Purification device and purification process for waste salt in by-product of glyphosate

A technology for purification equipment and by-products, applied in the purification of alkali metal halides, etc., can solve problems such as high processing costs, unsustainable development models, and consumption, and achieve the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

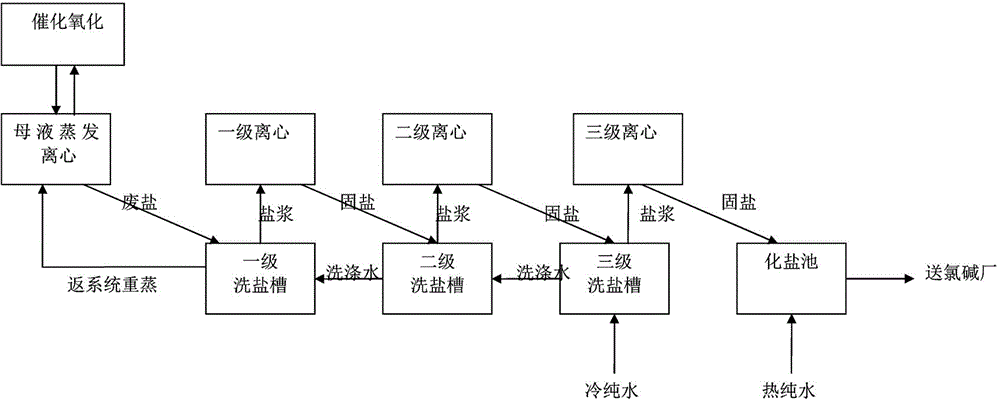

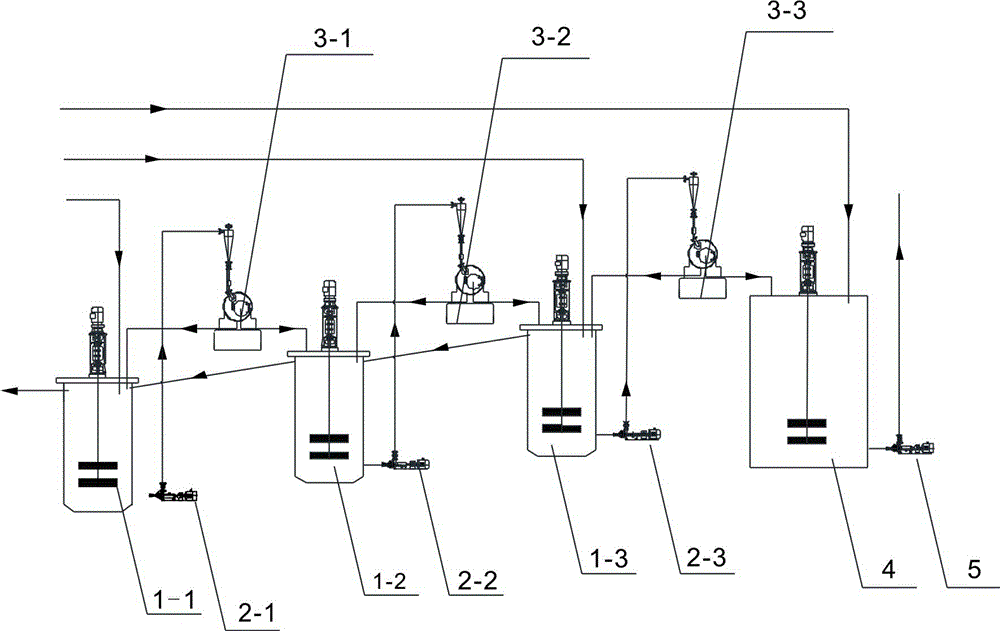

[0024] A device for purifying waste salt from glyphosate by-products. The bottom of the salt washing tank 1-1 is connected to the slurry pump 2-1 through a line pipeline, and then connected to the centrifuge 3-1. The centrifuge 3-1 is then re- It is connected to the upper part of the salt washing tank 1-2; the bottom of the salt washing tank 1-2 is connected to the slurry pump 2-2 through the pipeline and then connected to the centrifuge 3-2, and the centrifuge 3-2 is connected to the salt washing tank through the pipeline The upper part of 1-3 is connected; the bottom of the salt washing tank 1-3 is connected with the slurry pump 2-3 through the pipeline and then connected with the centrifuge 3-3, and the centrifuge 3-3 is connected with the salt tank 4 through the pipeline, and the bottom of the salt tank The end is connected with the brine delivery pump 5 through the line pipeline.

[0025] The hot pure water pipe is arranged on the salt-dissolving tank 4, and the cold wate...

Embodiment 2

[0029] ① Mother liquor evaporation and centrifugation: the glyphosate mother liquor is pumped to the evaporation system, and the flow rate is controlled to 25m 3 / h, after being distilled by the MVR system, the concentrated brine enters the centrifuge, which can produce 3-4 tons of waste salt per hour.

[0030] ②Waste salt washing and purification: the waste salt from the evaporation system enters the 1-1 salt washing tank through the scraper conveyor,

[0031] Mix it with the water from the upper centrifuge to form a salt slurry with a solid content of 25. After stirring evenly, pump it into the first centrifuge with a slurry pump. The centrifuged solid salt enters the salt washing tank 1-2, and the brine returns Wash salt tank 1-1. Adopt the same method, obtain 3 tons of refined salt after the purification after three stages of washing, its solid content rate is 60%.

[0032] ③ Refined salt dissolution: The refined salt from the centrifuge 3-3 is transported to the salt ta...

Embodiment 3

[0035] 1) Put the solid waste salt obtained by evaporation and centrifugation from the glyphosate mother liquor into the salt washing tank 1-1, pump pure water into the salt washing tank 1-3, and the pure water overflows into the washing salt tank 1-3 In the salt tank 1-2, and then overflow into the salt washing tank 1-1, control the amount of pure water added in the salt washing tank 1-3 to the coarse salt slurry with a waste salt solid content rate of 30%, and start the salt washing The stirring paddle in the tank 1-1, at a stirring rate of 20r / min and a stirring time of 30min, prepares a salt slurry, which is pumped into the centrifuge 3-1 through the slurry pump 2-1, and after centrifugal dehydration Get solid salt.

[0036] 2) Send the solid salt in step 1) to the salt washing tank 1-2) and pump pure water into the salt washing tank 1-3, and the pure water overflows through the salt washing tank 1-3 and flows into the salt washing tank 1-2 In the salt washing tank 1-2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com