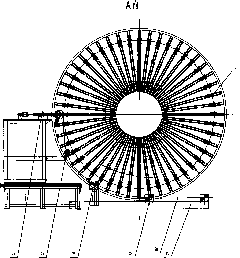

Double-reinforcement parallel-winding full-automatic reinforced concrete pipe reinforcement cage seam welder

A technology of reinforced concrete pipes and steel skeletons, applied in the direction of roller electrode welding, wire fences, other household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

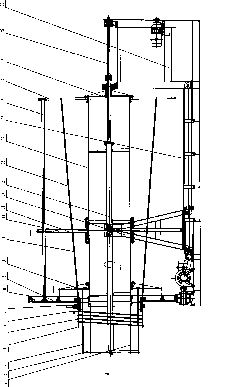

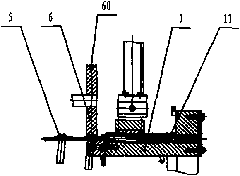

[0026] Such as figure 1 As shown, the main transmission parts are installed on the frame 23, the guide rod 19 passes through the through groove of the push rib faceplate 12, and the two ends thereof are respectively fixedly connected to the main faceplate 9 and the rear faceplate 20, and the main shaft 17 is connected to the rear faceplate 20 respectively. 20 is fixedly connected with main faceplate 9. When the main motor was working, the main faceplate 9, the rib pusher faceplate 12, the main shaft 17 and the rear faceplate 20 rotated to realize the winding of the steel bar ring bar 5 on the longitudinal bar 4.

[0027] The traction transmission device and the rib-pushing track 18 are fixedly connected on the frame 23, the longitudinal rib 4 of the steel bar and several rib-pushing round steels 11 are passed in the rib-piercing pipe 16, and one end of the rib-piercing pipe 16 is fixed to the rear flower disc 20, and the other One end passes through the through hole of the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com