Bidirectional in-out multifunctional filtering mechanism and corresponding high-efficiency large chamber type filter press

A filter mechanism and multi-functional technology, applied in the field of two-way entry and exit large-scale box-type filter mechanism, can solve the problems of slow one-way parallel feeding, poor filter cake dehydration performance, slow one-way dark flow out, etc., achieving good results and solving problems Comprehensive technical problems, fast effect of single-hole two-way dark outflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

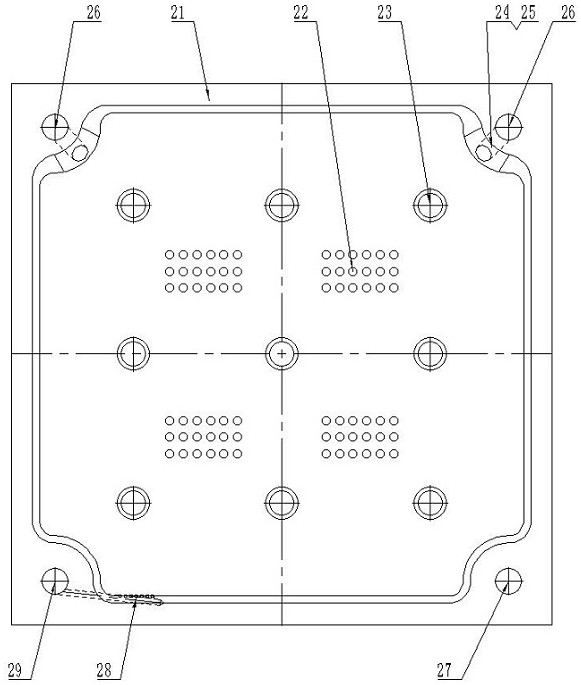

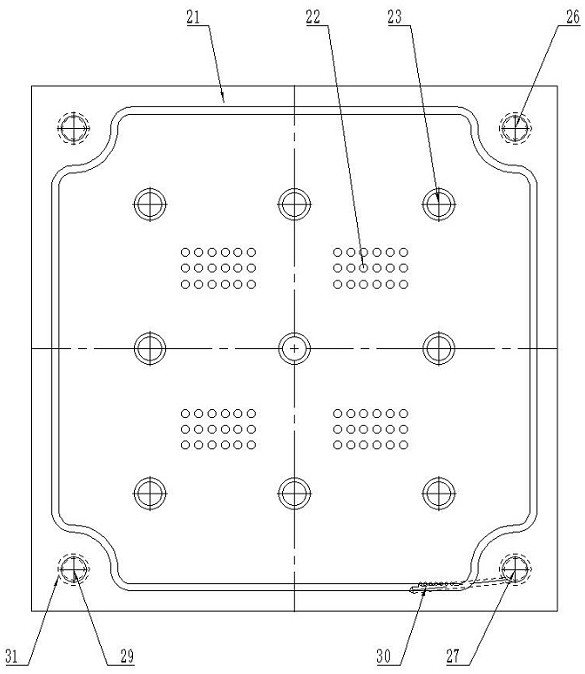

[0022] A two-way entry and exit filter plate (referred to as: two-way entry and exit filter plate) 2 for two-way entry and exit of multi-function filter mechanism is the key element of the two-way entry and exit multi-function filter mechanism; The innovative feeding method is a bidirectional parallel feeding method, and the double feeding holes are respectively bidirectional parallel feeding from the direction of the fixed thrust plate of the machine head and the direction of the movable pressing plate of the tail; Two-way underflow liquid mode, single liquid outflow hole 29 from the direction of the fixed thrust plate of the nose and the direction of the movable pressure plate of the tail. Hole 27 (PLC control solenoid valve automatic switching function).

[0023] The specific embodiment is: the two-way inlet and outlet filter plate 2 is a square double-hole two-way parallel feeding box filter plate 2, the double-sided structure is symmetrical, and it is the core element of ...

Embodiment 2

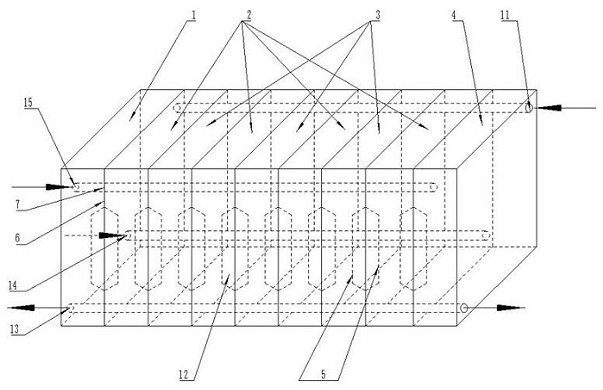

[0034] A two-way inlet and outlet multi-function filter mechanism, mainly composed of a single-sided filter plate 1 (stop plate anti-corrosion filter plate), a two-way inlet and outlet filter plate 2, a multi-functional feeding plate 3, and a single-sided filter plate 4 (push plate) at the tail. Anti-corrosion filter plate), complete set of filter cloth 5 (main and auxiliary plate filter cloth), clip cloth distributor 6 (distributor on both sides of clip cloth and filter plate), hole end lip seal 7, filter plate support handle, each in and out It is composed of components such as functional external pipelines. The main points of the innovative overall implementation plan are: to innovate the existing one-way parallel feeding method into a two-way parallel feeding method, and the double feeding holes are bidirectional from the direction of the fixed thrust plate of the machine head and the direction of the movable pressing plate of the tail of the machine. Parallel feeding is u...

Embodiment 3

[0045] A high-efficiency large-scale box-type filter press uses the bidirectional in-out multi-functional filtering mechanism provided by the present invention. The high-efficiency large-scale box filter press mainly consists of a frame, a pressing mechanism, a two-way in and out multi-functional filter mechanism (the present invention), a pulling plate mechanism, a cloth washing mechanism, a liquid-contacting flap mechanism, a hydraulic drive mechanism, and a PLC program control system. composed of other parts. The filter mechanism is the core component of the filter press. It is mainly composed of a single-sided filter plate 1 at the head, a two-way inlet and outlet filter plate 2, a multi-functional material distribution plate 3, a single-sided filter plate at the rear of the machine, and a complete set of filter cloth 5. It is composed of a distributor 6, a lip seal ring 7 at the hole end, a support handle for the filter plate, and an external pipeline for each inlet and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com