A treatment process for resource utilization of medical waste salt by medium-temperature pyrolysis

A treatment process and resource utilization technology, which is applied in the field of thermal pyrolysis and resource utilization of pharmaceutical waste salt, can solve the problems of waste salt residue easy to agglomerate, high energy consumption for high temperature treatment of waste salt, corrosion of equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

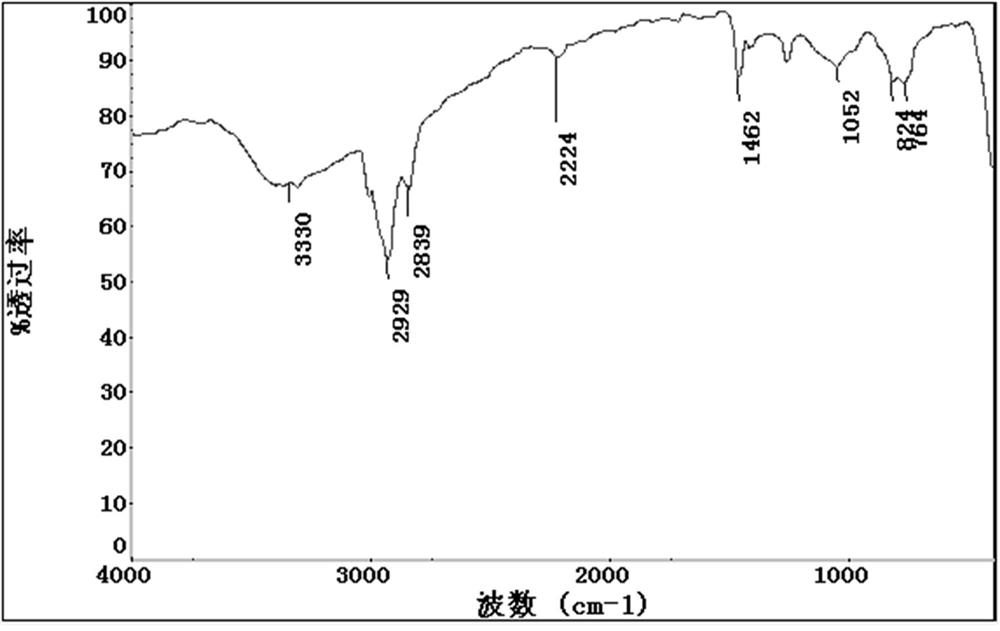

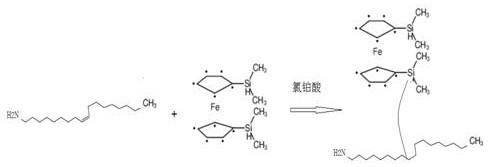

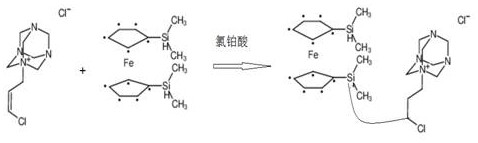

Image

Examples

Embodiment 1

[0026] A medium-temperature pyrolysis resource utilization treatment process for medical waste salt, the main scheme of which is:

[0027] Add 1 kg of anti-caking agent to 1000 kg of medical waste salt, mix and stir in the mixing tank for 10 minutes, then add the waste salt to the dryer, control the temperature at 80°C, and dry for 120 minutes to keep the water and volatile organic solvents in the waste salt Wait for the volatile component content to be 0.1%. After the completion, slowly add the waste salt into the medium temperature reactor with a feeder, the feed rate is 50kg / min; the temperature of the first section of the reactor is 350°C, and the heating reaction time is 30min; The temperature of the second stage in the reactor is 450°C, and the heating reaction time is 40 minutes; it is characterized in that the medium-temperature reactor is an ebullating bed reactor, and the waste salt is fed into the reactor bottom after being fed with compressed air , the waste salt i...

Embodiment 2

[0036] A medium-temperature pyrolysis resource utilization treatment process for medical waste salt, the main scheme of which is:

[0037]Add 5kg of anti-caking agent to 1200kg of medical waste salt, mix and stir in the mixing tank for 30 minutes, then add the waste salt to the dryer, control the temperature at 110°C, and dry for 80 minutes to keep the water and volatile organic solvents in the waste salt Wait for the volatile component content to be 2.5%. After completion, slowly add the waste salt into the medium temperature reactor with a feeder, the feed rate is 60kg / min; the temperature of the first section of the reactor is 400°C, and the heating reaction time is 20min; The temperature in the second section of the reactor is 550°C, and the heating reaction time is 30 minutes; it is characterized in that the medium-temperature reactor is an ebullating bed reactor, and the waste salt is fed into the reactor bottom after being fed with compressed air , the waste salt in the...

Embodiment 3

[0046] A medium-temperature pyrolysis resource utilization treatment process for medical waste salt, the main scheme of which is:

[0047] Add 10kg of anti-caking agent to 1500kg of medical waste salt, mix and stir in the mixing tank for 60 minutes, then add the waste salt to the dryer, control the temperature at 130°C, and dry for 10 minutes to keep the water and volatile organic solvents in the waste salt Wait for the volatile component content to be 05%. After completion, use the feeder to slowly add the waste salt into the medium-temperature reactor at a feed rate of 80kg / min; the temperature of the first section of the reactor is 450°C, and the heating reaction time is 5min; The temperature in the second section of the reactor is 650°C, and the heating reaction time is 10 minutes; the characteristic is that the medium temperature reactor is an ebullating bed reactor, and after the waste salt is added to the reactor, compressed air is introduced at the bottom of the reactor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com