MXene/sodium alginate derived carbon three-dimensional aerogel as well as preparation method and application thereof

A technology of sodium alginate and airgel, applied in the field of airgel, can solve the problems such as the inability to form three-dimensional gel materials, and achieve the effects of promoting ion diffusion and electron transmission, promoting exposure, and retaining activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Weigh 100mg of sodium alginate powder in 20ml of deionized water and stir at 50°C for 2h to obtain a concentration of 5mgml -1 aqueous sodium alginate solution. Weigh 100mg of calcium chloride in 50ml of deionized water and stir for 10min to obtain a concentration of 2mgml -1 aqueous calcium chloride solution.

[0033] (2) Measure 38.5ml Ti 3 C 2 T x MXene dispersion (2.6mg ml -1 ), adding 10 ml of sodium alginate aqueous solution (50 mg), and stirring for 1 h to obtain a mixed solution of MXene / sodium alginate. Add 12.5ml calcium chloride solution (25mg), let stand for 10min, carry out freeze-drying subsequently, obtain MXene / sodium alginate hydrogel (mass ratio, MXene:sodium alginate=2:1; Sodium alginate:calcium chloride =2:1).

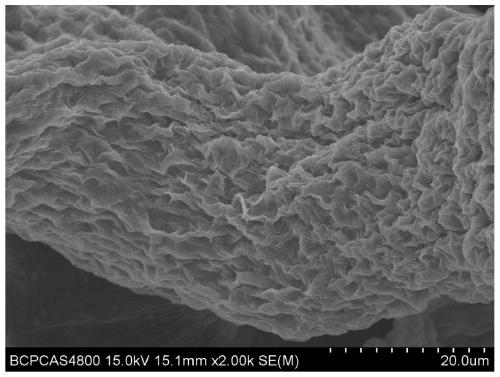

[0034] (3) Put Ti 3 C 2 T x / Sodium alginate hydrogel was treated at 500 ° high temperature for 2 h under argon atmosphere. Then the product was soaked in 1 mol / L hydrochloric acid solution for 1 h, washed with deionized wate...

Embodiment 2

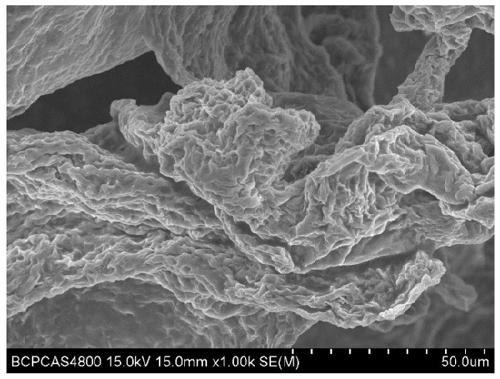

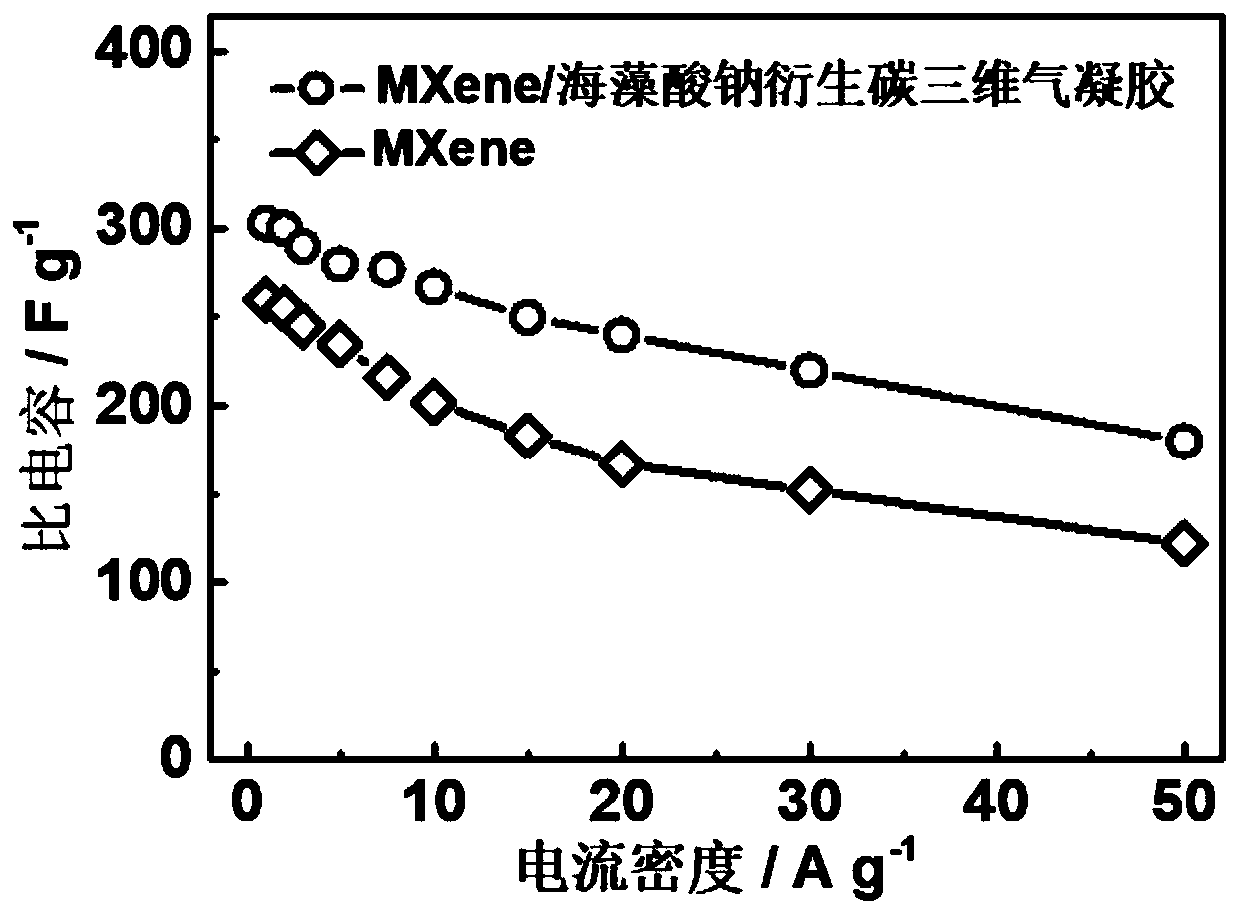

[0041] Other conditions were the same as in Example 1, except that 2 ml of sodium alginate aqueous solution (10 mg) was added, and after stirring for 1 h, a mixed solution of MXene / sodium alginate was obtained. 5ml of calcium chloride solution (10mg) was added, allowed to stand for 10min, and then freeze-dried to obtain MXene / sodium alginate hydrogel. (mass ratio, MXene: sodium alginate=10:1; sodium alginate: calcium chloride=1:1). Nitrogen adsorption / desorption test results show that the specific surface area of the MXene / sodium alginate carbon three-dimensional airgel reaches 156 m 2 / g, the pore volume is 3.8cm 3 / g, the pore size is 50nm. The morphology of MXene / sodium alginate derived carbon airgel materials was observed, as shown in image 3 shown. Even if the mass ratio of MXene to sodium alginate is as high as 10:1, the three-dimensional structure can still be maintained through sodium alginate gelation, which is beneficial to inhibit the stacking of MXene sheets...

Embodiment 3

[0045] Other conditions were the same as in Example 1, except that 1 ml of sodium alginate aqueous solution (5 mg) was added, and MXene / sodium alginate solution was obtained after stirring for 1 h. Add 2.5ml calcium chloride solution (5mg), leave standstill 10min, carry out freeze-drying subsequently, obtain MXene / sodium alginate hydrogel (mass ratio, MXene:sodium alginate=20:1; Sodium alginate:calcium chloride =1:1). Nitrogen adsorption / desorption test results show that the specific surface area of the MXene / sodium alginate carbon three-dimensional airgel reaches 136m 2 / g, the pore volume is 3.4cm 3 / g, the pore size is 80nm. At a current density of 1 A / g, the MXene / sodium alginate-derived carbon airgel exhibited a specific capacitance of 371 F / g, and the capacity remained at 238 F / g at a current density of 50 A / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com