Efficient biomass carbon electrochemical oxygen reduction catalyst and preparation method and application thereof

A carbon-based catalyst and electrochemical technology, applied in the field of electrocatalysis, can solve the problems that the catalytic performance of low-cost catalysts cannot meet the requirements and high cost, and achieve the effects of improving electrocatalytic performance, low cost, and improved dispersion state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

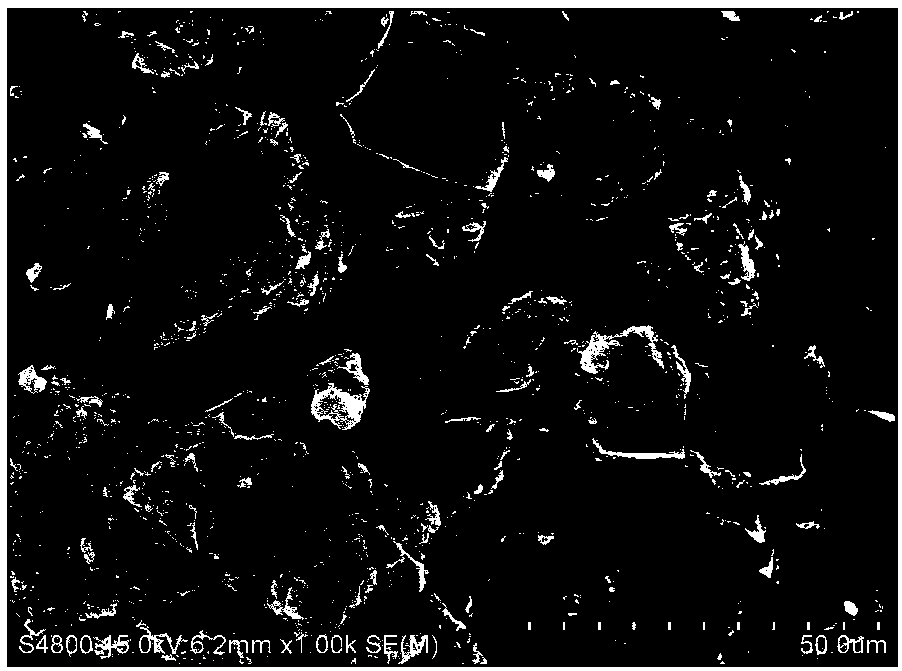

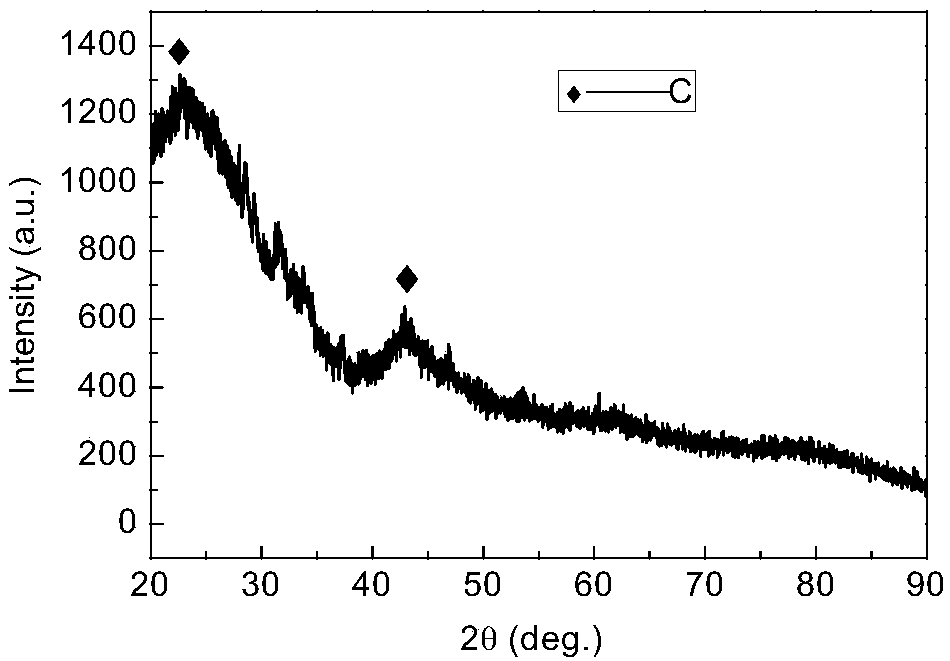

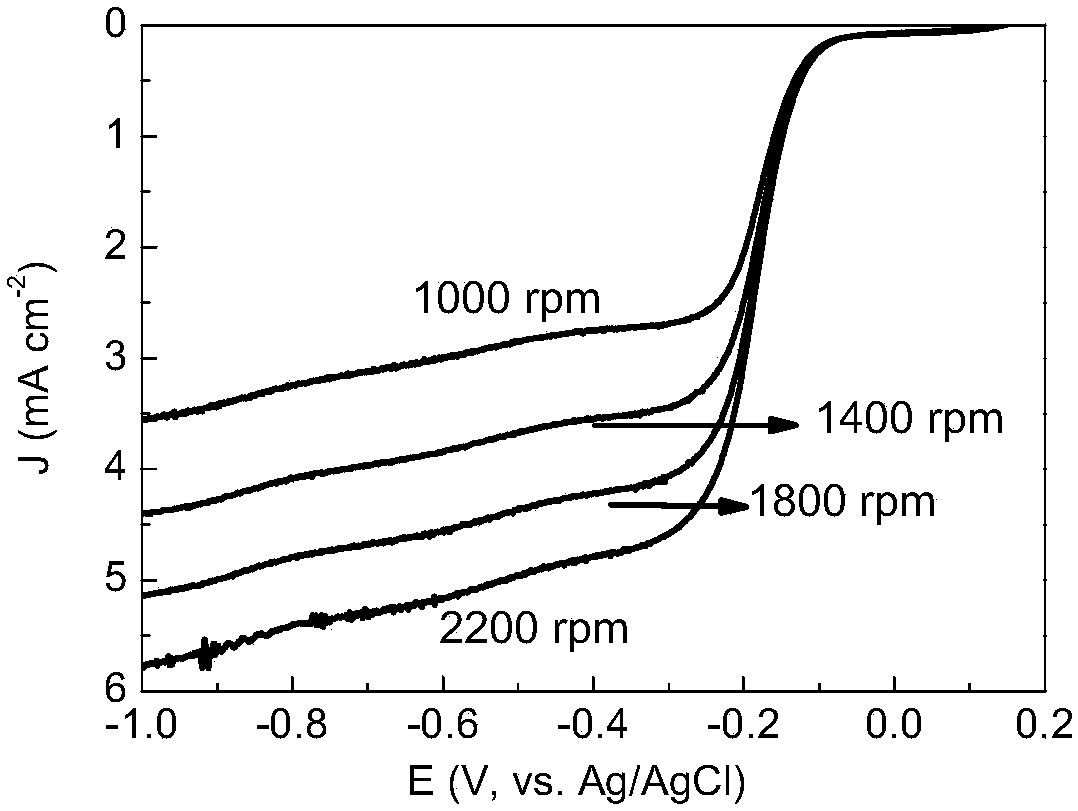

[0044] Collect the wild fungus fungus, soak the collected fungus in excess deionized water and 45 Hz ultrasonic for 12 hours, and change the deionized water every 2 hours until the cleaning is completed. Put the ultrasonically cleaned fungus in excess ethanol, soak it ultrasonically at 45 Hz for 4 hours, then take it out and let it dry naturally in the air. Finally, put the naturally dried fungus in a freeze-drying device to further remove the residual moisture inside the fungus. The freeze-drying temperature is minus 50°C and the freezing time is 48 hours. Put the freeze-dried fungus in a pulverizer for crushing and powdering, and pass through a 200-mesh sieve to obtain the fungus biomass powder. Put the powder in a corundum crucible, the volume of the powder is about one-fifth of the volume of the crucible, and then heat-treat it at 300°C for 1 hour in a nitrogen atmosphere, cool to room temperature and take it out to obtain pre-carbonized fungus. The pre-carbonized fungus ...

Embodiment 2

[0047] Wild fungus fungus was collected, and the collected fungus was ultrasonically soaked in deionized water for 18 hours, and the deionized water was replaced every 2 hours until the cleaning was completed. Put the ultrasonically cleaned fungus in excess ethanol, soak in 45 Hz ultrasonic for 5 hours, take it out and let it dry naturally in the air. Finally, put the naturally dried fungus in a freeze-drying device to further remove the residual moisture inside the fungus. The freeze-drying temperature is minus 50°C and the freezing time is 60 hours. Put the freeze-dried fungus in a pulverizer for crushing and powdering, and pass through a 200-mesh sieve to obtain the fungus biomass powder. Put the powder in a corundum crucible, the volume of the powder is about one-fifth of the volume of the crucible, then heat-treat at 350°C for 1.5 hours under a nitrogen atmosphere, cool to room temperature and take it out to obtain pre-carbonized fungus. The pre-carbonized fungus prepare...

Embodiment 3

[0050] Collect the wild fungus fungus, soak the collected fungus in deionized water at 45 Hz ultrasonic for 24 hours, and change the deionized water every 2 hours until the cleaning is completed. Put the ultrasonically cleaned fungus in ethanol, soak in ultrasonic for 6 hours, take it out and let it dry naturally in the air. Finally, put the naturally dried fungus in a freeze-drying device to further remove the residual moisture inside the fungus. The freeze-drying temperature is minus 50°C and the freezing time is 72 hours. Put the freeze-dried fungus in a pulverizer for crushing and powdering, and pass through a 200-mesh sieve to obtain the fungus biomass powder. The powder is placed in a corundum crucible, the volume of which is about one-fifth of the volume of the crucible, and then heat-treated at 400°C for 2 hours in a nitrogen atmosphere, cooled to room temperature and taken out to obtain pre-carbonized fungus. The pre-carbonized fungus prepared by the above steps was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com