Cement active mixed material prepared from waste incineration fly ash and cyanidation tailings and preparation method of cement active mixed material

A technology of waste incineration fly ash and active mixed material, which is applied in the field of cement active mixed material and its preparation, can solve the problems of waste incineration fly ash and cyanide tailings pollution, etc., and achieves expansion of stable sources, good economic benefits, and significant economic benefits. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

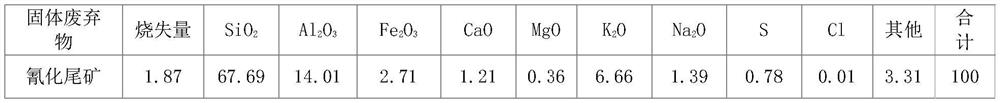

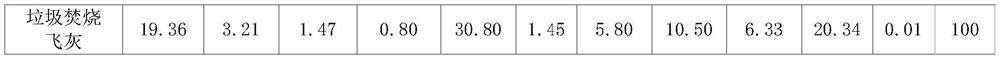

[0043] S1. Material preparation: select the original raw materials of waste incineration fly ash and the original raw materials of cyanide tailings for use;

[0044] S2. Compounding and mixing: 30 parts of the raw materials of waste incineration fly ash calculated on a dry basis and 70 parts of the original raw materials of cyanide tailings calculated on a dry basis are transported into the mixer for compounding and mixing to obtain a water content of 15%. A well-mixed compound mixture;

[0045] S3, granulation: the mixture in step S2 is transported into the ball-forming equipment, without adding any binder, directly rolled or pressed into compound wet granules with a particle size of 2-8 mm;

[0046] S4, sintering: transfer the compounded wet granules in step S3 to a sintering furnace, heat up to a sintering temperature of 1130° C. at a heating rate of 30° C. / min, hold for 50 mins, and then quench in cold air to obtain a complex with sintered body;

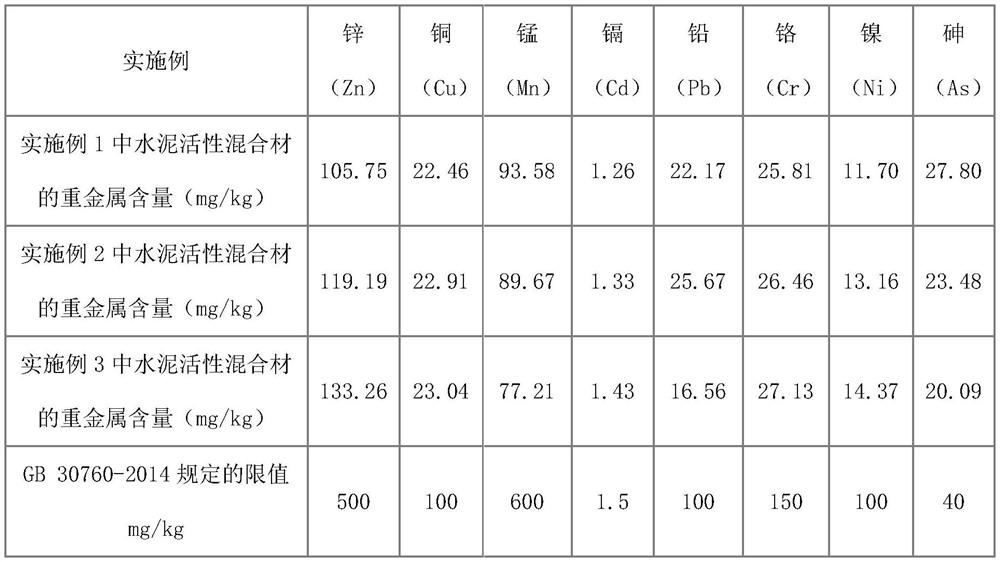

[0047] S5, grinding: th...

Embodiment 2

[0050] S1. Material preparation: select the original raw materials of waste incineration fly ash and the original raw materials of cyanide tailings for use;

[0051] S2. Compounding and mixing: 40 parts of raw materials of waste incineration fly ash calculated on a dry basis and 60 parts of original raw materials of cyanide tailings calculated on a dry basis are transported into a mixer for compounding and mixing, and a water content of 13.3% is obtained. A well-mixed compound mixture;

[0052] S3, granulation: the mixture in step S2 is transported into the ball-forming equipment, without adding any binder, directly rolled or pressed into compound wet granules with a particle size of 2-8 mm;

[0053] S4, sintering: transfer the compound wet granules in step S3 to a sintering furnace, heat up to a sintering temperature of 1140°C at a heating rate of 25°C / min, keep the temperature for 40mins, and then quench in cold air to obtain a complex with sintered body;

[0054] S5. Grin...

Embodiment 3

[0057] S1. Material preparation: select the original raw materials of waste incineration fly ash and the original raw materials of cyanide tailings for use;

[0058] S2. Compounding and mixing: 50 parts of the original raw materials of waste incineration fly ash calculated on a dry basis and 50 parts of the original raw materials of cyanide tailings calculated on a dry basis are transported into the mixer for compounding and mixing to obtain a water content of 11.5%. A well-mixed compound mixture;

[0059] S3, granulation: the mixture in step S2 is transported into the ball-forming equipment, without adding any binder, directly rolled or pressed into compound wet granules with a particle size of 2-8 mm;

[0060] S4, sintering: transfer the compounded wet granules in step S3 to a sintering furnace, heat up to a sintering temperature of 1150°C at a heating rate of 20°C / min, hold for 30mins, and then quench in cold air to obtain a complex with sintered body;

[0061] S5, grindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com