Wastewater zero discharge system of chlorine-alkali industry

A chlor-alkali industry, zero-discharge technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of wasting resources, not being used, and less recycling of waste water, etc. Achieve the effect of reducing processing load and reducing design and construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

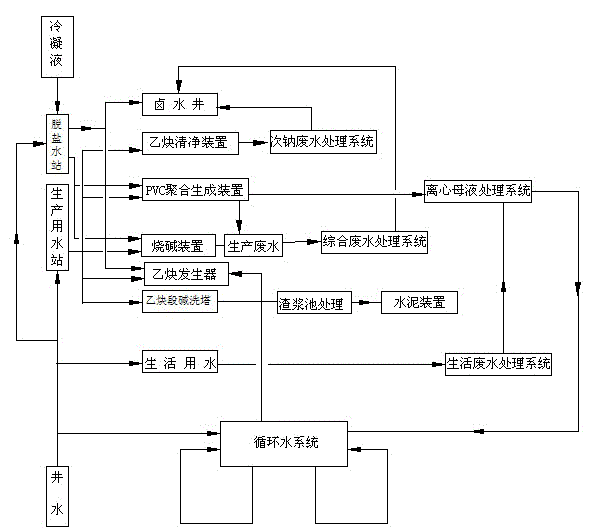

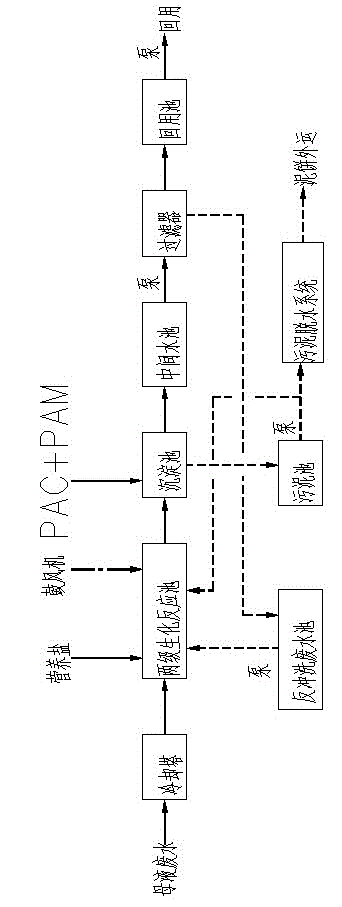

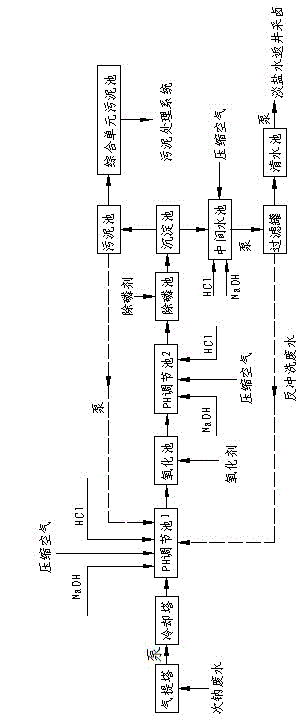

[0057] like Figure 1-Figure 6 A zero discharge system for chlor-alkali industrial wastewater is shown, including a sub-sodium wastewater treatment system, a centrifuge mother liquor treatment system, a comprehensive wastewater treatment system, a domestic sewage treatment system and a circulating water system. The desalinated water is sent to the caustic soda unit and the PVC polymerization unit for production use. Part of the concentrated brine produced by the desalinated unit is used for the acetylene generator, and the other part is sent to the light brine tank to return to the brine well for brine extraction. The production water station is mainly used for the acetylene cleaning unit, It is used in PVC polymerization generation device, caustic soda device and acetylene section alkali washing tower. The sub-sodium wastewater from the acetylene purification device is treated by the sub-sodium wastewater treatment system and is reused in brine wells for brine extraction. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com