A coal-fired thermal power plant flue gas pollutant zero discharge and waste recovery system

A recycling system and thermal power plant technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of white smoke visual pollution, health hazards, environmental pollution, etc., to reduce pollutant emissions, reduce operating costs, Realize the effect of waste heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

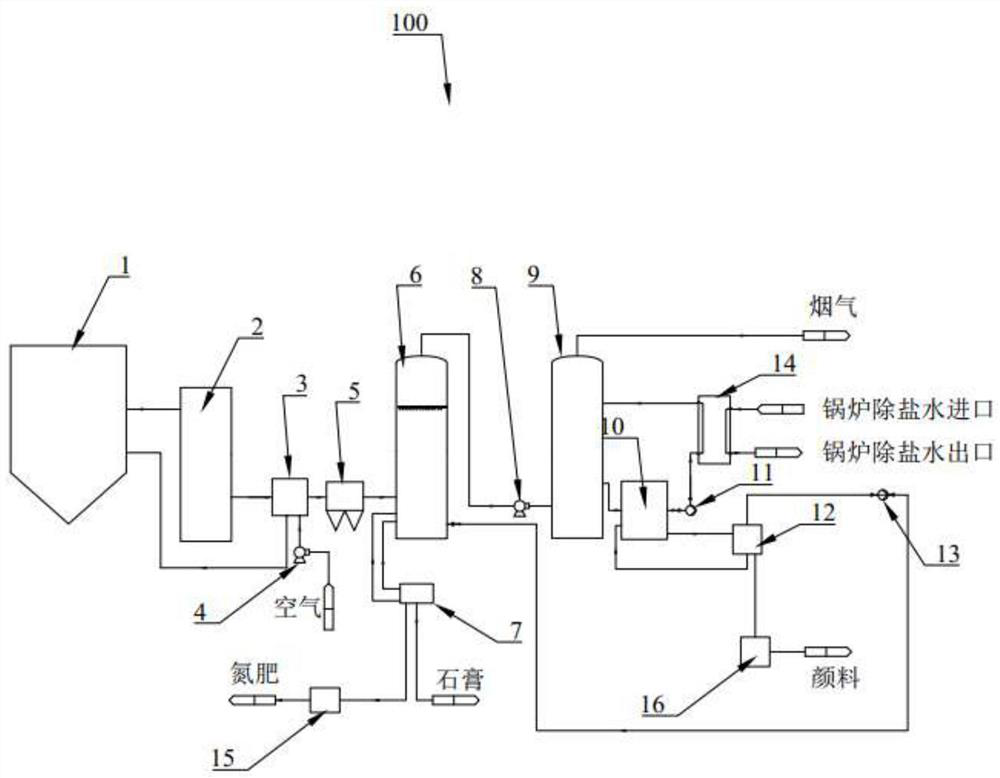

[0024] like figure 1 As shown, a coal-fired thermal power plant flue gas pollutant zero discharge and waste recovery system 100 includes: a coal-fired boiler 1, a denitrification device 2, an air preheater 3, a blower 4, a dust collector 5, a desulfurization tower 6, and a desulfurization tower 6. Unit 9, liquid storage tank 10, circulating solution pump 11, heat exchanger 14, spray pipe (not shown), whitening regeneration device 12 and condensate pump 13.

[0025] The denitration device 2 is connected to the flue gas outlet of the coal-fired boiler 1 to remove nitrogen oxides in the flue gas. Specifically, the denitrification device 2 adopts a low-temperature catalytic oxidation denitrification method to perform denitrification treatment. The blower 4 blows air into the coal-fired boiler 1 via the air preheater 3 . Both the blower 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com