Low-carbon treatment system for high-concentration organic wastewater and method thereof

An organic wastewater and high-concentration technology, applied in water/sewage treatment, water treatment parameter control, water/sewage multi-stage treatment, etc., can solve problems such as neglect of discharge, and achieve the goal of reducing consumption, reducing CO2 emissions, and reducing energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

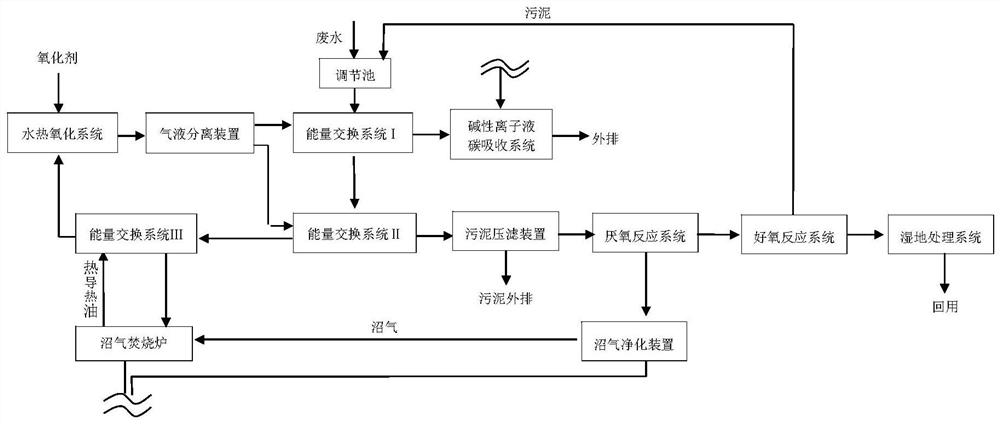

[0042] Such as figure 1 As shown, the high-concentration organic wastewater low-carbon treatment system of the present invention includes a regulating tank, energy exchange system I, energy exchange system II, energy exchange system III, hydrothermal oxidation system, gas-liquid separation device, sludge filter press device, Anaerobic reaction system, aerobic reaction system, wetland treatment system, biogas purification device, biogas incinerator and alkaline ionic liquid carbon absorption system.

[0043] Among them, the regulating tank, the inner pipe of the energy exchange system I, the inner pipe of the energy exchange system II, the inner pipe of the energy exchange system III, the hydrothermal oxidation system, and the gas-liquid separation device are connected through pipelines in sequence.

[0044] The gas generated by the gas-liquid separation device is sequentially connected to the outer pipe of the energy exchange system I, the alkaline ionic liquid carbon absorpti...

Embodiment 2

[0068] Adopt the system described in embodiment 1 to process the method for high-concentration organic waste water:

[0069] The waste water to be treated is: the production waste water of a chemical plant, the pH value is 9, and the COD is 21100mg / L.

[0070]Treatment steps: import the wastewater to be treated into the regulating tank, stir evenly, and then enter the three-stage energy exchange system and then enter the hydrothermal oxidation system for treatment; the continuous hydrothermal oxidation system controls the reaction temperature to 300°C, 30% hydrogen peroxide as the oxidant, and the auxiliary concentration It is 96% pure oxygen, the oxidation coefficient is 2, the reaction pressure is 7MPa, and the reaction time is 2h. After being treated by the continuous hydrothermal oxidation system, the COD conversion rate of wastewater is 93.1%, the biodegradability of the effluent is 0.51, and the pH is 7.2; After gas-liquid separation, the effluent is heat-exchanged and c...

Embodiment 3

[0072] Adopt the system described in embodiment 1 to process the method for high-concentration organic waste water:

[0073] The waste water to be treated is: the production waste water of a chemical plant, the pH value is 9, and the COD is 21100mg / L.

[0074] Treatment steps: import the wastewater to be treated into the regulating tank, stir evenly, and then enter the three-stage energy exchange system and then enter the hydrothermal oxidation system for treatment; the continuous hydrothermal oxidation system controls the reaction temperature to 300°C, 30% hydrogen peroxide as the oxidant, and the auxiliary concentration It is 96% of ozone, many times of oxidant excess, the reaction pressure is 7MPa, and the reaction time is 2h. After being treated by the continuous hydrothermal oxidation system, the COD conversion rate of wastewater is 94.1%, the biodegradability of the effluent is 0.53, and the pH is 7.2; After gas-liquid separation, heat exchange and cooling, the sludge is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com