Assembling type overlapped cavity floor cover

A cavity floor and prefabricated technology, applied in the direction of floors, building components, buildings, etc., can solve problems such as heavy weight, affecting construction speed, and slow project progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

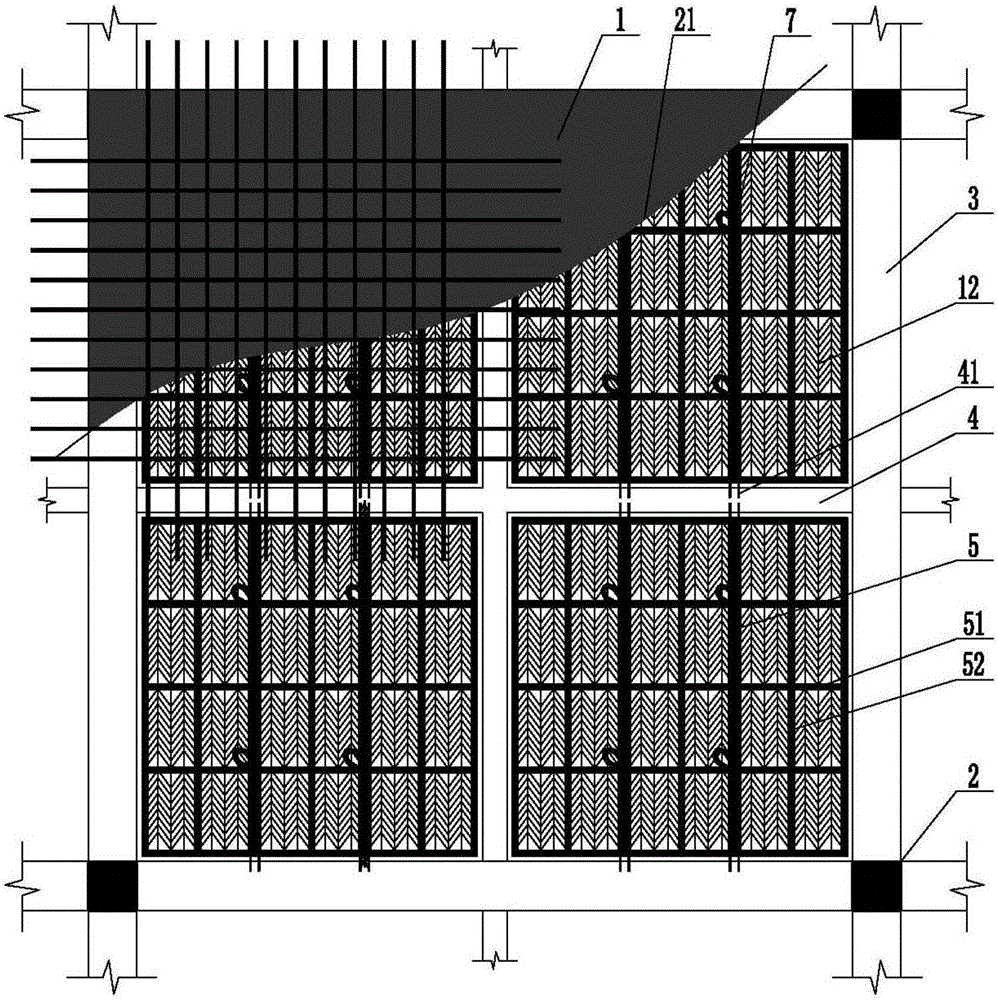

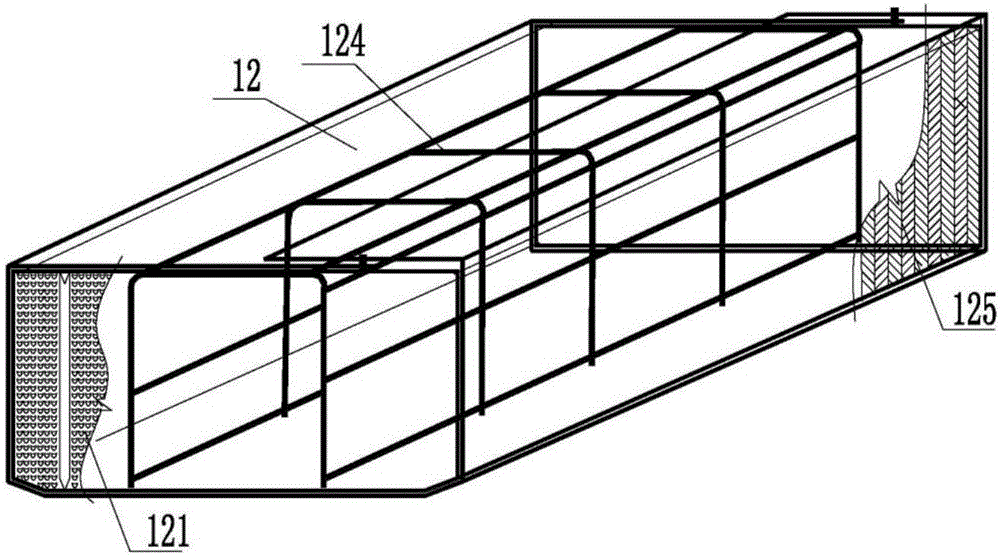

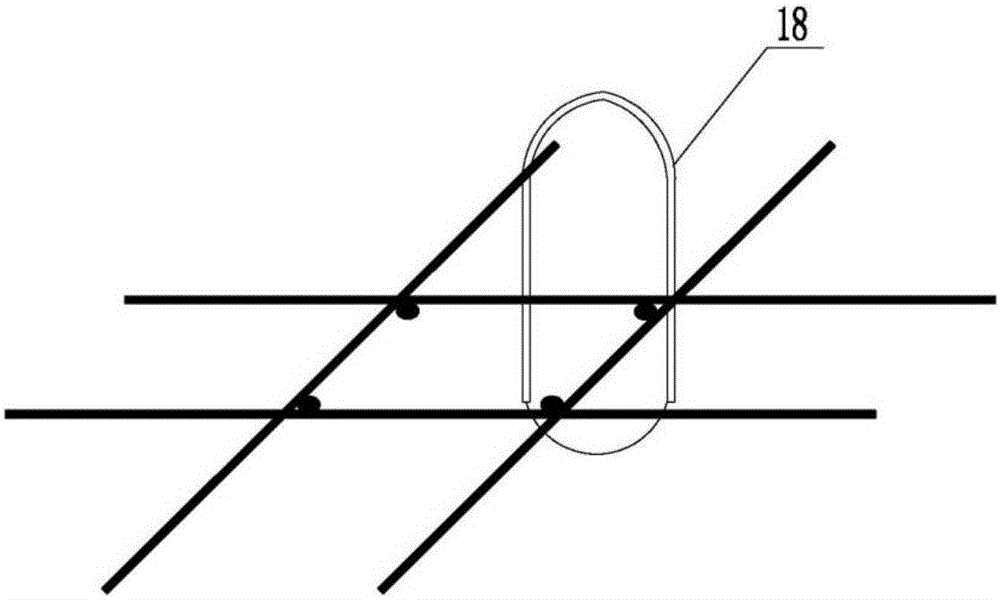

[0020] figure 1 This is a plan view of a prefabricated laminated cavity floor slab of the present invention. When the present invention is implemented, the prefabricated assembly line without upper flange cavity plate member 7 produced in the factory assembly line is transported to the construction site; the so-called columns and beams are steel bars Concrete structure or section steel structure; the fabricated upper flangeless cavity plate member and beam are divided into vertical stacking or horizontal stacking; the vertical stacking is to stack the fabricated upper flangeless cavity plate member on The top surface of the beam; the horizontal stacking is to stack the assembled non-top flange cavity plate member on the horizontal plane of the beam. When the column 2 and the beam 3 are shaped steel structures, the exposed ribbed steel bars 41 are directly welded to the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com