Power extraction system and process for glyphosate mother liquor by IDA method

A glyphosate mother liquor and glyphosate technology, which are applied in chemical instruments and methods, organic chemistry, compounds of Group 5/15 elements of the periodic table, etc., can solve the problem that the glyphosate mother liquor is difficult to handle and the glyphosate powder is economical. Low efficiency and other problems, to achieve the effect of reducing pollution emissions and environmental protection pressure, reducing total volume, and improving economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

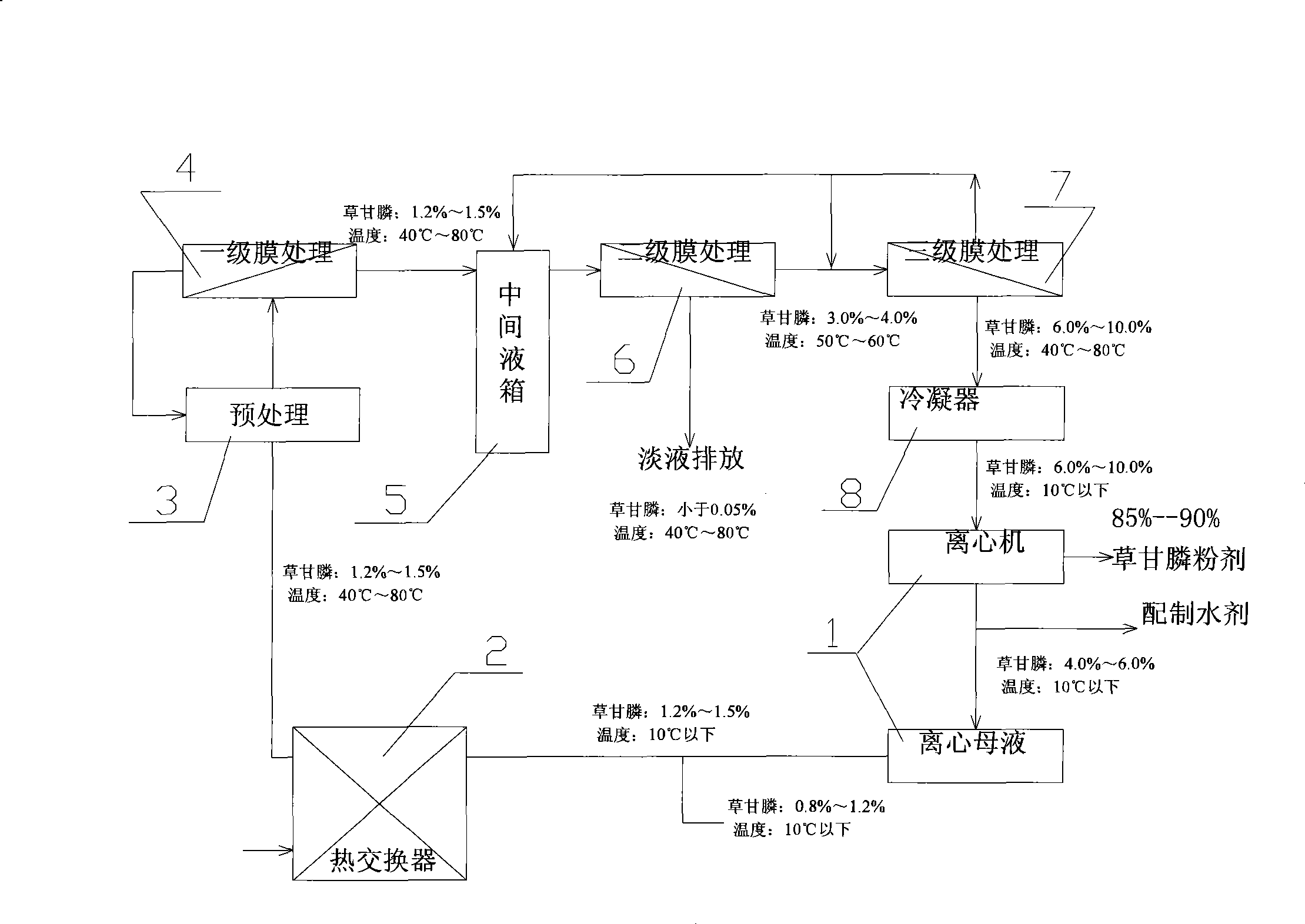

[0010] Embodiment 1: with reference to attached figure 1 . IDA method glyphosate mother liquor powder extraction system, centrifuge 1 outlet to heat exchanger 2, heat exchanger 2 outlet to pretreatment device 3 inlet----pretreatment device 3 consists of coarse filter, activated carbon The inlet of the coarse filter is connected with the outlet of the heat exchanger, the outlet of the coarse filter is connected with the inlet of the activated carbon filter, and the outlet of the activated carbon filter is connected with the outlet of the fine filter. The inlet is connected, the outlet of the fine filter is connected with the inlet of the microporous filter, the outlet of the microporous filter is connected to the inlet of the first-level membrane processor 4, the outlet of the pretreatment device 3 is connected to the inlet of the first-level membrane processor 4, and the first-level membrane The processor 4 returns to the inlet of the pretreatment device 3 one way, the other...

Embodiment 2

[0011] Embodiment 2: On the basis of Embodiment 1, the secondary membrane processor 6 and the tertiary membrane processor 7 constitute a circulation loop.

Embodiment 3

[0012] Embodiment 3: On the basis of Embodiment 1, the primary membrane processor 4 returns one way to the inlet of the pretreatment device 3 , the other way to the inlet of the intermediate liquid tank 5 , and the outlet of the intermediate liquid tank 5 to the inlet of the secondary membrane processor 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com