Novel process for zero discharge of glyphosate production waste water

A technology that produces waste water and zero discharge. It is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, phosphate, etc. It can solve the problems of membrane pollution, poor adaptability, and high operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

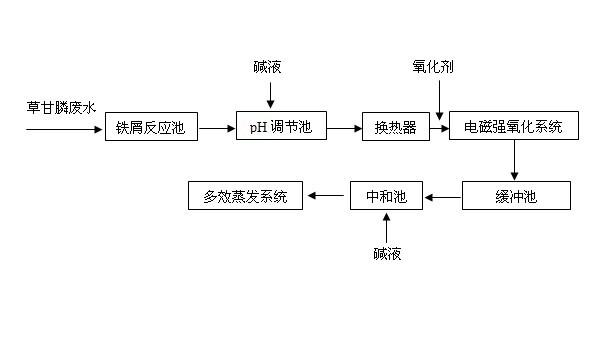

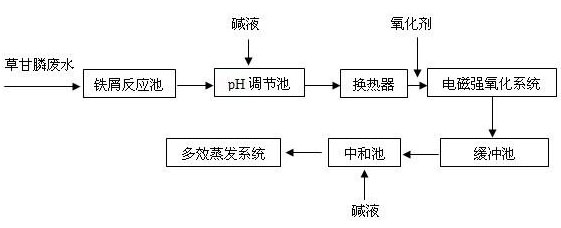

Image

Examples

Embodiment 1

[0015] Get the glyphosate production wastewater of a certain chemical plant, measure the total phosphorus (TP) of this wastewater to be 10200mg / L, the wastewater treatment steps are as follows:

[0016] 1) Take 1.5L of raw water, add sodium hydroxide to adjust pH=3, heat to 60°C, then add a small amount of ferrous sulfate and hydrogen peroxide (30% by mass, H2O2), add activated carbon, and pass through electromagnetic waves for 10 minutes.

[0017] 2) Take 700mL of the oxidized effluent from step 1), heat and evaporate until 100mL of the filtrate remains (equivalent to 7 times of concentration), take out the crystalline substance and weigh it, which is equivalent to 270.54g / L.

Embodiment 2

[0019] Get the glyphosate production wastewater of a certain chemical plant, measure the total phosphorus (TP) of this wastewater to be 10200mg / L, the wastewater treatment steps are as follows:

[0020] 1) Take 3L of raw water, add a certain amount of iron filings to soak for 24 hours, add sodium hydroxide to adjust pH=3, heat to 60°C, then add ferrous sulfate (FeSO4??7H2O) and hydrogen peroxide (30% by mass, H2O2), add activated carbon (accounting for 15% of the volume of wastewater), and pass the electromagnetic wave for 10 minutes.

[0021] 2) Take 2L of the oxidized effluent from step 1), heat and evaporate until 50mL of the filtrate remains (equivalent to 40 times of concentration), the crystallization effect is good, and no oil appears.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com