Grid structure

A grid structure, grid technology, applied in the direction of structural elements, wire fences, building components, etc., can solve the problems of firmly holding, weakening rods and wire strip materials, etc., and achieve the effect of simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

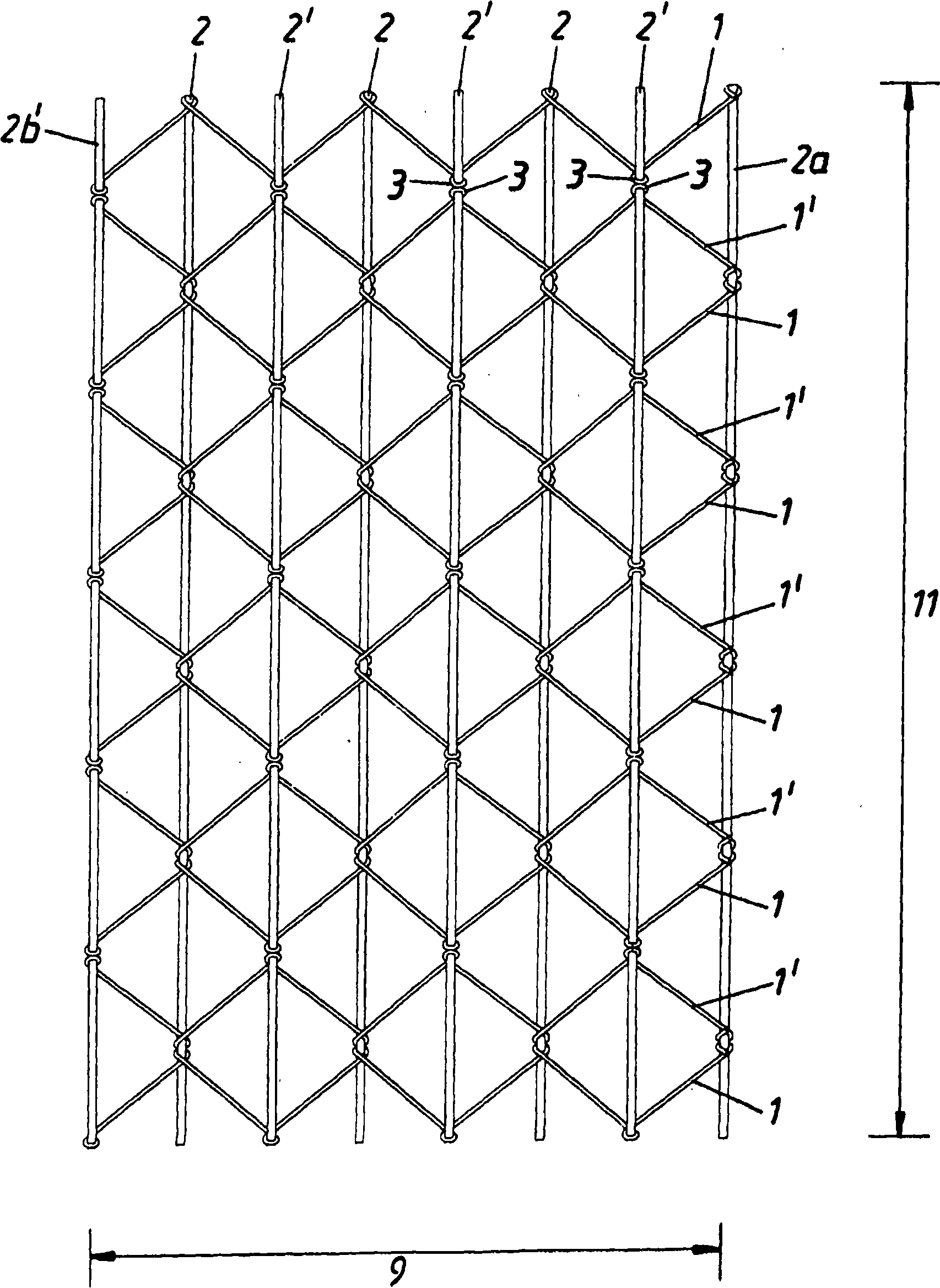

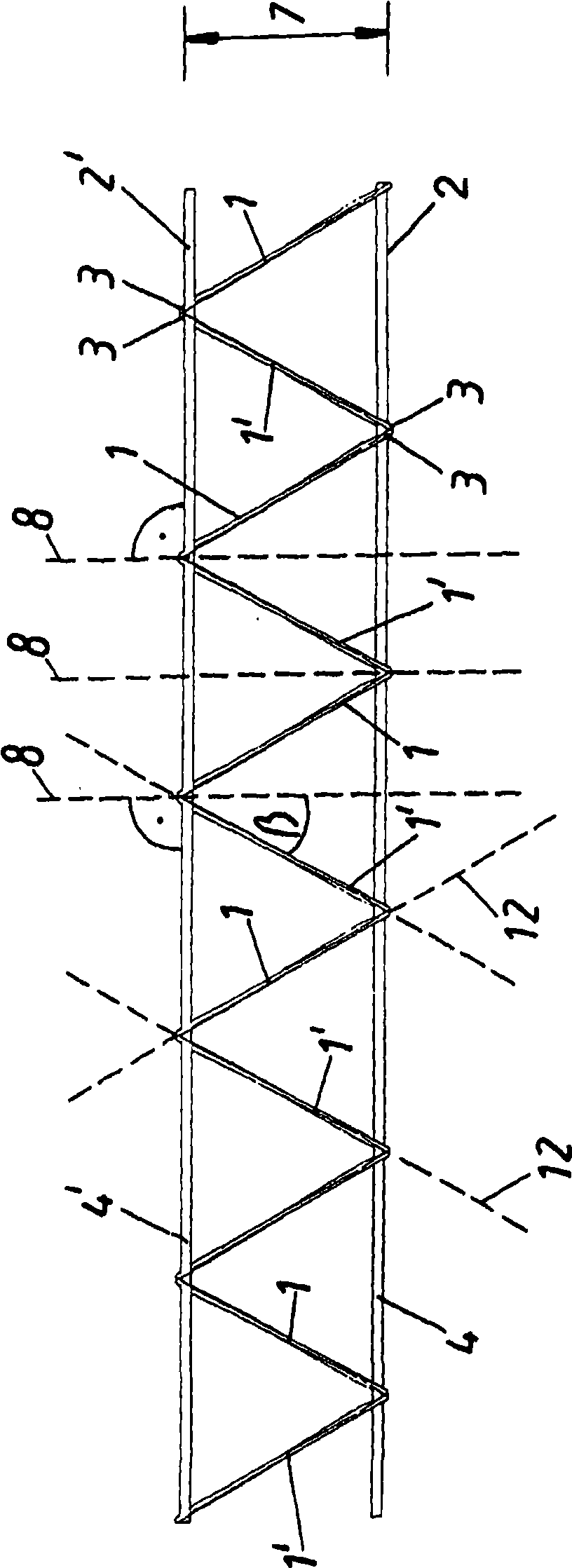

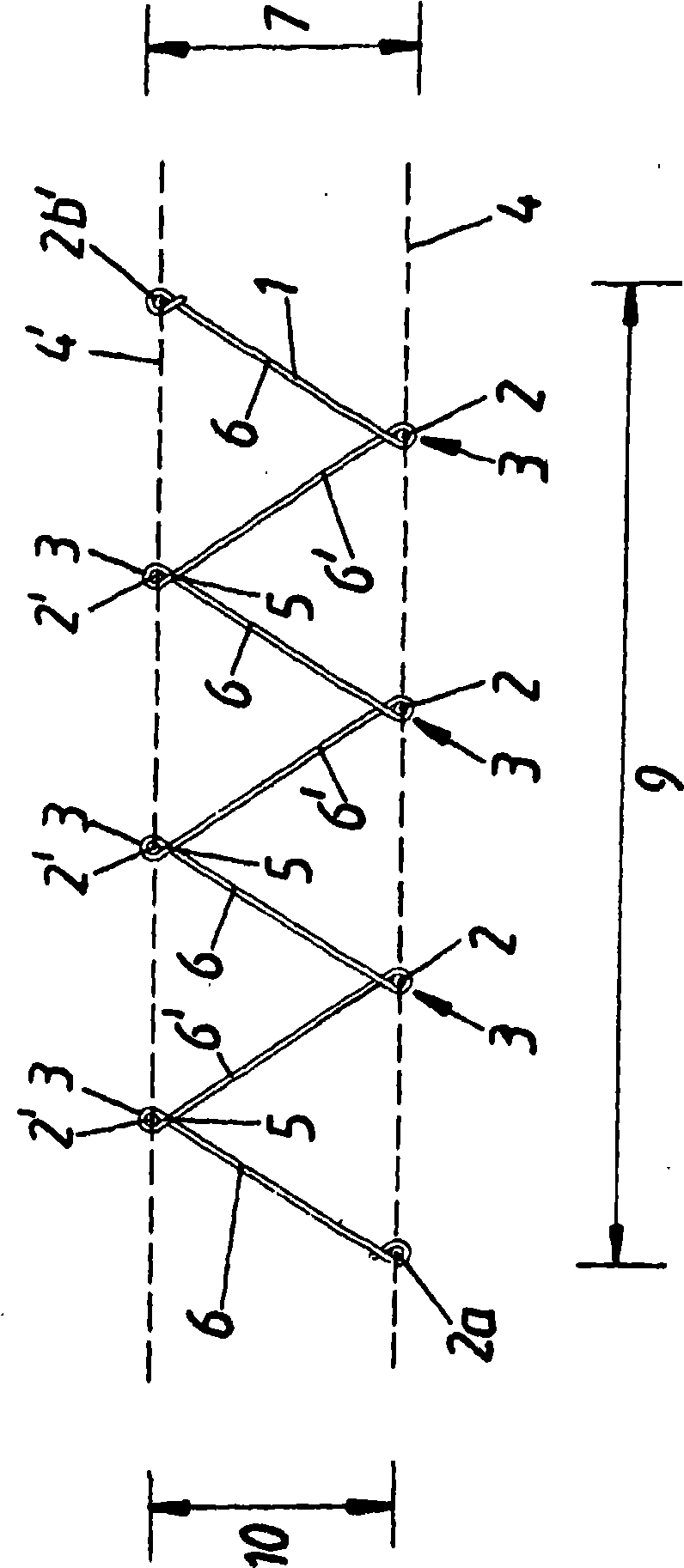

[0024] in press Figures 1 to 10 In the grid structure of , steel wire strips 1 , 1 ′ surround rods 2 , 2 ′ by means of loops 3 . The rods 2' are arranged in an upper plane 4'. The lower rods 2 are arranged in a lower plane 4 . The distance 7 between the planes 4 and 4' formed by the rods 2 and 2' is a multiple, preferably at least ten times, the largest diameter of the rods 2, 2'. This results in a three-dimensional structure which ensures very good stability or stabilization not only as a concrete reinforcement but also as a fixed grid. Two adjacent legs 6 and 6 ′ of the wire strip 1 intersect to form a loop 3 in the area of intersection 5 . Here, the two legs 6 and 6' rest against each other or are only slightly spaced apart from each other. The smallest distance in the intersection region 5 is here less than three times the wire thickness, preferably less than the wire thickness. A substantially closed loop 3 is thereby formed. Therein, the rods 2 , 2 ′ are secured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com