Iron wire supporting and stretching device and preparation process of metal protective mesh

A preparation process and metal protection technology, applied in the direction of wire processing, wire fence, other household appliances, etc., can solve the problem of high false alarm rate of monitoring equipment, and achieve the effect of convenient operation, simple process and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

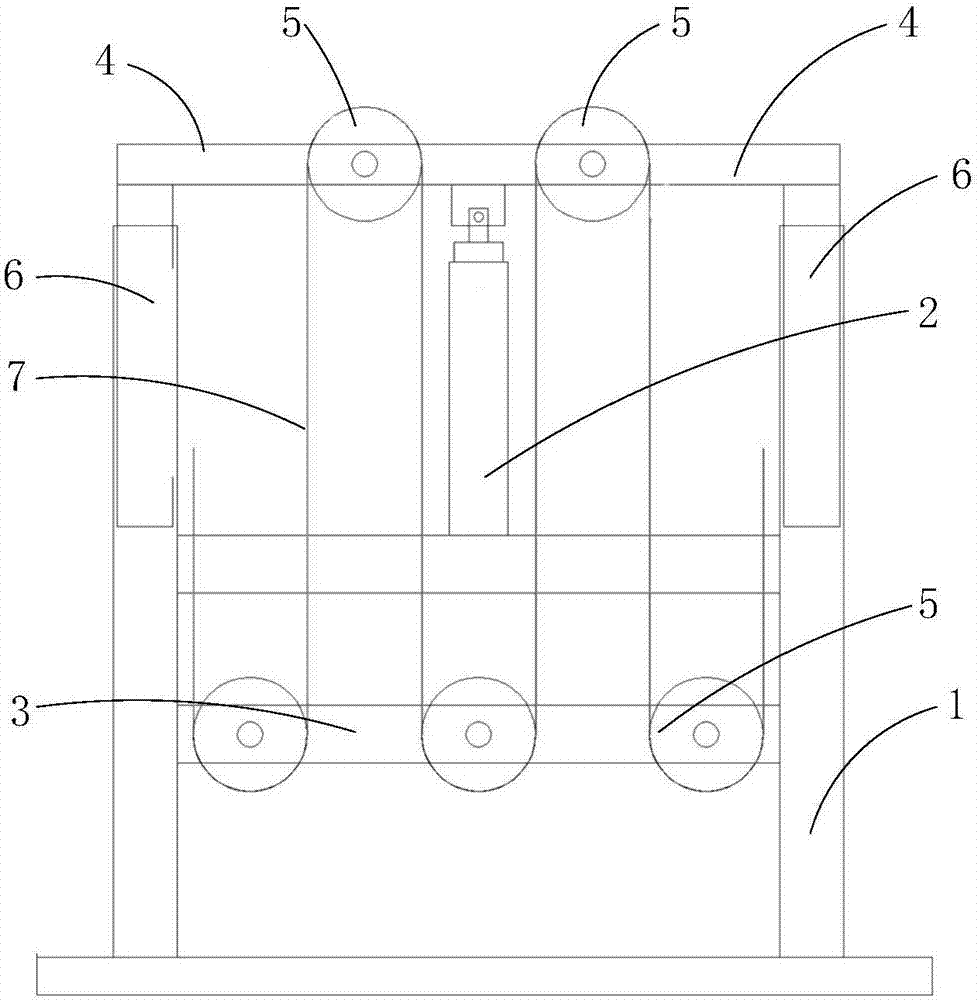

[0040] Such as Figure 1-Figure 6 As shown, a device for supporting stretched iron wire in this embodiment is used to straighten and shape extruded iron wire; it includes a bracket 1, a hydraulic cylinder 2, a first connecting rod 3, a second connecting rod 4 and a plurality of pulleys 5 , the lower end of the hydraulic cylinder 2 is fixed on the support 1 and arranged vertically, the first connecting rod 3 is installed on the support 1 and arranged horizontally, the second connecting rod 4 is installed on the hydraulic The upper end of the cylinder 2 is arranged in parallel with the first connecting rod 3 up and down; the hydraulic cylinder 2 stretches up and down to increase or decrease the distance between the first connecting rod 3 and the second connecting rod 4 Small;

[0041] Such as figure 1 As shown, the pulley 5 is installed on the first connecting rod 3 and the second connecting rod 4 of this embodiment, and the pulley 5 on the first connecting rod 3 and the secon...

Embodiment 2

[0050] A kind of preparation technology of metal protective net, comprises the following steps:

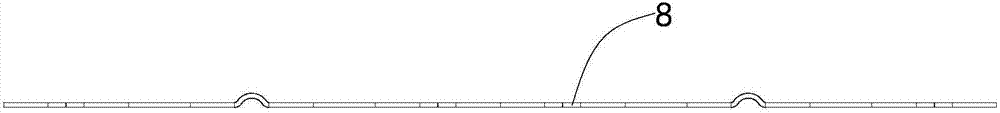

[0051] S1, using the device described in Example 1 to stretch an independent extruded iron wire into a forming iron wire 7 integrally connected by a plurality of linear iron wires in an arc shape, and then fix a supporting frame around the forming iron wire 7 10 so that the forming iron wire 7 is fixed on a plane;

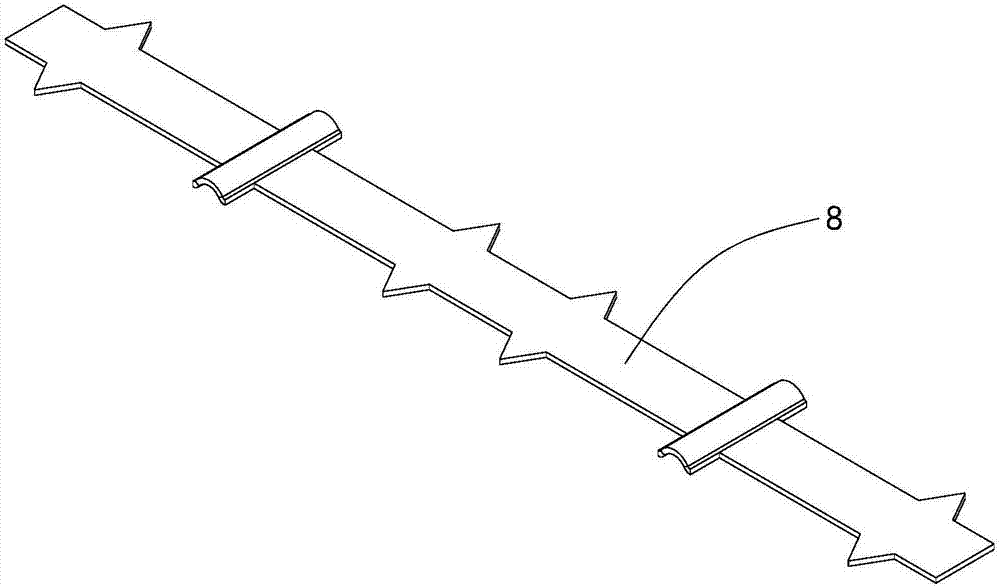

[0052] S2, a plurality of elongated first metal sheets 8 and a plurality of elongated second metal sheets 9 are respectively arranged on both sides of the forming iron wire 7; a plurality of the first metal sheets 8 and a plurality of second metal sheets The two metal sheets 9 are arranged in one-to-one correspondence on both sides of the forming iron wire 7 and are arranged to cross the straight iron wire;

[0053] S3, stamping the first metal sheet 8 and the second metal sheet 9 that are oppositely arranged, so that the first metal sheet 8 and the second metal sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com