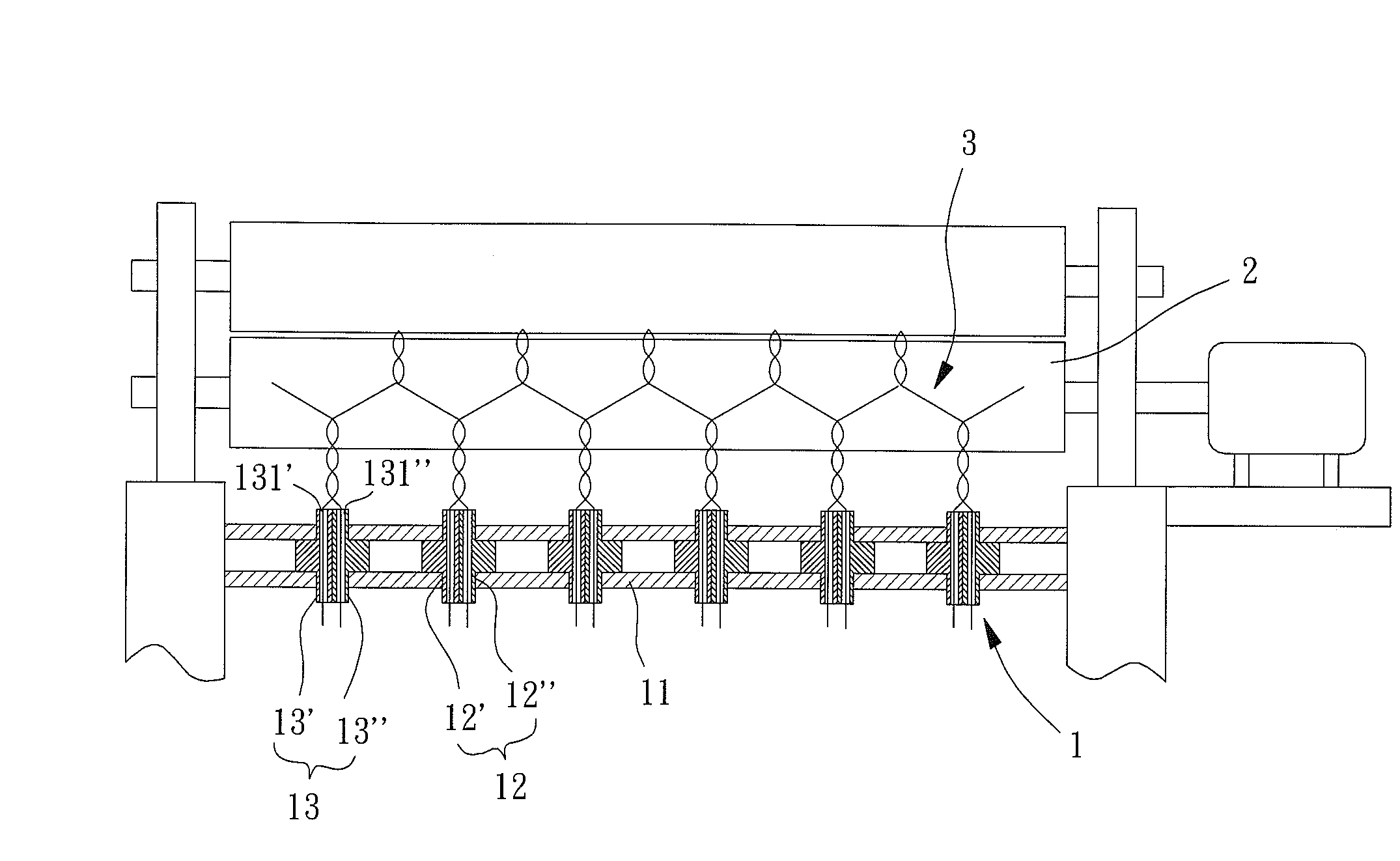

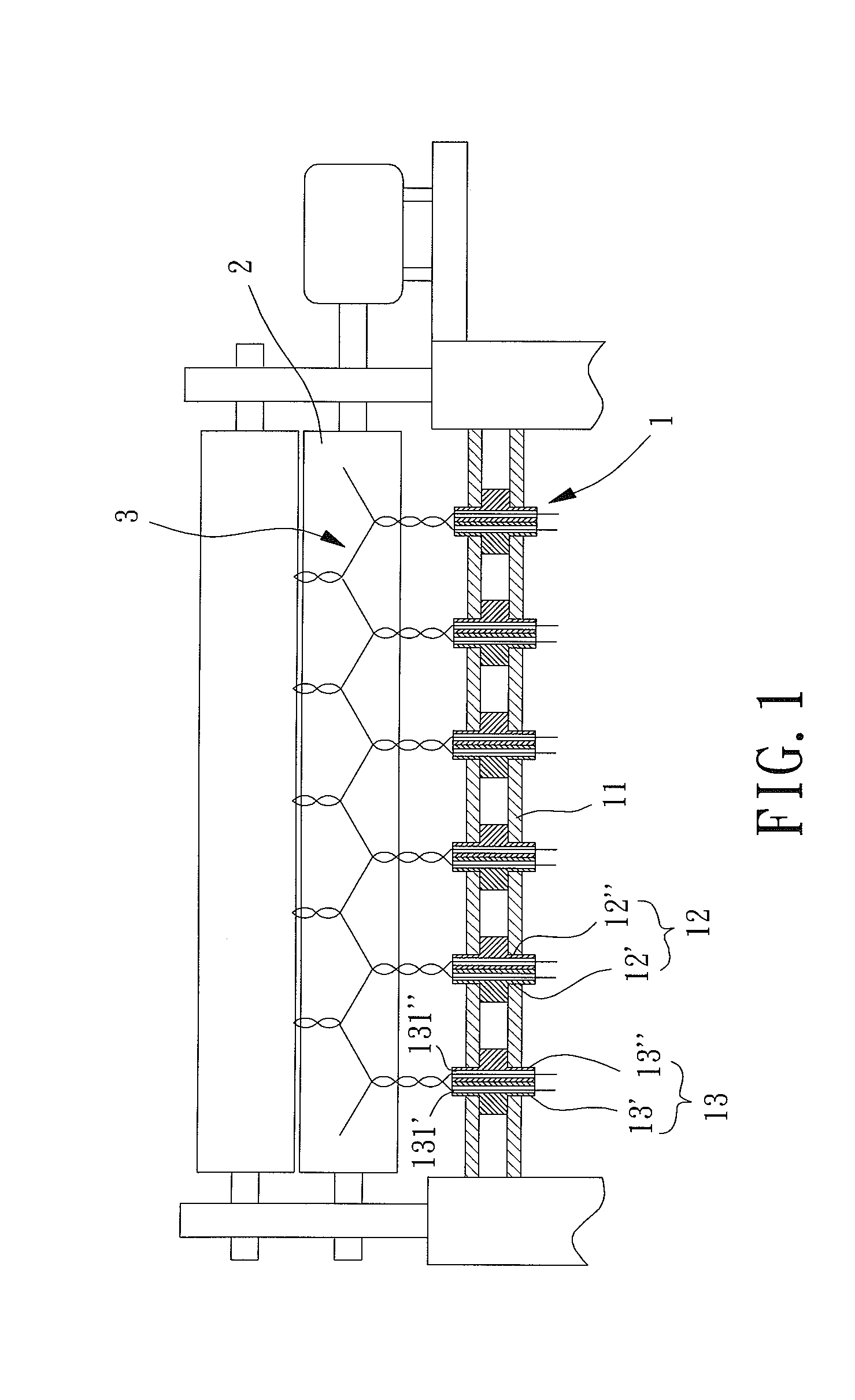

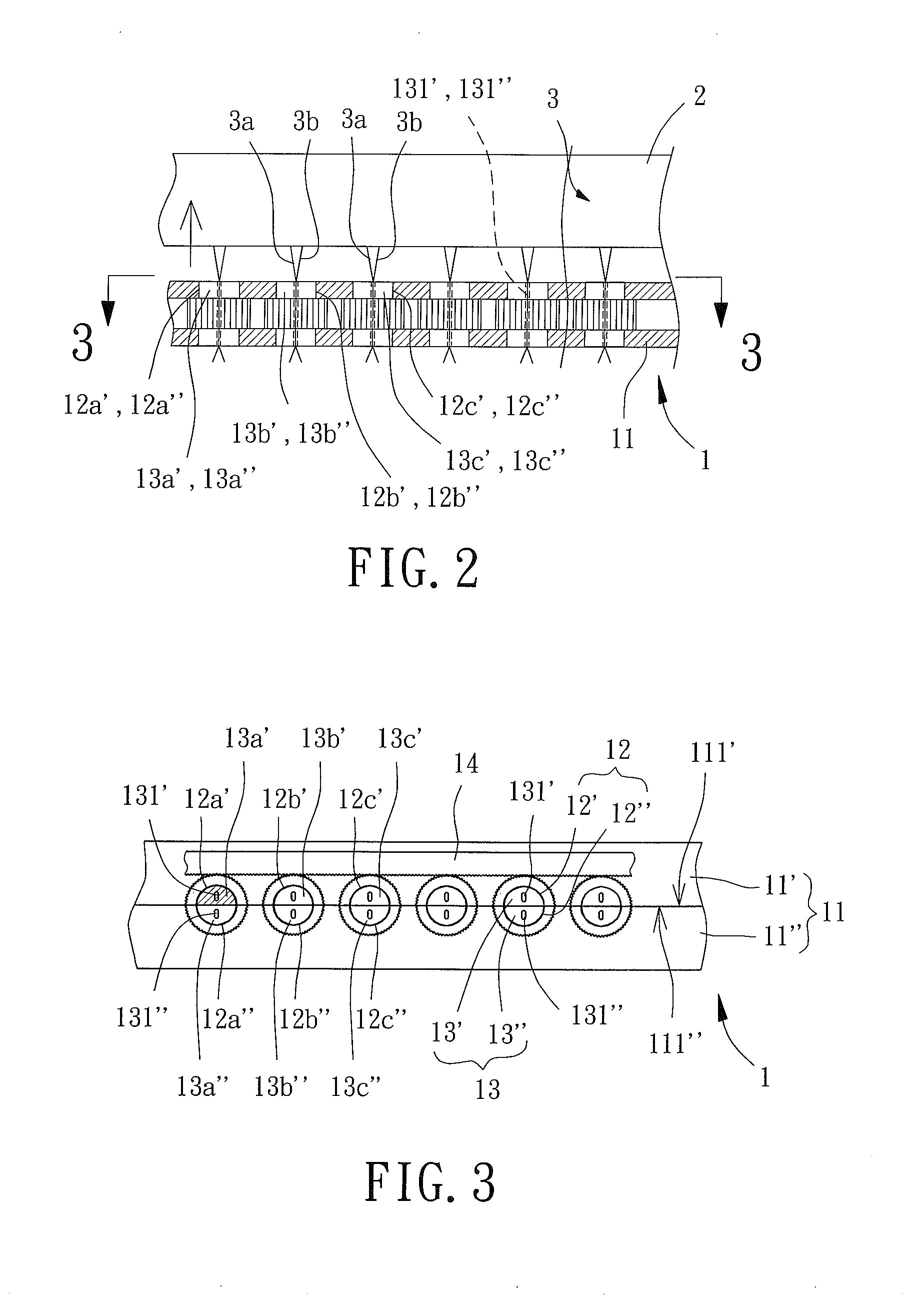

Method, An Apparatus and A Means For Making A Reinforcement Mesh

InactiveUS20080276564A1Precise positioningRapid and simple and stableFencing wireWire networkMesh reinforcementEngineering

Production of a reinforcement mesh comprising reinforcement bars (3), which are tied together by means of twisted wires (1, 2), may take place according to the invention by a method wherein two wires (1, 2) are rolled up on their respective wire coils (4, 5), which are mounted opposite each other on a rotatable shaft (12), and wherein each of the wires is guided by a wire guide element (6) downwards in a direction toward the common twisting point of the wires (1, 2). Meshes of surface-treated, coated, wires and bars may be made in this manner, there being no external impact that can damage the surface.

Owner:PEDAX GMBH

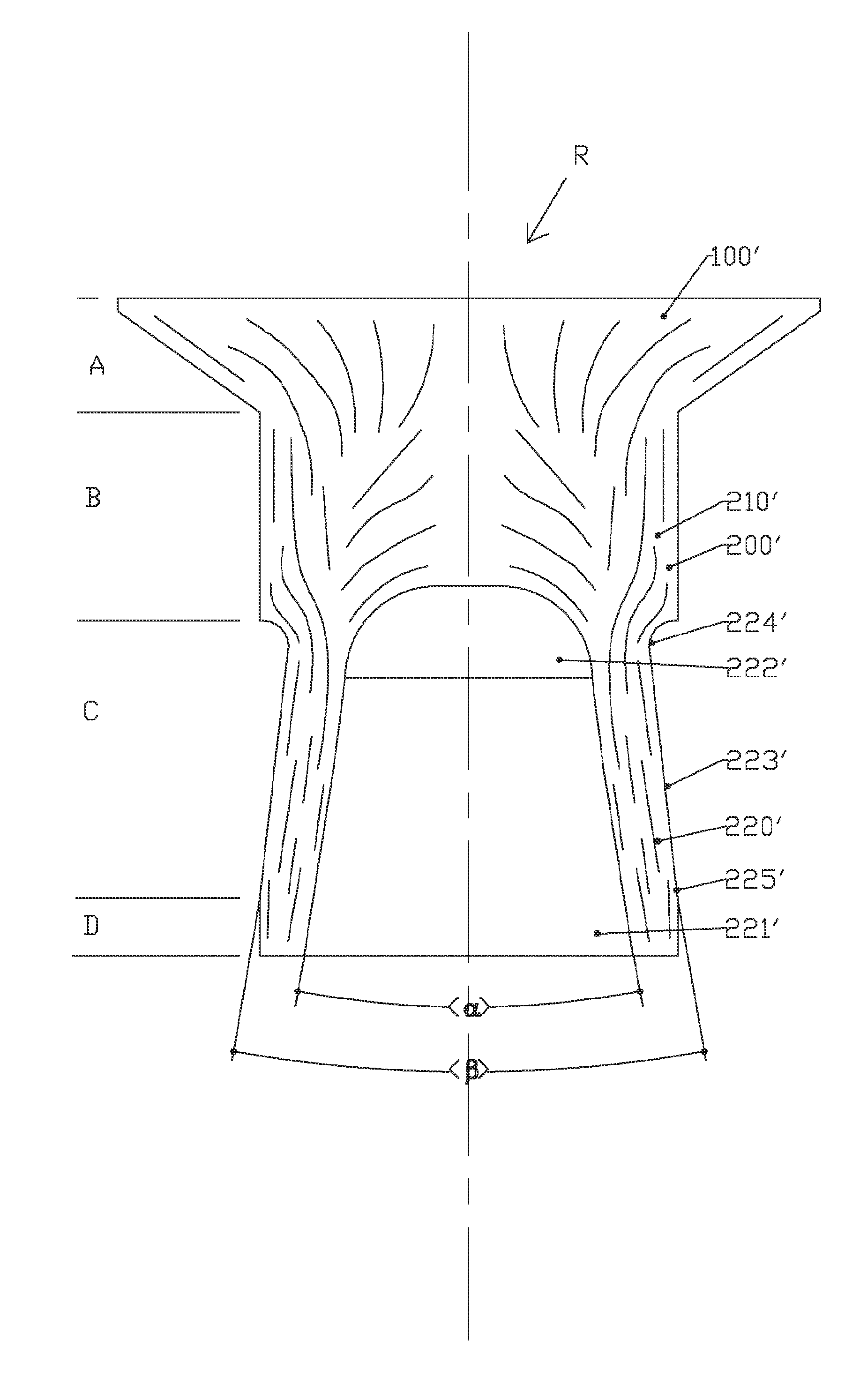

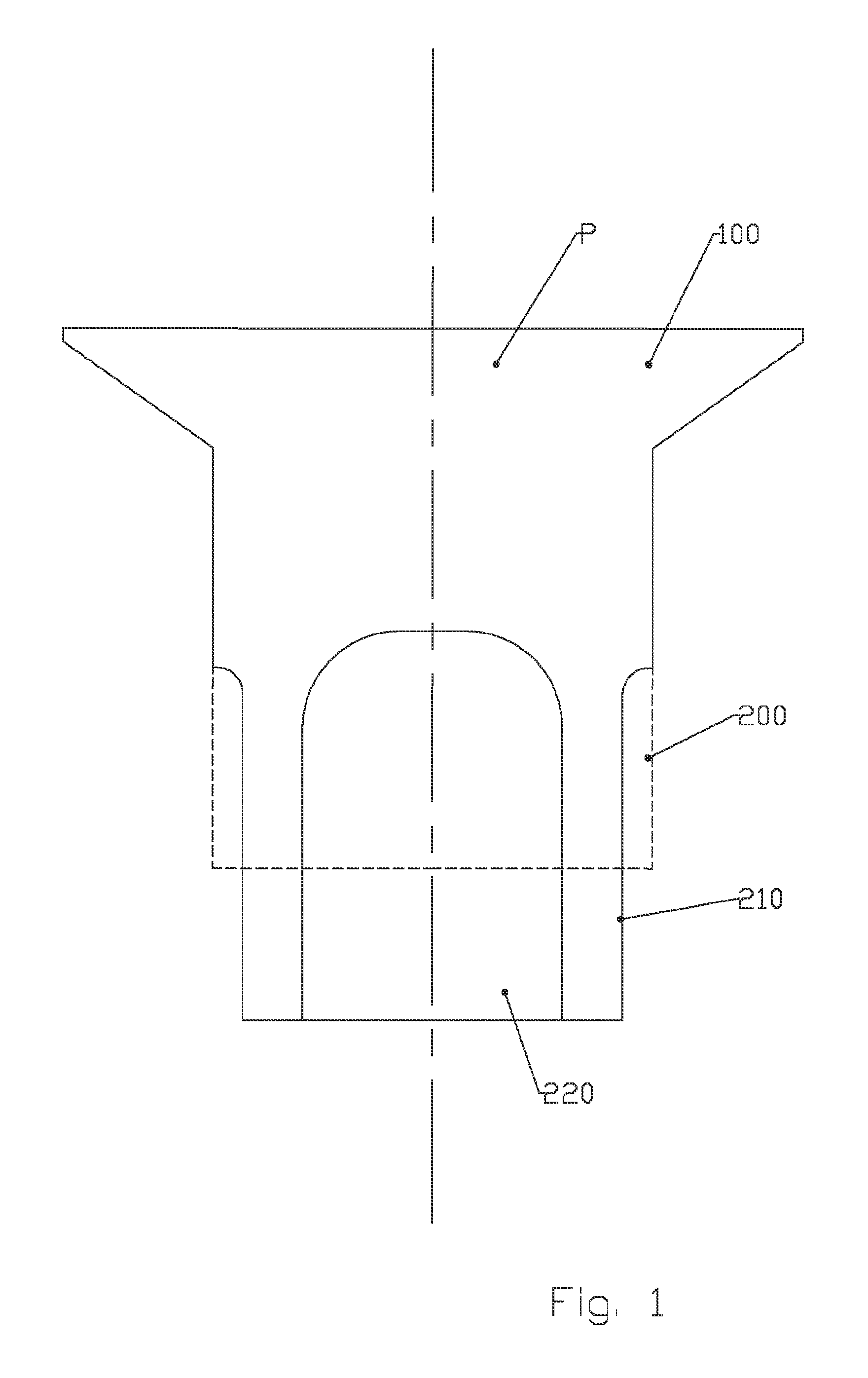

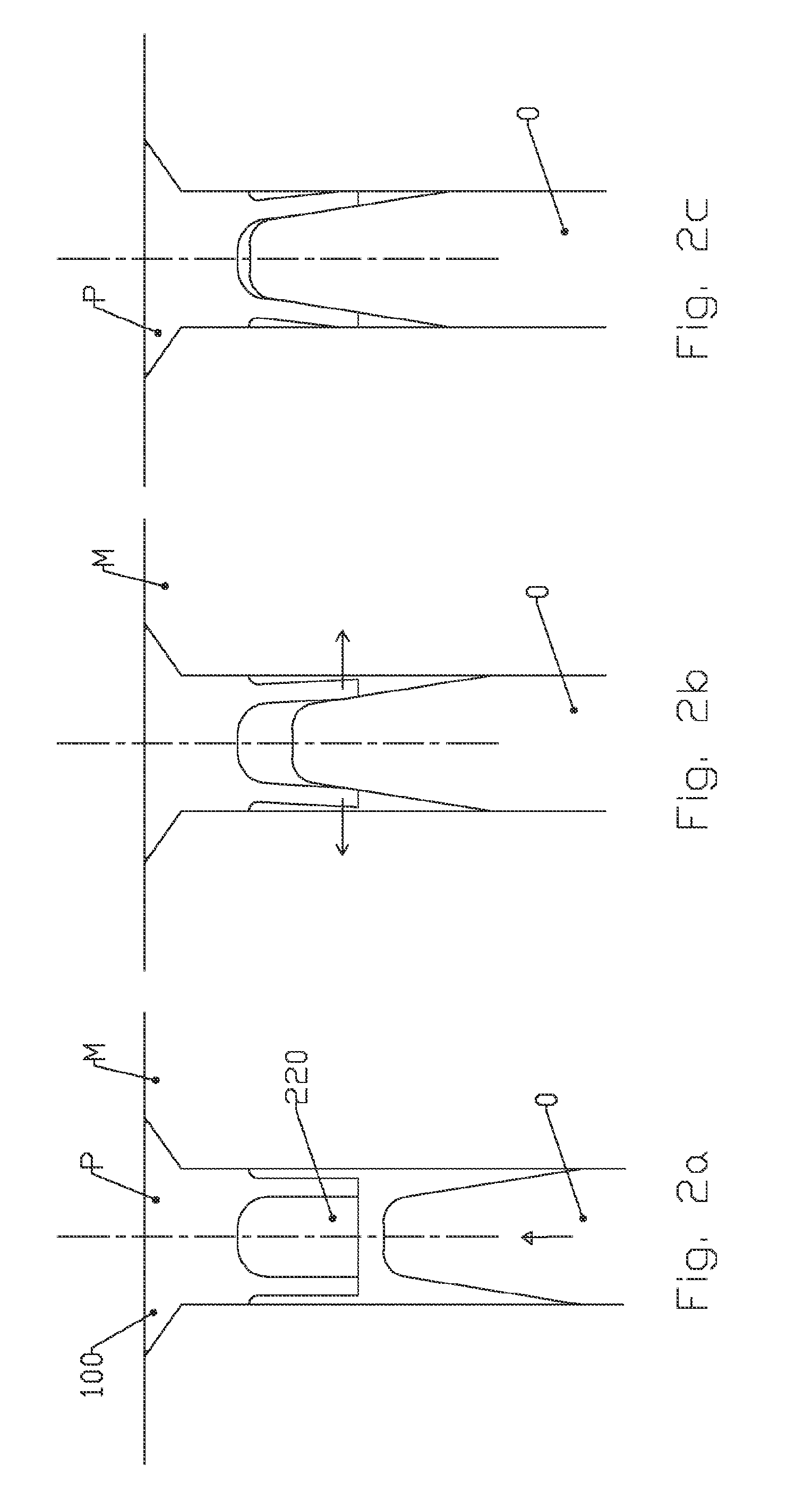

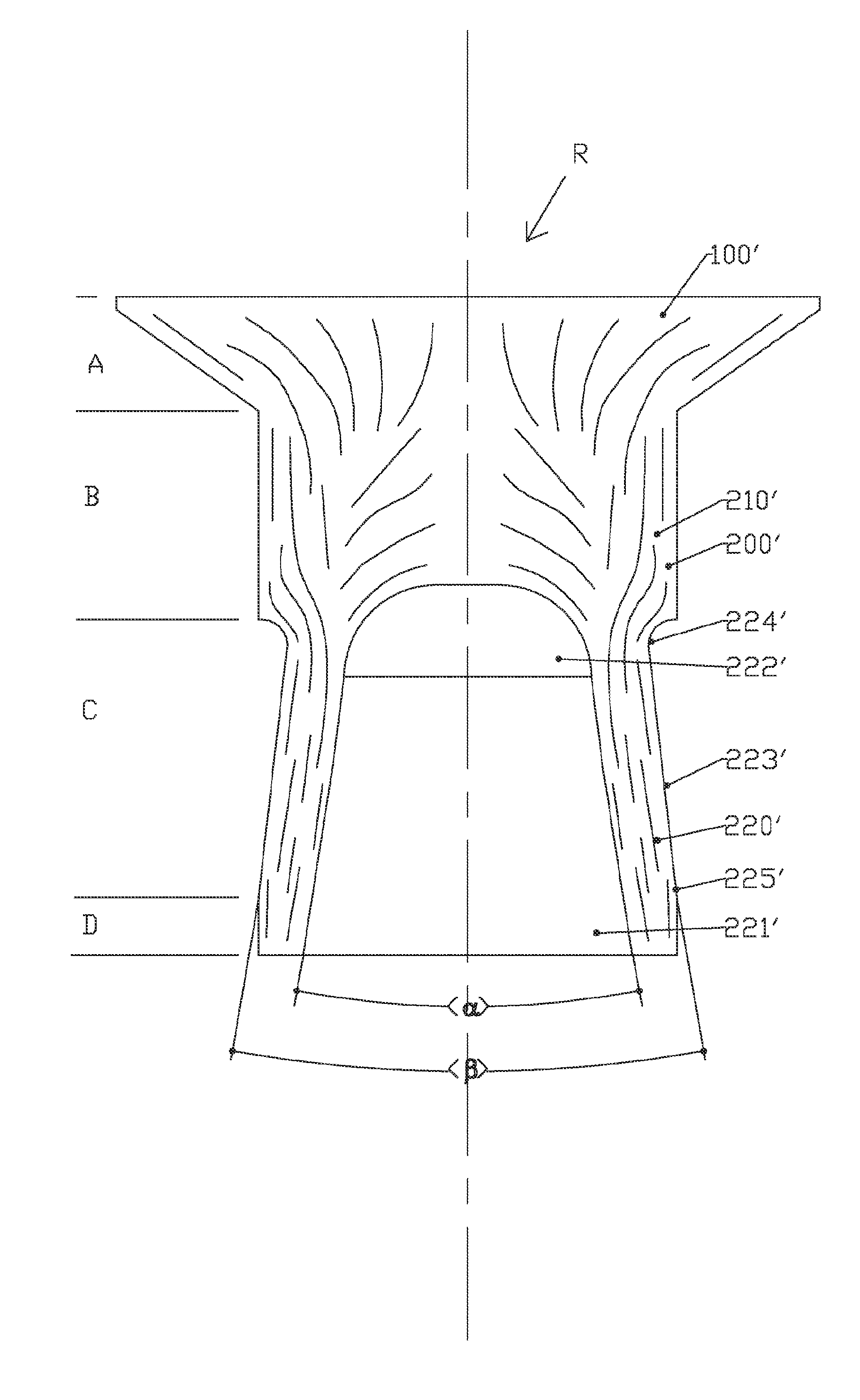

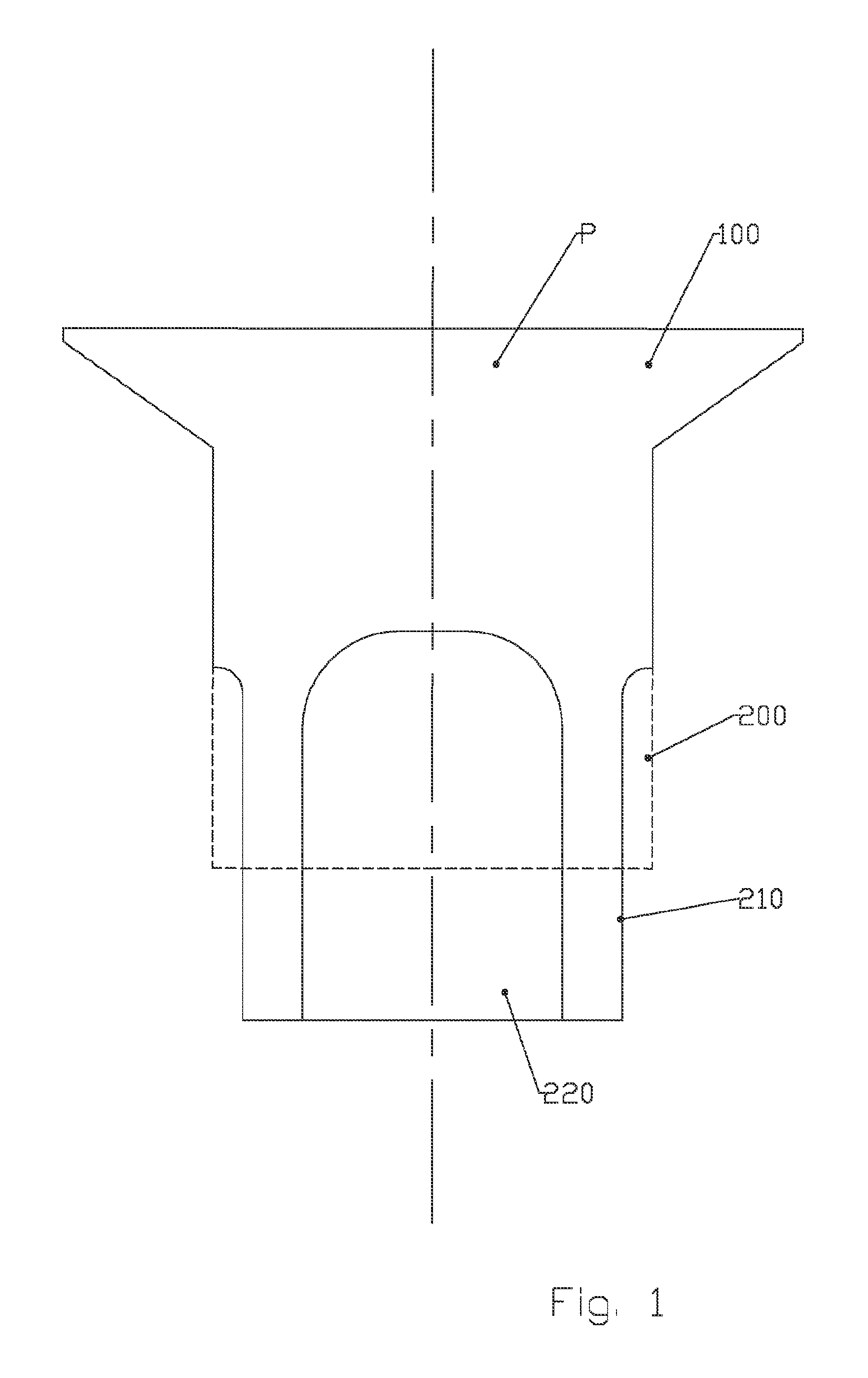

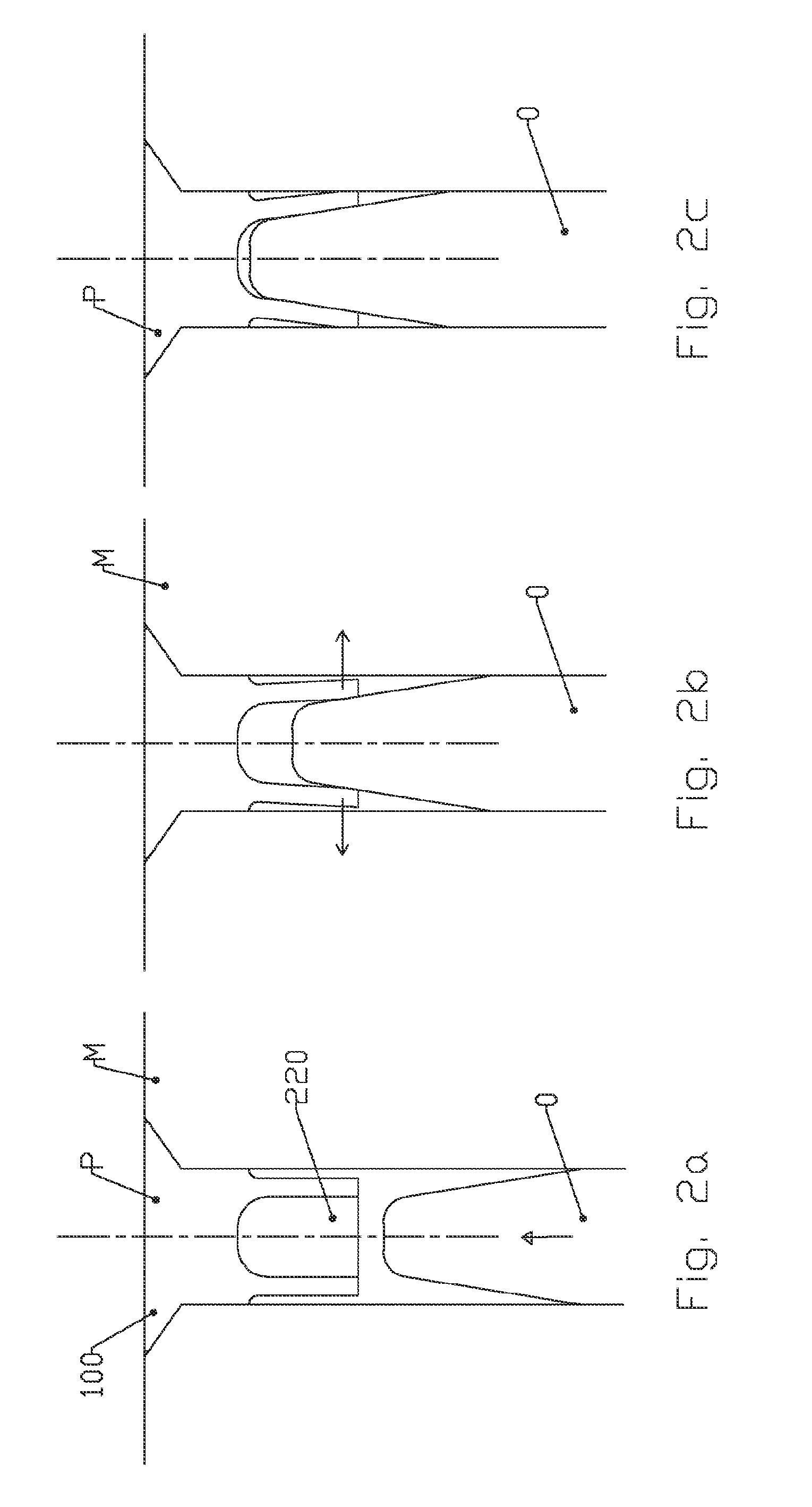

Method for making a rivet and rivet obtained by said method

The invention relates to a method for making a rivet (R), of the type comprising, by deformation of the material of a substantially cylindrical metal segment, the operations of preforming a milled head (100) at the end of a rod (200), characterised in that it comprises, by deformation of the material (cold stamping) the following operations: creating a portion with a lower diameter (210) from the free end; creating a substantially cylindrical hollow core (220) for forming a tubular portion; preforming the hollow core (220) as a truncated cone; performing the lower diameter outer surface as a truncated cone. The invention also relates to the rivet obtained by said method.

Owner:ERIS

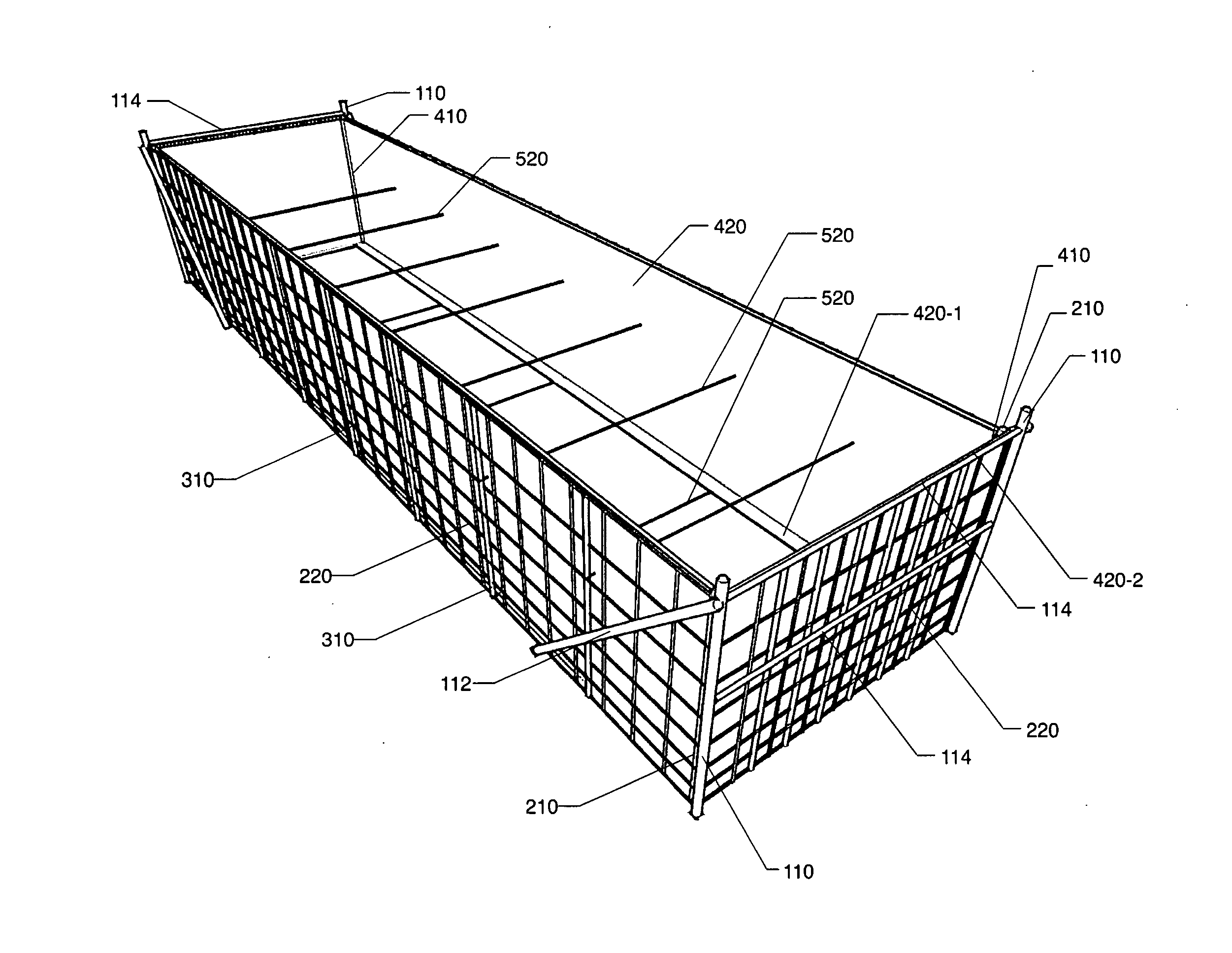

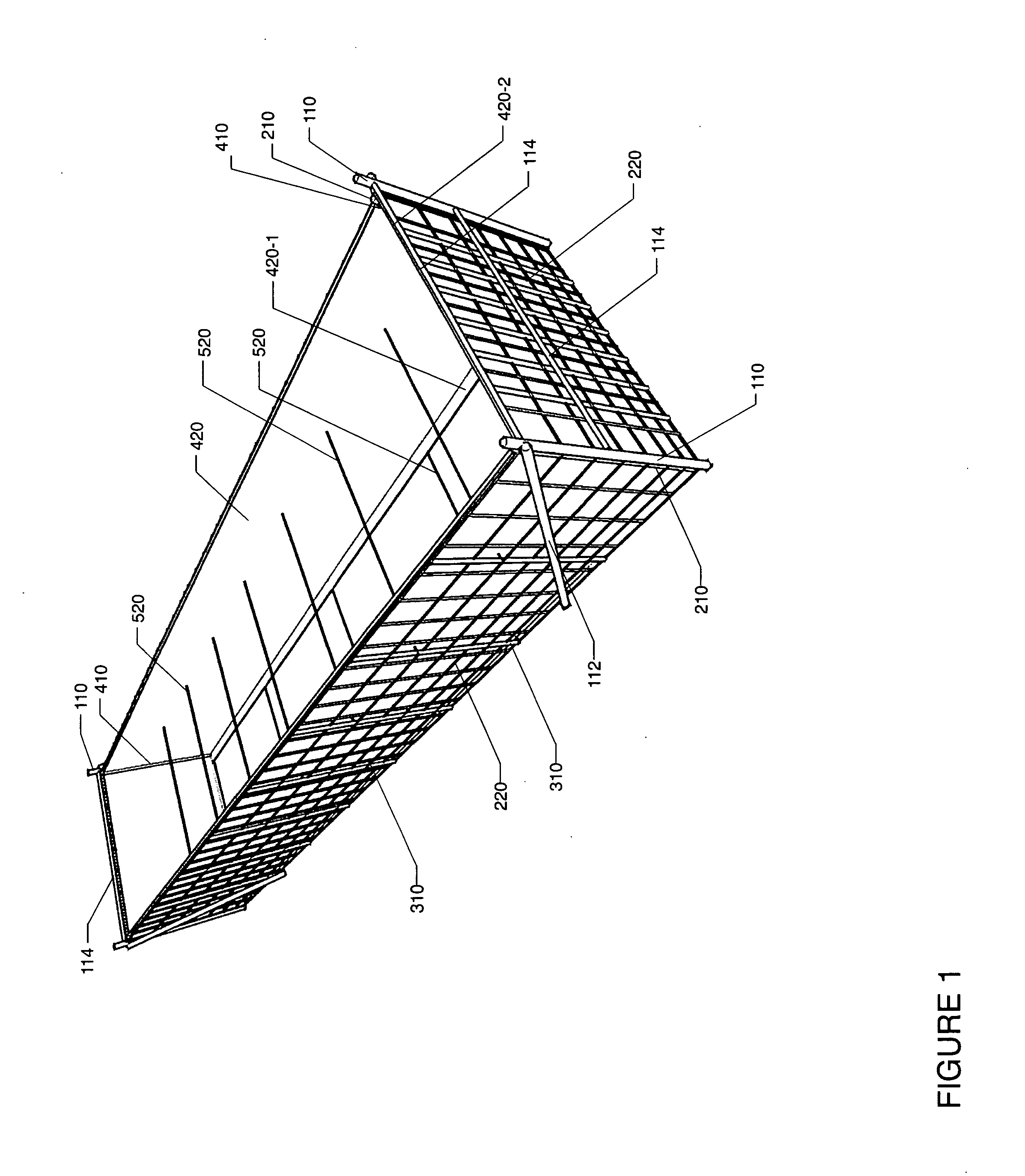

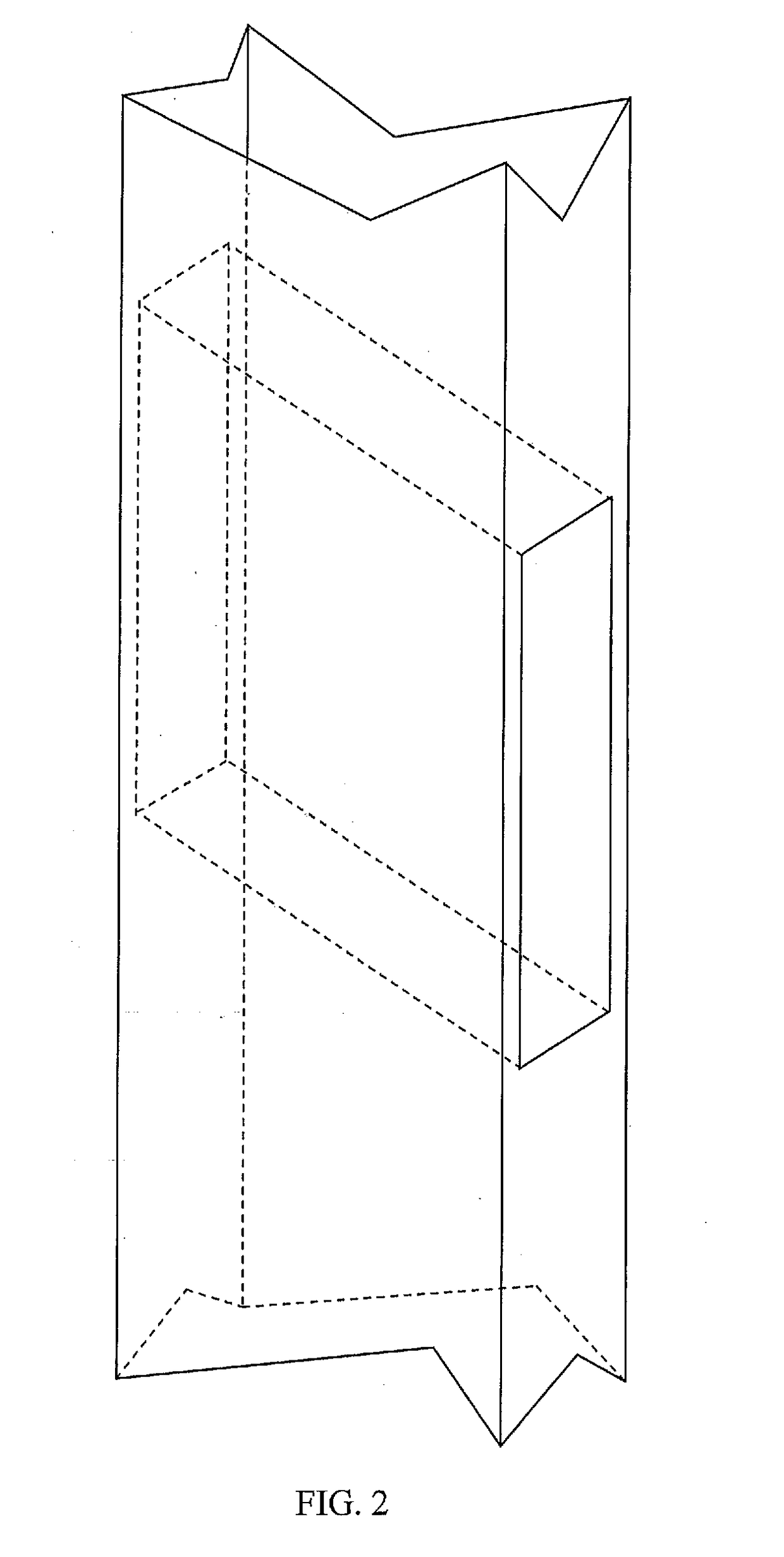

High raised garden bed planter

InactiveUS20130174480A1Efficient and effective useHigh compressive strengthPlanting bedsFencing wireSeederWire rod

A planter assembly o raise a garden bed to a height that eliminates or minimizes stoop labour is comprised of lightweight, flexible, materials with adequate tensile strength as well as a rigid element with adequate compressive strength.Flexible wire mesh is formed into a perimeter frame of pre-determined width, length and height in combination with rods and wire.A textile lines the perimeter frame, providing a barrier impervious to soil. The textile encloses the top horizontal wire of the mesh within a hem held fast by wire and is thereby restrained. A band of the textile, sufficiently wide to be held to the ground by the placement of soil, extends from the base of the perimeter frame towards its middle.Wire is also used as crossties to enable the lateral earth pressure pushing against one side to resist the lateral earth pressure pushing against the side opposite.

Owner:GABELMANN DOUGLAS LEONARD

Method, an apparatus and a means for making a reinforcement mesh

InactiveUS7909067B2Precise positioningRapid and simple and stable mannerFencing wireWire networkWire rodEngineering

Owner:PEDAX GMBH

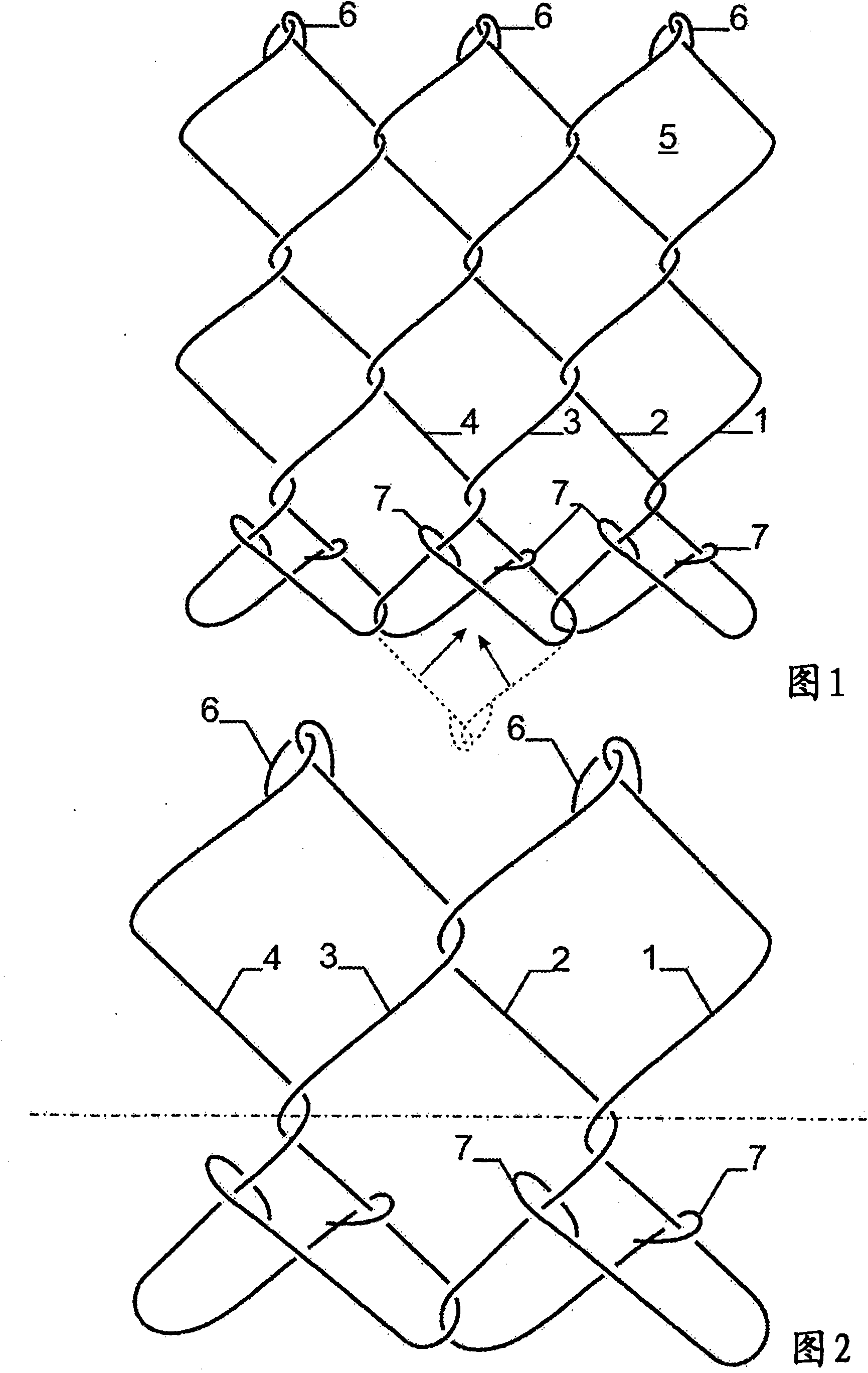

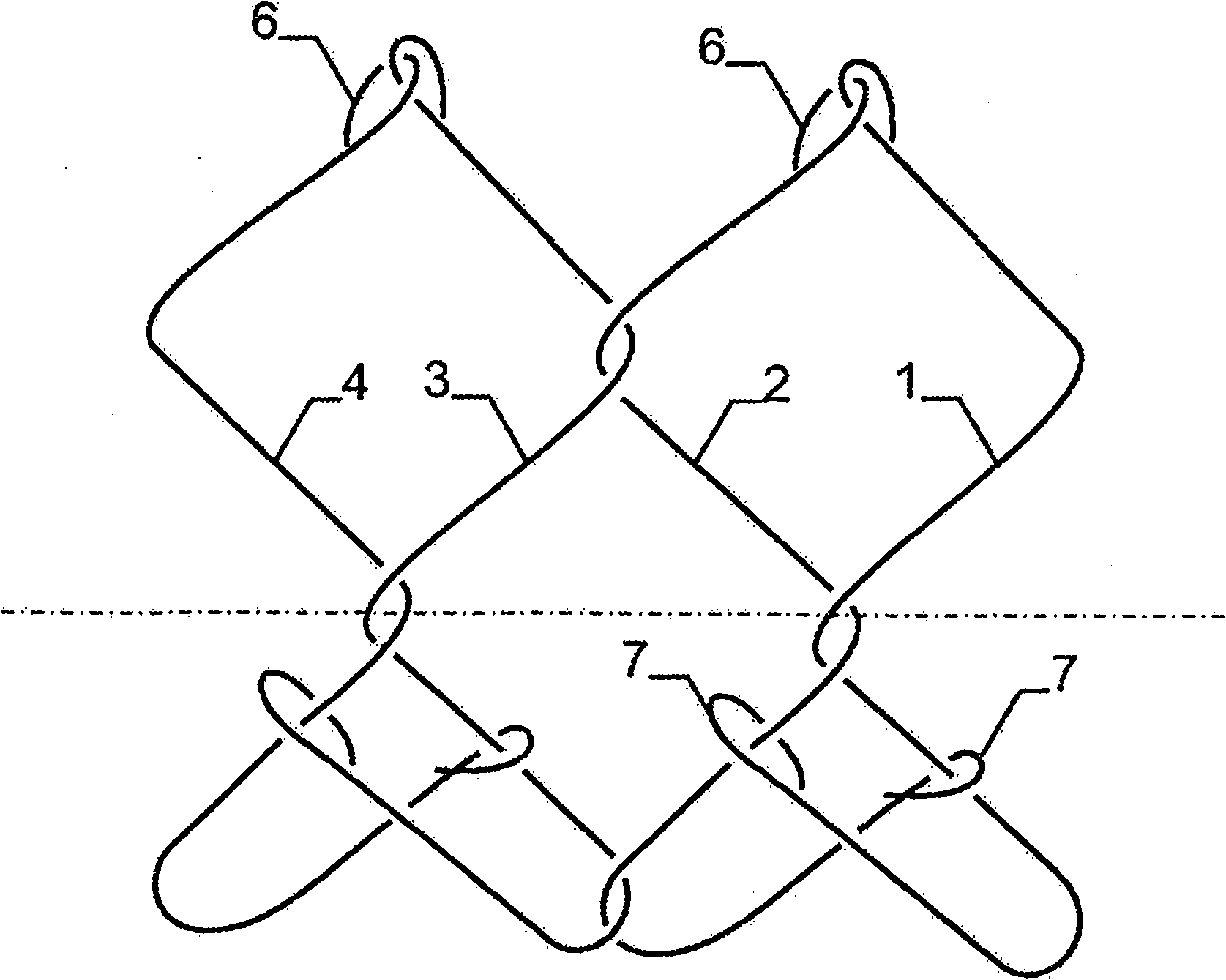

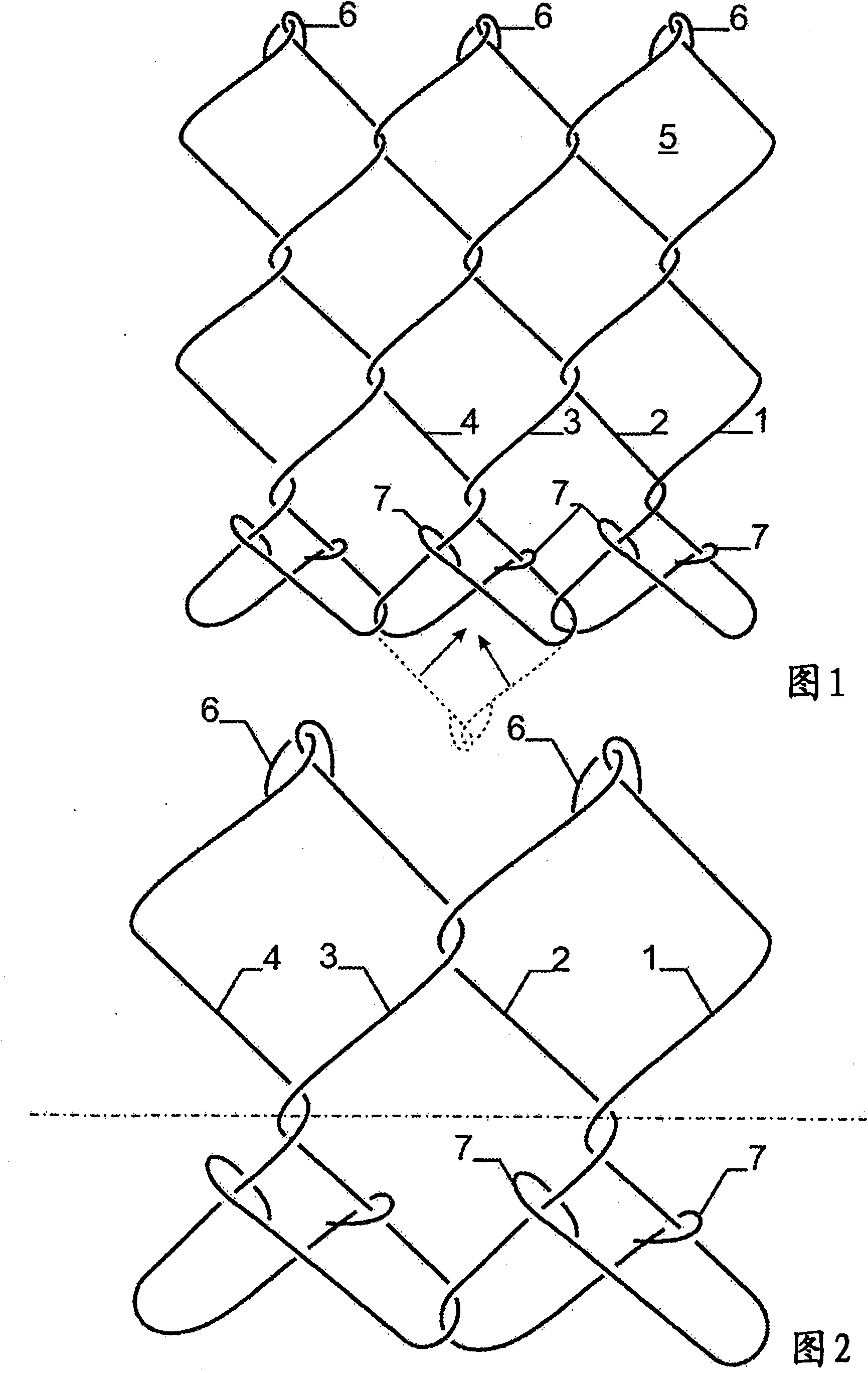

Chain link woven mesh with double knot

A chain link woven mesh comprises successive undulated transverse links (1,2,3,4), which are interconnected together at the bent portions of the links, whereby each pair of successive undulated links (1,2), (3,4) forms a row of adjacent rectangular or square meshes (5) with four sides. At least at one border of the mesh, for each pair of successive links, the last side of the first link (1) is bent upwardly and backwardly over a sharp angle, whereby the end of this last side is hooked around the penultimate (last but one) side of the second link (2). The last side of the second link (2) is bent downwardly and backwardly over a sharp angle, whereby the end of this last side is hooked around the penultimate (last but one) side of the first link (1). The advantage is that a very strong border is obtained.

Owner:NV BEKAERT SA

Material formed of multiple links and method of forming same

A material includes a frame having at least one elongate member formed of a first polymer. At least one link is formed of a second polymer, with a portion of each link co-molded about a portion of at least one elongate member, and at least one link movable with respect to a corresponding elongate member.

Owner:NIKE INC

Apparatus and method for making an improved chain link fabric

An apparatus for processing chain link fabric including a welding assembly and / or a compressing assembly. The welding assembly is configured to weld together wire-end portions of the chain link fabric. The welding assembly includes a guiding assembly having a finger and a cam, which are configured to restrict the movement of the wire-end portions while the welding assembly welds them together. The finger and the cam are configured to move relative to the wire-end portions both before and after the wire-end portions are welded together. The compressing assembly is configured to compress the wire-end portions after they are welded together. The compressing assembly includes a stabilizing assembly having a stabilizing die, which is configured to interface with the chain link fabric and to restrict the movement of the welded wire-end portions while the compressing assembly compresses the welded wire-end portions.

Owner:BERGANDY MACHINERY

Automatic reducing device of seam welder

InactiveCN102009295AReduce wasteRealize the effect of variable diameterFencing wireWelding/cutting auxillary devicesSteering wheelEngineering

The invention provides an automatic reducing device of a seam welder, relating to a reducing mechanism of a cement tube reinforcement cage welding device, which can adapt a continuous vertical rib feeding mode. The automatic reducing device comprises a reducing cylinder and a reducing cylinder control mechanism, wherein the reducing cylinder is arranged on a main disk and used for driving a welding head to move radically, and the reducing cylinder control mechanism is arranged on a tie bar trolley and used for controlling the reducing cylinder to move axially. The main disk is provided with a central hole; the reducing cylinder comprises a reducing screw rod, a rear disk, a front disk, a chain 1, a steering wheel group 1, a chain 2, a steering wheel group 2 and a connection link. The reducing cylinder control mechanism comprises a reducing control rod the cross section of which is a hexagon, a clutch and a driving mechanism; the driving mechanism is fixedly connected to the trolley; and the reducing control rod is connected with the driving mechanism through the clutch. After the reducing control rod of the invention is meshed with the reducing screw rod,, the reducing control rod can drive the reducing screw rod to rotate when rotating; the rotation of the reducing screw rod drives the front disk and the rear disk to move axially; and the axial movement of the front disk and the rear disk can drive the welding head to move radically via the chain 1 and the chain 2, thereby realizing reducing.

Owner:江苏江桥机械制造有限公司

Apparatus and method for making wire screen

Owner:BUFFALO WIRE WORKS

Apparatus and method for making an improved chain link fabric

ActiveUS20050263564A1Quickly and easily preparedLow costFencing wireWelding/cutting auxillary devicesEngineeringCam

An apparatus for processing chain link fabric including a welding assembly and / or a compressing assembly. The welding assembly is configured to weld together wire-end portions of the chain link fabric. The welding assembly includes a guiding assembly having a finger and a cam, which are configured to restrict the movement of the wire-end portions while the welding assembly welds them together. The finger and the cam are configured to move relative to the wire-end portions both before and after the wire-end portions are welded together. The compressing assembly is configured to compress the wire-end portions after they are welded together. The compressing assembly includes a stabilizing assembly having a stabilizing die, which is configured to interface with the chain link fabric and to restrict the movement of the welded wire-end portions while the compressing assembly compresses the welded wire-end portions.

Owner:BERGANDY MACHINERY

Grid structure

InactiveCN101534977AEasy to manufactureEnhanced clamping abilityFencing wireBuilding reinforcementsRebarMechanical engineering

Owner:约瑟夫·克里斯默

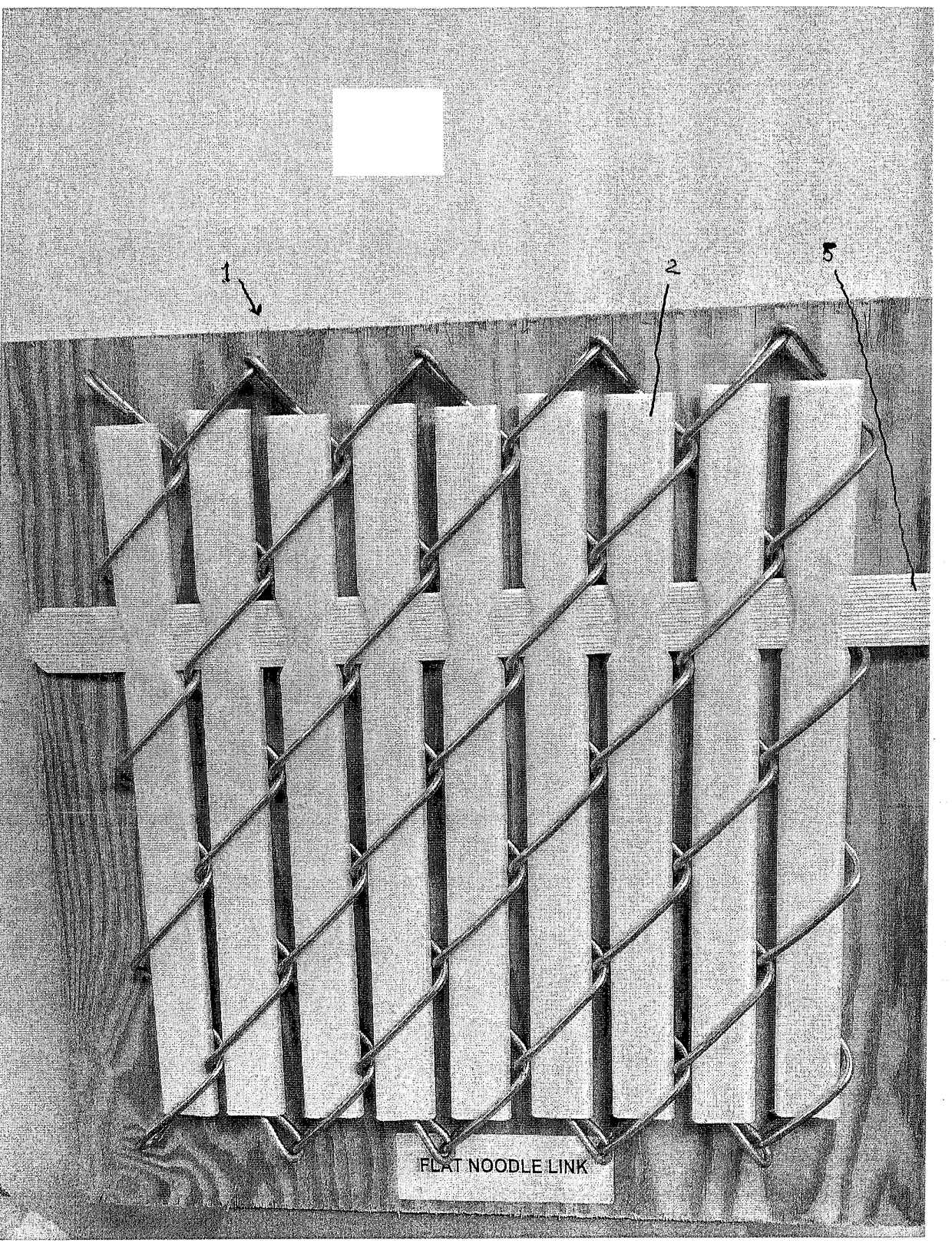

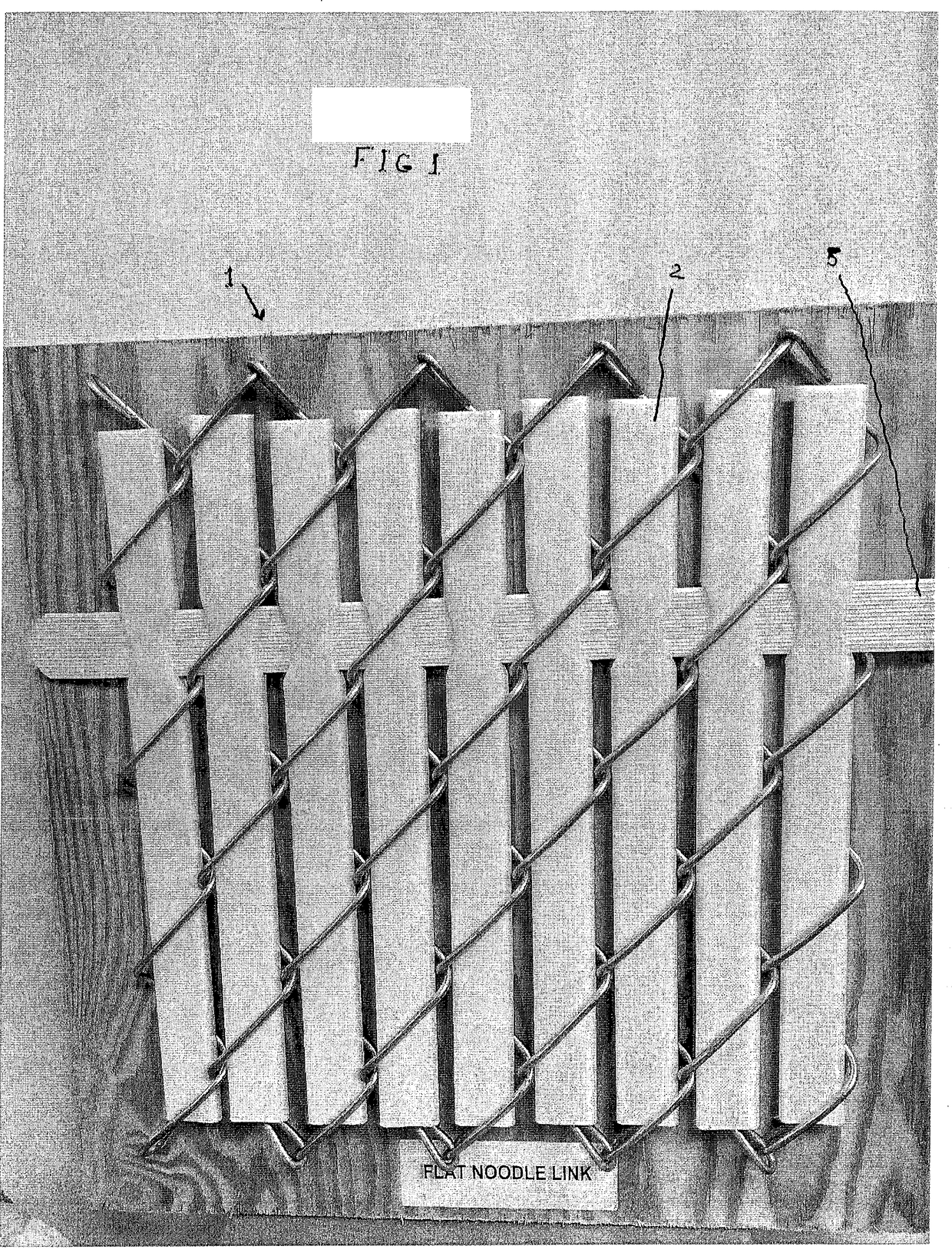

Chain Link Fence with Internally Retained Slats

Owner:PRIVACYLINK LLC

Wire cloth

ActiveUS7204461B2Reduce material consumptionIncrease productionSynthetic resin layered productsFencing wireEngineeringMechanical engineering

A wire cloth includes metallic warp wires and metallic weft wires interwoven with one another, wherein the weft wires have each a diameter which is equal or smaller than a clear distance between two neighboring warp wires, and wherein the weft wires are constricted in crossing regions with the warp wires.

Owner:HAVER & BOECKER

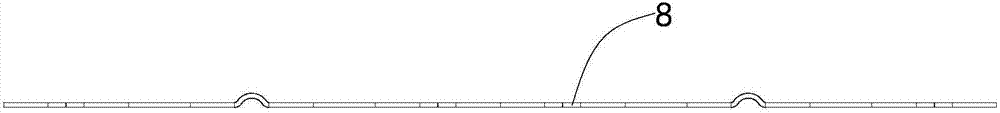

Iron wire supporting and stretching device and preparation process of metal protective mesh

The invention relates to an iron wire supporting and stretching device and a preparation process of a metal protective mesh. The iron wire supporting and stretching device is used for straightening and forming an extruded iron wire and comprises a bracket, a hydraulic cylinder, a first connection rod, a second connection rod and a plurality of pulleys. The lower end of the hydraulic cylinder is fixed to the bracket and is vertically arranged, the first connection rod is installed on the bracket and is horizontally arranged, and the second connection rod is installed at the upper end of the hydraulic cylinder and is parallel to the first connection rod in a vertical correspondence manner; the hydraulic cylinder is stretched out or drawn back up and down so that the distance between the first connection rod and the second connection rod can be increased or decreased; the first connection rod and the second connection rod are both provided with the pulleys, and the pulleys on the first connection rod and the pulleys on the second connection rod are arranged in a staggered manner; and the extruded iron wire is sequentially arranged on the multiple pulleys up and down in a wound manner. According to the iron wire supporting and stretching device and the preparation process of the metal protective mesh, an independent extruded iron wire can be stretched according to requirements, the extruded iron wire is shaped through the pulleys, and the preparation process is simple and convenient.

Owner:BEIJING LONG FLY SCI & TECH CO LTD

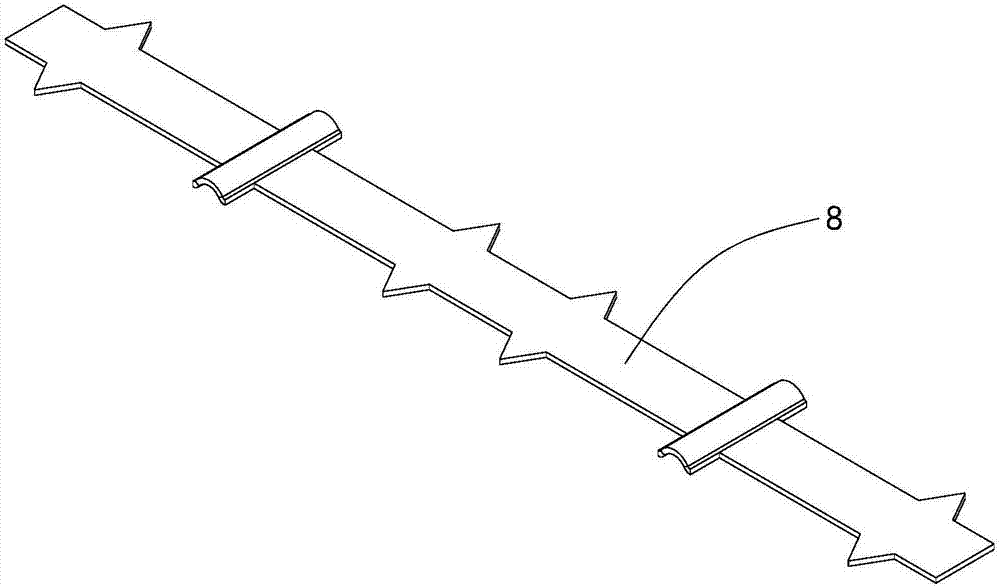

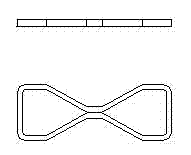

Method for machining '8'-shaped grid

InactiveCN102896259AGuarantee the shape of the facadeEasy to operateFencing wireEngineeringAssembly line

The invention discloses a method for machining a '8'-shaped grid. The method is characterized by comprising the following steps of: a. bending a reinforcing steel bar into a rectangle, and welding the ends of the reinforcing steel bar to form a rectangular reinforcing steel bar with a closed structure; b. horizontally stamping the two long sides of the rectangular reinforcing steel bar to form a '8'-shaped reinforcing steel bar; and c. vertically stamping the middle part of the '8'-shaped reinforcing steel bar so that the middle part of the '8'-shaped reinforcing steel bar sinks to form an inverted trapezoidal concave part. The method has the beneficial effects of simpleness in operation and process, needing fewer welding joints during mechanical operation, guaranteeing the shape of the '8'-shaped vertical surface, needing less labor force, realizing assembly line work, improving the machining efficiency and saving cost.

Owner:CHINA RAILWAY HI TECH IND CORP LTD +1

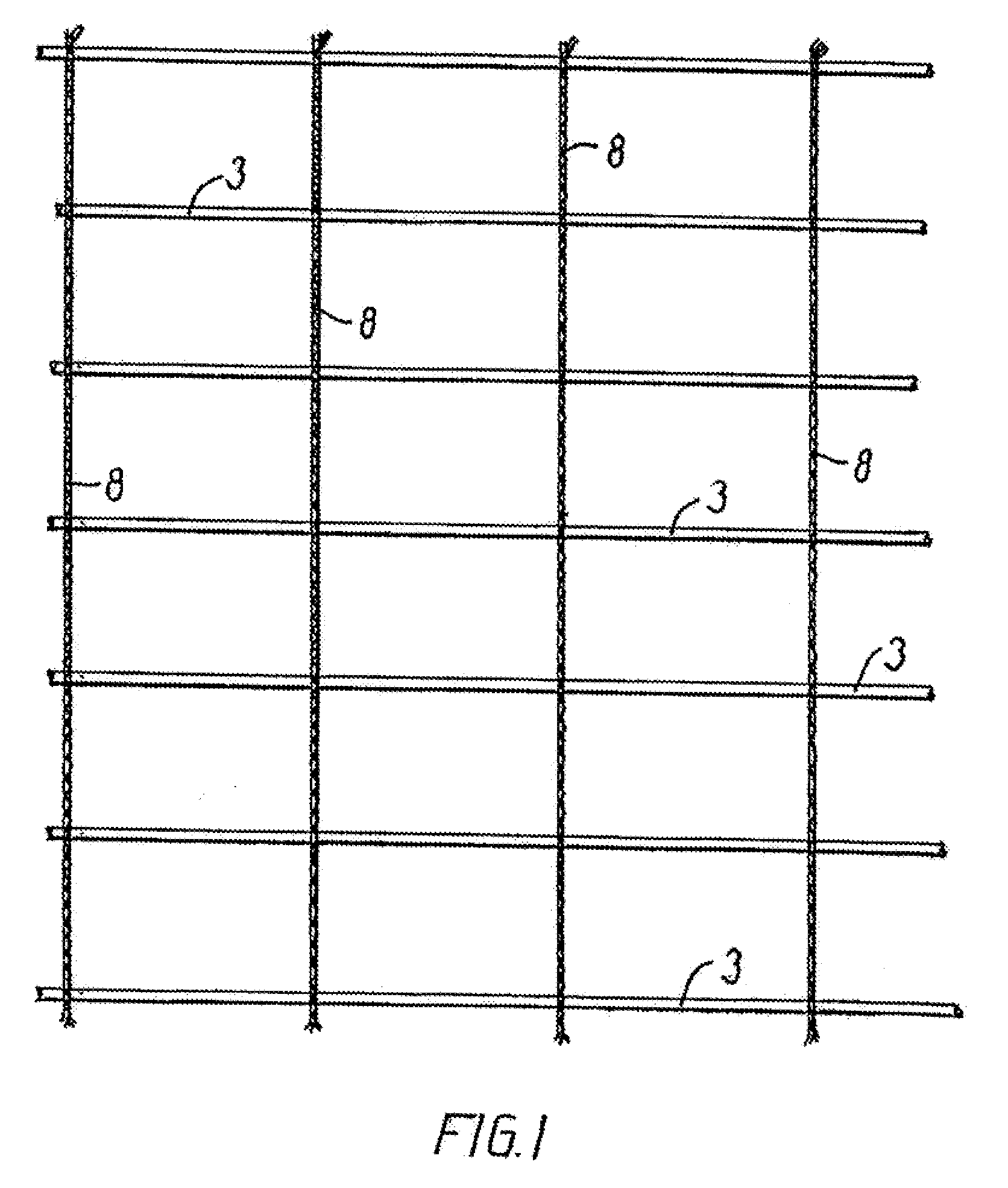

Fence mesh and machine for the formation thereof

Fence mesh including line wires, and stay wires extending laterally across and intersecting the line wires to form a mesh, wherein a first type of wire knot is formed by a knot wire around the line wire and stay wire at intersections of the stay wires with the line wires in a primary zone, and wherein a second type of wire knot is formed by a knot wire around the line wire and stay wire at intersections of the stay wires with the line wires in a secondary zone, characterised in that the first type of wire knot is different from the second type of wire knot; and a machine for the formation of such a mesh.

Owner:UMC INNOVATION LTD

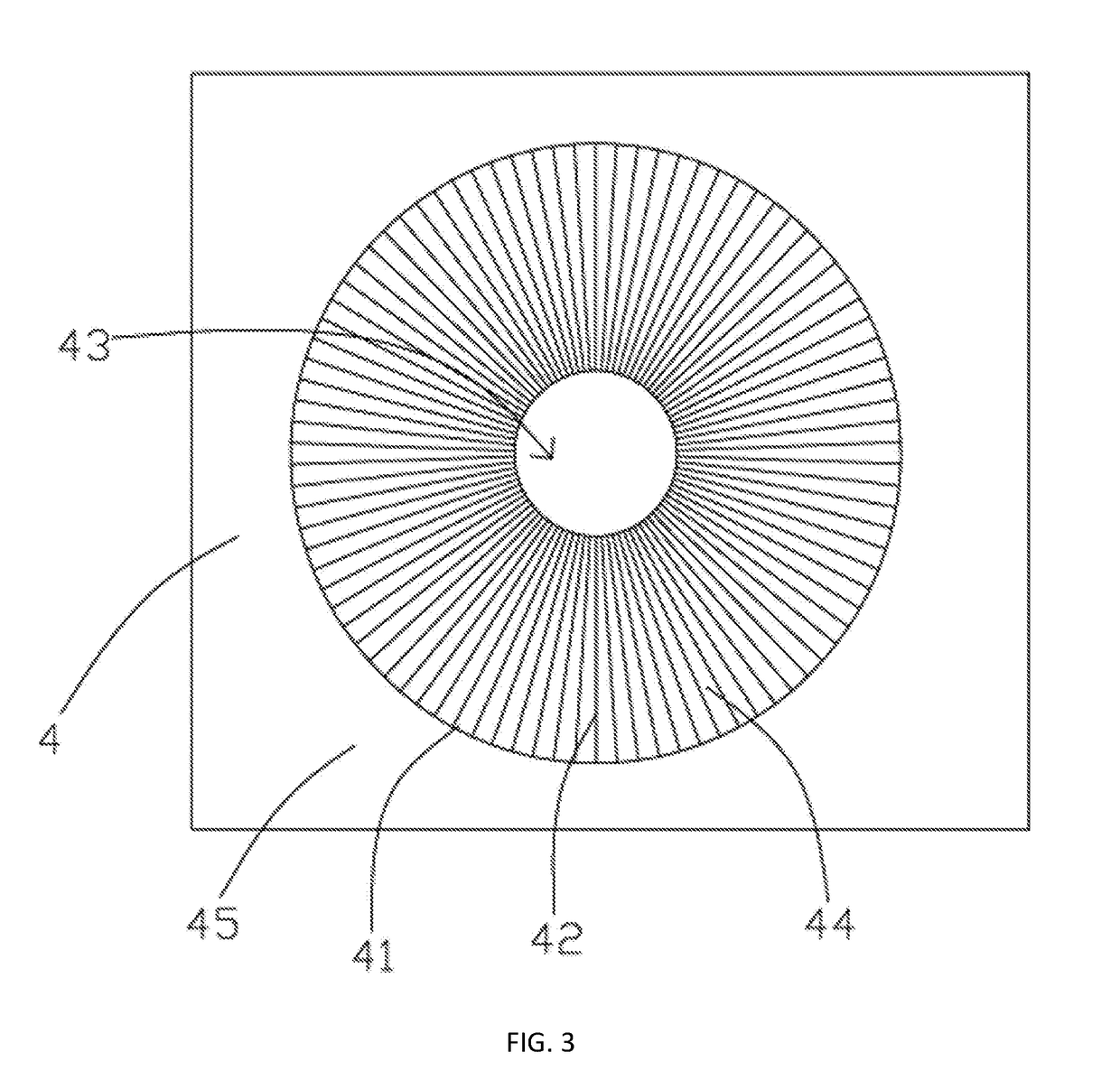

Method of manufacturing a rotary-type physical shield purifier

InactiveUS20170151517A1Easy to useIncrease chanceFencing wireDispersed particle separationEngineeringSpoke

A method for manufacturing a rotary physical shielding purifier, comprising the following steps: (1) respectively placing an outer rim, spokes and a central clamp base in an outer rim groove, spoke grooves and a central hole, and pressing a pressing die on the spokes; (2) using a welder to weld the contact parts between the spokes and the outer rim; (3) installing a central clamp gland on the central clamp base; and (4) separating the pressing die from a clamping die, and taking the finished product out.

Owner:HU DUANZHI

Chain link woven mesh with double knot

InactiveCN101910534BIncrease resistancePrevent openingUnderground chambersFencing wireSquare meshSharp angle

A chain link woven mesh comprises successive undulated transverse links (1,2,3,4), which are interconnected together at the bent portions of the links, whereby each pair of successive undulated links (1,2), (3,4) forms a row of adjacent rectangular or square meshes (5) with four sides. At least at one border of the mesh, for each pair of successive links, the last side of the first link (1) is bent upwardly and backwardly over a sharp angle, whereby the end of this last side is hooked around the penultimate (last but one) side of the second link (2). The last side of the second link (2) is bent downwardly and backwardly over a sharp angle, whereby the end of this last side is hooked around the penultimate (last but one) side of the first link (1). The advantage is that a very strong border is obtained.

Owner:NV BEKAERT SA

A method and device for processing a reinforced keel

ActiveCN105057511BImprove processing efficiencyImprove reliabilityFencing wireWire networkKeelEngineering

The invention relates to a processing method and equipment for a reinforced keel. The method for processing a reinforced keel, the steps comprising: arranging a plurality of overall cylindrical reinforced cages in parallel; ; Or cut and then reassembled to form a reinforced keel that matches the shape of the prefabricated wall module. The beneficial effect of the present invention is: use the welded mesh machine to obtain sheet steel mesh, and then bend the steel mesh to obtain a columnar reinforcement cage; use the columnar reinforcement cage to connect the upper weft reinforcement and the lower weft reinforcement to quickly process the continuous reinforcement cage, and then Cut or cut into the required steel keel. The invention solves the bottleneck problem of low processing efficiency of the steel keel in the prefabricated wall module; the finished steel keel can be quickly processed through a complete set of equipment by using commercially available steel plate feeding, creating conditions for the wide application of the prefabricated wall module .

Owner:赵光林

Net Knitting Method

InactiveUS20140116568A1Improve structural strengthAvoid it happening againWeft knittingFencing wireEngineering

Owner:CHEN CHUNG PING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com