Machining method and equipment for steel bar keels

A technology of steel keel and processing method, applied in the direction of wire rod processing, wire mesh, wire fence, etc., can solve problems such as confusion and defective products, confusion of steel keel, time-consuming and labor-intensive, etc., to improve construction efficiency, The effect of reducing labor intensity and construction period and reducing construction waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

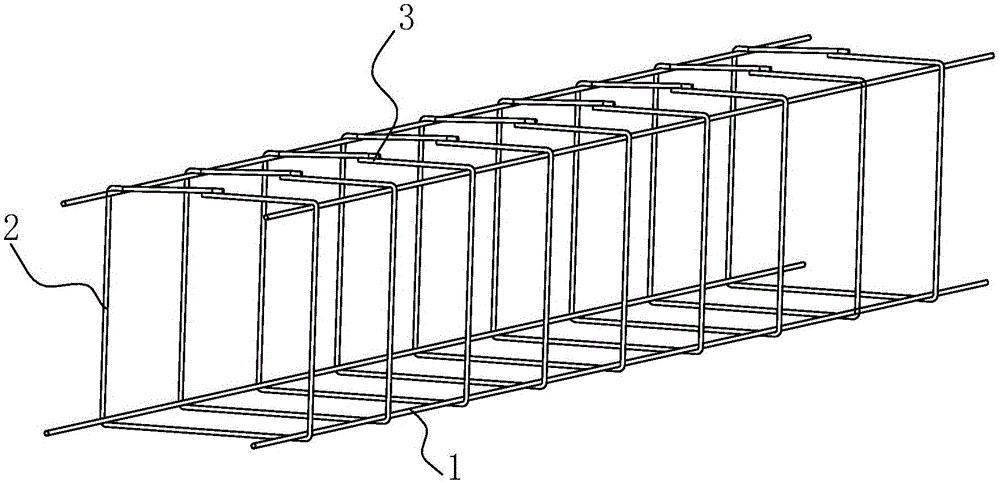

[0045] The core technical problem to be solved by the present invention is exactly how to process figure 1 The cylindrical reinforcement cage shown. The reinforcement cage includes four longitudinal reinforcement bars 1 along the length direction, which are formed by connecting a plurality of stirrup bars 2 . There can also be more reinforcing bars along the length direction, for example, adding a longitudinal reinforcing bar 1 to each of the four faces of the four columns, then there are 8 reinforcing bars in the longitudinal direction of the reinforcing cage; the structural strength of the reinforcing cage can be further improved .

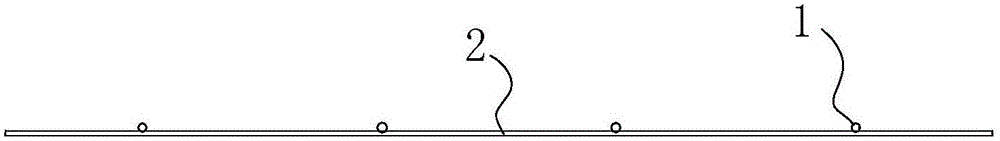

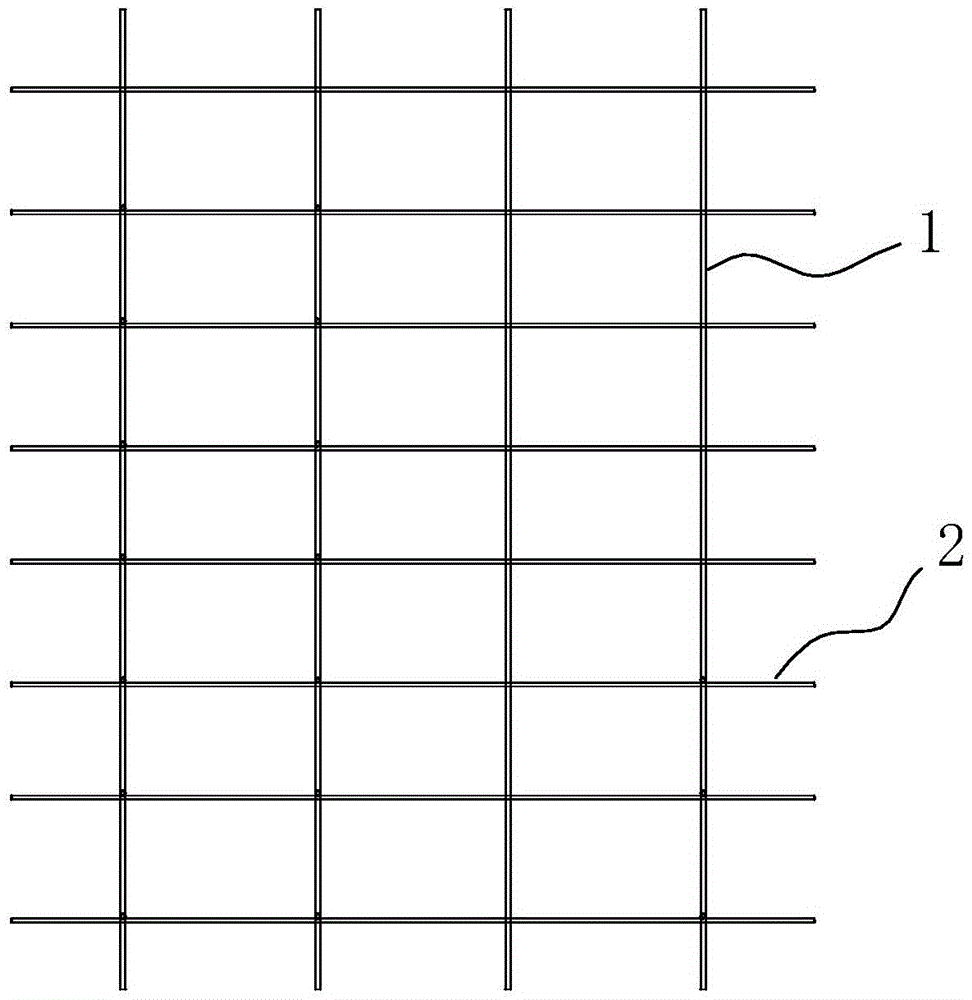

[0046] The method of processing the reinforcement cage is to make the combined figure 2 , 3 The sheet steel mesh shown. There are longitudinal steel bars 1 arranged along the length direction and stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com