Graphite negative electrode material for low temperature, preparation method thereof and lithium battery

A graphite anode and graphite material technology, applied in the directions of graphite, battery electrodes, secondary batteries, etc., can solve problems such as slow kinetic process, and achieve the effect of simple and easy method, conducive to infiltration, and satisfying user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention provides a method for preparing a low temperature graphite anode material, comprising the steps of:

[0041] S1: The organic nitrogen-containing metal frame compound containing cobalt is constructed in the surface of the graphite to obtain a graphite material of coating a nitrogen-containing organic metal frame compound (i.e., ZiF-67), i.e., graphite @ ziF-67.

[0042] The median particle diameter (D50) of the graphite can preferably be 4 to 13 um graphite.

[0043] Among them, the nitrogen-containing organic metal frame compounds of cobalt can be soluble with a nitrogen-containing organic compound in the surface of the graphite. Among them, soluble cobalt salt is preferably one or more of sulfate, cobalt nitrate, and cobalt chloride, preferably 2-methylimidazole. Preferably, the surface of the graphite can be treated with an anionic surfactant, CO 2+ Adsorbed on the surface of graphite, then add 2-methylimidazole to react, CO 2+ The distribution will ...

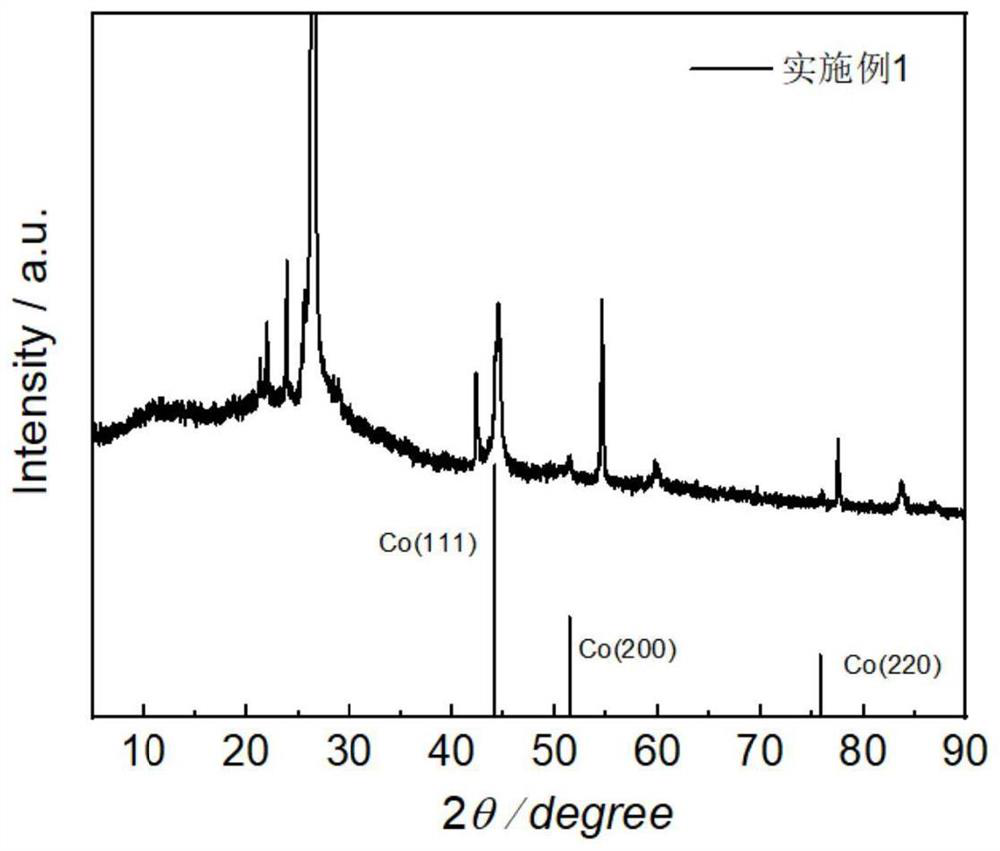

Embodiment 1

[0058] A method for preparing a low temperature graphite anode material, comprising the steps of:

[0059] S1: Pretreatment was carried out by a graphite surface of D50 of 4 to 6 um using sodium D50, wherein sodium dodecyl sulfonate and graphite were 1: 0.7. The mass concentration of sodium dodecyl sulfonate was 8 g / L, and NaCl was dissolved with 0.3 mol / L.

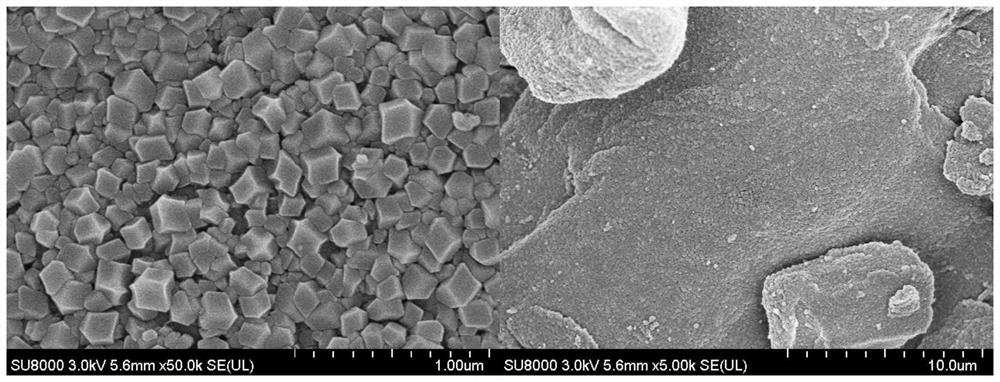

[0060] S2: Cobalt chloride and 2-methylimidazole were formed by hydrothermalization of the graphite surface after pretreatment, and a graphite material coated with ZIF-67 was obtained. Among them, 0.3 mmol of cobalt chloride was added to 1 g of cobalt chloride, and the molecular ratio of 2-methylimidazole was 1: 5. The thickness of the formed ZIF-67 coating is 60 nm. Micro-morphology figure 1 As shown, it is possible to see that ZIF-67 is successfully loaded on the surface of the graphite, which is a polyhedron structure, and the particle size is about 200 nm.

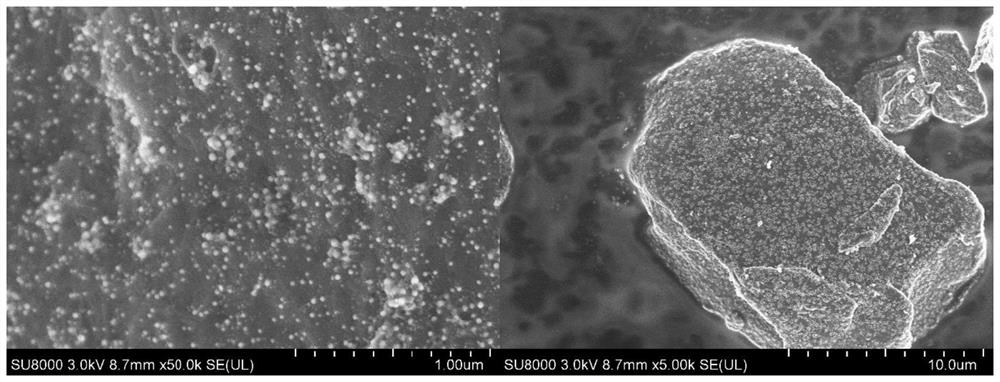

[0061] S3: Pyrolysis treatment of graphite materials coated ...

Embodiment 2

[0068] A method for preparing a low temperature graphite anode material, comprising the steps of:

[0069] S1: Pretreatment of a graphite surface of D50 of 5 to 8 um using polystyrene sulfonate, wherein the mass ratio of sodium polystyrene sulfonate and graphite is 1: 1. The mass concentration of sodium polystyrene sulfonate is 22 g / L, and NaCl is dissolved with 0.7 mol / L.

[0070] S2: Through the cobalt sulfate and 2-methylimidazole in the pretreated graphite surface, ZIF-67 is formed by hydrothermal method, resulting in a graphite material coated with ZIF-67. Among them, 0.5 mmol of cobalt sulfate is added, the molar ratio of cobalt sulfate and 2-methylimidazole is 1: 7. The thickness of the formed ZIF-67 coating is 100 nm.

[0071] S3: Pyrolysis treatment of graphite materials coated with ZIF-67 at a temperature of 700 ° C to obtain a graphite negative electrode material for a low temperature.

[0072] The lithium battery was prepared using the graphite anode material and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com