Recycled concrete block prepared from CO2 reinforced recycled powder

A technology for concrete blocks and recycled powder, which can be used in applications, household appliances, ceramic products, etc., and can solve problems such as reducing the performance of prepared concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

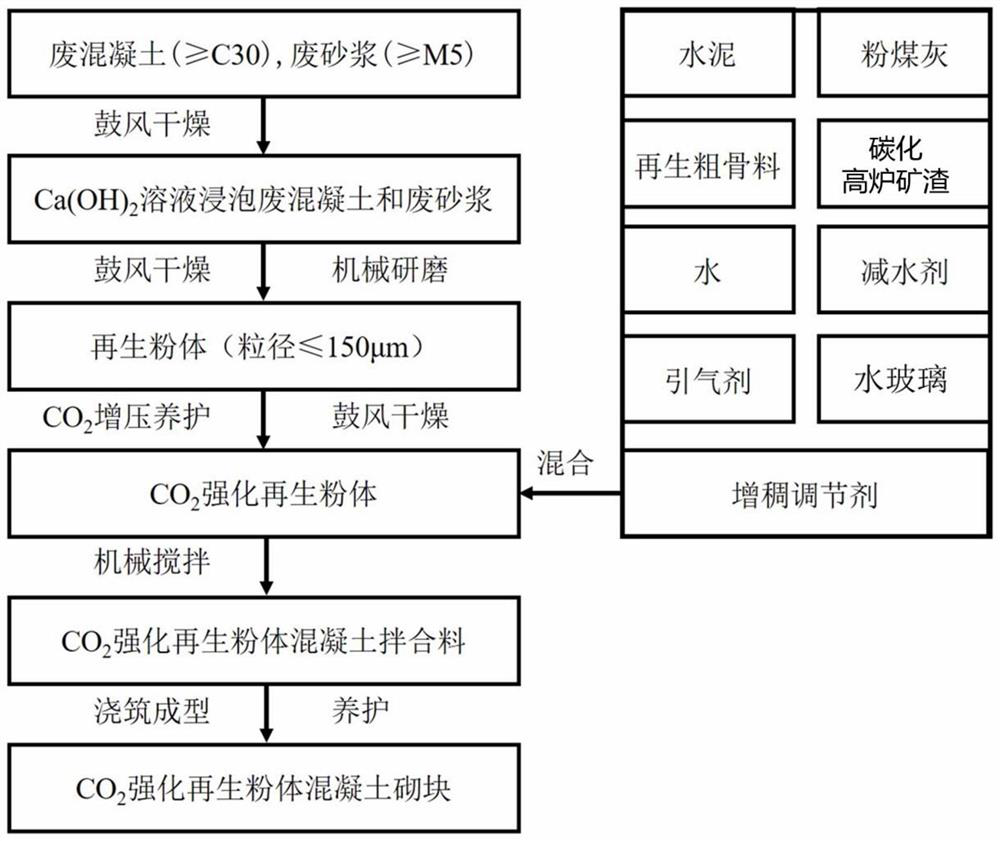

Method used

Image

Examples

Embodiment 1

[0085] First, prepare a CO 2 Strengthen the recycled powder, that is, place the waste concrete and waste mortar in the construction waste in 0.0224mol / L saturated Ca(OH) 2 Soak in the solution at 20°C for 1 hour to make the waste concrete and waste mortar fully absorb Ca(OH) 2 After solution, the waste concrete and waste mortar were taken out and placed in a blast dryer for the first drying at 50°C for 30 hours, dried to constant weight, and then ground by a ball mill for 1.5 hours to form a powder, and then the powder was used Mechanical high-strength vibration sieving to obtain the required recycled powder with a particle size of ≤45 μm. Among them, the strength of waste concrete ≥ C40. The strength of waste mortar ≥ M20.

[0086] Then the obtained regenerated powder was placed in CO 2 In the pressurized curing box, it is cured for 35 hours in a curing environment with a temperature of 20°C, a relative humidity of 60%, and a curing pressure of 0.3Mpa. After the carboniza...

Embodiment 2

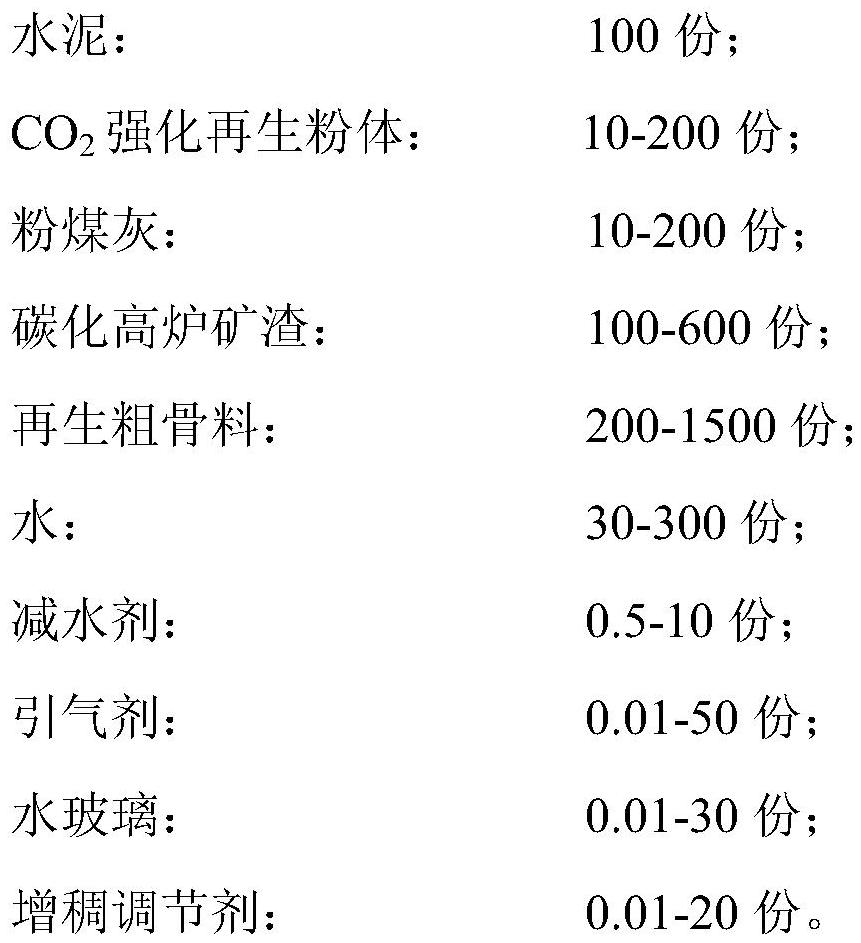

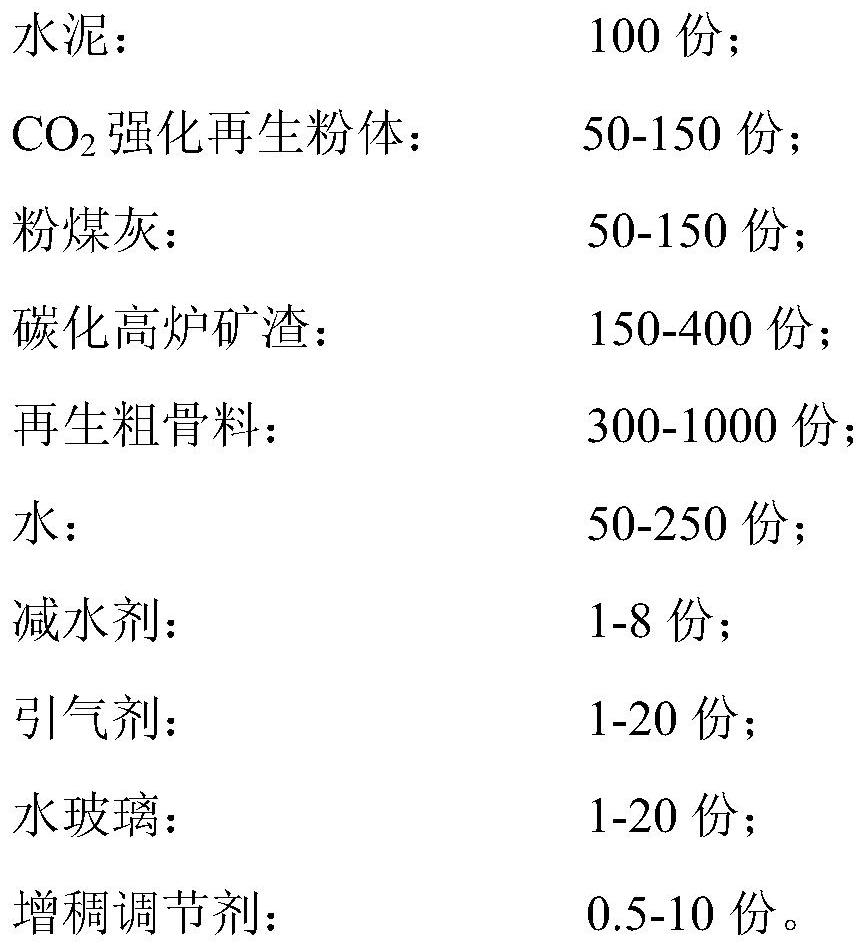

[0089] According to the weight ratio of recycled concrete block, measure and take ordinary portland cement 100g, the CO prepared in embodiment 1 2 Strengthen regeneration powder sample 1*90g, fly ash 90g, carbonized blast furnace slag sample 1*300g in saturated surface-dry state, and 650g recycled coarse aggregate in saturated surface-dry state, perform the first slow stirring for 1-2 minutes, until the ingredients are evenly mixed. Then measure 70g of tap water, 2g of polycarboxylate water reducer, 1g of rosin soap foaming agent, 4g of water glass, and 1.8g of methyl cellulose. After mixing, add in 3 times, carry out rapid stirring for the second time for 2 minutes, and obtain admixture. The obtained mixture is poured under the conditions of temperature ≥ 20°C and relative humidity ≥ 80%, and then demoulded by mechanical pressing, and the standard curing is carried out at temperature ≥ 20°C and relative humidity ≥ 95% for 28 days to obtain concrete blocks Sample 1#.

[009...

Embodiment 3

[0092] According to the weight ratio of recycled concrete block, measure and take ordinary portland cement 100g, the CO prepared in embodiment 1 2 Strengthen regeneration powder sample 1*90g, fly ash 90g, carbonized blast furnace slag sample 1*300g in saturated surface-dry state, and 650g recycled coarse aggregate in saturated surface-dry state, perform the first slow stirring for 1-2 minutes, until the ingredients are evenly mixed. Then measure 70g of tap water, 2g of polycarboxylate water reducer, 3g of rosin-based air-entraining agent, 4g of water glass, and 1.2g of methylcellulose. After mixing, add in 3 times, and then stir rapidly for the second time for 2 minutes to obtain admixture. The obtained mixture is poured under the conditions of temperature ≥ 20°C and relative humidity ≥ 80%, and then demoulded by mechanical pressing, and the standard curing is carried out at temperature ≥ 20°C and relative humidity ≥ 95% for 28 days to obtain concrete blocks Sample 2#.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com