Graded desorption method for volatile organic compound adsorbed active carbon

A technology of volatile organic compounds and activated carbon, which is applied in the field of exhaust gas treatment and the hierarchical desorption of activated carbon for adsorption of volatile organic compounds. It can solve the problem of large fluctuations in the concentration of volatile organic compounds in the desorption gas, the mismatch between the desorption process and the combustion process, and the cost of operation and maintenance. Advanced problems, to achieve the effect of reducing treatment costs and operation and maintenance costs, reducing operation and maintenance costs, and improving desorption efficiency and desorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

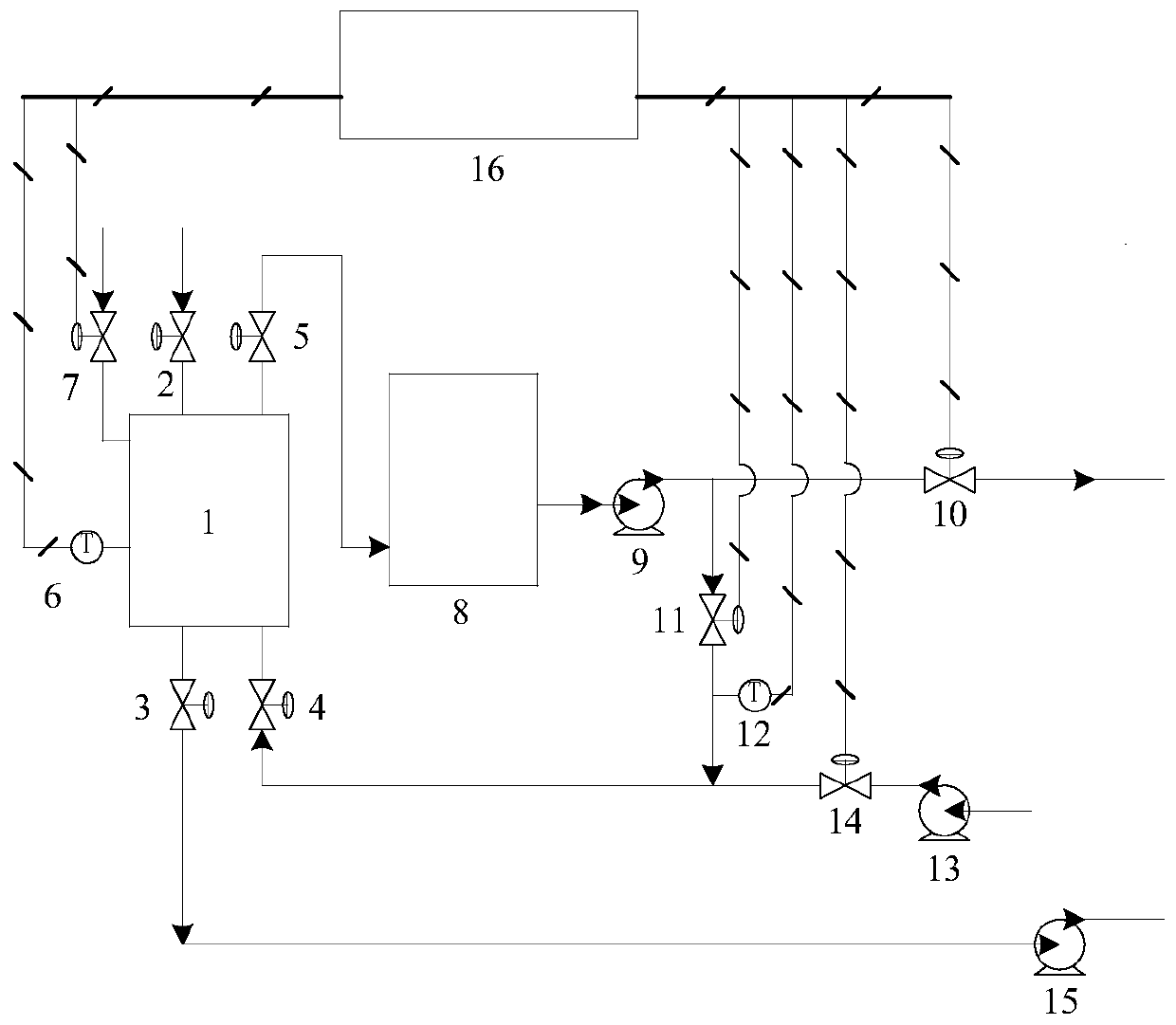

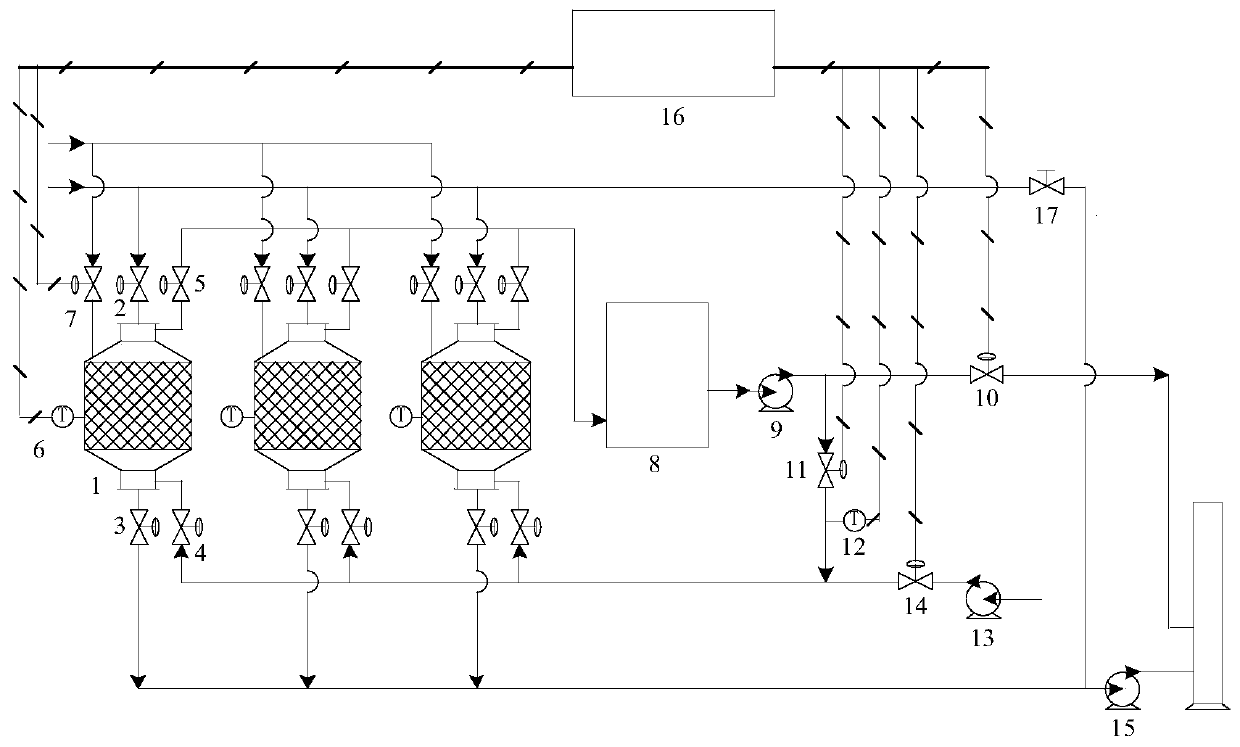

[0053] The activated carbon adsorption method for adsorbing volatile organic compounds of the present invention is adopted to desorb the saturated activated carbon adsorption device. The activated carbon adsorption device is filled with conventional activated carbon adsorption materials, the number of periods is 4 periods, the temperature range of the desorbed gas is 60°C to 160°C, and the linear velocity of the desorbed gas in the activated carbon is 0.2-0.3m / s. The temperature of the gas is achieved by mixing the high-temperature gas discharged from the combustion device with the room temperature air in different proportions through the temperature online instrument and the automatic valve.

[0054] The temperature of the desorption gas fed in the first period (starting the furnace) is 60-90°C, the desorption time is 20min-30min, and the concentration of volatile organic compounds desorbed from the activated carbon adsorption device is not more than 500mg / m 3 , although the ...

Embodiment 2

[0059] The activated carbon adsorption method for adsorbing volatile organic compounds of the present invention is adopted to desorb the saturated activated carbon adsorption device. The activated carbon adsorption device is filled with conventional activated carbon adsorption materials, the number of periods is 5 periods, the temperature range of the desorbed gas is 60°C to 160°C, and the linear velocity of the desorbed gas in the activated carbon is 0.2-0.3m / s. The temperature of the gas is achieved by mixing the high-temperature gas discharged from the combustion device with the room temperature air in different proportions through the temperature online instrument and the automatic valve.

[0060] The temperature of the desorption gas fed in the first period (starting the furnace) is about 60-90°C, the desorption time is 20min-30min, and the concentration of volatile organic compounds desorbed from the activated carbon adsorption device is not more than 500mg / m 3 , although ...

Embodiment 3

[0065] The activated carbon adsorption method for adsorbing volatile organic compounds of the present invention is adopted to desorb the saturated activated carbon adsorption device. The activated carbon adsorption device is filled with activated carbon loaded with copper catalyst. The copper loading is 0.2% (mass percentage). When the temperature rises above 120°C, it can partially catalyze the oxidation of volatile organic compounds. The number of periods is 4 periods, The temperature range of the desorbed gas is 60℃~160℃, the linear velocity of the desorbed gas in the activated carbon is 0.2-0.3m / s, the temperature of the desorbed gas is adjusted by the temperature online instrument and the automatic valve, and the high temperature gas discharged from the combustion device and the Room temperature air is mixed in different proportions.

[0066] The temperature of the desorption gas fed in the first period (starting the furnace) is about 60-90°C, the desorption time is 20min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com