A section design method of deep buried pba subway station

A section design, subway station technology, applied to mining equipment, earthwork drilling, underground chambers, etc., can solve the problems of reducing land subsidence, complex surrounding environment, difficult to ensure safety, etc., to reduce the impact of noise and vibration, Good construction environment and guaranteed quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

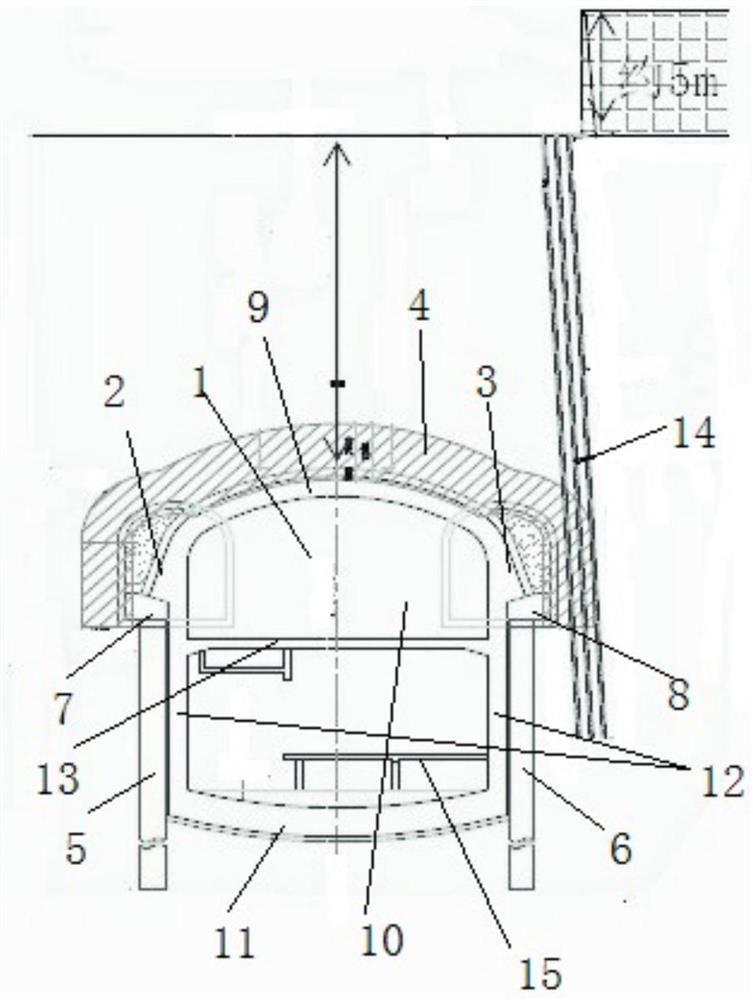

[0038] see figure 1 , the construction of a subway station in the central area of a certain northern city. The construction of the subway station runs through the existing city center bridge, and the subway station is symmetrically located on both sides of the bridge. The bridge is equipped with prefabricated concrete retaining walls on both sides of the high fill of the road. Those with a fill height of less than 3m are cantilevered; Set up a settlement joint (expansion joint) at intervals of 2-28m (at the junction of the foundation staggered abutment and the retaining wall and the abutment), the width of the joint is 2cm, and the joint is filled with asphalt and hemp. Linoleum waterproof layer, foundation, ground burden, anti-collision guardrail expansion joints and settlement joints are all consistent with the board joints; the distance between the drain holes is 4m, and they are located at the board joints, and the drain holes are 30cm above the ground line and adopt ga...

Embodiment 2

[0058] A method for designing a section of a subway station using a deeply buried PBA, comprising the following steps:

[0059] a. Detect the ground cavity above the section structure of the station;

[0060] b. Arrange ground dewatering wells and horizontal wells in the cave, and set composite anchor piles 14 on the ground;

[0061] c. Build a large pipe shed 4 at the position above the main arch 1 and the small pilot holes 2 and 3, and carry out deep hole grouting to reinforce the soil;

[0062] d. Construct small pilot tunnels 2 and 3 and pre-embed connecting steel bars;

[0063] e. Erect the grid arches of the small pilot holes 2 and 3, and connect them with the pre-embedded connecting steel bars;

[0064] f. Perform initial support in the small pilot holes 2 and 3, and then install side piles 5 and 6 in the small pilot holes 2 and 3 respectively. Concrete backfill, and then form the crown beams 7 and 8 of the side piles 5 and 6 respectively;

[0065] g. Starting from ...

Embodiment 3

[0086] A method for designing a section of a subway station using a deeply buried PBA, comprising the following steps:

[0087] a. Detect the ground cavity above the section structure of the station;

[0088] b. Arrange ground dewatering wells and horizontal wells in the cave, and set composite anchor piles 14 on the ground;

[0089] c. Build a large pipe shed 4 at the position above the main arch 1 and the small pilot holes 2 and 3, and carry out deep hole grouting to reinforce the soil;

[0090] d. Construct small pilot tunnels 2 and 3 and pre-embed connecting steel bars;

[0091] e. Erect the grid arches of the small pilot holes 2 and 3, and connect them with the pre-embedded connecting steel bars;

[0092] f. Perform initial support in the small pilot holes 2 and 3, and then install side piles 5 and 6 in the small pilot holes 2 and 3 respectively. Concrete backfill, and then form the crown beams 7 and 8 of the side piles 5 and 6 respectively;

[0093] g. Starting from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com