Patents

Literature

66results about How to "Fully carbonized" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extra coarse grain WC-Co hard alloy and preparation process thereof

ActiveCN102534344APromote grain growthIncrease the carbon content of tungsten carbideCemented carbideGrain distribution

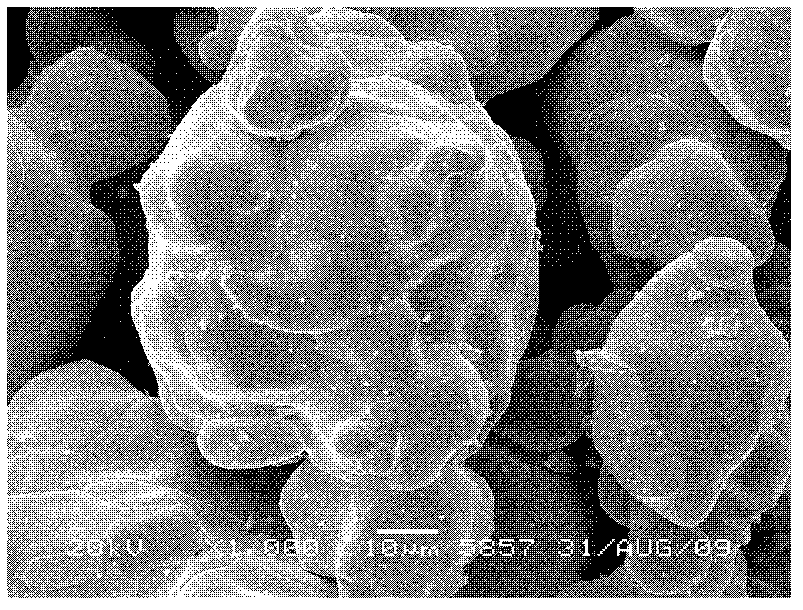

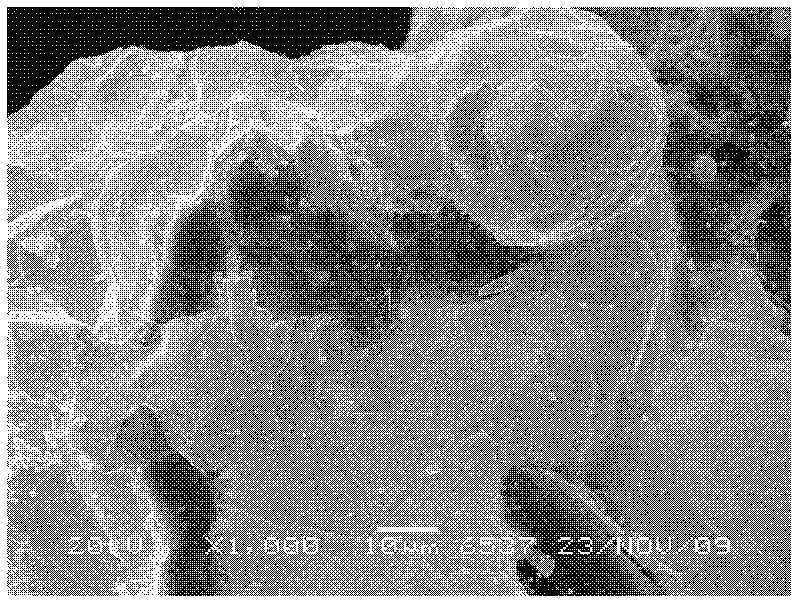

The invention relates to an extra coarse grain WC-Co hard alloy. The hard alloy comprises 5 to 15 weight percent of Co and the balance of WC, wherein the average grain size of the WC is 6 to 10mu m. A preparation process for the hard alloy comprises the following steps of: pre-ball-milling coarse and fine tungsten carbide to prepare mixed tungsten carbide powder, preparing mixed tungsten carbide powder-cobalt-former mixed powder, pressing, and sintering, wherein the sintering step is divided into a former removing part and a high-temperature sintering part. The average grain size of a metallographic structure of the WC-Co hard alloy prepared by the process is 6mu m or more than 6mu m, the process method is simple and convenient to operate, the prepared hard alloy has a large average grainsize, a narrow grain distribution range, a low thermal expansion coefficient and high heat conductivity, high-temperature wear resistance, transverse rupture strength and rupture toughness, and is suitable for a mining tool and an excavating tool, and the thermal fatigue crack resistance of the alloy is effectively improved.

Owner:HUNAN BOYUN DONGFANG POWDER METALLURGY

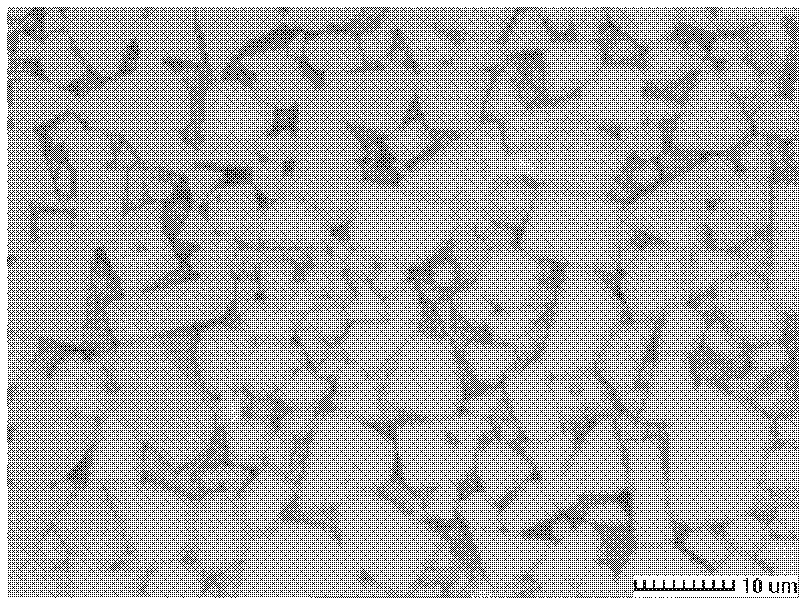

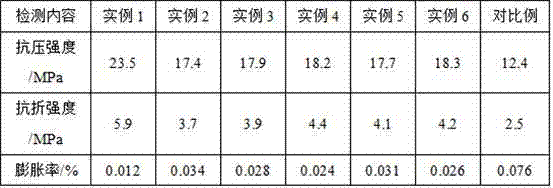

Method for preparing composite steel slag carbonized bricks

The invention discloses a method for preparing composite steel slag carbonized bricks, and belongs to the technical field of industrial waste slag utilization. According to the method, steel slags, kerosene and grinding aids are mixed, ball milled, ignited and cooled to obtain combustion slags; the combustion slags are then crushed and sieved to obtain pretreated steel slag powder; aggregates, thepretreated steel slag powder and hydrated lime are stirred and mixed with dispersion liquid to be poured into shape and placed at constant temperature and humidity to obtain unburned bricks; the unburned bricks are subjected to autoclave oxidation and fumigated with vinegar to obtain fumigated bricks; the fumigated bricks are then transferred to a carbonization box and subjected to carbonizationat constant temperature and humidity, and the composite steel slag carbonized bricks are obtained after discharge. The composite steel slag carbonized bricks prepared by adopting the method have excellent strength and stability.

Owner:CHANGZHOU OPTICAL MATERIAL

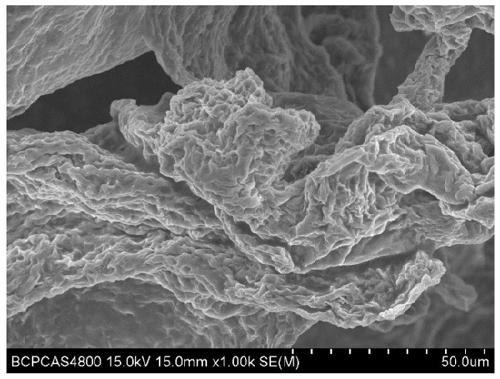

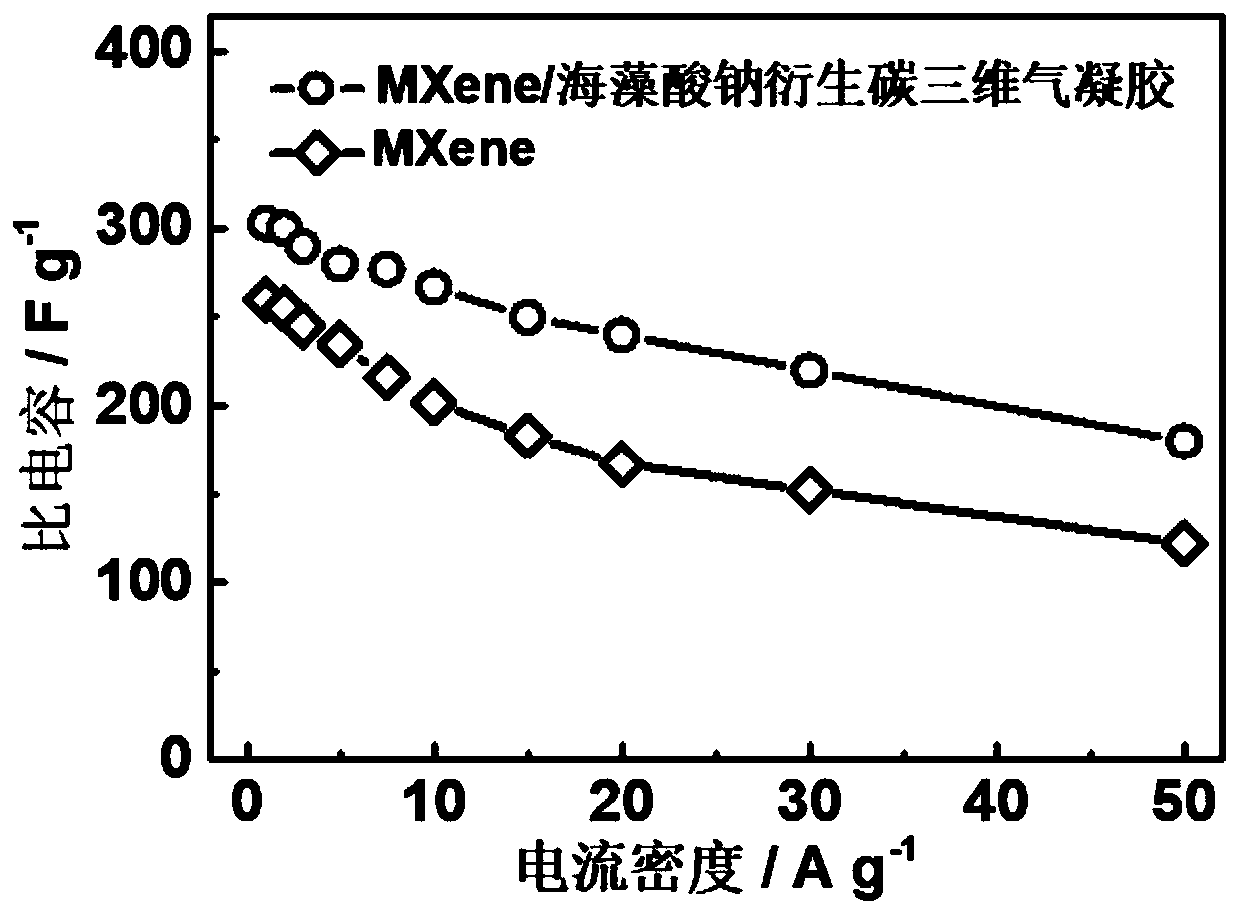

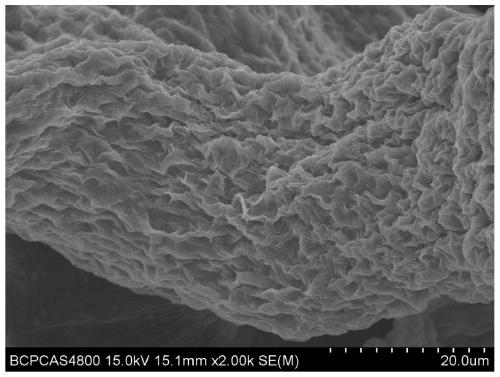

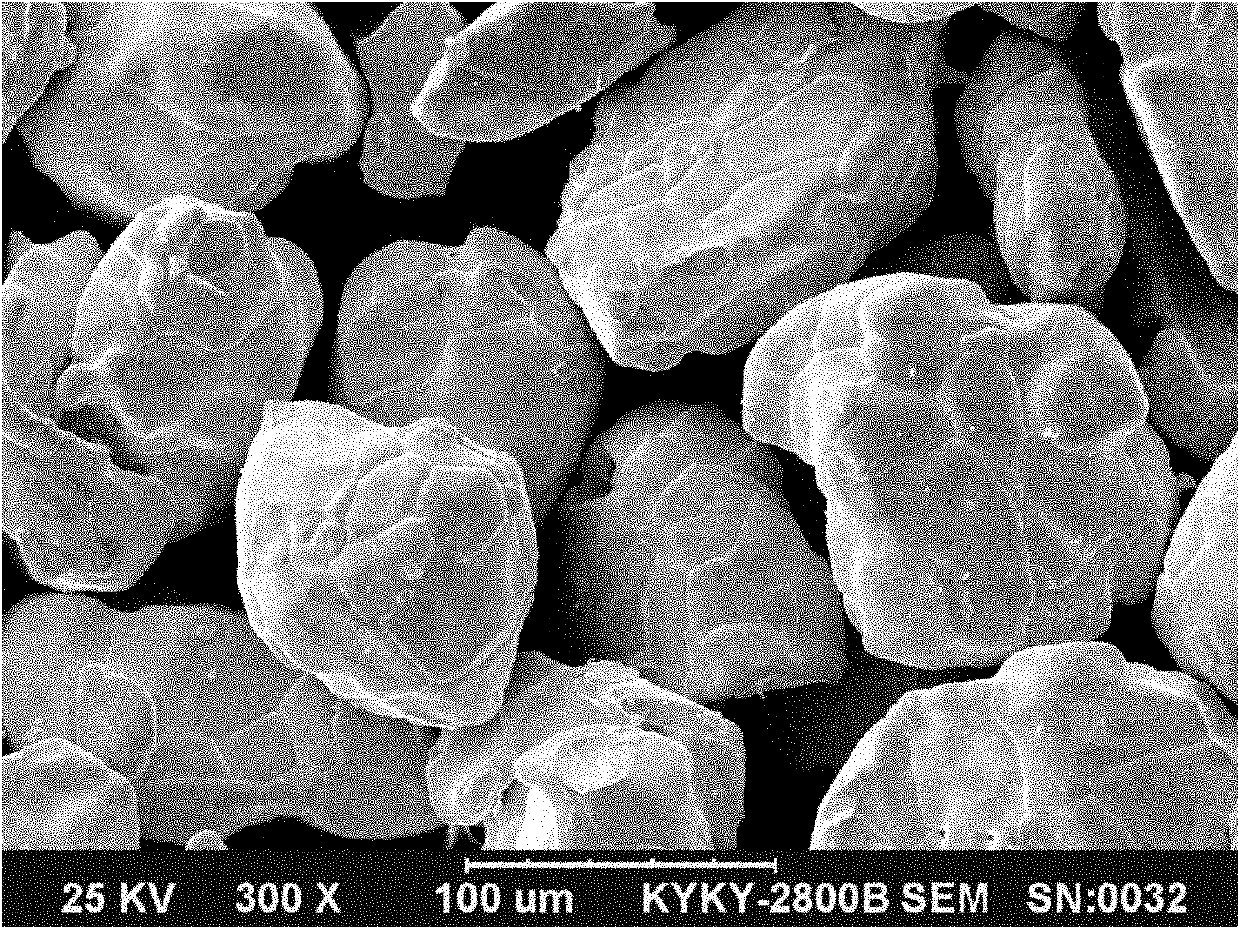

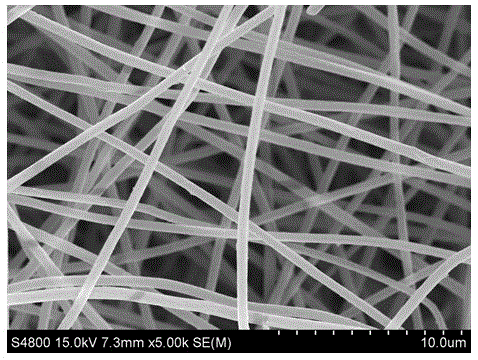

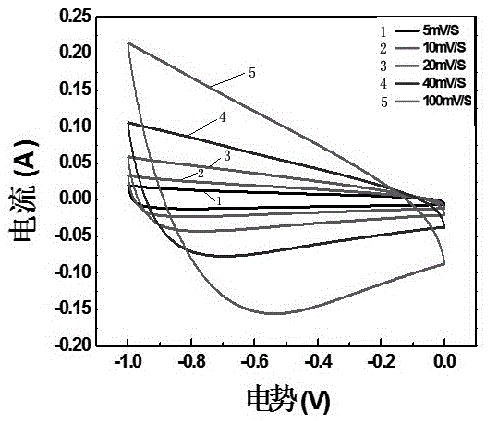

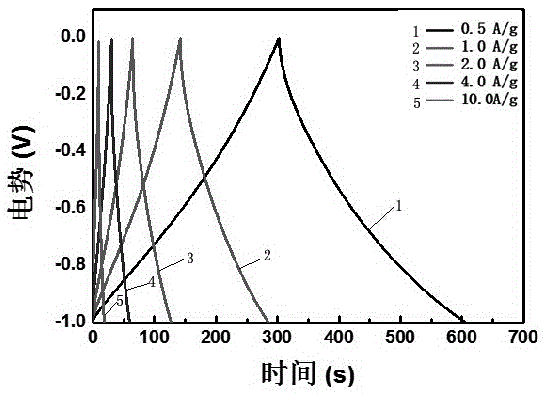

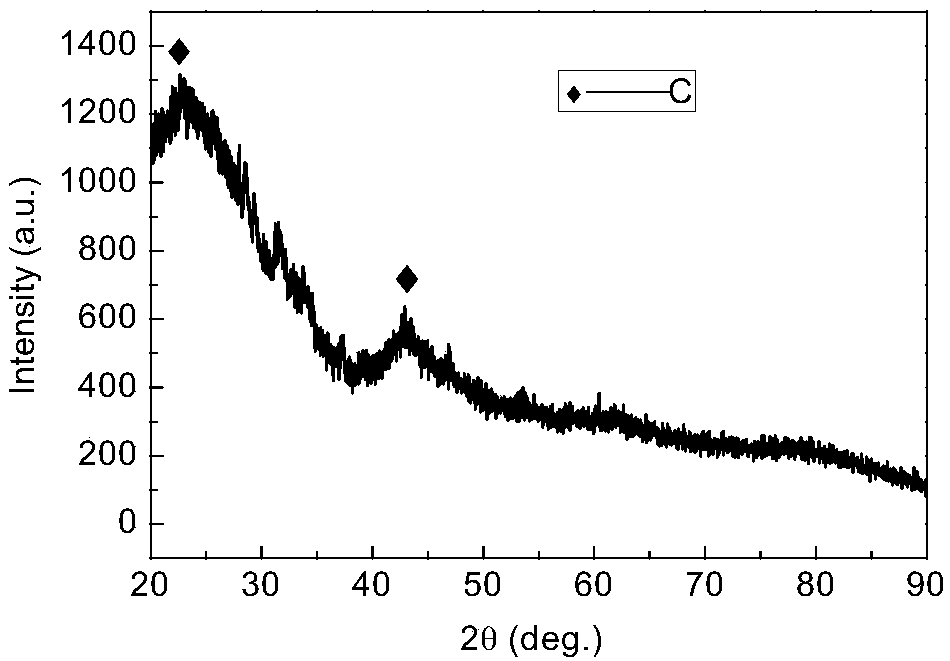

MXene/sodium alginate derived carbon three-dimensional aerogel as well as preparation method and application thereof

ActiveCN111422873AAvoid stackingImprove electrochemical performanceMaterial nanotechnologyHybrid capacitor electrodesFluid phaseSupercapacitor

The invention provides MXene / sodium alginate derived carbon three-dimensional aerogel as well as a preparation method and application thereof. The preparation method of the MXene / sodium alginate derived carbon three-dimensional aerogel, provided by the invention, comprises the following steps: carrying out liquid-phase mixing on an MXene dispersion liquid and a sodium alginate aqueous solution toobtain an MXene / sodium alginate mixed solution; adding a calcium chloride solution into the MXene / sodium alginate mixed solution, and gelatinizing sodium alginate to obtain MXene / sodium alginate hydrogel; carbonizing sodium alginate through high-temperature treatment, and then washing with 1-3mol / L hydrochloric acid and deionized water to obtain the MXene / sodium alginate derived carbon three-dimensional aerogel material. The MXene / sodium alginate derived carbon three-dimensional aerogel material provided by the invention has good electrochemical performance when used in the field of supercapacitors.

Owner:BEIJING UNIV OF CHEM TECH

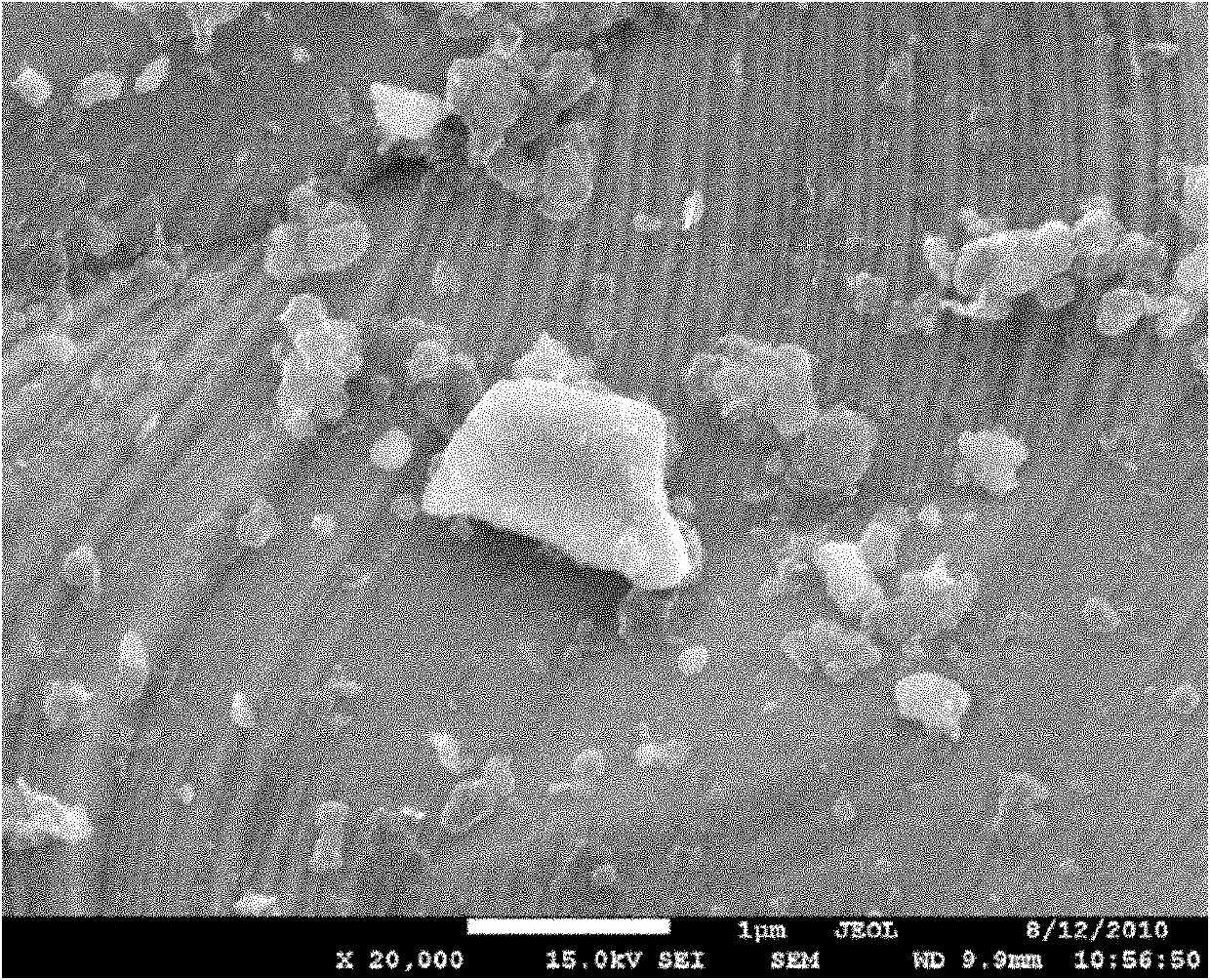

Preparation method of high-stability high-purity extra-coarse tungsten carbide powder

InactiveCN102557028ANarrow particle size distributionImprove stabilityTungsten/molybdenum carbideGranularityCarbonization

A preparation method of a high-stability high-purity extra-coarse tungsten carbide powder contains the following steps of: (1) grinding a high-purity extra-coarse tungsten carbide powdered raw material with its chemical purity being greater than or equal to 99.98 wt%, and carrying out size grading to obtain the required average granularity and a high-purity extra-coarse tungsten powder according to the particle size distribution; (2) carrying out carbon addition by the use of carbon black according to the total carbon content of the obtained tungsten carbide powder being 6.13+ / -0.05%, followed by ball milling and mixing to obtain a ball-milling mixture; (3) filling the obtained ball-milling mixture into a graphite boat and a carbide furnace, and carrying out high-temperature carbonization at 1600-2500 DEGC for the carbonization time of 1-10 hours; and (4) carrying out coarse crushing on the obtained carbonized material, followed by grinding and crushing, and carrying out size grading to obtain the high-purity extra-coarse tungsten carbide powder. The method provided by the invention can be adopted to produce the high-purity extra-coarse tungsten carbide powder with good crush resistance, morphology and structure and excellent thermal stability. The high-purity extra-coarse tungsten carbide powder is used to prepare an extra-coarse crystal cemented carbide product with high performance.

Owner:江西耀升钨业股份有限公司 +1

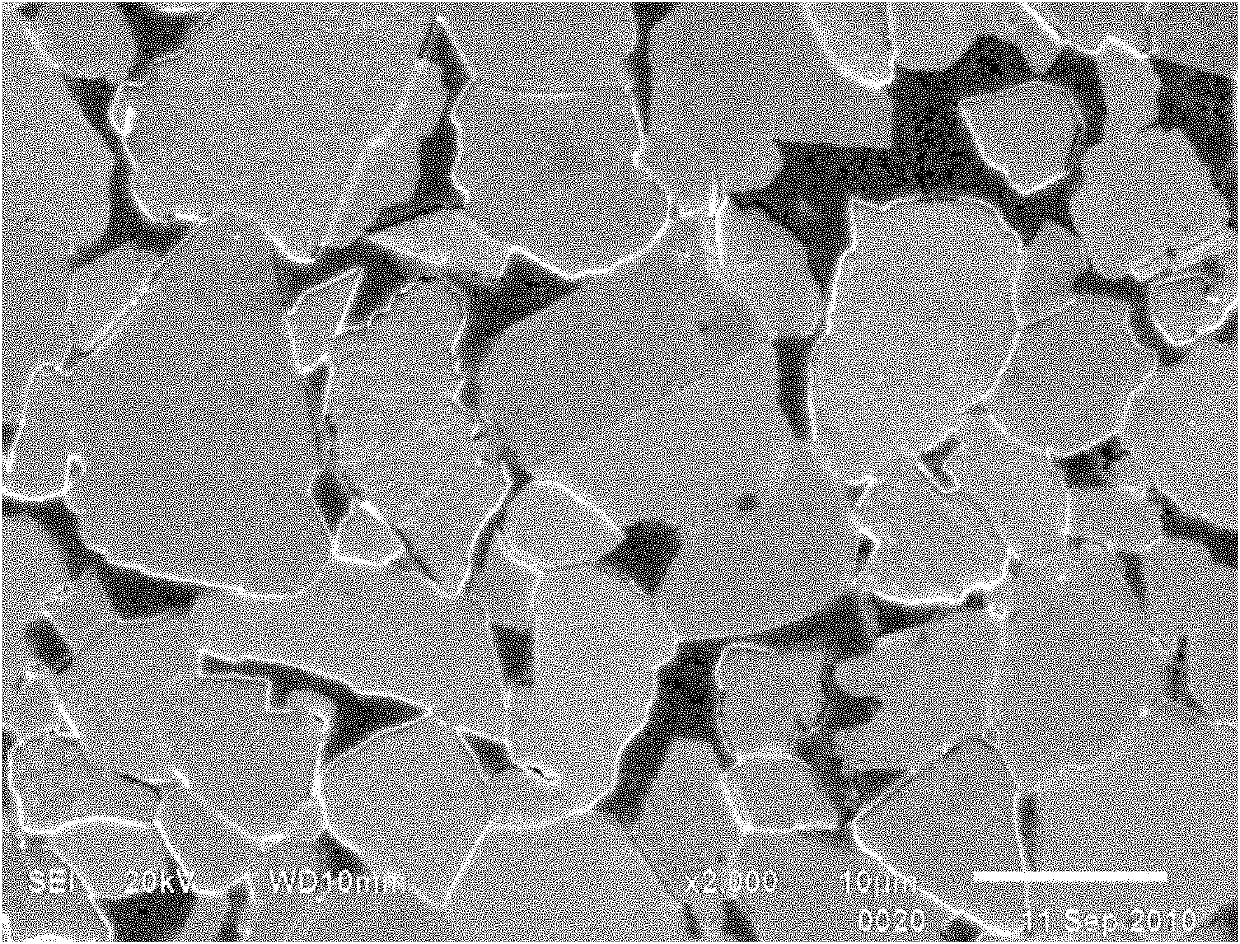

Preparation method of melamine resin modified nitrogen-rich porous carbon fiber electrode material

ActiveCN105671692AIncrease productivityReduce manufacturing costFibre chemical featuresHybrid/EDL manufactureCarbon fibersPorous carbon

The invention provides a preparation method of a melamine resin modified nitrogen-rich porous carbon fiber electrode material and relates to the technical field of production of functional materials. Melamine resin is synthesized by melamine and formaldehyde; polyacrylonitrile is dissolved in N,N-dimethyl formamide, and then the melamine resin is added to prepare a spinning solution; MF / PAN composite precursor fiber is prepared through electrostatic spinning; the MF / PAN composite precursor fiber is subjected to preoxidation, carbonization and other heat treatment to obtain nitrogen-rich carbon fiber; the NCNF is made into a super capacitor electrode. The problem that existing carbon fiber nitrogen doping and pore formation needs to be performed in a step-by-step mode, a production process is complicated and the cost is higher is solved.

Owner:YANGZHOU UNIV

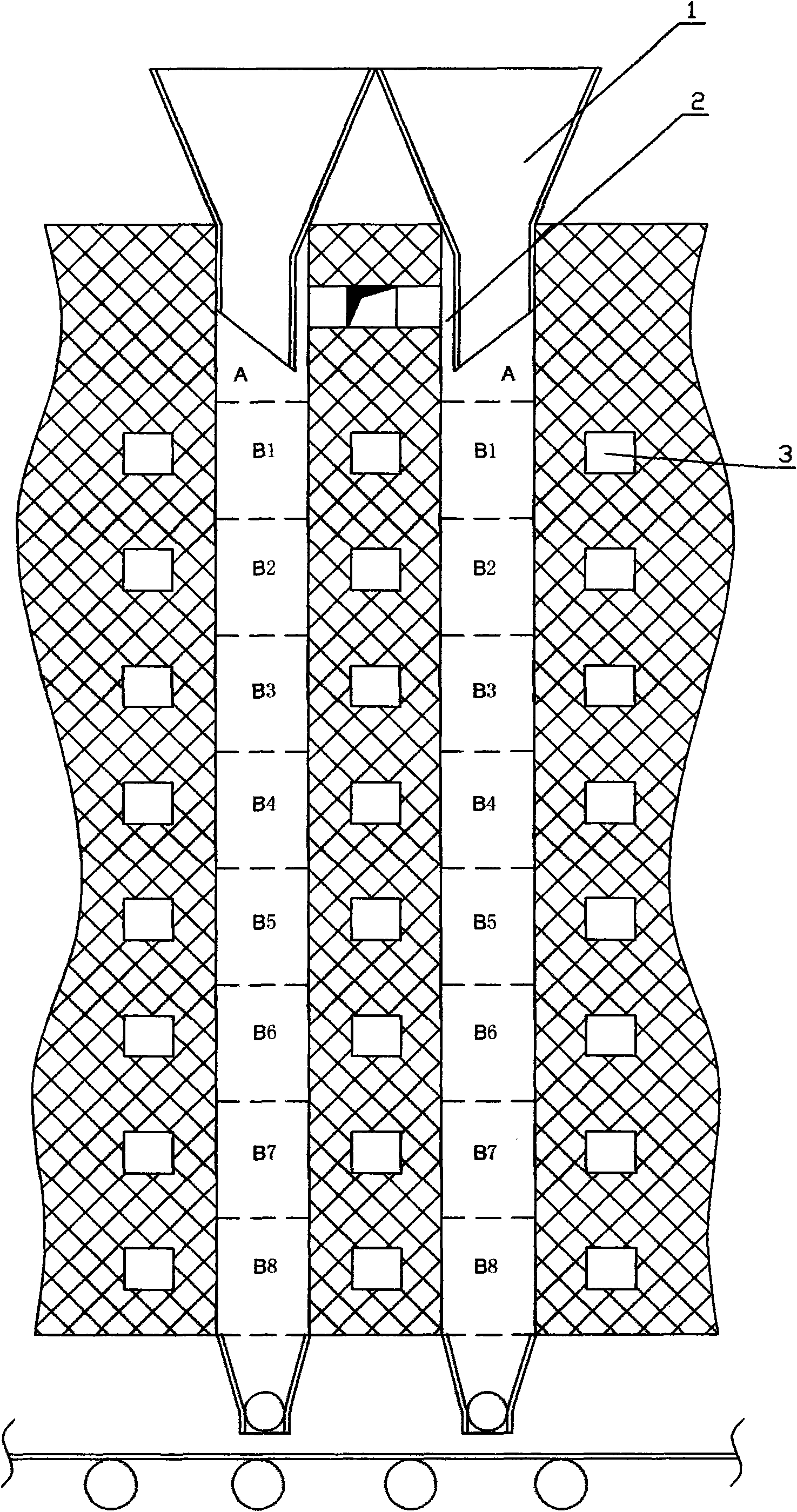

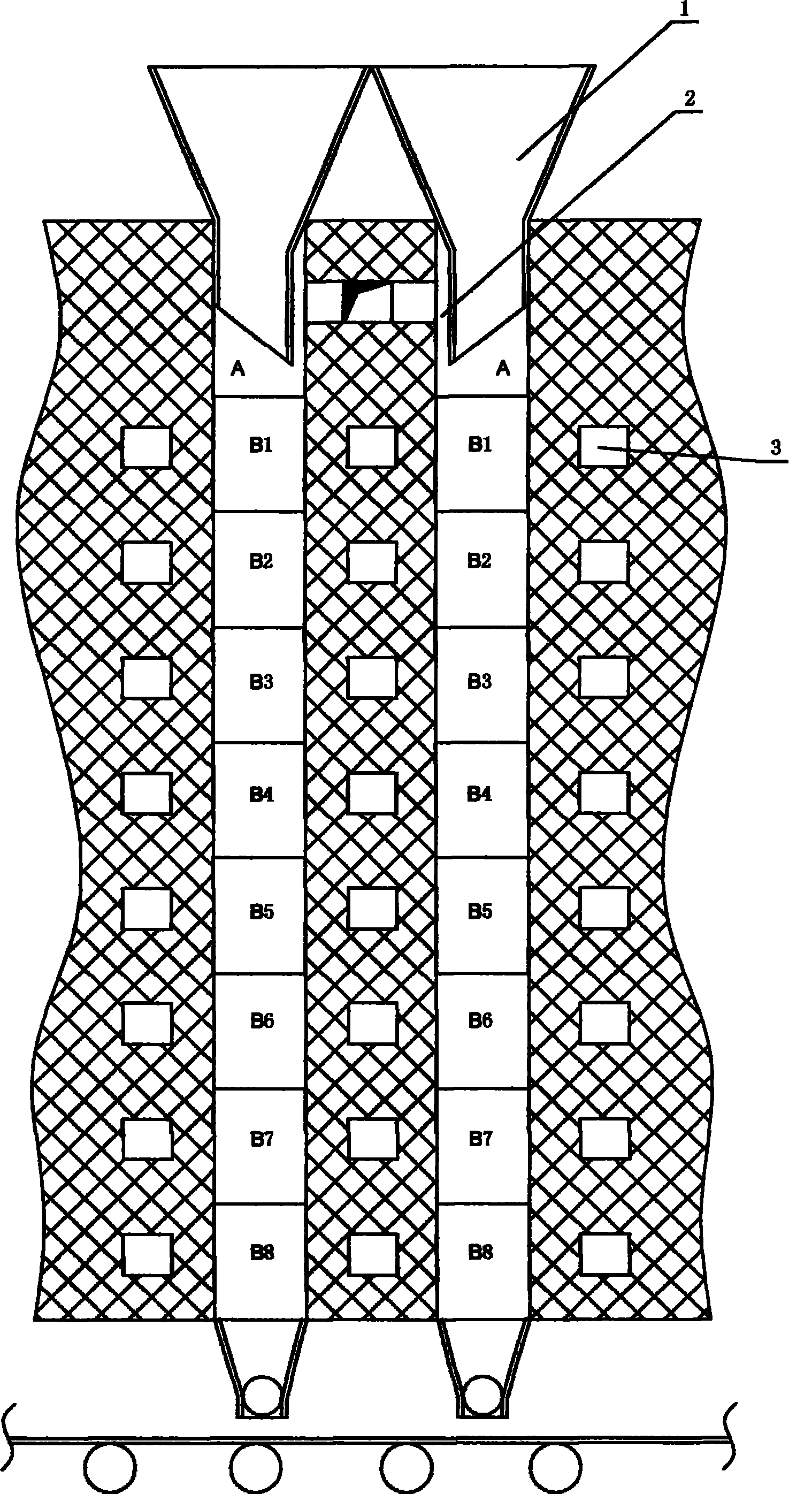

Process for calcining petroleum coke

The invention discloses a process for calcining petroleum coke. The calcination of the petroleum coke is carried out in a tank type calcining furnace, and the tank body of the tank type calcining furnace is provided with a preheating zone and 6-8 calcining zones sequentially from top to bottom, wherein the calcining temperature of the first calcining zone at the uppermost part is controlled in the maximum calcining temperature interval allowed by the petroleum coke; the calcining temperature of the second calcining zone in the downstream position of the first calcining zone is kept in the maximum calcining temperature interval and is not higher than the calcining temperature of the first calcining zone; starting from the third calcining zone, the calcining temperature of each calcining zone gradually reduces relative to the calcining temperature of the adjacent calcining zone in the upstream position; and in the undermost calcining zone, the calcining temperature is reduced to the discharging temperature. In the invention, when the petroleum coke is calcined, the high temperature zone is positioned at the top end of the calcining furnace, thereby relieving the high temperature deformation phenomenon of the furnace body, being more favorable for overflow of combustible gas in the petroleum coke, reducing the corrosion of the combustible gas on wall bricks, and being favorable for prolonging the service life of the tank type furnace.

Owner:WEIFANG LIANXING NEW MATERIAL TECH

Preparation method of tungsten carbide-cobalt cemented carbide

The invention discloses a method for preparing tungsten carbide-cobalt cemented carbide by one step through discharge plasma in-situ synthesis. The method comprises the steps that tungsten powder, cobalt powder, carbon black, glucose and paraffin are used as raw materials, and the tungsten powder, the cobalt powder, the carbon black and the glucose are subjected to ball milling and mixing in proportion and then are dried and sieved for standby application; the paraffin is heated and dissolved through anhydrous ethyl alcohol and poured into ultrafine-grain tungsten-cobalt mixed powder and is continuously subjected to water-bath heating and stirring until the anhydrous ethyl alcohol is volatilized; the obtained product is dried, sieved and charged into a high-strength graphite mold and is subjected to discharge plasma sintering, and the WC grain controllable compact tungsten carbide-cobalt cemented carbide is prepared by controlling the processes such as the heating rate, the pressurization rate and the heat holding time. Through the method, the preparation process of the cemented carbide can be effectively shortened, and the comprehensive performance of the cemented carbide can be improved.

Owner:KUNMING UNIV OF SCI & TECH

Method for making surface antibiotic product using physical gaseous phase deposition technology

InactiveCN1814853AAvoid exclusionPrevent target poisoningVacuum evaporation coatingSputtering coatingTarget surfaceGas phase

This invention relates to a method for manufacturing surface anti-bacterium product by a physical gas phase deposition technology including utilizing the physical gas phase deposition technology to plate an anti-bacterium target material on a matrix surface to form a film, characterizing in drilling small air holes on said anti-bacterium target and penetrating reaction gas by windpipes, in which, said target is made of As, Se, Hg, Ag, Cu, Zn, CE, Ca, Co, Ni, Al, Fe, S and their oxides, which drills holes on the target surface to prevent the target from poisoning to realize multi-arc plating and magnetic controlled sputtering plating.

Owner:姜培齐

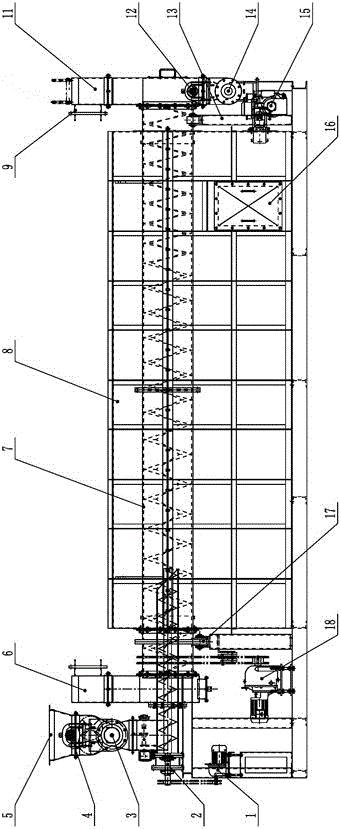

Horizontal pushing type vertical biomass charcoal gas-oil co-production device and use method thereof

InactiveCN103146401AAvoid the phenomenon of crushing and pulverizationGood ventilation characteristicsDirect heating destructive distillationBiofuelsLiquid productSmall footprint

The invention relates to a horizontal pushing type vertical biomass charcoal gas-oil co-production device. Biomass moves down in a reciprocating manner by layers in a vertical pyrolyzing furnace by a horizontal pushing device; and a gas carrying heat medium directly passes through a material layer, and the biomass is heated in form of convection. The structure specifically comprises an external furnace body and a drying destructive distillation reaction space surrounded by a brasque in the furnace body, wherein the drying destructive distillation reaction space is substantially modularized and separated to six layers of horizontal box type spaces equally; the six layers of space are divided into three areas: a water removing area, a low-temperature pyrolysis area and a high-temperature pyrolysis area; and a horizontal fire grate is arranged in each layer of horizontal box space of the device in a pull back manner in many times. According to the invention, physical partition of the pyrolyzing process is realized, the adjustability of the destructive distillation process is greatly improved, pyrolysis products and the material layer are fast separated, and the liquid product yield in the pyrolysis products is high; the power consumption of a draught fan is greatly reduced, and the operating cost is lowered; and the device provided by the invention is vertically arranged, small in occupied area, and easy for parallel operation of multiple sets.

Owner:河北省隆盛生物质能源开发有限责任公司

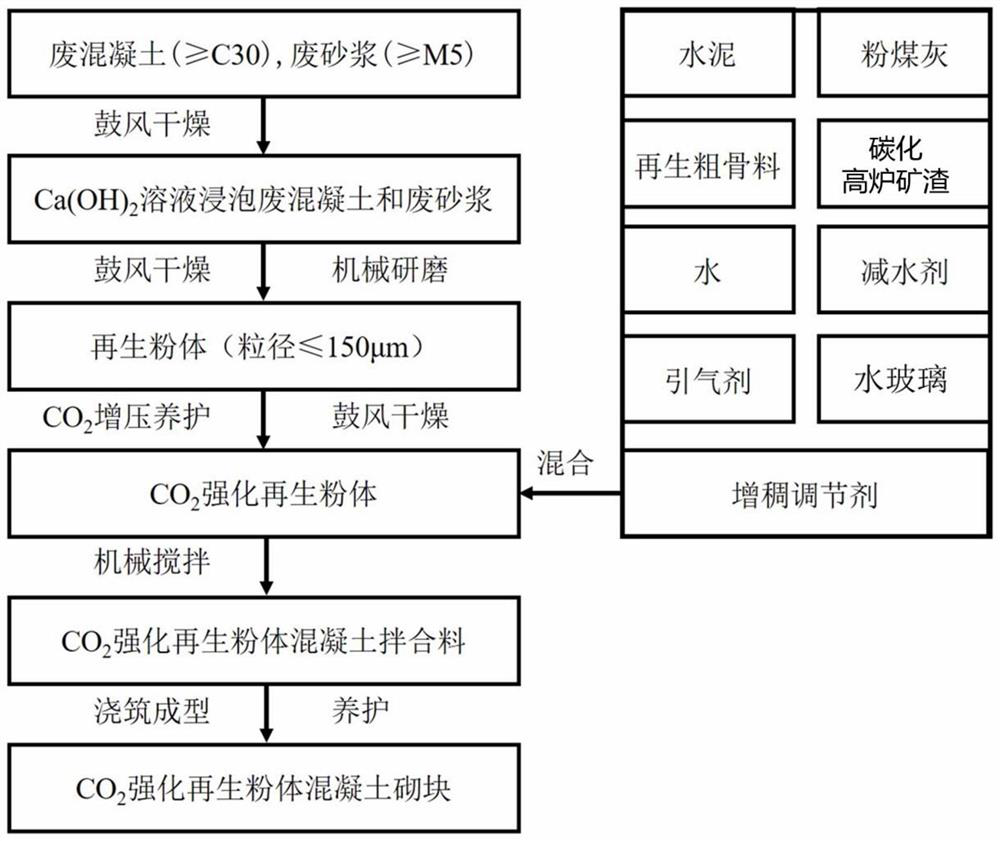

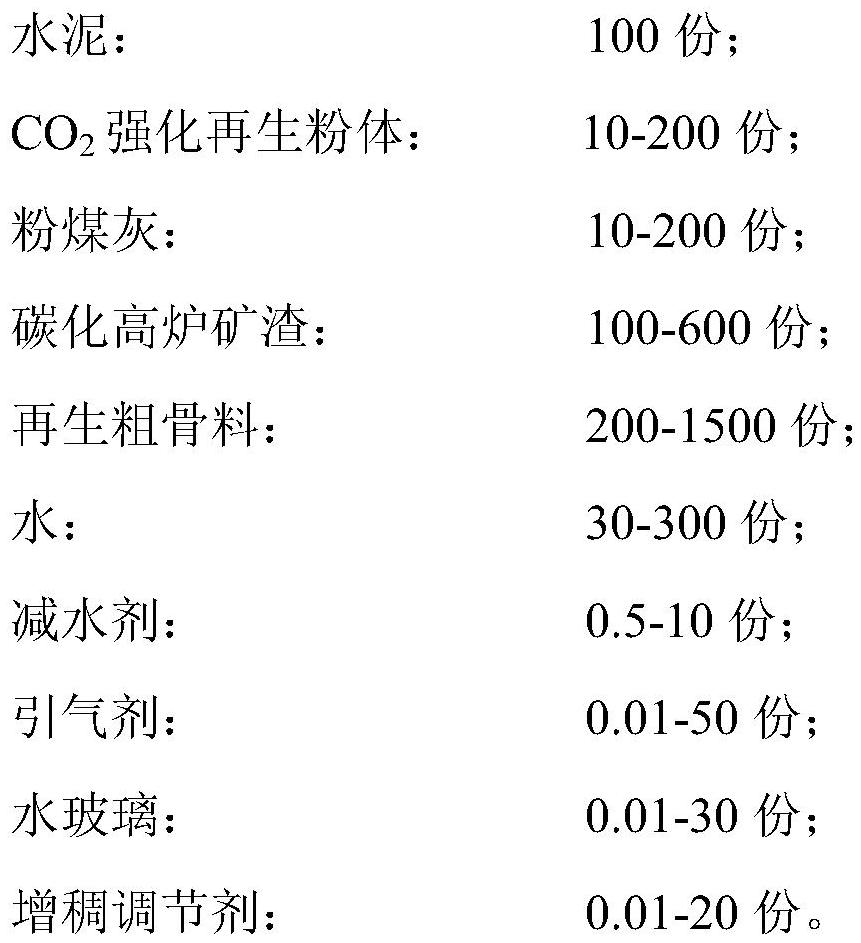

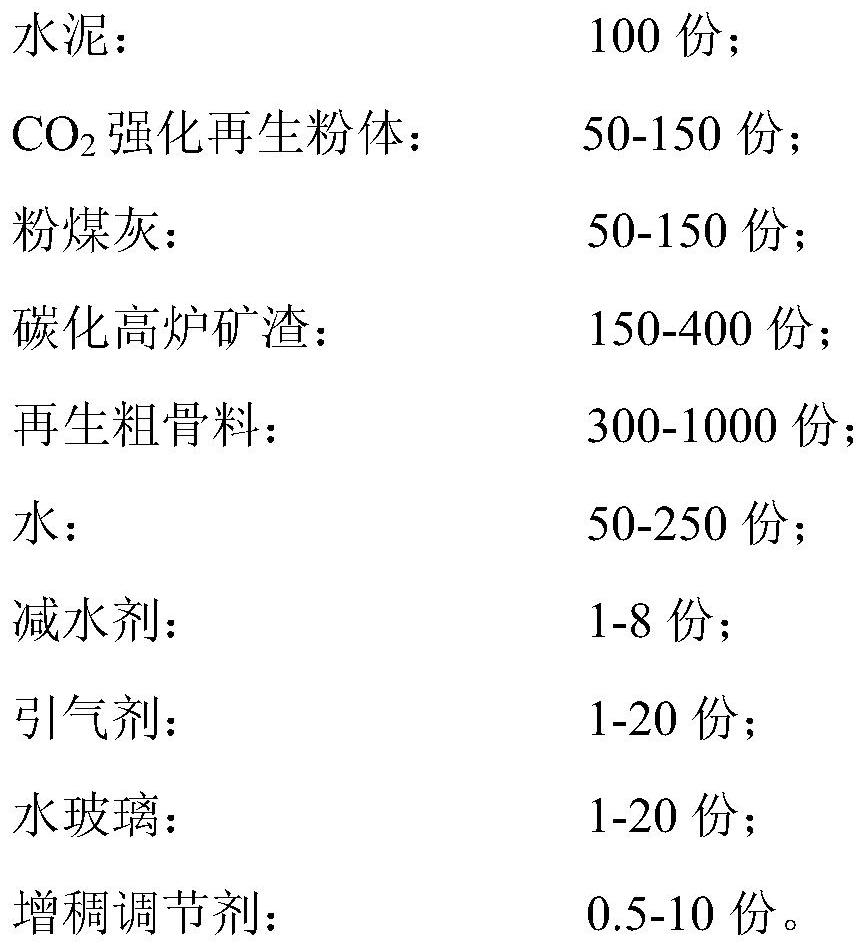

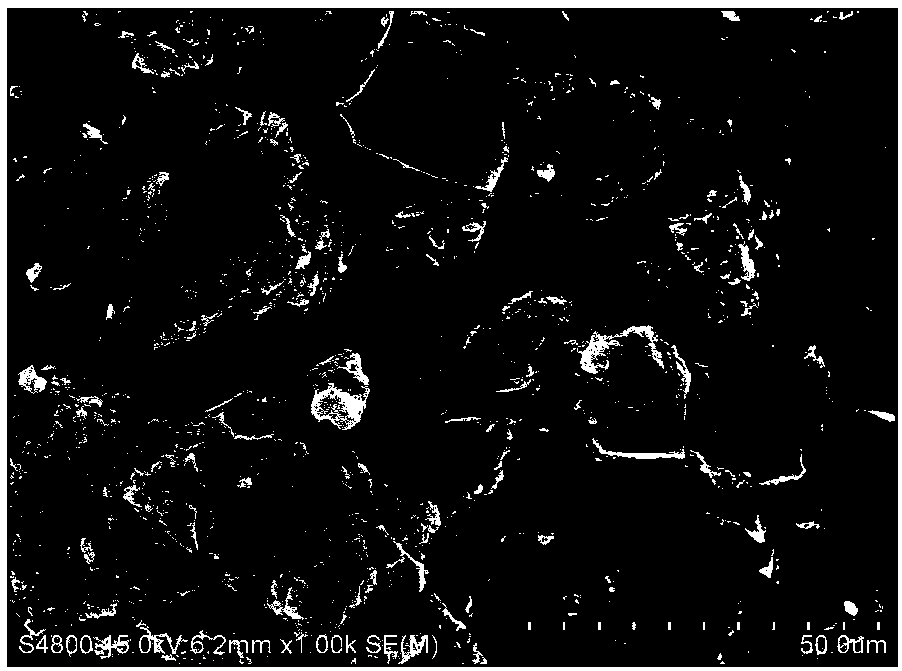

Recycled concrete block prepared from CO2 reinforced recycled powder

The invention provides a concrete block prepared from CO2 reinforced regenerated powder. The invention further provides a preparation method for preparing the concrete block by utilizing the CO2 reinforced regenerated powder. According to the concrete block prepared from the CO2 reinforced regenerated powder, the CO2 reinforced regenerated powder is used as an auxiliary cementing material, the carbonization maintenance reinforced industrial blast furnace slag is used as a fine aggregate, and the regenerated coarse aggregate is used as a coarse aggregate, so that the regenerated concrete blockis prepared; the method realizes full substitution and full regeneration of cementing materials and aggregates in concrete, can be used for preparing recycled concrete blocks meeting different strength requirements, reduces the production cost of block products, can meet functional requirements of sound insulation, heat insulation and the like, has the characteristics of simple process and the like, and is remarkable in economic benefit and suitable for large-scale popularization.

Owner:TONGJI UNIV

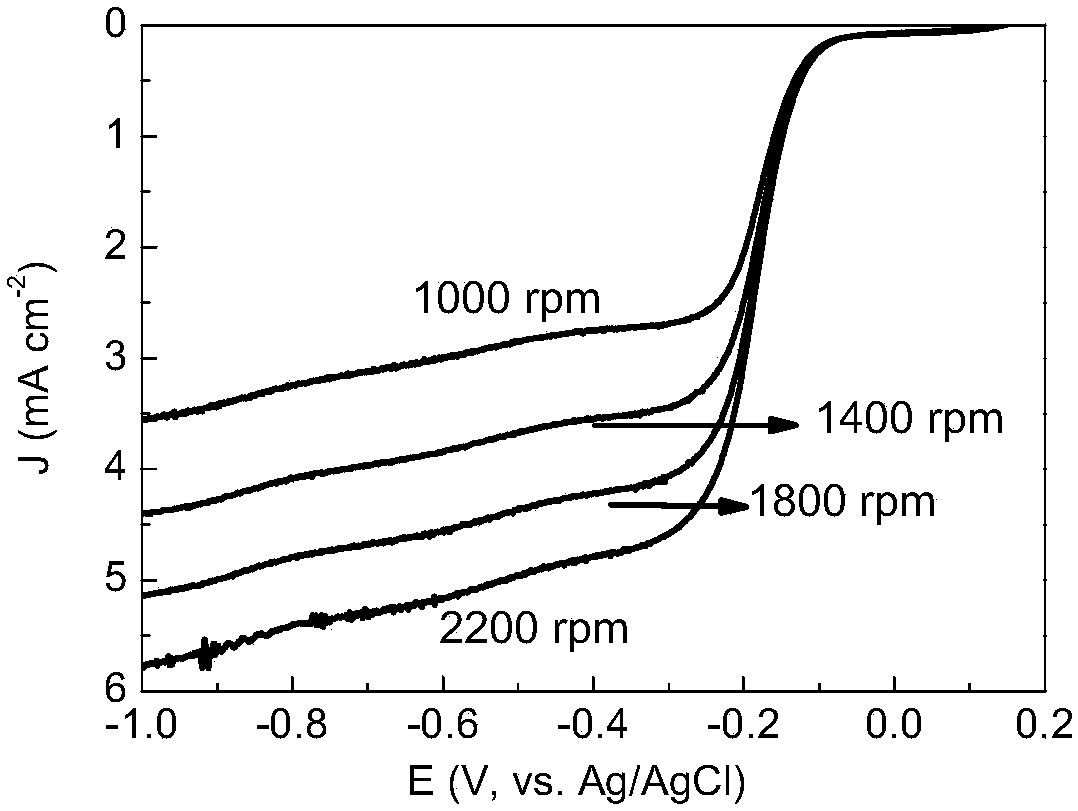

Efficient biomass carbon electrochemical oxygen reduction catalyst and preparation method and application thereof

ActiveCN108134098AImprove performanceImprove stabilityFinal product manufactureCell electrodesElectricityBiomass carbon

The invention belongs to the technical field of electrocatalysis, and in particular relates to an efficient biomass carbon electrochemical oxygen reduction catalyst and a preparation method and application thereof. By taking agaric as a biomass raw material, the biomass carbon-based catalyst with good hydrophilicity is prepared by acid-boiling the biomass raw material by means of a carbonizing mode combining pre-carbonization and full carbonization. By taking the fungi agaric which is low in price, easily available and environment-friendly as the raw material, the demand on equipment is relatively low in the preparation process, the preparation flow is short, and the preparation method is simple to operate. The preparation method is environment-friendly in preparation process, free of waste discharge and quite beneficial to scale production, and has wide industrial application prospect.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

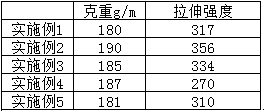

Processing method of heat-not-burn cigarette with curling structure

ActiveCN110810897AFacilitated releaseEasy to overflowTobacco preparationTobacco treatmentAdhesiveCarbonization

The invention discloses a processing method of a heat-not-burn cigarette with a curling structure. The method comprises the following steps of rolling and pressing a dry and wet material mixture to obtain atomized reconstituted tobacco leaves; dispersing a graphene nanometer material, a solid adhesive and an atomization agent mixture into water; uniformly spraying the solution onto one sides of the atomized reconstituted tobacco leaves; performing primary heating drying to obtain semi-dried heat-not-burn reconstituted tobacco leaves; performing shredding to obtain semi-wet heat-not-burn reconstituted tobacco leaves; performing secondary heating drying to obtain cut tobacco of the heat-not-burn reconstituted tobacco leaves; and performing rolling connection and packaging to obtain the heat-not-burn cigarette with the curling structure. The problem of great addition proportion of atomization agents is solved, so that the cut tobacco is changed from a straight shape to a naturally curlingshape; a filling value is increased; the smoke overflowing is easy; the smoke release quantity is increased; the smoking feeling is improved; the cut tobacco elasticity is improved; the holding forceis increased; the cut tobacco cannot easily fall; the tensile strength of the heat-not-burn reconstituted tobacco leaves is improved; breakage cannot easily occur; rolling packaging processing is convenient to perform; and the heat conductivity is improved, so that the carbonization of heating cigarettes is safer.

Owner:HUBEI CHINA TOBACCO IND +1

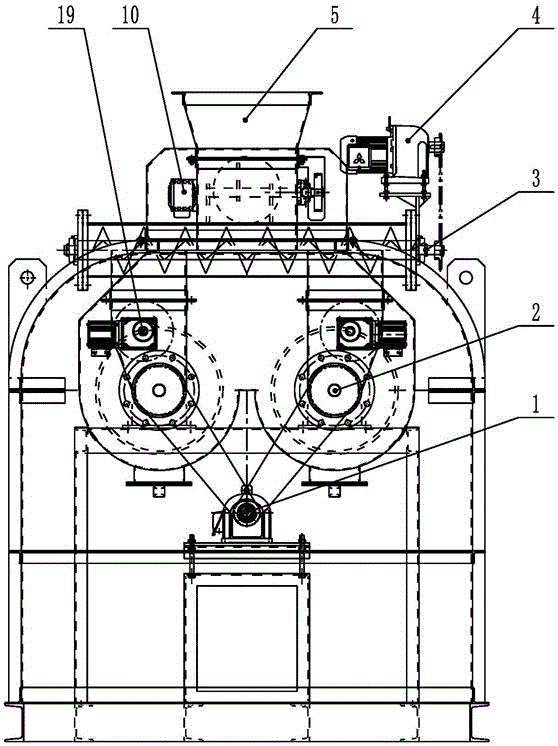

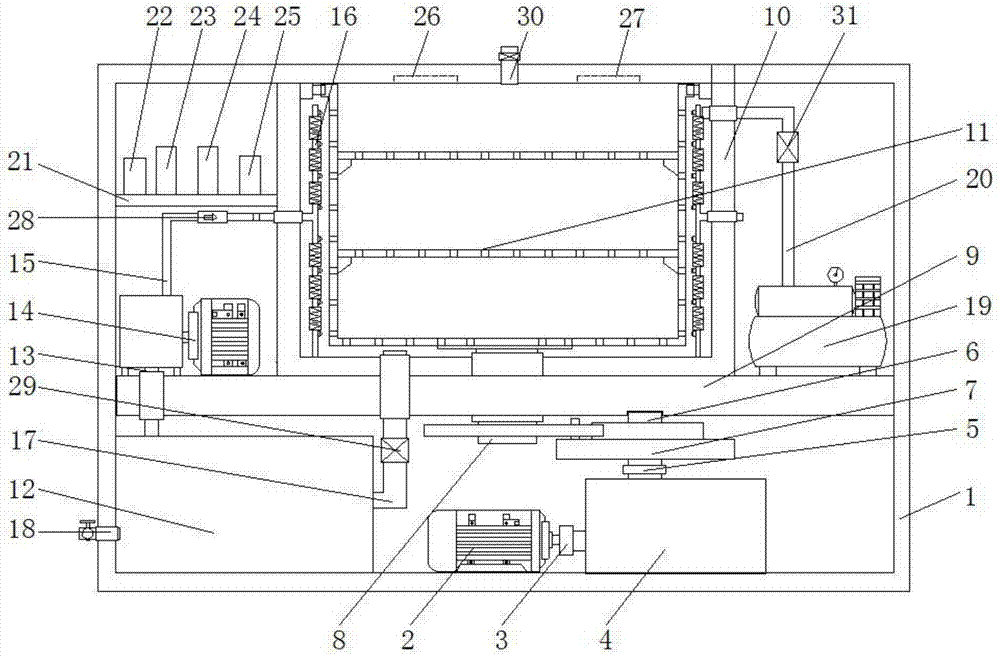

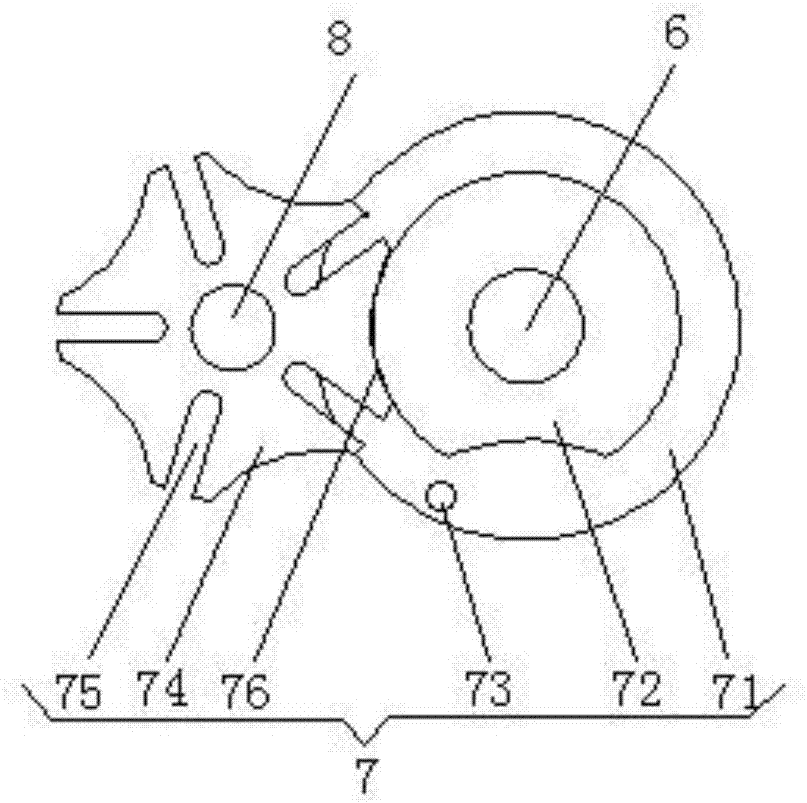

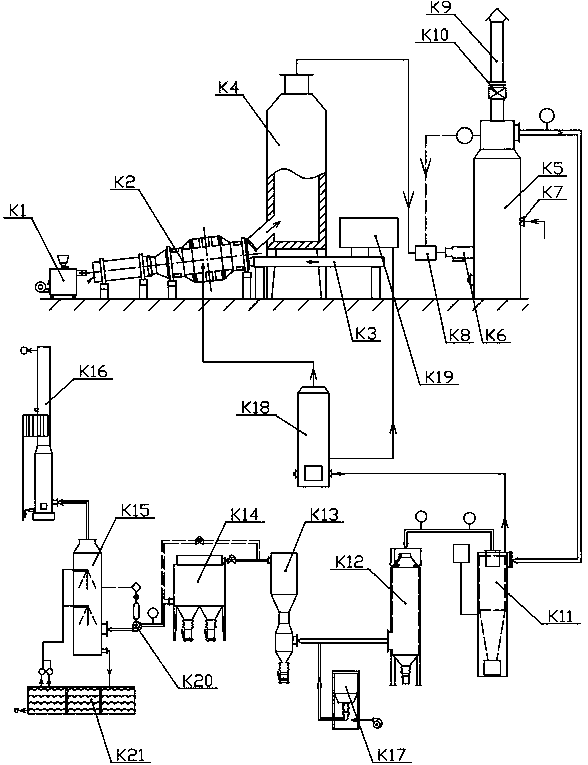

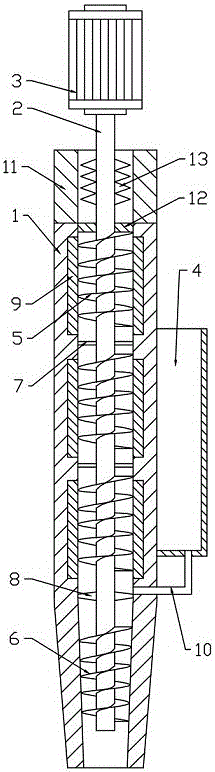

Screw propelling type solid waste continuous carbonization equipment and continuous carbonization method

The invention provides screw propelling type solid waste continuous carbonization equipment and a continuous carbonization method. The screw propelling type solid waste continuous carbonization equipment is characterized by comprising a feeding system, a material distributing system, a carbonization system, a product collecting system and a discharging system which are successively connected with one another, wherein a sealed connected screw propelling material channel is formed from a feeding opening of the feeding system to a discharging opening of the discharging system; and the carbonization system is connected with a deodorization system. The feeding system comprises a feeding screw conveyer, a feeding gear motor, a first stirring motor and the feeding opening, the feeding opening of the feeding system is an inverted-cone-shaped feeding hopper, the first stirring motor drives a stirring shaft to rotate, blades are mounted on the stirring shaft, and the stirring shaft is positioned in the inverted-cone-shaped feeding hopper of the feeding system. The screw propelling type solid waste continuous carbonization equipment is high in universality, the generated carbonization products are used extensively, and secondary pollution is avoided. The screw propelling type solid waste continuous carbonization equipment is reasonable and compact in structure, good in airtightness, relatively low in manufacturing cost, high in degree of automation and high in working efficiency.

Owner:CHENGHE ENVIRONMENTAL PROTECTION SCIEN TECH CO LTD

Carbonizing device for bamboo wood processing

InactiveCN107310005AFully carbonizedShorten carbonization timeWood charring/burningSimultaneous control of multiple variablesClutchCarbonation

The invention discloses a carbonization device for bamboo and wood processing, comprising a box body, a motor is fixedly connected to the bottom of the inner wall of the box, the output shaft end of the motor is fixedly connected to a transmission through a first coupling, and the output shaft end of the transmission The first rotating shaft is fixedly connected through the second coupling, and the surface of the first rotating shaft is fixedly connected with the second rotating shaft through the rotating device. A steam boiler is fixedly connected, an air pump is fixedly connected to one side of the top of the fixed plate, an air compressor is fixedly connected to the side far from the air pump on the top of the fixed plate, and an air pipe is connected to the air outlet of the air compressor. The invention relates to bamboo and wood field of processing technology. The carbonization device for bamboo and wood processing solves the problem of the lack of intelligence of the existing carbonization device, and at the same time solves the problem of slow decomposition of traditional organic matter, ensures the carbonization effect and improves work efficiency.

Owner:安吉县瑞旺竹木制品厂

Lightweight early-strength magnesium-based cement concrete mixing equipment and application thereof

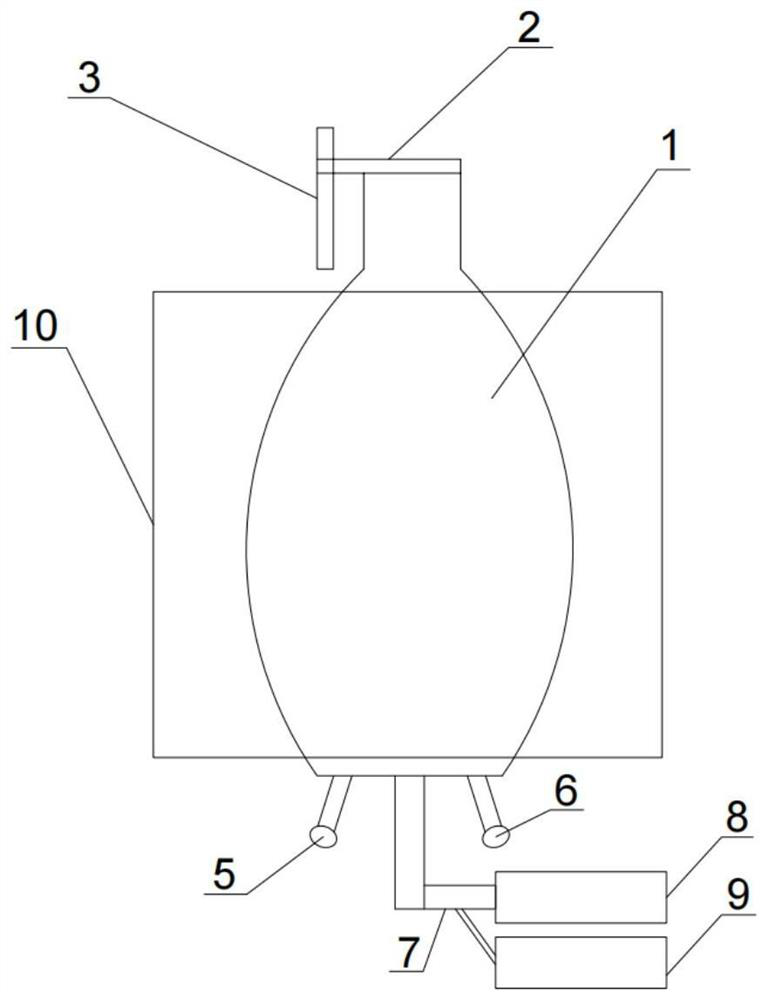

PendingCN113500698AExpand the use of geographical spacePromote hydrationCement mixing apparatusHydration reactionTemperature control

The invention discloses lightweight early-strength magnesium-based cement concrete mixing equipment and application. The equipment comprises a hopper, the lower part of the hopper is provided with a temperature control facility, and the temperature control facility can regulate and control the temperature in the hopper; the hopper is fusiform and can axially rotate; one end of the hopper is provided with a hopper cover, and the hopper is provided with a barometer and a thermometer; a rotating shaft is arranged at the other end of the hopper and is in transmission connection with a motor; the temperature control facility comprises a material groove, a temperature control material is arranged in the material groove, cement concrete can be mixed in a sealed manner through the equipment, mixing can be conducted at different temperatures and pressures, and the application range of magnesium-based cement concrete is expanded; according to the equipment, fresh slurry is fully hydrated and carbonized, the microstructure in magnesium-based cement is improved, and the compactness, macroscopic mechanical property and durability of the magnesium-based cement are improved; meanwhile, water granulated slag sand and engineering residue soil can be directly applied to concrete products; and magnesium-based standard sand can replace quartz standard sand and participate in a hydration reaction.

Owner:天应(深圳)生态建材科技有限公司

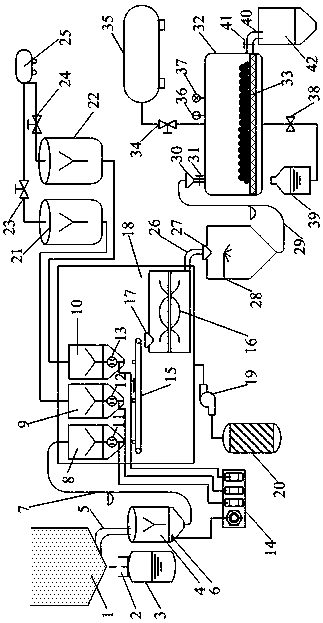

Treatment system for carbonizing and curing silt soil by heterotopic active magnesium oxide

ActiveCN108128991AAdjust dosage in real timeGuaranteed work efficiencyFixation/solidifcation sludge treatmentProcess orientedSludge

The invention discloses a treatment system for carbonizing and curing silt soil by heterotopic active magnesium oxide. The system comprises a pretreatment device, a curing agent supply device, a uniform mixing device, a granulation device, a carbonization device and a collection device. Through the sequential working of the devices, the sufficient blending of silt and a curing and the quick carbonization of a magnesium oxide cured silt granule are completed; thus, the problems of the difficult carbonization and curing of high-water-content and low-permeability silt / sludge soil are solved; multiple sensors particularly arranged in the system are cooperatively used; the supply quantity of the curing agent can be regulated through actually measuring a water content; the particle size of the granule and the pressure of carbon dioxide are regulated according to the property of the soil; the work efficiency is greatly improved; all the devices are more systematized and process-oriented; milldust and the carbon dioxide can be absorbed in the use process of the devices; the secondary pollution is avoided; the carbonized granule of the silt, generated after the devices finish working, is high in hardness and high in shear strength, and can be used as a filling material for a roadbed, an airport runway, engineering backfilling and the like, and the treatment system has great engineeringconstruction significance for the reutilization of silt / sludge in engineering.

Owner:SOUTHEAST UNIV

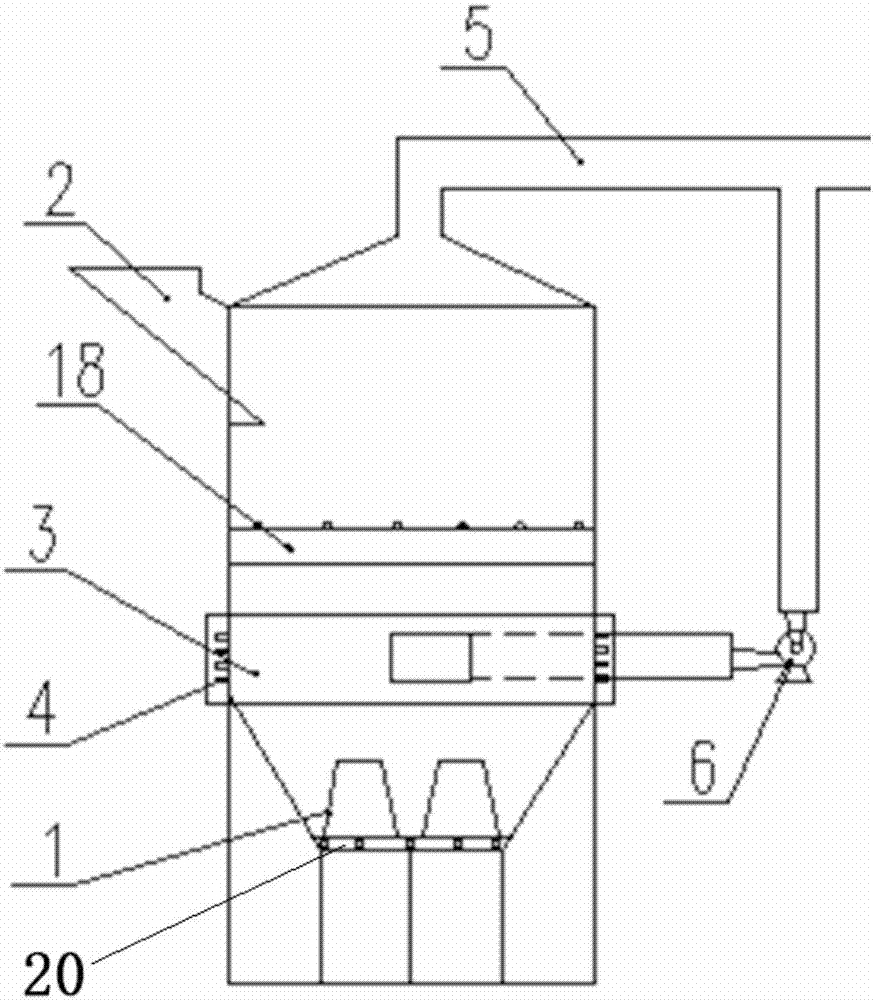

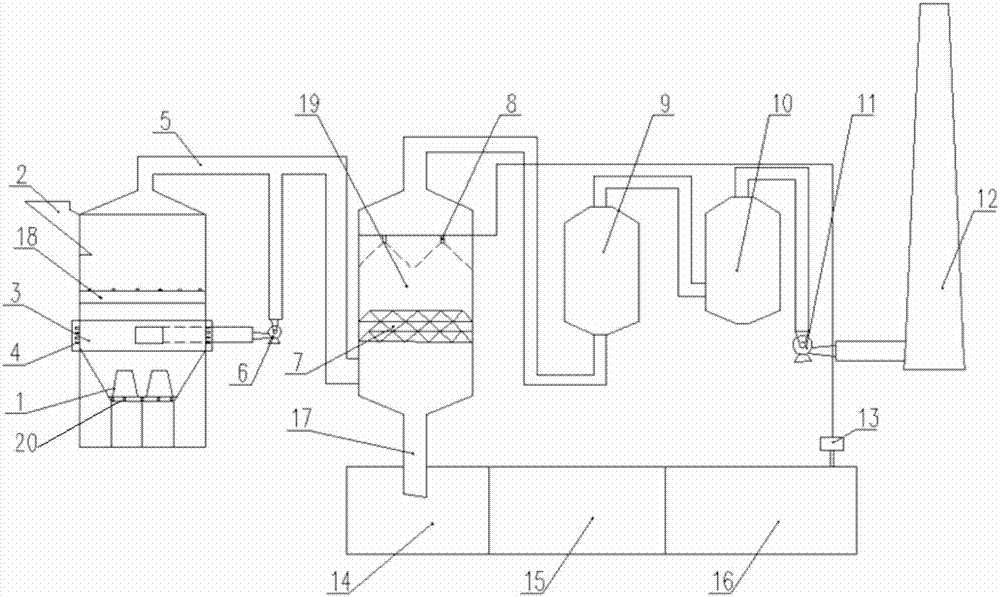

Small domestic garbage pyrolysis gasifying furnace and purifying system

ActiveCN107461746AReduce contentReduced purification process requirementsGas treatmentUsing liquid separation agentCombustion chamberSludge

The invention discloses a small domestic garbage pyrolysis gasifying furnace and a purifying system. The gasifying furnace comprises a furnace body, the top of the furnace body is provided with a smoke outlet, the upper portion of the furnace body is provided with a feed inlet, a first fire grate set is arranged inside the furnace body and located below the feed inlet, the first fire grate set divides the interior of the furnace body into a pyrolysis chamber on the upper side and a combustion chamber on the lower side, the bottom of the combustion chamber is provided with a second fire grate set, an annular air flue is arranged in the furnace body and located in the middle of the combustion chamber, the annular air flue is provided with multiple nozzles facing the combustion chamber, an air inlet of the annular air flue is connected with one end of a three-way pipe installed on the smoke outlet through an induced draft fan, and the purifying system comprises the gasifying furnace, an adsorption module, a deodorization module, a sludge pool, a flocculation sedimentation basin, a clean water basin and a deacidification module. The content of dust, tar, dioxin and other hazardous gas in flue gas is effectively reduced, and the requirements for the tail gas purifying technology are effectively lowered.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

Corrosive granular waste carbon regeneration method

PendingCN108217651AReasonable configurationIncrease productivityOther chemical processesCarbon compoundsExhaust gasCorrosion resistant

The invention relates to a corrosive granular waste carbon regeneration method which is as follows: first drying corrosive granular waste carbon, and then carbonizing and activating the corrosive granular waste carbon by using a carbon activating integrated rotary kiln to obtain a regenerated activated carbon product; using a corrosion-resistant exhaust gas collection tower for collecting and drying high-temperature exhaust gas generated by the carbon activating integrated rotary kiln, sending the high-temperature exhaust gas into a second combustion chamber for combustion treatment, and sequentially performing heat recovery, neutralization treatment, dioxin absorption treatment, dust removal treatment and lye spray treatment on the combusted high-temperature exhaust gas to facilitate theharmless treatment of the high temperature exhaust gas. The method is a set of scheme mainly designed for regenerative production of the corrosive granular waste carbon, and the method comprises the regenerative processing of the corrosive granular waste carbon and the harmless tail gas treatment, the process flow is configured reasonably, and energy in the process flow is efficiently used, production efficiency is high, and the method helps an enterprise to improve the capacity of regeneration of the corrosive granular waste carbon.

Owner:福建省芝星炭业股份有限公司

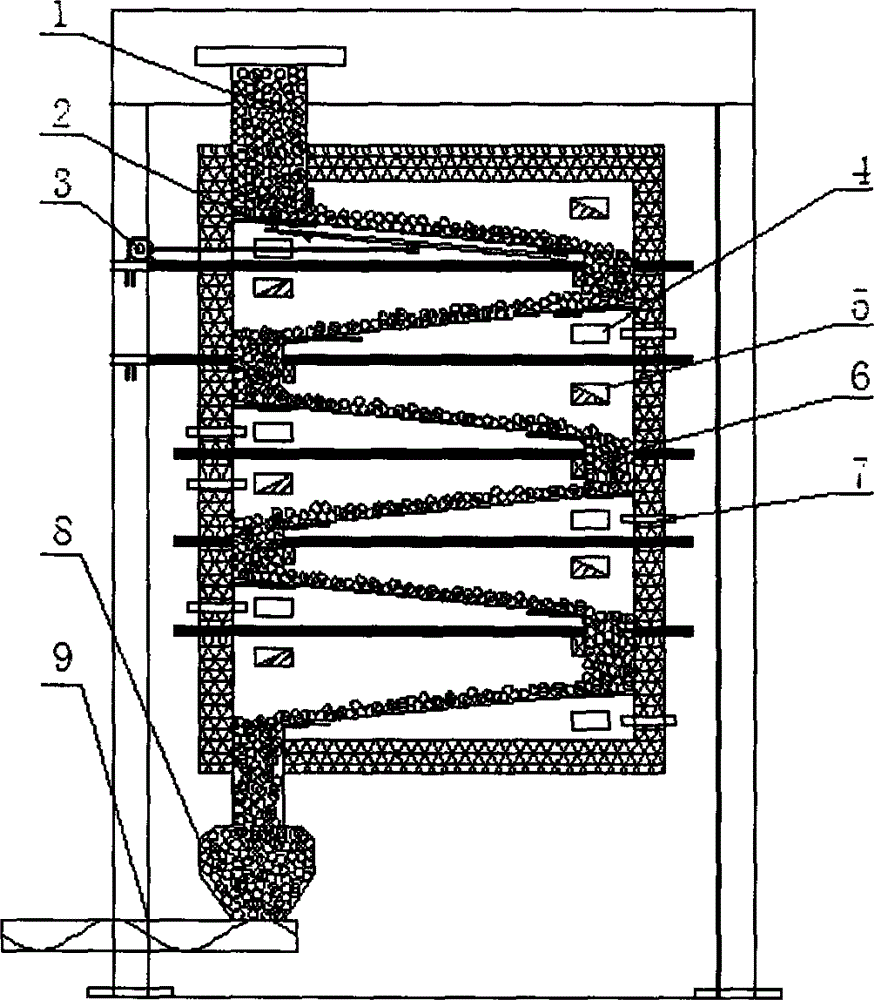

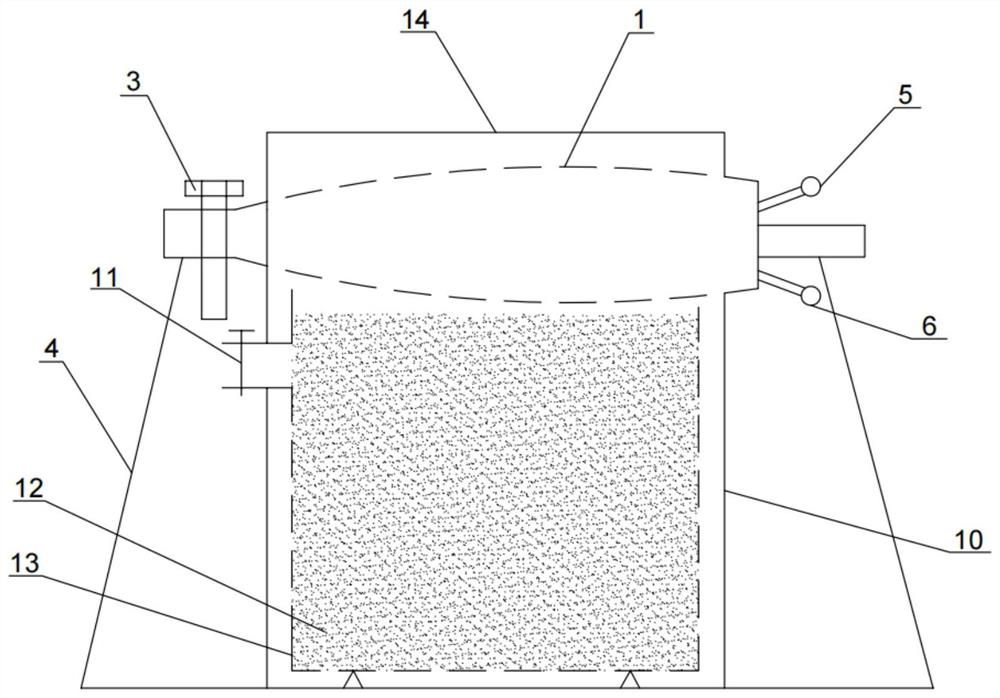

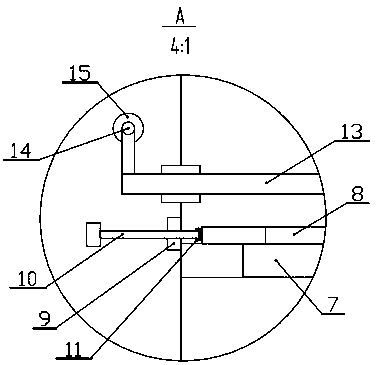

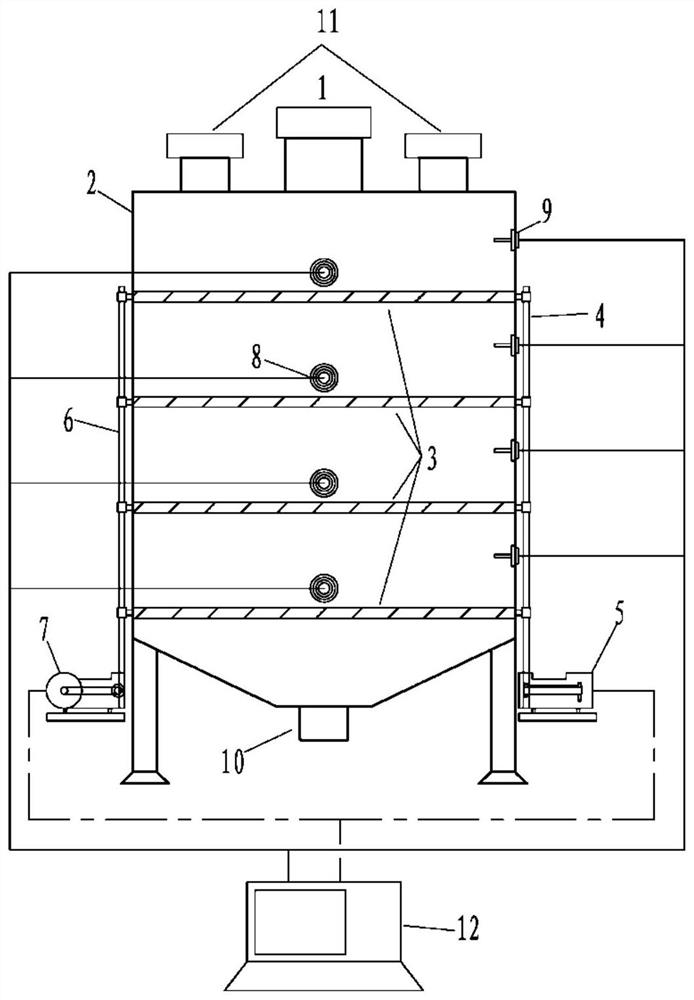

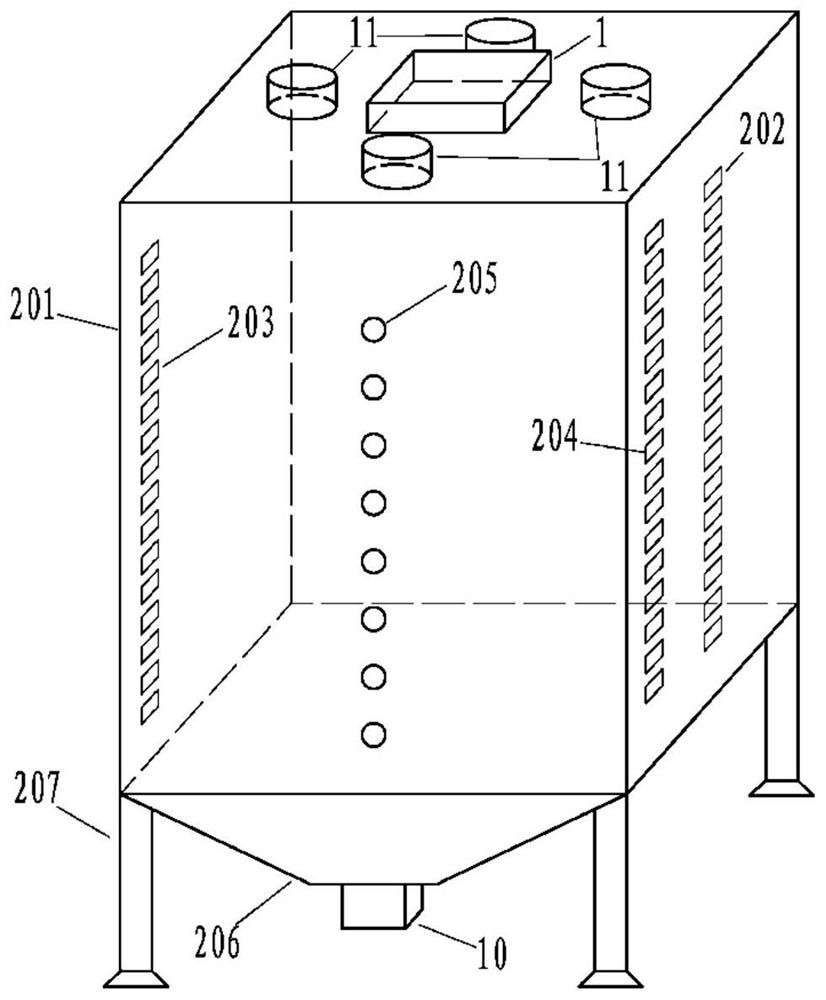

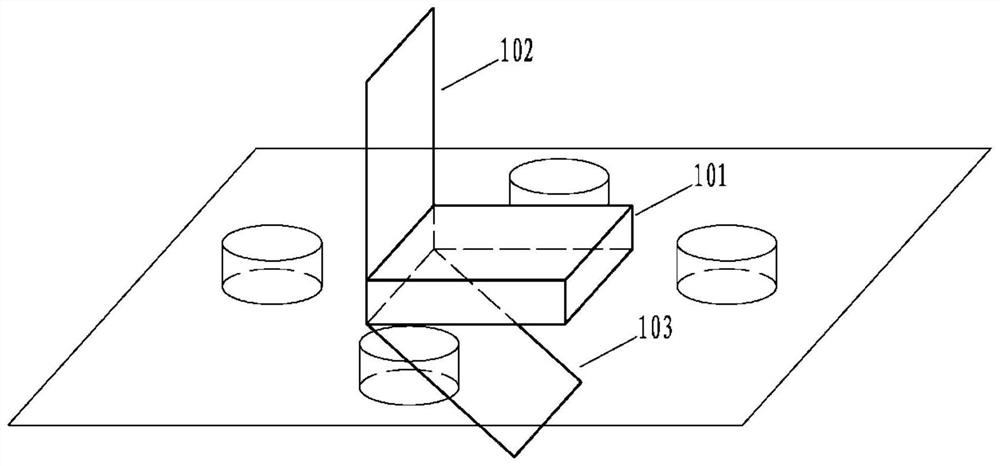

Thermal cycle accurate temperature control gradient carbonization equipment and method for sludge treatment

PendingCN112939396AReduce viscosityPromote carbonizationSludge treatment by pyrolysisByproduct vaporizationTemperature controlSludge

The invention discloses thermal cycle accurate temperature control gradient carbonization equipment and a method for sludge treatment. According to the equipment, more than one vibration turning plate is arranged in the furnace body of the vertical sludge carbonization equipment, the vibration turning plates are arranged vertically, a heating device is arranged on the outer wall surface of the equipment, and heating ports of the heating device are positioned on the two sides of the vibration turning plate; the vibration turning plate has the effects of vibrating and turning the sludge on the plate surface; the heating device enables the temperature in the equipment to have gradient transformation, and hot air flow in the equipment circularly flows in the equipment. The vertical structure plays a role in internal circulation of heat, the heating device enables the temperature in the equipment to have gradient transformation, hot air in the equipment flows in an internal circulation mode, sludge on the topmost layer falls into the next layer after being pyrolyzed at the highest temperature, and the lower layer enables the sludge to be continuously heated. The equipment also has an incineration mode, and the sludge can be incinerated.

Owner:博仕燊环保科技(广州)有限公司

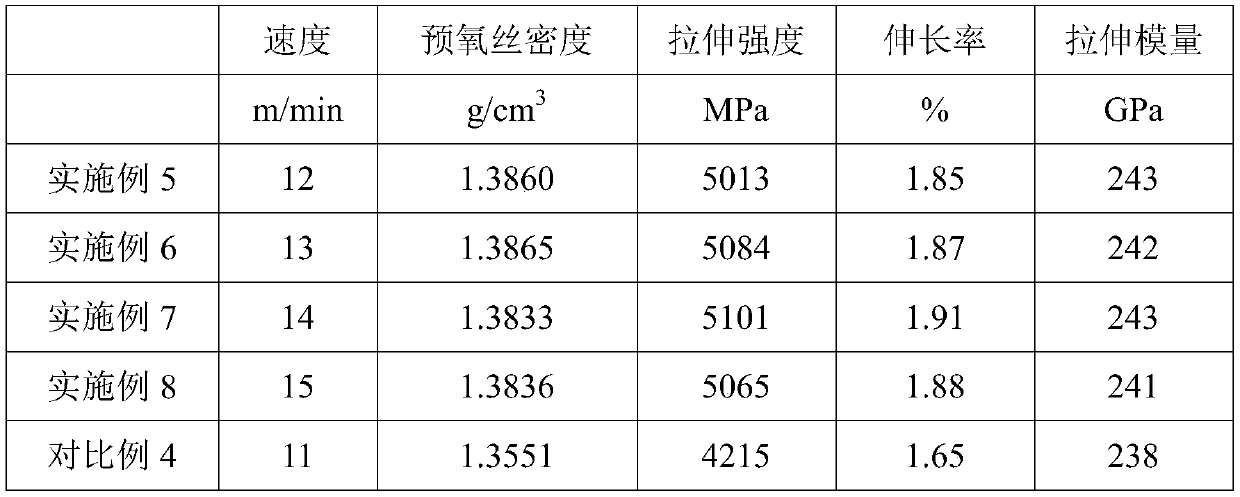

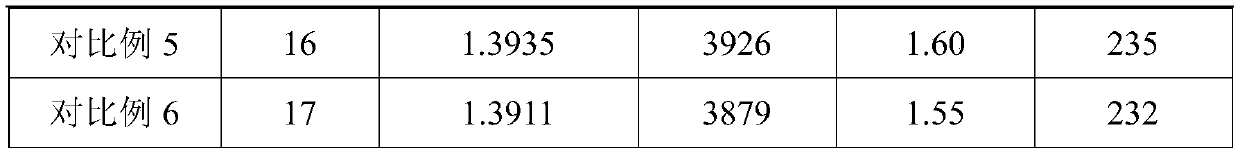

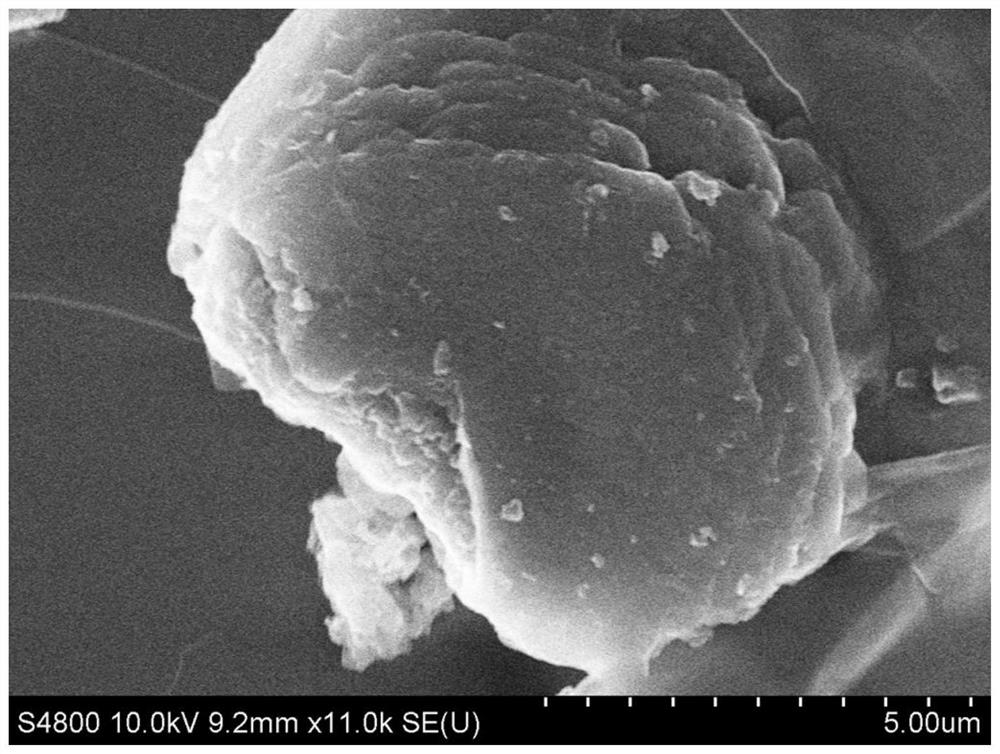

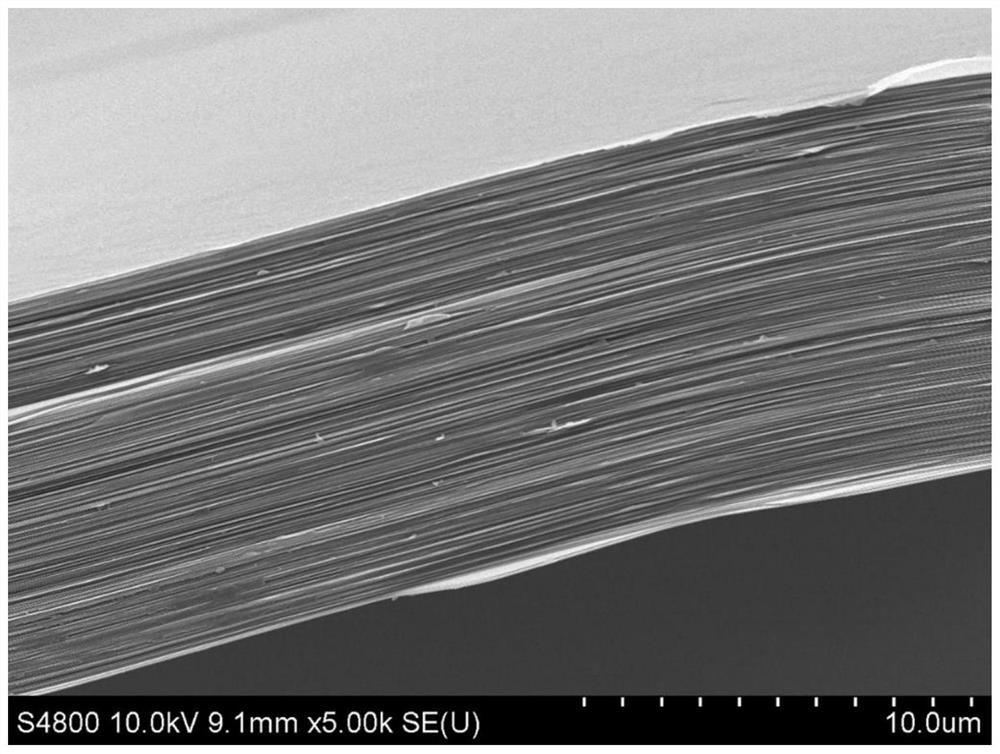

High-speed preparation method for producing large-tow carbon fibers

ActiveCN111020750AImprove performanceGuaranteed performanceFibre chemical featuresPolymer scienceCarbon fibers

The invention provides a high-speed preparation method for producing large-tow carbon fibers, and belongs to the technical field of preparation of large-tow carbon fiber materials. The method comprises the following steps of pre-oxidizing large-tow polyacrylonitrile copolymer fibers in an air atmosphere at the temperature of 220-300 DEG C, and performing heat treatment in an oxidation furnace in asix-gradient temperature rising mode for 45-90 minutes to obtain pre-oxidized filaments of tow carbon fibers, wherein the temperature gradient is 9+ / -3 DEG C, the production speed is 12-15m / min, andthe draw ratio is 0.98-1.20; performing low-temperature carbonization treatment on the pre-oxidized filaments; and performing high-temperature carbonization treatment on the carbon fibers subjected tolow-temperature carbonization treatment to obtain the large-tow carbon fibers. The tensile strength of the prepared carbon fibers is over 5,000 MPa, and the modulus is 240-250 GPa.

Owner:CHANGCHUN UNIV OF TECH +1

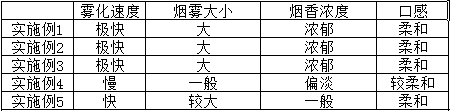

Application of heating aid in heat-not-burn fuming material and product

ActiveCN111194941ALower the onset pyrolysis temperatureFully carbonizedTobacco treatmentFiberCarbonization

The invention discloses an application of a heating aid in a heat-not-burn fuming material and the product; the heating aid is sylvite or a mixture of sylvite and sodium salt, and the heating aid is added into the heat-not-burn fuming material. The heating aid is applied to the heat-not-burn fuming material, so that the pyrolysis state of the fuming material is changed, the initial pyrolysis temperature of the fuming material is reduced, the fuming material is carbonized more fully, wood miscellaneous odor caused by incomplete carbonization of fibers is reduced, and fragrant substances are released more completely.

Owner:深圳新火瑞升技术有限公司

Method for full utilization of sodium chloride waste salt residue as resources by combining low-temperature roasting and interface regulating

ActiveCN109455741AEfficient carbonizationFully carbonizedCarbon preparation/purificationAlkali metal chloridesRoom temperatureHexane

The invention discloses a method for full utilization of sodium chloride waste salt residue as resources by combining low-temperature roasting and interface regulating. The method comprises the following steps of (1) roasting the sodium chloride waste salt residue, cooling to room temperature, adding water into solid after cooling, stirring, and completely dissolving, so as to obtain a solution; (2) using the solution obtained in step (1), stirring, adding n-hexane and sodium oleate, standing and delaminating after adding, separating the liquids at upper layer and lower layer, drying the liquid at upper layer, and recycling, so as to obtain carbon; (3) using the separated liquid at lower layer in step (2), stirring, adding sodium carbonate, standing after adding, filtering, drying the filter residue after filtering, and recycling; (4) adding hydrochloric acid into the filtered solution in step (3), standing, heating, separating the separated crystal after heating, and drying. The method has the advantages that the technology is simple, the cost is low, the effect is quickly taken, the treatment amount is large, the purifying is thorough, and all waste salt can be utilized.

Owner:SOUTH CHINA UNIV OF TECH

High-graphitization graphite thick film and preparation method thereof

The invention discloses a high-graphitization graphite thick film and a preparation method thereof, and belongs to the technical field of graphite thick films. The method firstly prepares a nanosheet material doped polyimide film, and then sequentially carrying out carbonization treatment and graphitization treatment on the film to obtain a high-graphitization graphite thick film. The process is simple, spraying is not needed in the preparation process, practicability is high, energy is saved, industrial production is easy to achieve, and wide industrial prospects are achieved. The graphite thick film prepared by adopting the method is light in weight and has flexibility, the introduction of a nanosheet material is beneficial to improving the graphitization degree in the polyimide thick film, and the problems that a finished product is fragile, the internal graphitization is incomplete and the like are solved, so that the electric conduction and heat conduction properties of the finished product are improved, and the application range of the finished product is widened.

Owner:SUN YAT SEN UNIV

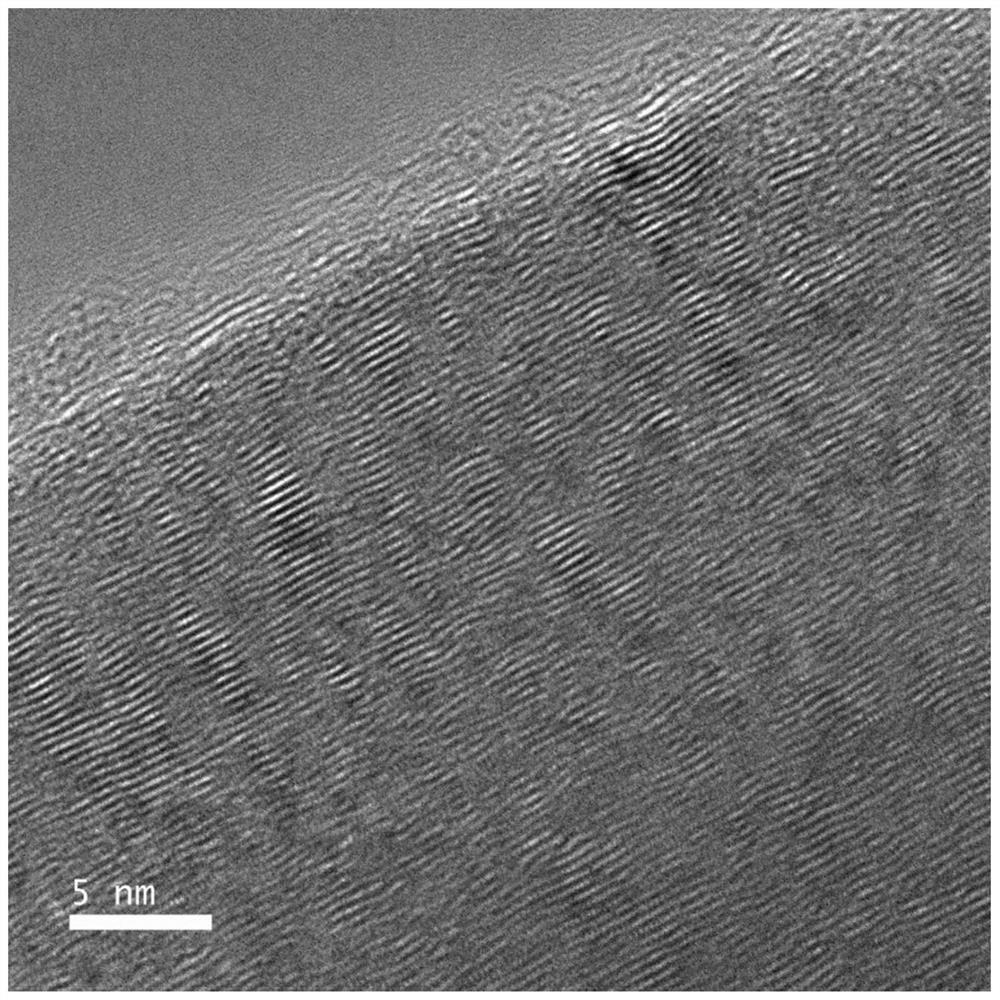

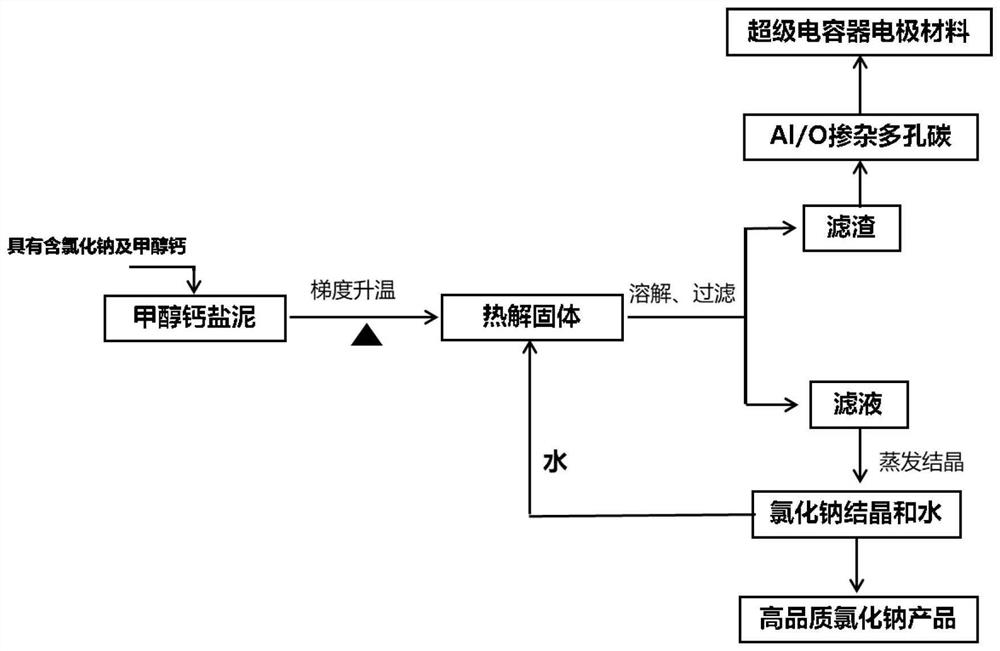

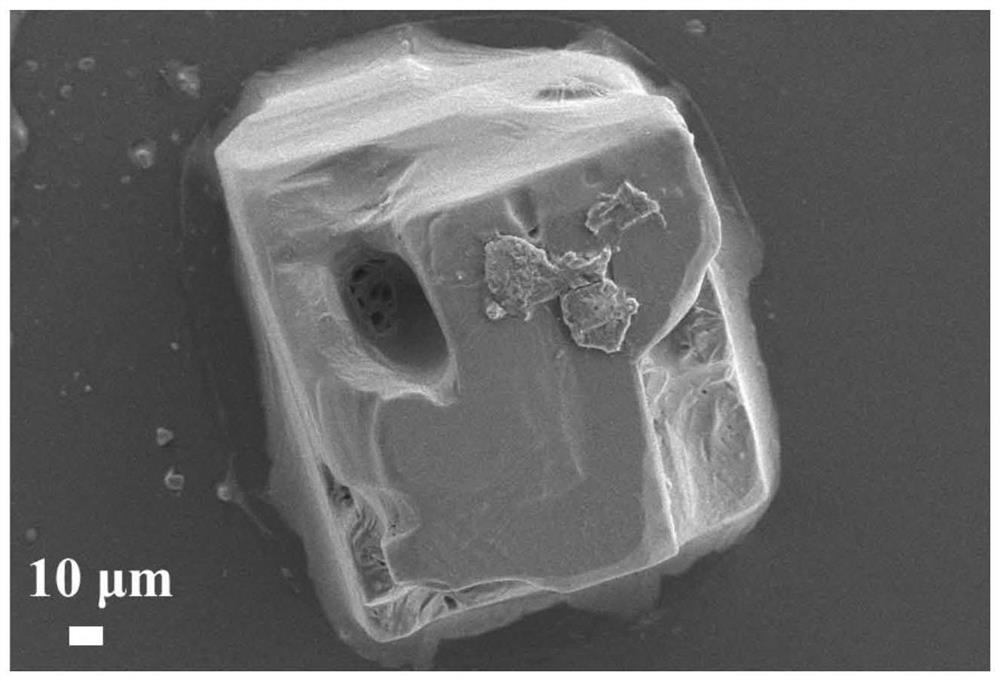

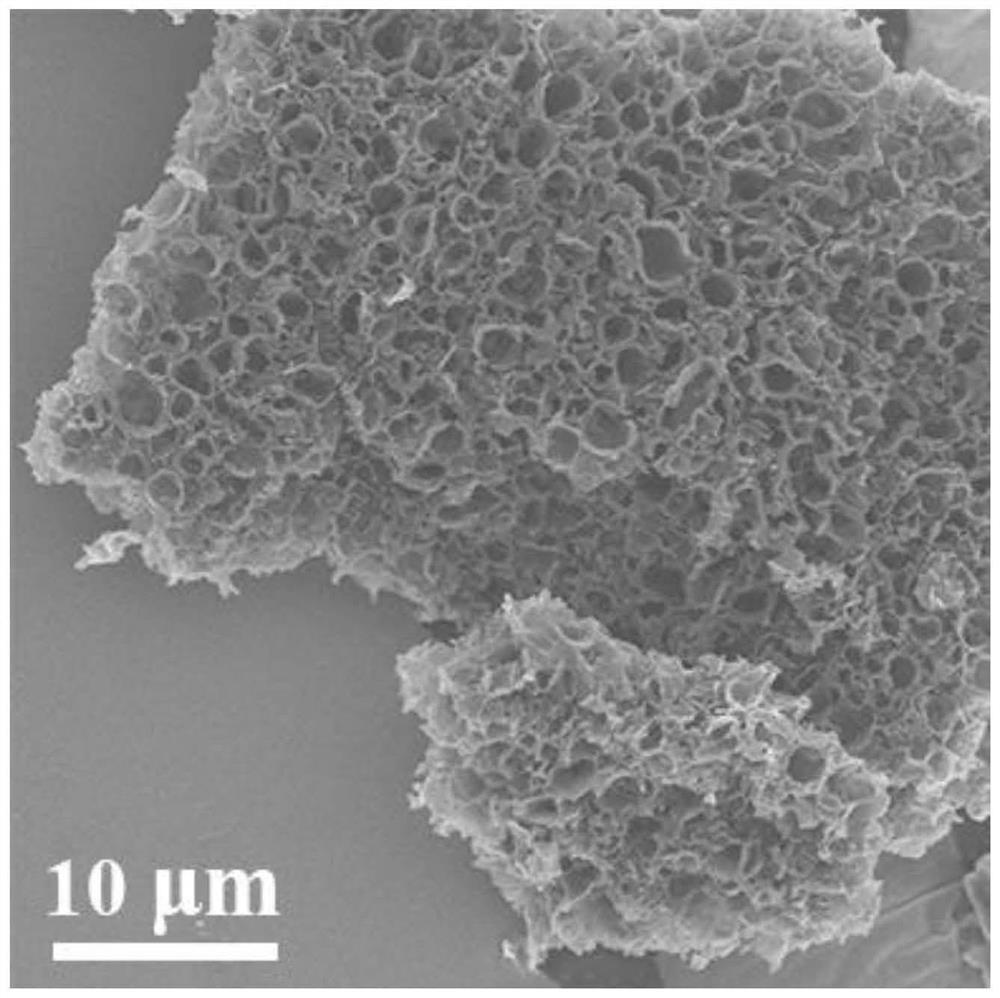

Method for purifying sodium chloride and preparing doped carbon by pyrolyzing organic waste salt

PendingCN114014338AEfficient carbonizationFully carbonizedCarbon preparation/purificationAlkali metal halide purificationTube furnacePhysical chemistry

The invention discloses a method for purifying sodium chloride and preparing doped carbon by pyrolyzing organic waste salt. The method comprises the following steps of: (1) fully grinding waste calcium methoxide salt, and sieving; (2) putting the uniform-texture waste calcium methoxide salt obtained in the step (1) into a tubular furnace, and pyrolyzing in an inert atmosphere; (3) adding water into the pyrolysis solid cooled to the room temperature in the step (2), stirring to completely dissolve the pyrolysis solid, and standing for layering to obtain upper-layer liquid and the lower-layer liquid; (4) filtering and separating the upper-layer liquid and the lower-layer liquid obtained in the step (3), and drying and recycling filter residues obtained after the upper-layer liquid is filtered to obtain an Al / O doped carbon material; and (5) evaporating and crystallizing the filtrate obtained in the step (4) and the lower-layer liquid obtained in the step (3), and further drying, separating and heating to separate out sodium chloride crystals. The method is simple in process, low in cost and large in treatment capacity, and can realize high-value utilization of waste salt.

Owner:CHINA-SINGAPORE INT JOINT RES INST

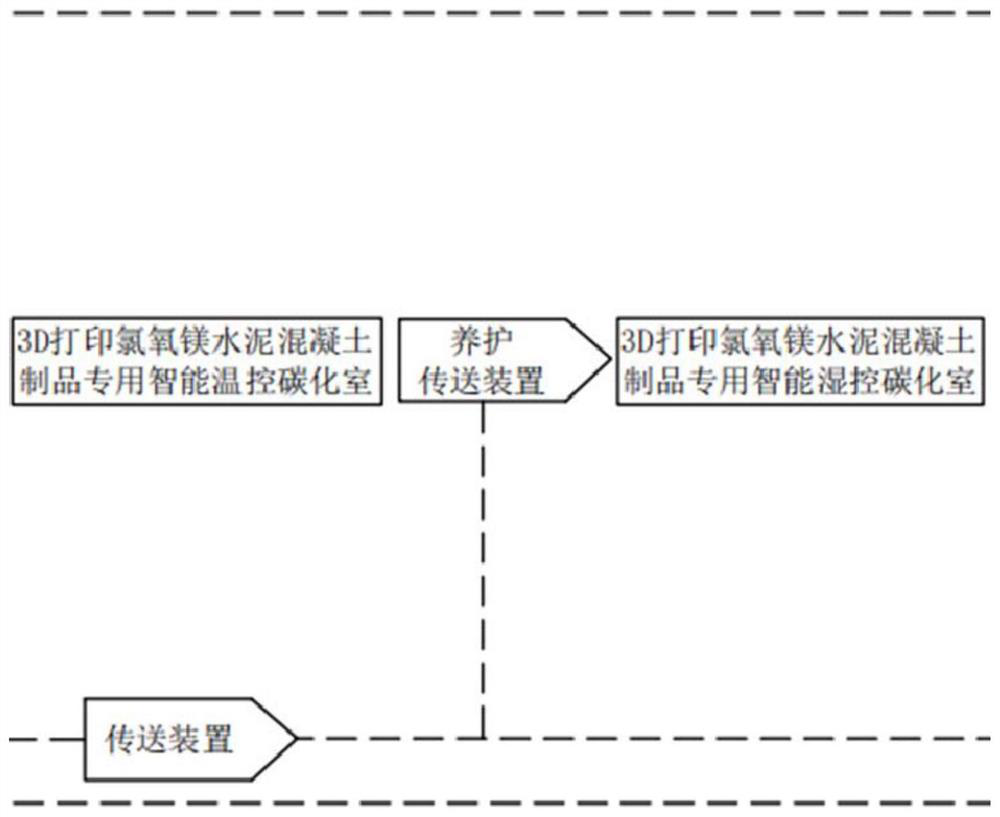

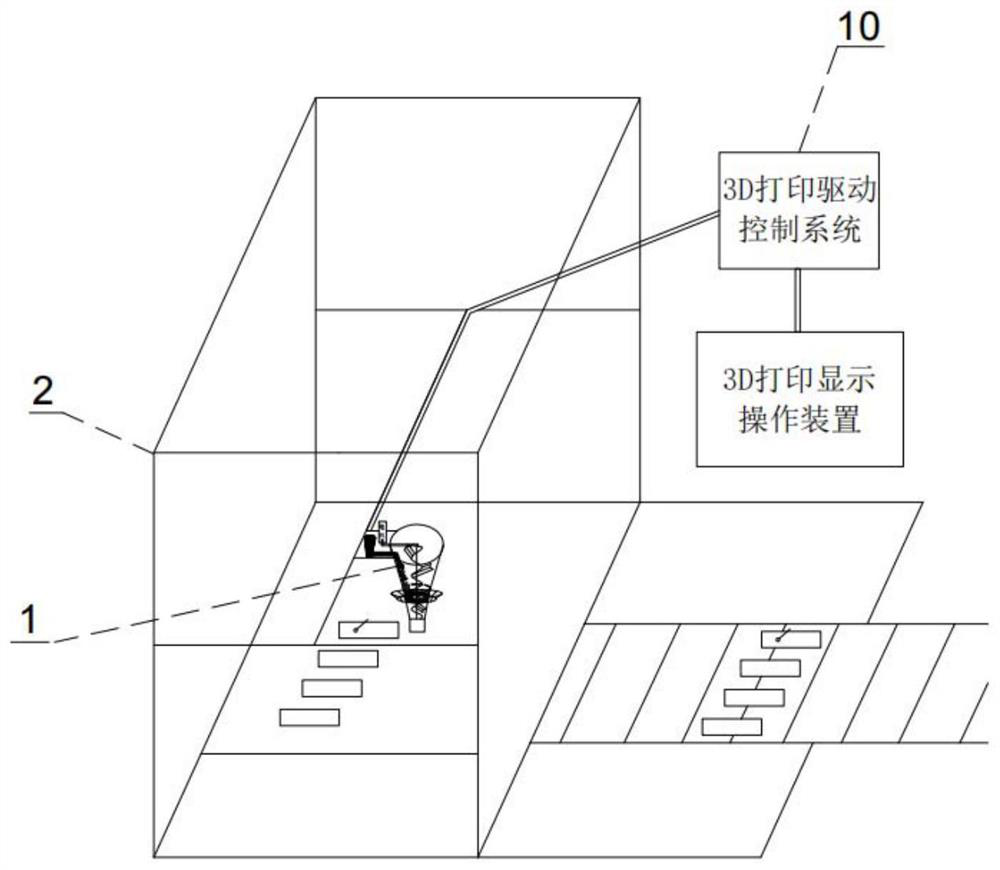

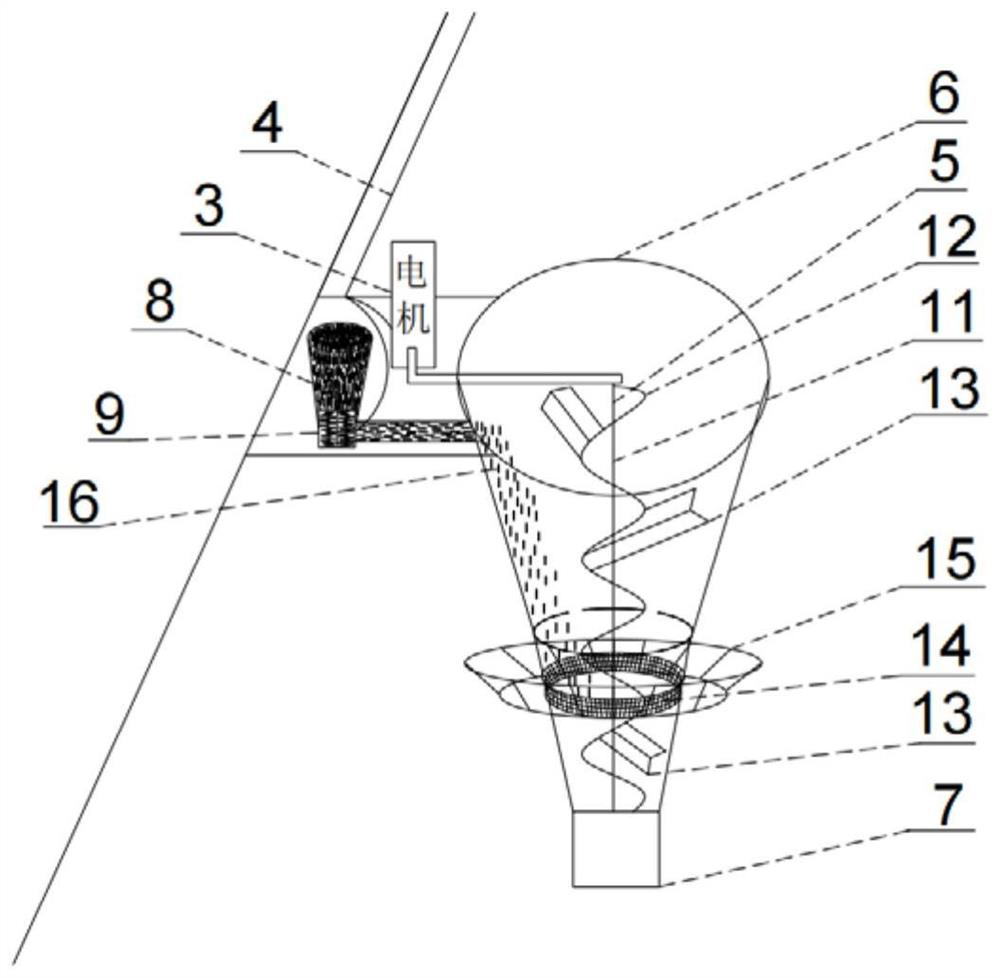

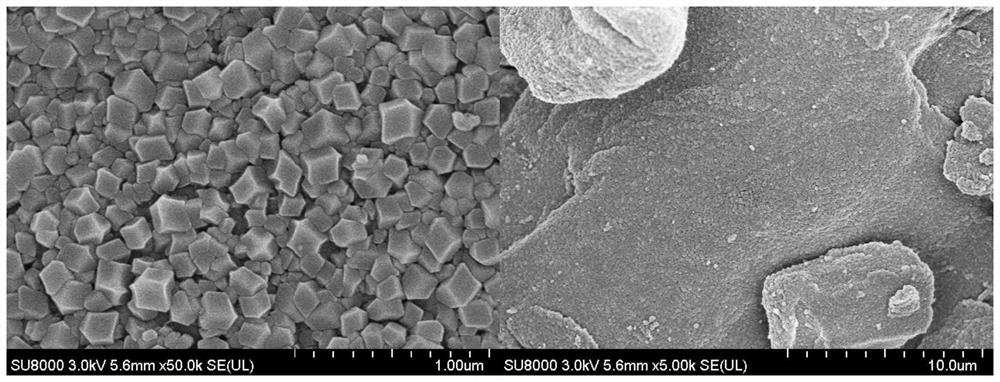

3D printing magnesium oxychloride cement concrete product and maintenance method thereof

ActiveCN113213882AImprove the level of industrializationPromote engineering applicationAdditive manufacturing apparatusSolid waste managementSteelmakingSlurry

The invention discloses a 3D printing magnesium oxychloride cement concrete product and a maintenance method thereof. The magnesium oxychloride cement concrete product comprises the following raw materials in parts by weight: 100 parts of light calcined magnesia, 100-150 parts of magnesium-based standard sand, 0-70 parts of water granulated slag sand, 130-200 parts of magnesium chloride hexahydrate, 0-40 parts of engineering residue soil, 0.5-10 parts of an additive, 10-30 parts of dry ice and 30-60 parts of water. According to the method, the dry ice is added into the magnesium oxychloride cement mortar additive newly-mixed slurry, the temperature of the newly-mixed slurry before final setting of magnesium oxychloride cement is reduced at low cost, carbon dioxide gas is conveniently introduced into the magnesium oxychloride cement newly-mixed slurry, magnesium hydroxide generated by reaction is fully carbonized, and the carbonization degree of the magnesium oxychloride cement newly-mixed slurry is remarkably improved; and the water granulated slag sand and the engineering residue soil generated by steelmaking are directly added into a magnesium oxychloride cement concrete product, resource utilization is achieved, the magnesium oxychloride cement mortar additive is used for 3D printing, and engineering application of magnesium oxychloride cement is promoted.

Owner:SHENZHEN UNIV

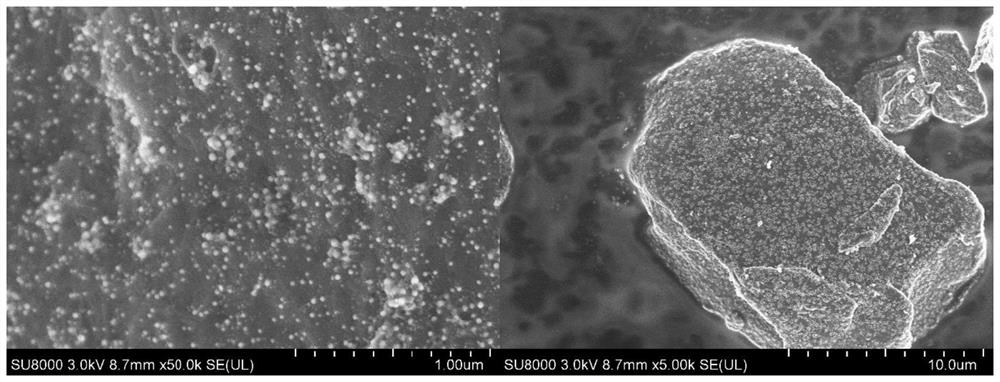

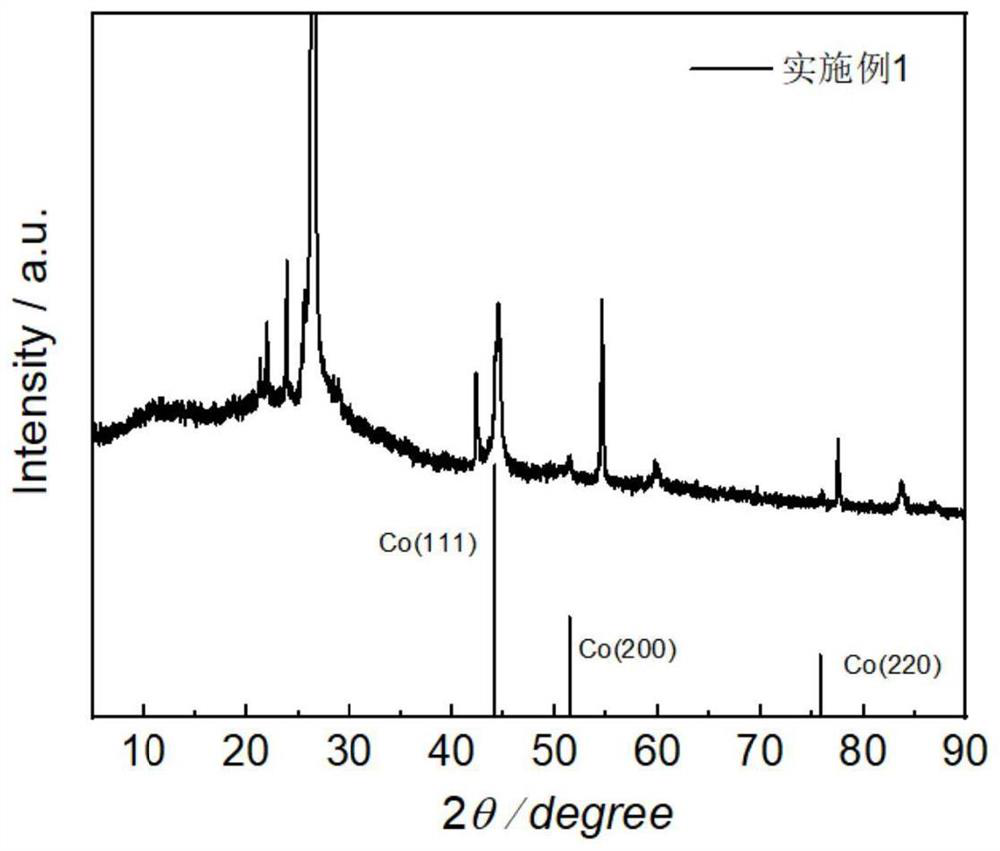

Graphite negative electrode material for low temperature, preparation method thereof and lithium battery

ActiveCN114335462AEasy transferReasonable designGraphiteCell electrodesElectrolytic agentPorous carbon

The invention discloses a graphite negative electrode material used at low temperature, a preparation method thereof and a lithium battery, and the graphite negative electrode material is prepared by the following steps: constructing a nitrogen-containing organic metal framework compound containing cobalt on the surface of graphite to obtain a graphite material of the nitrogen-containing organic metal framework compound coated with cobalt; and carrying out pyrolysis treatment on the graphite material of the nitrogen-containing organic metal framework compound coated with cobalt to obtain the graphite negative electrode material used at low temperature. The surface of the graphite negative electrode material has a porous structure, and the porous structure is beneficial to infiltration and liquid retention of an electrolyte, strengthens liquid-phase transportation of Li < + >, and enhances the feasibility of the graphite negative electrode material in use at low temperature. Meanwhile, the surface of the graphite negative electrode material contains elemental cobalt, a cobalt-nitrogen multi-element ligand and graphitized porous carbon, and the composition is beneficial to charge transmission. And the lithium ion battery can be normally used in an environment of-40 DEG C to 50 DEG C, so that the application in a low-temperature scene is effectively met.

Owner:SHAANXI COAL & CHEM TECH INST +1

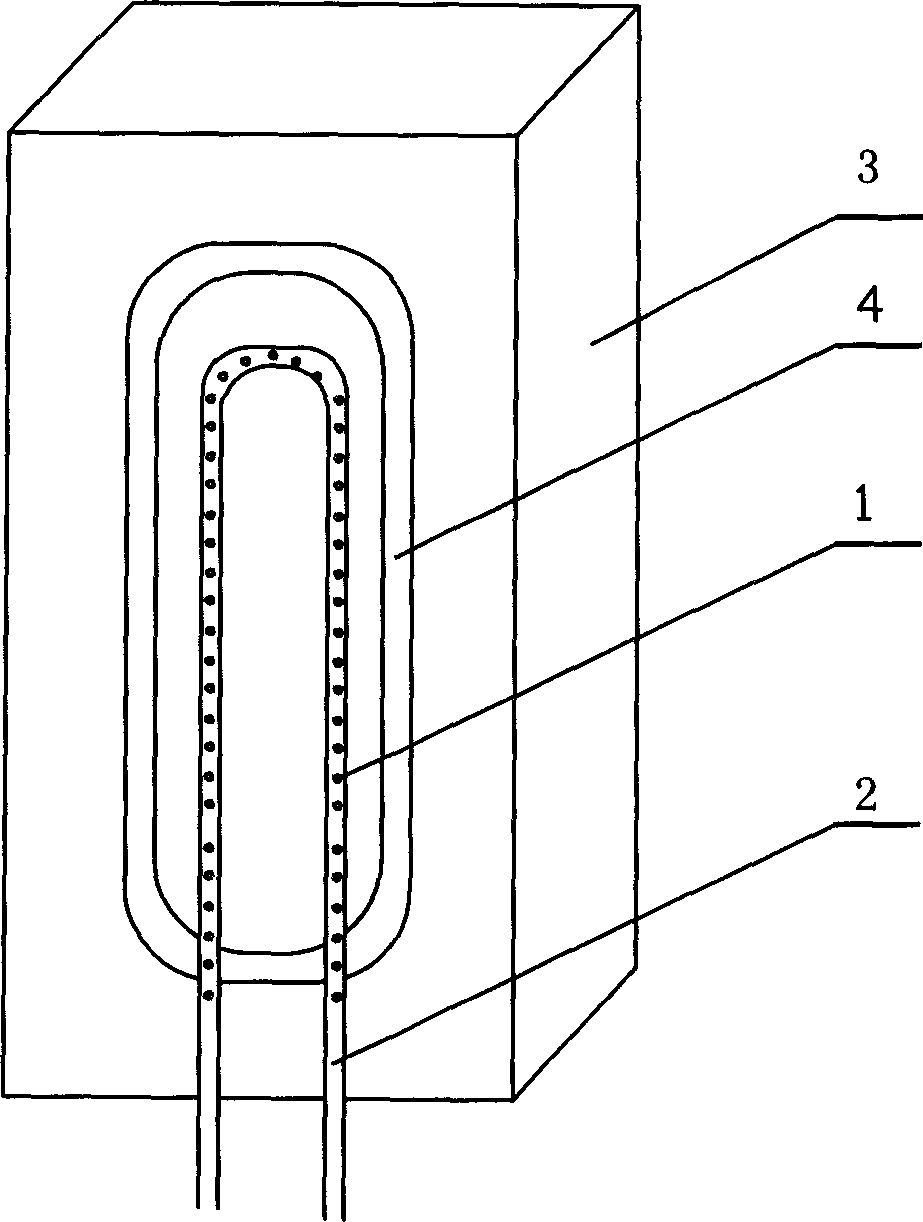

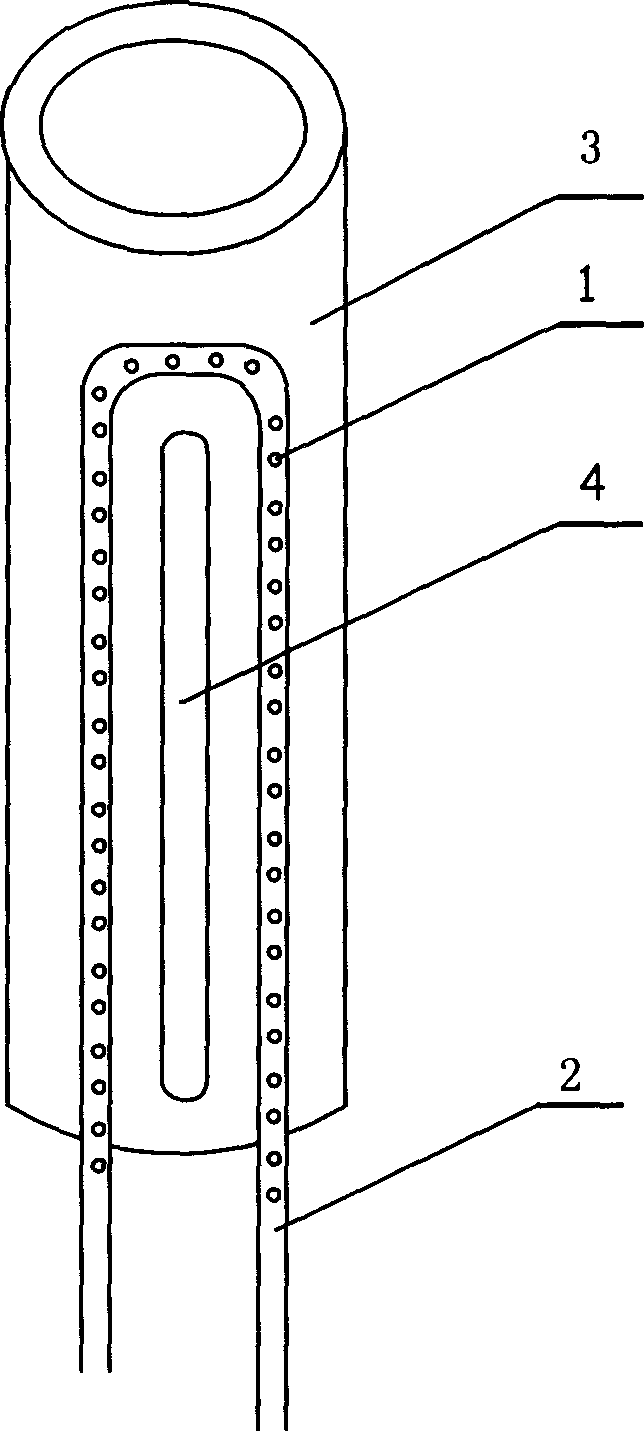

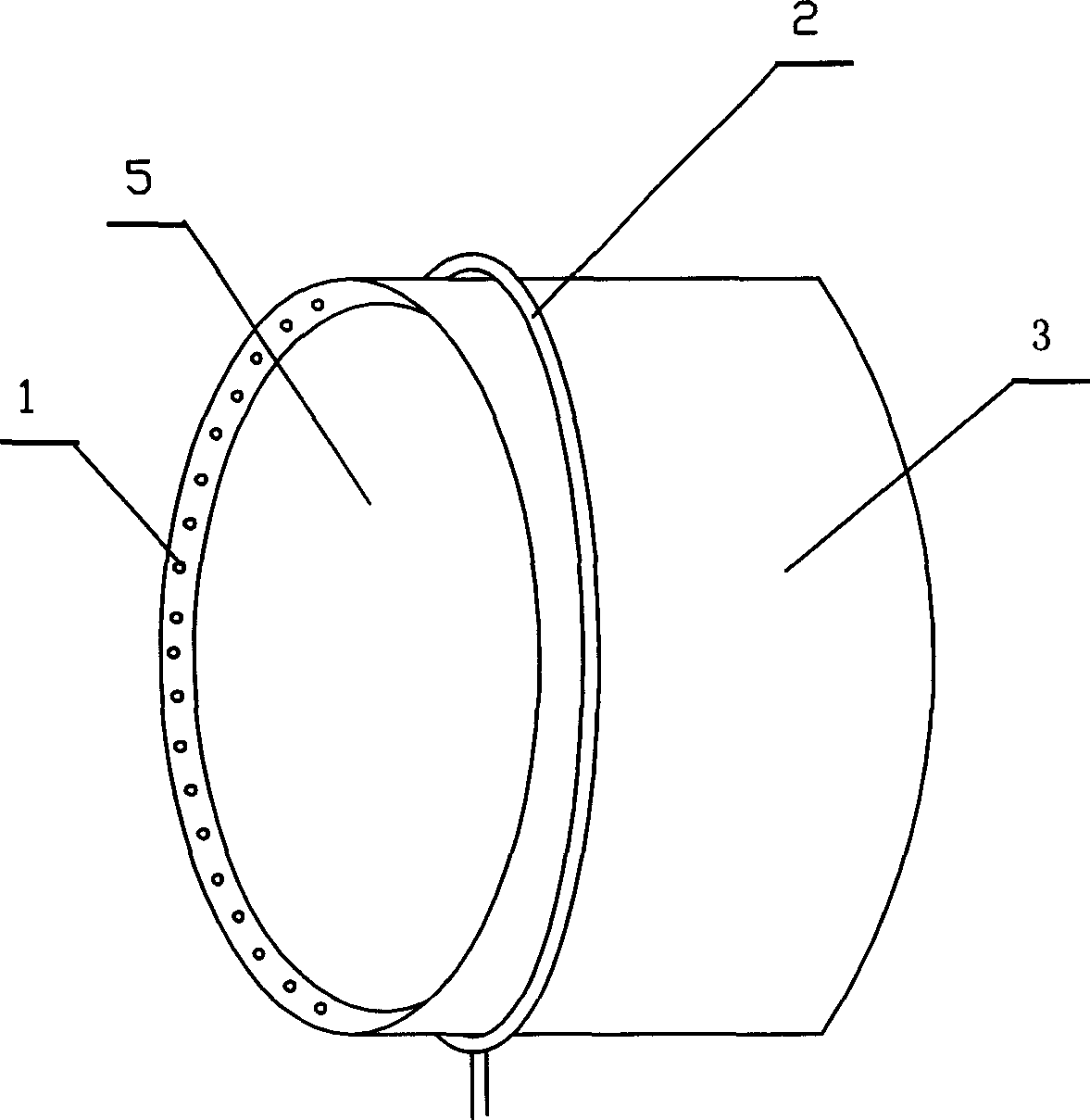

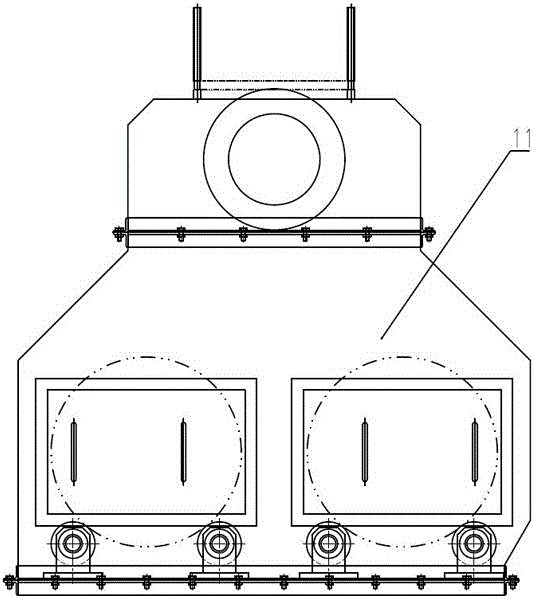

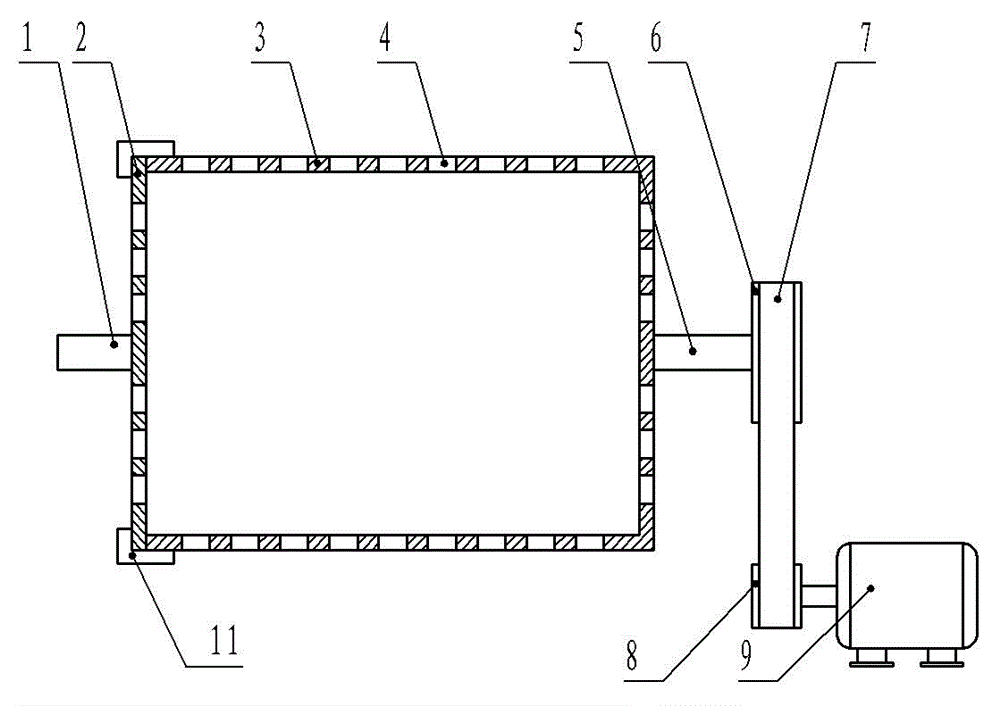

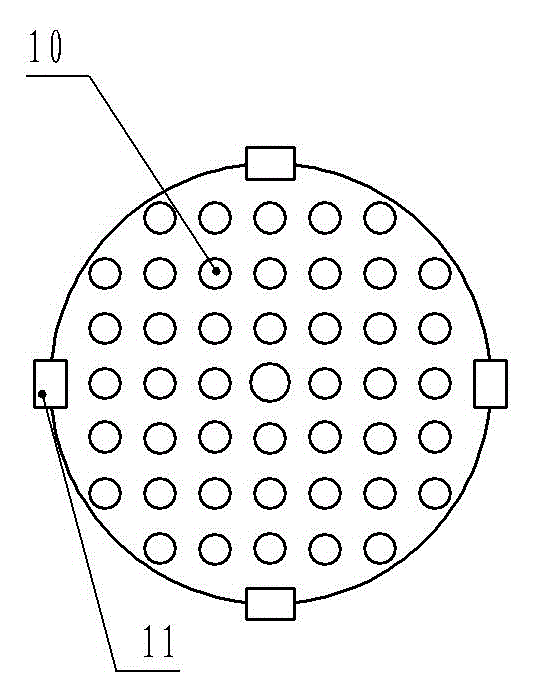

Reconsolidated bamboo floor carbonization apparatus

The present invention discloses a reconsolidated bamboo floor carbonization apparatus, and relates to the technical field of bamboo product manufacture. The reconsolidated bamboo floor carbonization apparatus comprises a cylindrical shell; the cylindrical shell is a cylinder with one end open and the other end closed; the cylindrical shell is provided with a plurality of through holes; the middle portion of an outer side of the closed end is provided with a driving shaft; a free end of the driving shaft is provided with a driven pulley; a lower portion of the driven pulley is provided with a motor; an output shaft of the motor is provided with a driving pulley; a belt is connected between the driven pulley and the driving pulley; the open end of the cylindrical shell is provided with a cylinder cover; the cylinder cover is provided with a plurality of through holes; and the middle portion of an outer side of the cylinder cover is provided with a driven shaft. According to the reconsolidated bamboo floor carbonization apparatus, the problem that in an existing reconsolidated bamboo floor carbonization apparatus, contact of a bamboo fiber board and steam is insufficient, and the carbonization effect is poor can be solved.

Owner:LIUZHOU LONGTAI BAMBOO IND CO LTD

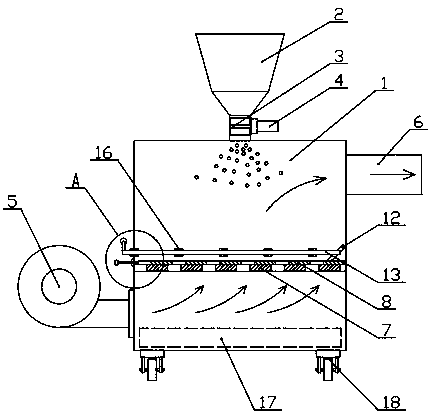

Charcoal production machine

The invention relates to the technical field of recycling and environment protection, and discloses a charcoal production machine, which comprises a housing, a shaft, a motor, and a liquid storage tank for containing adhesive, the motor is connected to the shaft, the housing is cylindrical, both ends of the housing are open, the shaft is rotatably connected into the housing, the shaft is coaxial with the housing, a carbonizing screw and an extruding screw are arranged on the shaft, a first agitator and a second agitator are arranged on the shaft, the housing is provided with a liquid inlet corresponding to the second agitator, the liquid inlet communicates with a duct, the duct communicates with the liquid storage tank, the extruding screw section is tapered, the part, which corresponds to the extruding screw, of the housing is tapered to be matched with the extruding screw section, and a heater is arranged at a position, which corresponds to the carbonizing screw, on the inner wall of the housing; further comprised is a feed channel, one end, which is close to the carbonizing screw, of the housing communicates with the interior of the feed channel, and a grinding mechanism and a screen are arranged in the feed channel. The invention is intended to provide the charcoal production machine which utilizes wood chips to produce compact charcoal rods, the interiors of which are sufficiently carbonized.

Owner:MINGFENG DOORS

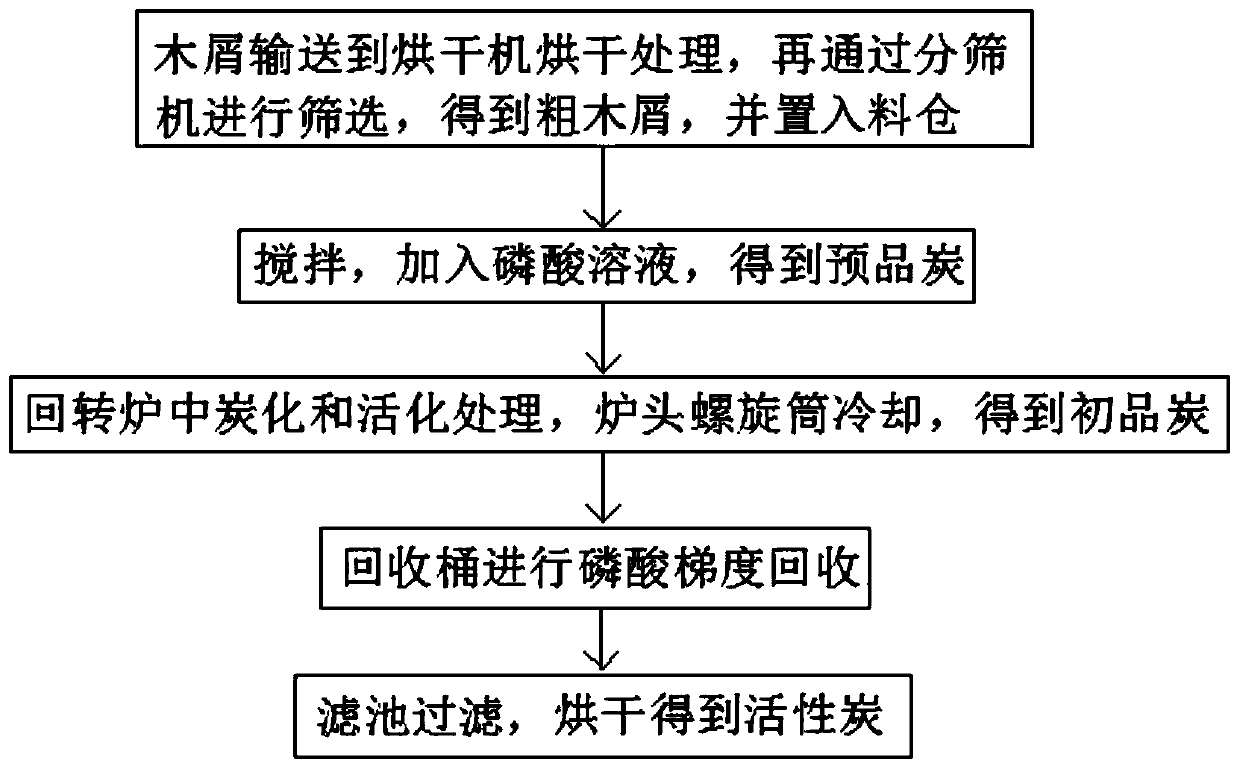

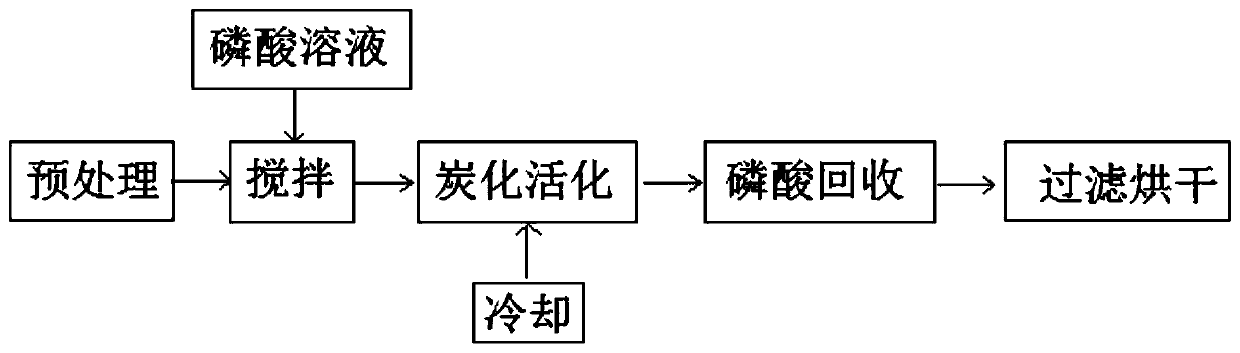

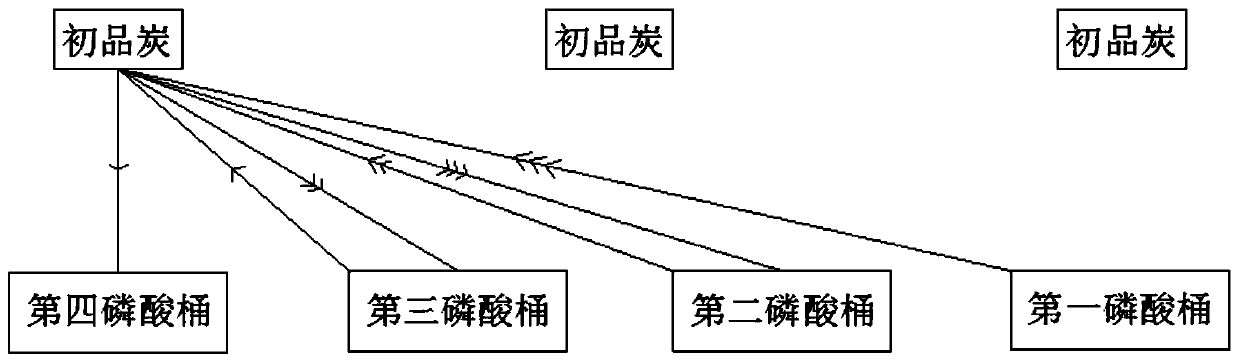

Phosphoric acid method active carbon production method

The invention discloses a phosphoric acid method active carbon production method, which comprises the following steps: S1, pretreatment: conveying wood chips to a dryer, carrying out drying treatment,screening the wood chips through a screening machine to obtain coarse wood chips, and putting the coarse wood chips into a material bin; S2, stirring: conveying the coarse wood chips from the material bin to a double-auger device, stirring, and adding a phosphoric acid solution into the double-auger device to obtain a pre-product wood chips; S3, carbonizing and activating: conveying the pre-product carbon into a rotary furnace through a belt conveyor, carrying out carbonization and activation treatment, arranging a spiral cylinder at the furnace head of the rotary furnace, and cooling to obtain a primary product carbon; S4, phosphoric acid recovery: conveying the primary product carbon into a recovery barrel, and carrying out phosphoric acid gradient recovery; and S5, dehydrating drying:introducing the primary product carbon into a filter tank, filtering, and finally drying to obtain the active carbon. According to the invention, waste can be effectively utilized, and the productioncost can be greatly reduced by recovering phosphoric acid.

Owner:JINGZHOU HUARONG ACTIVATED CARBON CO LTD

Porous charcoal adsorbent and preparation method of same

InactiveCN108940195AEasy to makeMild conditionsGas treatmentOther chemical processesSorbentCatalytic effect

The invention discloses a porous charcoal adsorbent produced from, by weight, 3-5 parts of biomass powder, 1-2 parts of mixed acid liquid, 5-8 parts of nitric acid, and 3-5 parts of a manganese nitrate solution. A method includes: weighing the raw materials, soaking the biomass powder in the mixed acid liquid and washing the biomass powder with 95 vol% ethanol for 2-3 times; carbonizing the cleaned biomass powder and washing the carbonized product with water, thus preparing a carbon substrate; acidifying the carbon substrate with the nitric acid and drying the carbon substrate, and soaking thecarbon substrate in the manganese nitrate solution; finally calcining the carbon substrate to prepare the porous charcoal adsorbent. In the invention, adsorption effect and large specific surface area of the active charcoal and catalytic effect of the manganese oxide are effectively combined, so that the product has great adsorption effect and catalytic activity, can effectively reduce concentration of organic waste gas and finally degrades the harmful gas.

Owner:马鞍山中粮生物化学有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com