Phosphoric acid method active carbon production method

A technology for activated carbon production and phosphoric acid, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as waste of heat and raw materials, reduce production costs, improve full utilization efficiency, and recover simple and effective phosphoric acid Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

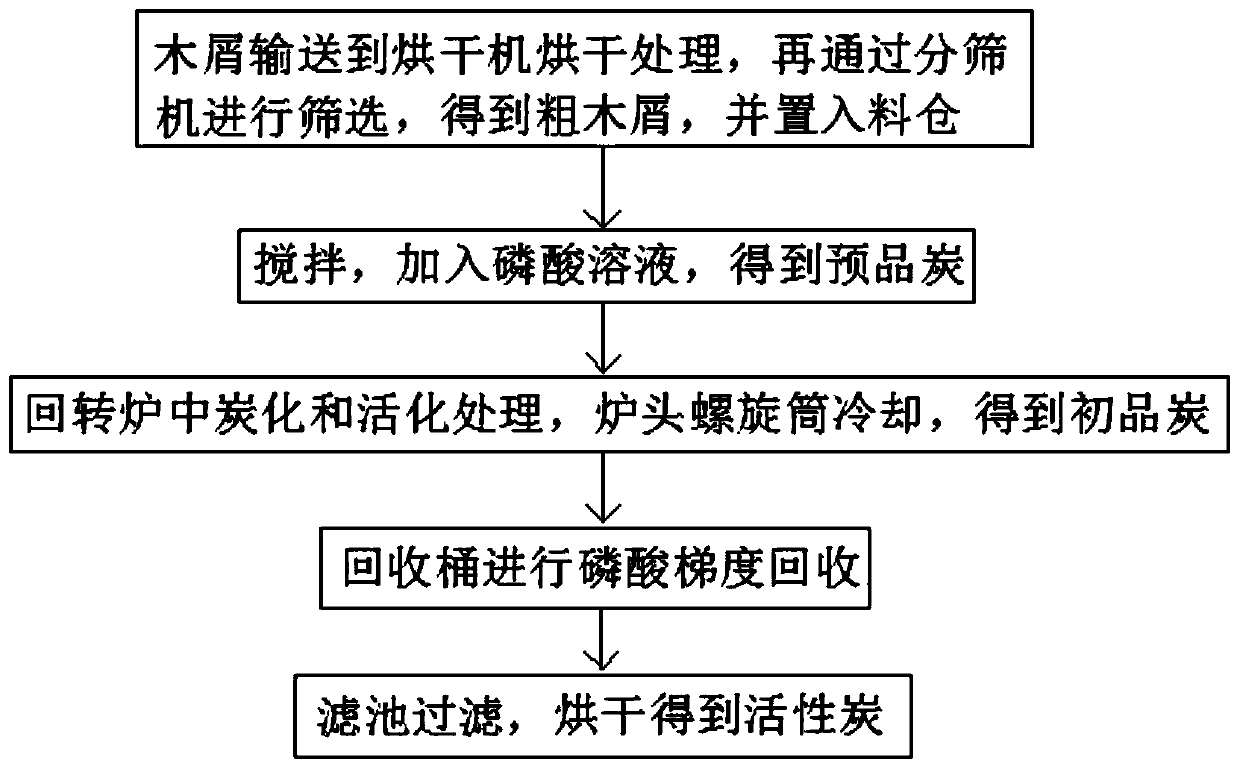

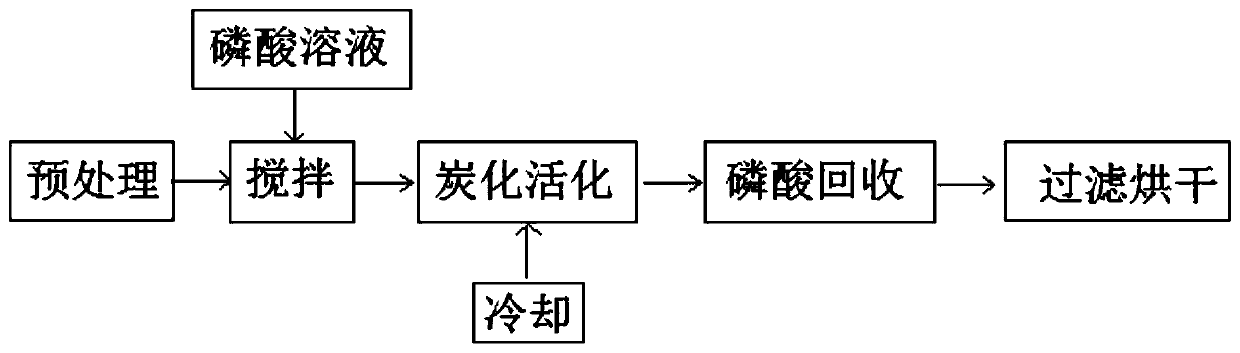

[0033] In one embodiment of the present invention, refer to Figure 1 to Figure 3 , provide a kind of phosphoric acid process active carbon production method, comprise the following steps:

[0034] S1. Pretreatment: transport the sawdust to the dryer for drying treatment, and then screen through the sieving machine to obtain coarse sawdust and put it into the silo;

[0035] S2, stirring; the coarse wood chips are transported from the silo to the double auger device, stirred, and phosphoric acid solution is added thereto to obtain pre-product carbon;

[0036] S3, carbonization and activation: the pre-product charcoal is transported to the rotary furnace by a belt conveyor for carbonization and activation treatment, and a spiral cylinder is set at the furnace head of the rotary furnace for cooling to obtain the primary product charcoal;

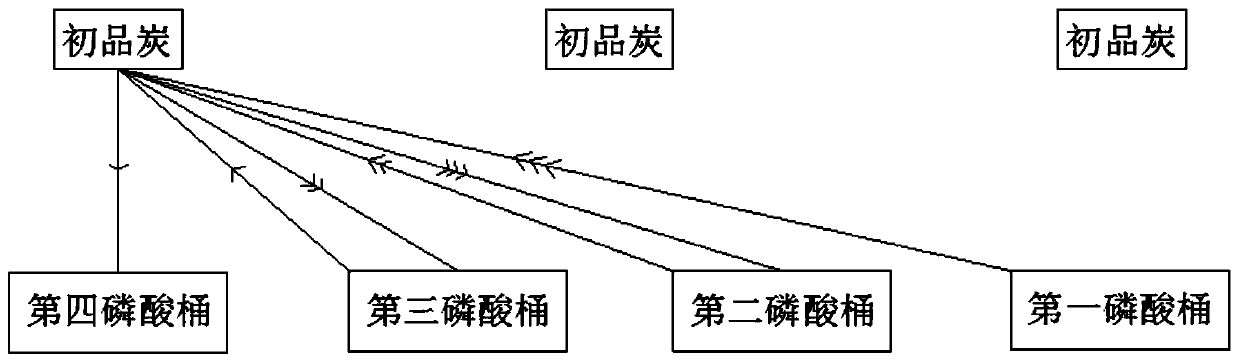

[0037] S4. P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com