Small domestic garbage pyrolysis gasifying furnace and purifying system

A technology of pyrolysis and gasification of domestic waste, applied in the direction of incinerator, gas treatment, combustion type, etc., to achieve high moisture content, low slump, and good tail gas treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

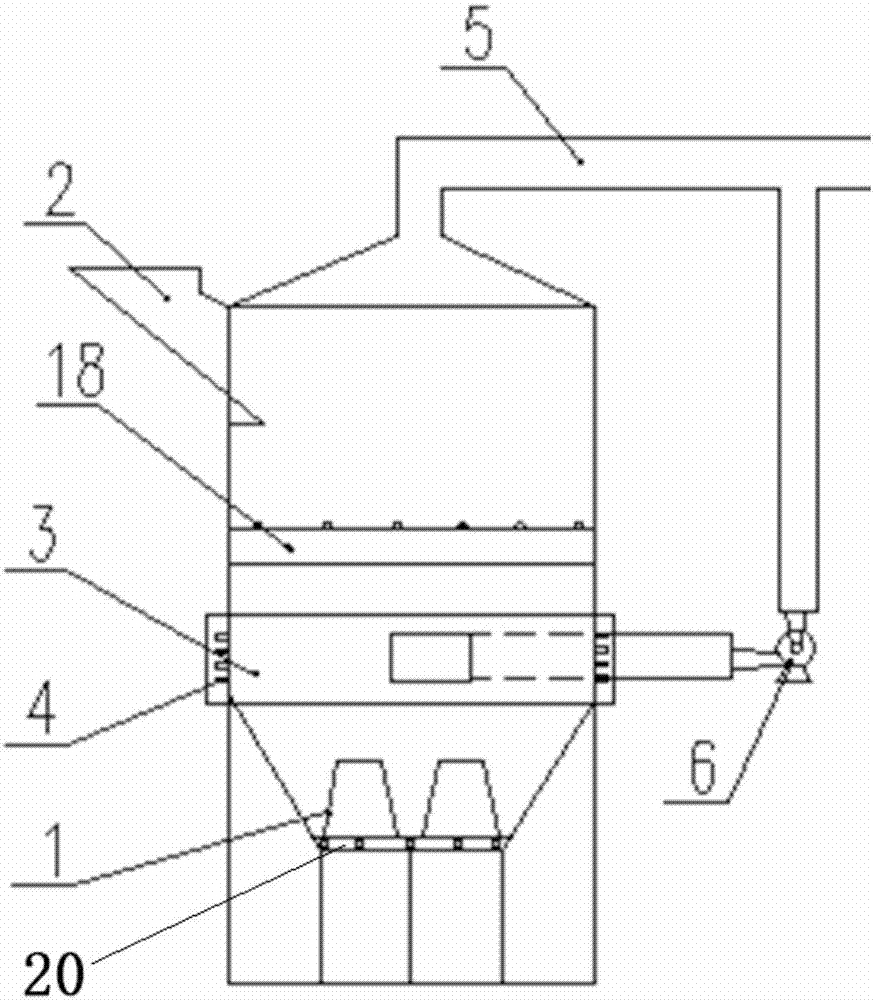

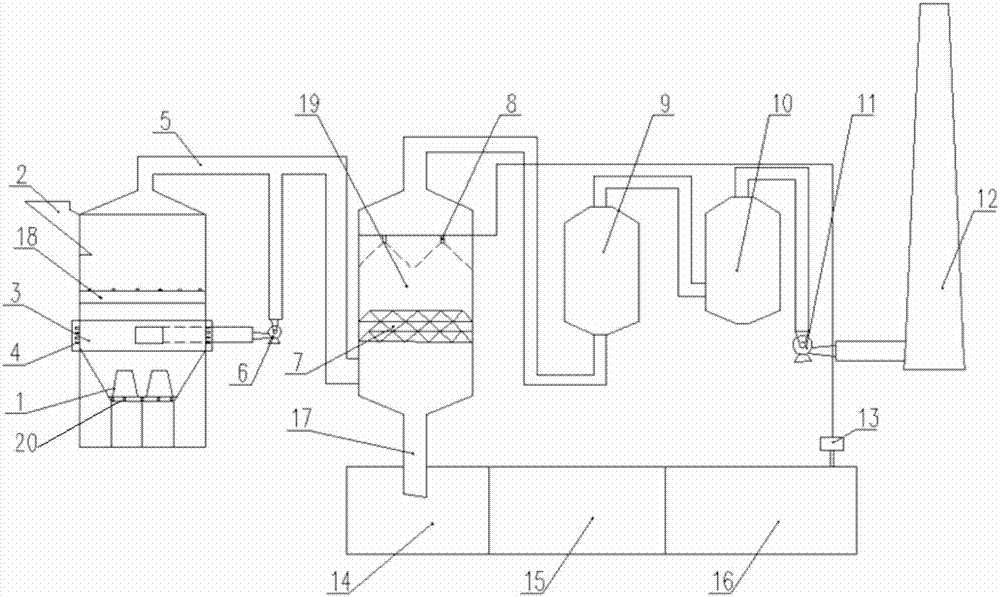

[0024] see figure 1 , figure 2 , the present invention provides a small domestic waste pyrolysis gasification furnace and purification system,

[0025] A small domestic waste pyrolysis gasifier, including a furnace body, the top of the furnace body is provided with a smoke exhaust port, the upper part of the furnace body is provided with a feed port 2, and the feed port 2 is provided with a material guide The garbage deflectors form a feed hopper, and the furnace body is provided with a first grate group 18 below the feed port 2, and the first grate group 18 divides the furnace body into a pyrolysis chamber on the upper side and a pyrolysis chamber on the upper side. The combustion chamber on the lower side, the bottom of the combustion chamber is provided with a second grate group 20, the first grate group 18 and the second grate group 20 are fixed grate groups, and the fixed grate group is made of resistant Composed of a high-temperature fixed furnace bridge and a high-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com