Composition for degrading polycyclic organic compounds and its preparation method and application

A technology of organic matter and composition, which is applied in the field of degrading polycyclic organic matter composition and its preparation, can solve problems such as difficulty in meeting economic and technical requirements, incomplete removal of pollutants, and difficulty in the operation of biological treatment to achieve optimal treatment Effect, low cost, long-term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

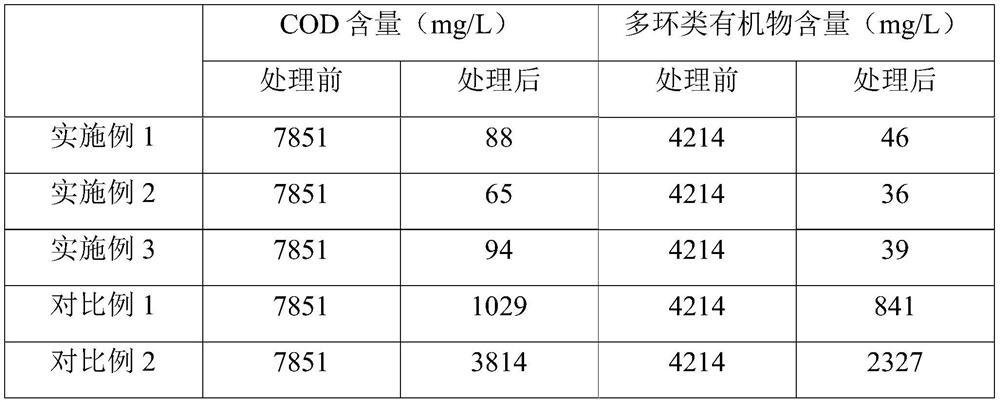

Examples

Embodiment 1

[0031] A composition for degrading polycyclic organic matter comprises biomass charcoal, ferric nitrate, composite microorganisms, sodium alginate and calcium phosphate; the composite microorganisms include Bacillus subtilis, Pseudomonas aeruginosa and Serratia gasseri.

[0032] Among them, the preparation method of biomass charcoal is as follows: roasting corn stalks at 500 ° C for 6 hours to obtain roasted products, adding the roasted products to 0.8mol / L hydrochloric acid solution and soaking for 12 hours, and then sequentially filtering, washing and drying to obtain raw materials. material charcoal;

[0033] The mass ratio of biomass charcoal, iron salt, sodium alginate and calcium phosphate is 50:5:2:4;

[0034] The total viable count of the composite microorganisms contained in the composition for degrading polycyclic organic compounds is 1×10 3 CFU / g; the ratio of viable counts of Bacillus subtilis, Pseudomonas aeruginosa and Serratia gasseri in the composite microorga...

Embodiment 2

[0039] A composition for degrading polycyclic organic matter comprises biomass charcoal, ferric nitrate, composite microorganisms, sodium alginate and calcium phosphate; the composite microorganisms include Bacillus subtilis, Pseudomonas aeruginosa and Serratia gasseri.

[0040] Among them, the preparation method of biomass charcoal is as follows: roasting corn stalks at 600 ° C for 7 hours to obtain a roasted product, adding the roasted product to 0.9 mol / L hydrochloric acid solution and soaking for 11 hours, and then filtering, washing and drying in sequence to obtain a raw material. material charcoal;

[0041] The mass ratio of biomass charcoal, iron salt, sodium alginate and calcium phosphate is 50:8:2.5:5;

[0042] The total viable count of the composite microorganisms contained in the composition for degrading polycyclic organic compounds is 1×10 4 CFU / g; the ratio of viable counts of Bacillus subtilis, Pseudomonas aeruginosa and Serratia gasseri in the composite microo...

Embodiment 3

[0047] A composition for degrading polycyclic organics, comprising biomass charcoal, ferric nitrate, composite microorganisms, sodium alginate and calcium phosphate; the composite microorganisms include Bacillus subtilis, Pseudomonas aeruginosa and Serratia gasseri.

[0048] Among them, the preparation method of biomass charcoal is as follows: roasting corn stalks at 700 ° C for 8 hours to obtain a roasted product, adding the roasted product to a 1 mol / L hydrochloric acid solution and soaking for 10 hours, and then filtering, washing and drying in sequence to obtain biomass carbon;

[0049] The mass ratio of biomass charcoal, iron salt, sodium alginate and calcium phosphate is 50:10:3:6;

[0050] The total viable count of the composite microorganisms contained in the composition for degrading polycyclic organic compounds is 1×10 5 CFU / g; the ratio of viable counts of Bacillus subtilis, Pseudomonas aeruginosa and Serratia gasseri in the composite microorganism was 1:1:0.8.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com