Construction method of shallow buried underground excavating tunnel super large section using PBA method

A technology of shallow burial and deep excavation and super large section, applied in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of reducing land subsidence, poor geological conditions, complex surrounding environment, etc., to ensure construction quality and ensure structural integrity. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

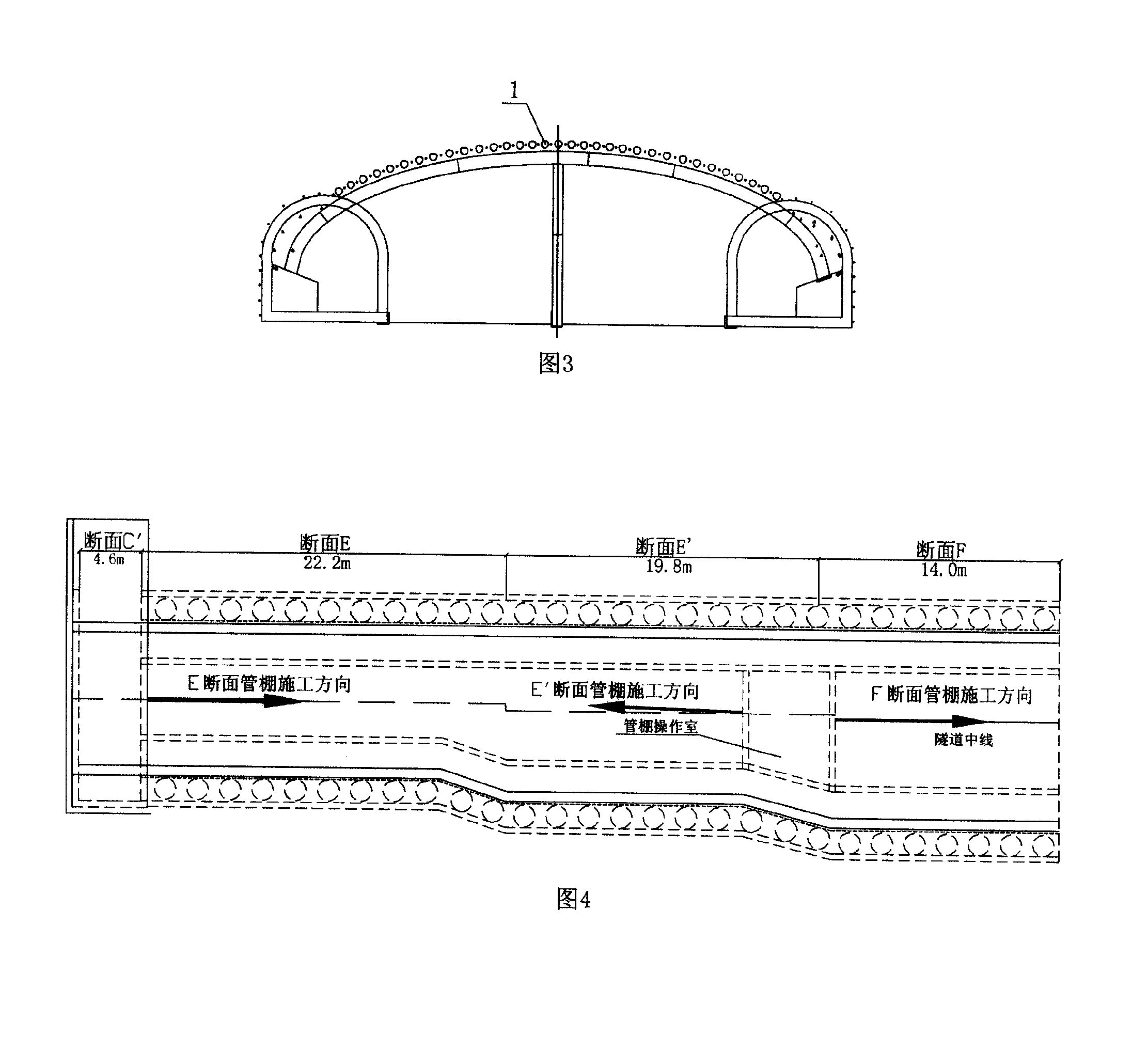

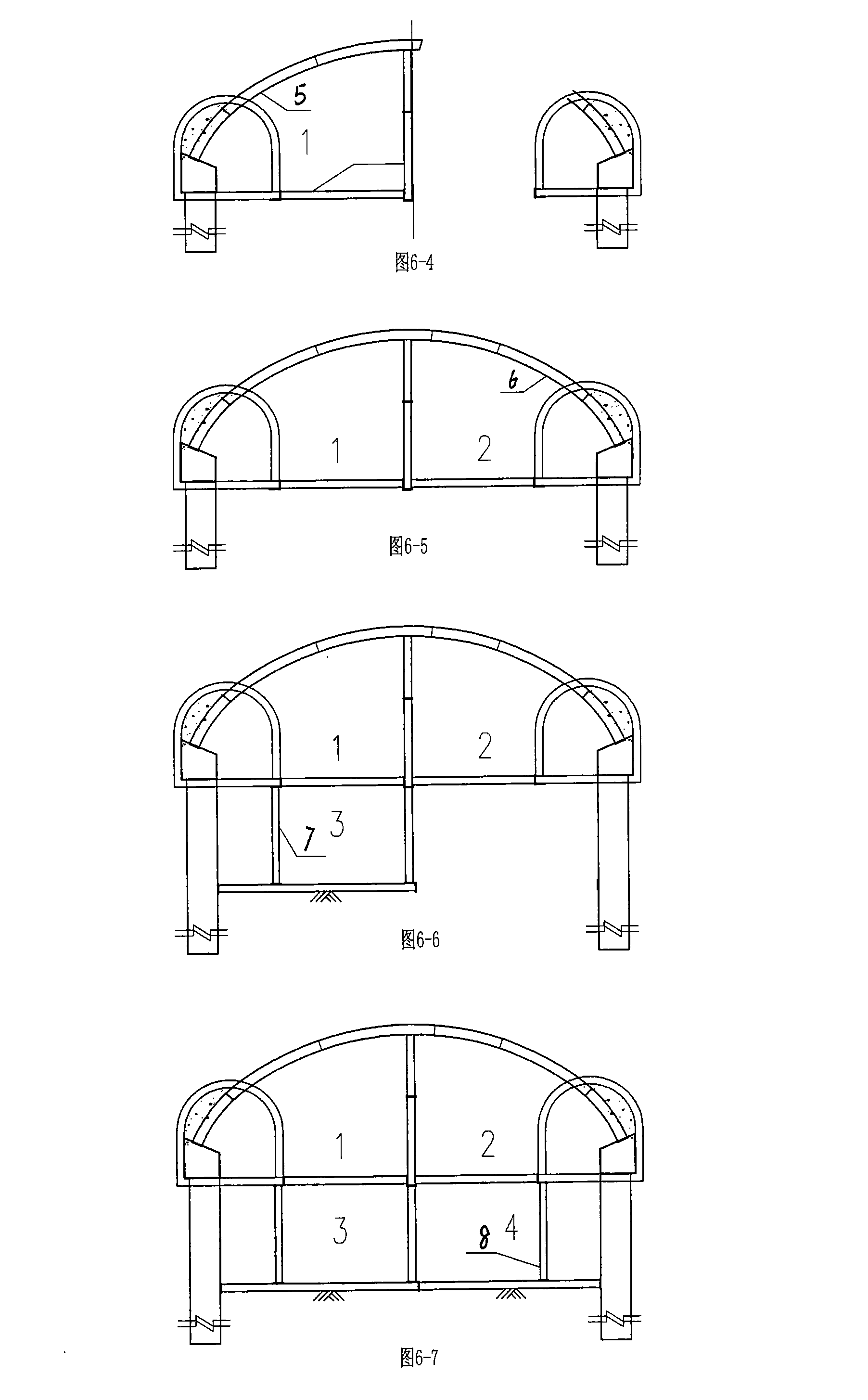

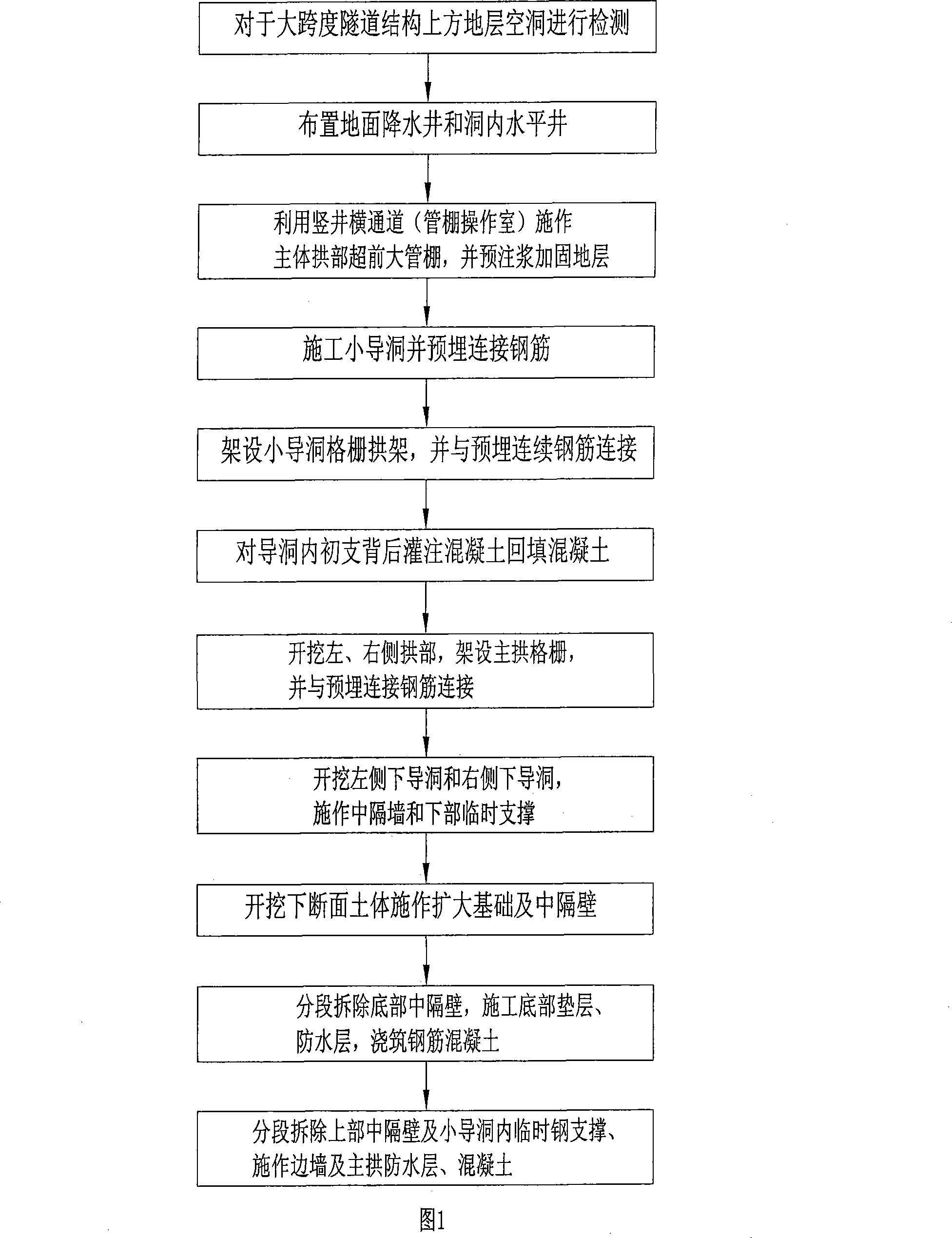

[0036] The super-large-section tunnel in the Su-Huang section is a fork section of the connection line of Beijing Metro Lines 4 and 10, which transitions from a single-hole double-track to a single-hole three-track section. The design adopts a vaulted straight-wall section. At the same time, the long-span tunnel is divided into three different sections according to the direction of the line: section E, mileage K2+240.3~K2+262.5, 22.2m long, span 15.076m, height 9.3m; section E', mileage K2+262.5~ K2+282.3, length 19.8m, span 15.937m, height 9.855m; Section F, mileage K2+282.3~K2+296.3, length 14.0m, span 17.5m, height 10.5m. The construction method is carried out according to the following steps: (as shown in Figure 1)

[0037] 1. To detect the ground cavity above the long-span tunnel structure:

[0038] This detection work adopted the advanced high-resolution SIR-2 ground-penetrating radar detection system made in the United States at home and abroad. The ground penetrating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com