Assembled integral shear wall structure system and construction method thereof

A shear wall, integral technology, applied in the direction of walls, building components, building structures, etc., can solve problems such as leakage prevention at joints, and achieve the effect of accelerating construction speed, simplifying construction procedures, and reducing project cost.

Active Publication Date: 2010-09-01

华筑(辽宁)建筑工程设计有限公司

View PDF7 Cites 54 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of this invention is to provide an assembled integral shear wall structure system and its construction method, to solve the problem of anti-leakage at the joints between prefabricated wall panels

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

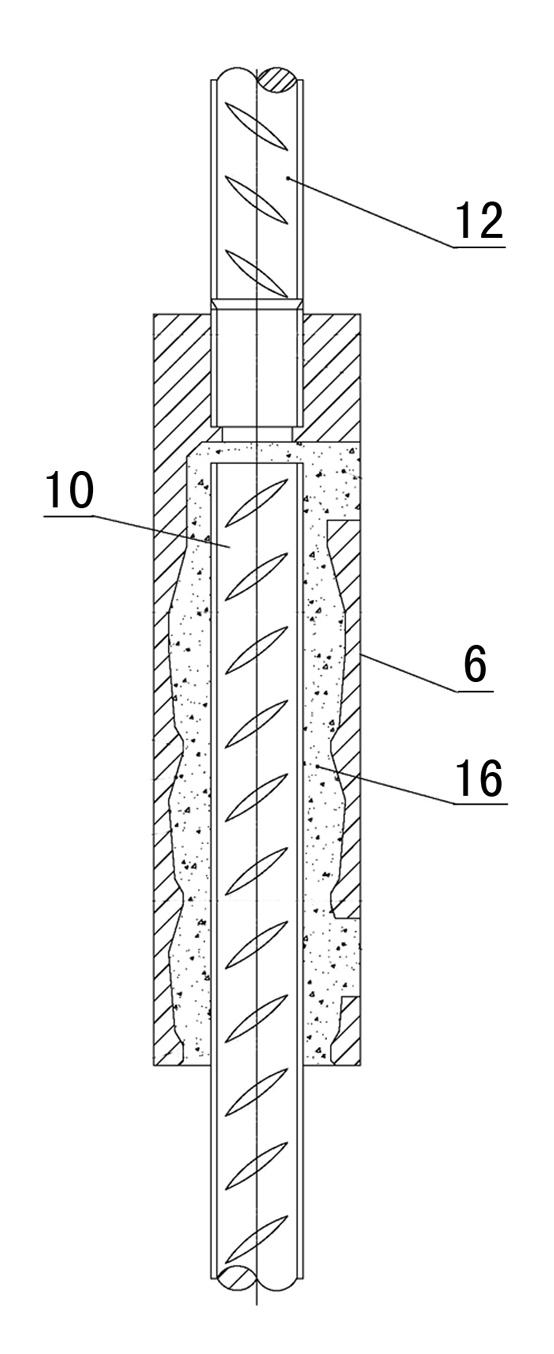

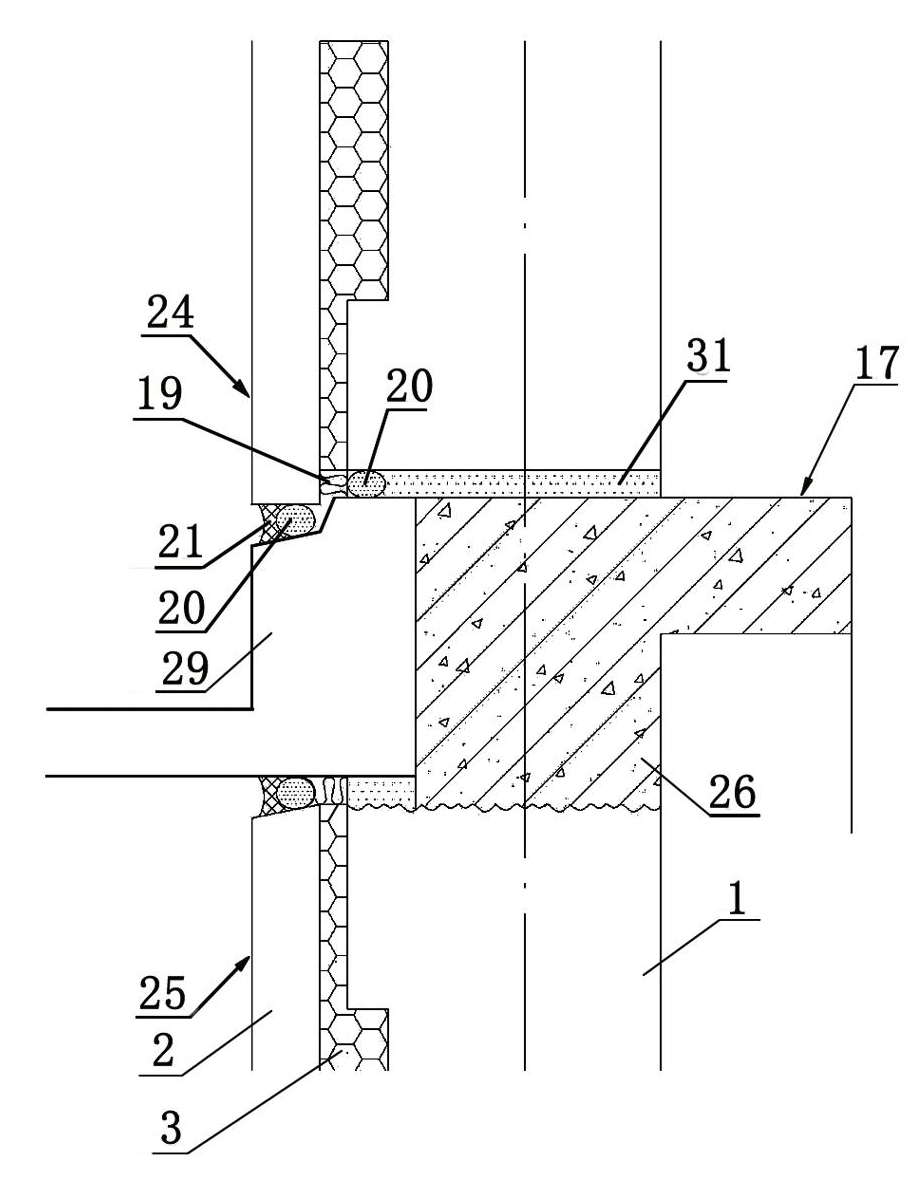

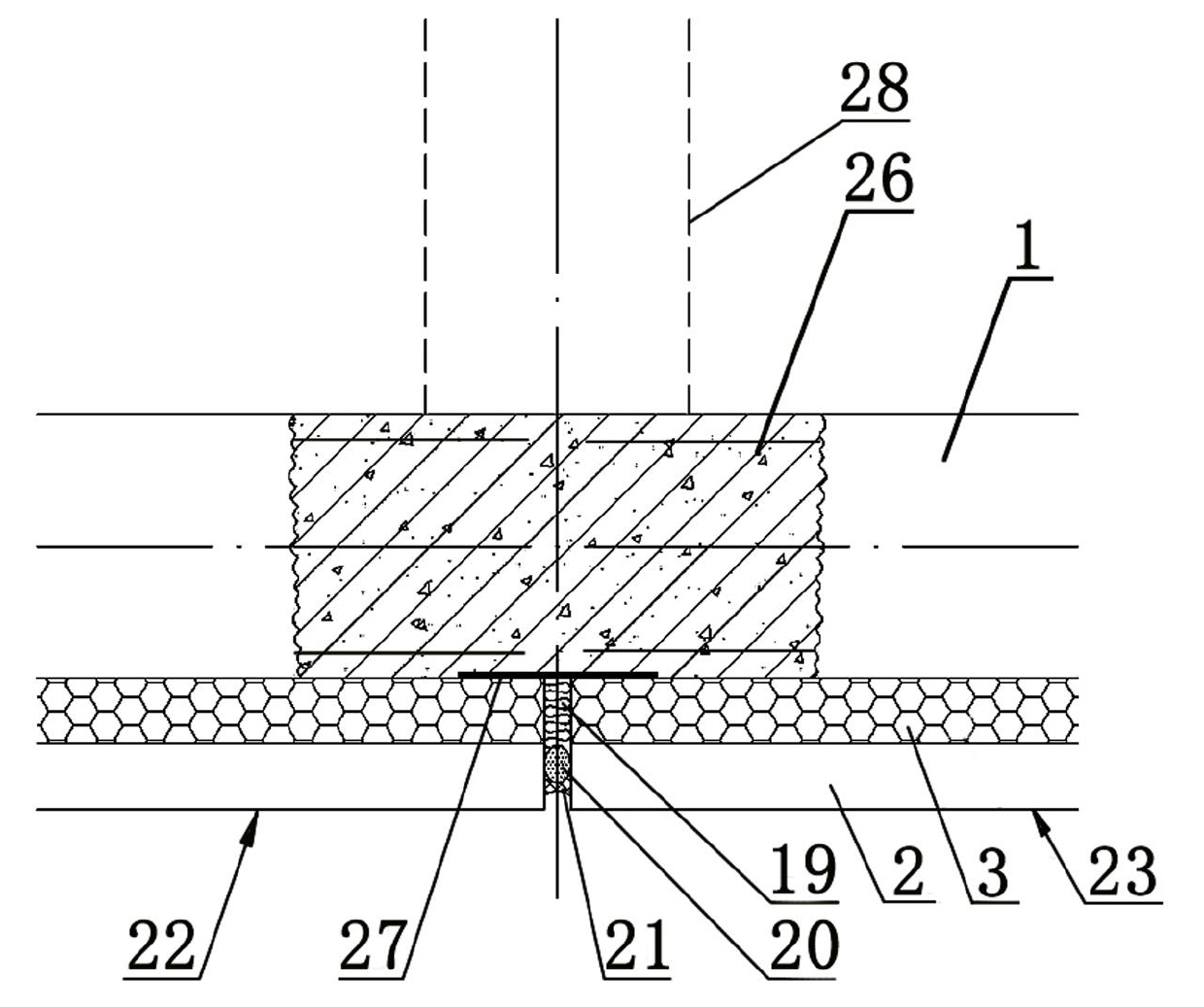

The invention discloses an assembled integral shear wall structure system and a construction method thereof. Prefabricated composite wallboards are hoisted and assembled integrally at a construction site; a board body of the prefabricated composite wallboards comprises a structural layer, an insulating layer and a protective layer from the inside to the outside in turn; a reinforcement cage is arranged in the structural layer; the insulating layer is an extruded polystyrene foam plastic board; steel meshes are arranged in the concrete of the protective layer; and anchor bolts in a dotted distribution are connected among the structural layer, the insulating layer and the protective layer. Vertical seams and horizontal seams of prefabricated composite walls adopt structural self-waterproofing, so that common quality problems such as leakage and cracks and the like in a traditional process are solved. The prefabricated composite walls simplify construction processes, speed up the construction, and lower the construction cost. Furthermore, products prefabricated in a factory have uniform specifications and unified quality, so that the construction quality of a building construction can be sufficiently guaranteed; the industrialization, standardization, and generalization of the building walls are realized; and the products can be widely applicable to the construction of reinforced concrete buildings in the construction industry.

Description

technical field The invention relates to a shear wall structure and a construction method thereof. Background technique The traditional construction of the main structure of the external wall basically adopts the original construction method of erecting steel bars, supporting formwork, binding steel bars, pouring concrete and then demolishing the formwork. A series of tedious tasks such as the construction of the decorative layer and the construction of the decorative layer make the construction cost relatively large, the on-site construction procedure and management complicated, and the final construction quality is not easy to be guaranteed. In addition, the original semi-manual and semi-mechanized construction method produces a large amount of scraps and construction waste, which is not conducive to environmental protection, making the construction site difficult to clean, and the construction noise seriously affects the life and work of the surrounding residents. Altho...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04B2/00E04B2/72E04C2/288E04G21/14

Inventor 秦珩周松刘国权李建树张景明

Owner 华筑(辽宁)建筑工程设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com