Screw propelling type solid waste continuous carbonization equipment and continuous carbonization method

A solid waste and spiral propulsion technology, applied in combustion methods, lighting and heating equipment, incinerators, etc., can solve the problems of single processing materials, high cost, and large floor area, and achieve a variety of types and strong versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

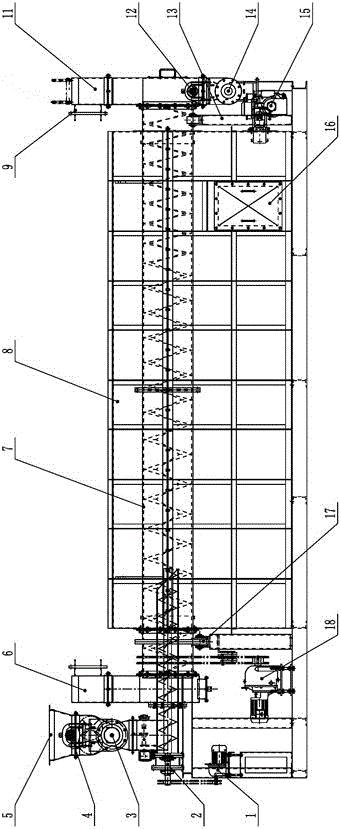

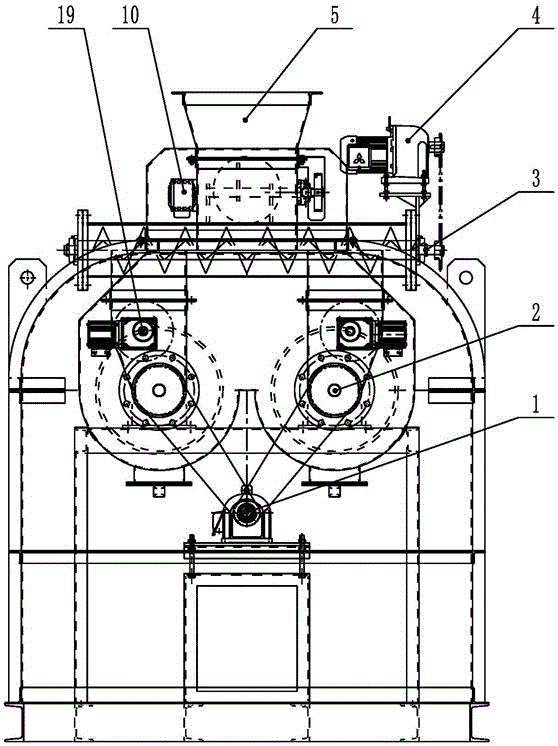

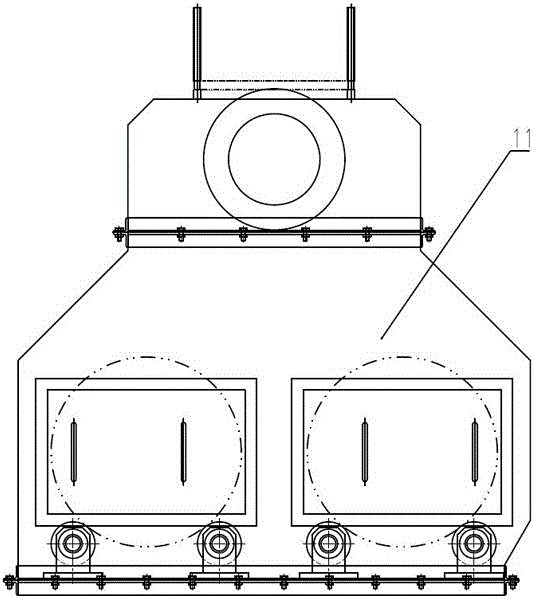

[0036] see Figure 1-Figure 9 , is an embodiment of a spiral-propelled continuous carbonization equipment for solid waste in the present invention, comprising a feeding system, a material distribution system, a carbonization system, a product collection system, and a discharging system connected in sequence. The material outlet 5 to the outlet 32 of the outlet system forms a sealed and connected spiral propulsion material channel, and the carbonization system is connected to the deodorization system.

[0037] Specifically: if figure 2 , Figure 9 As shown, the above-mentioned feed system includes a feed reduction motor 36, a feed screw conveyor 38, a feed port 5, and a first stirring motor 10, and the feed port 5 of the feed system is an inverted cone feed hopper, The first stirring motor 10 drives a stirring shaft to rotate. Blades are installed on the stirring shaft, and the stirring shaft is located in the inverted cone-shaped feeding hopper of the feeding system.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com