High-graphitization graphite thick film and preparation method thereof

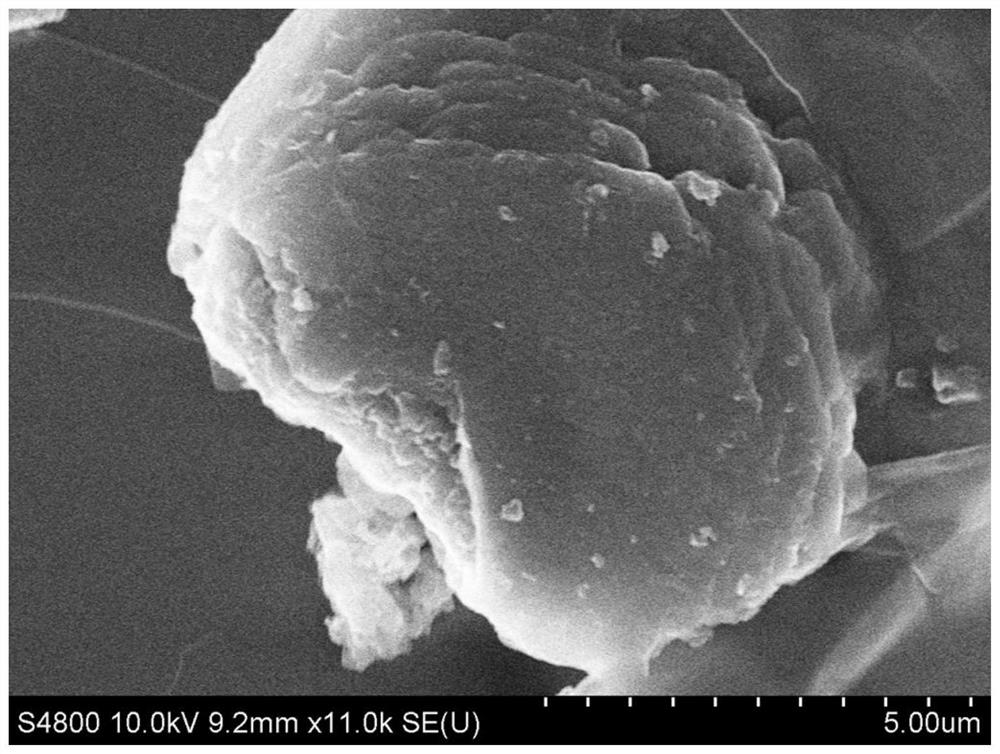

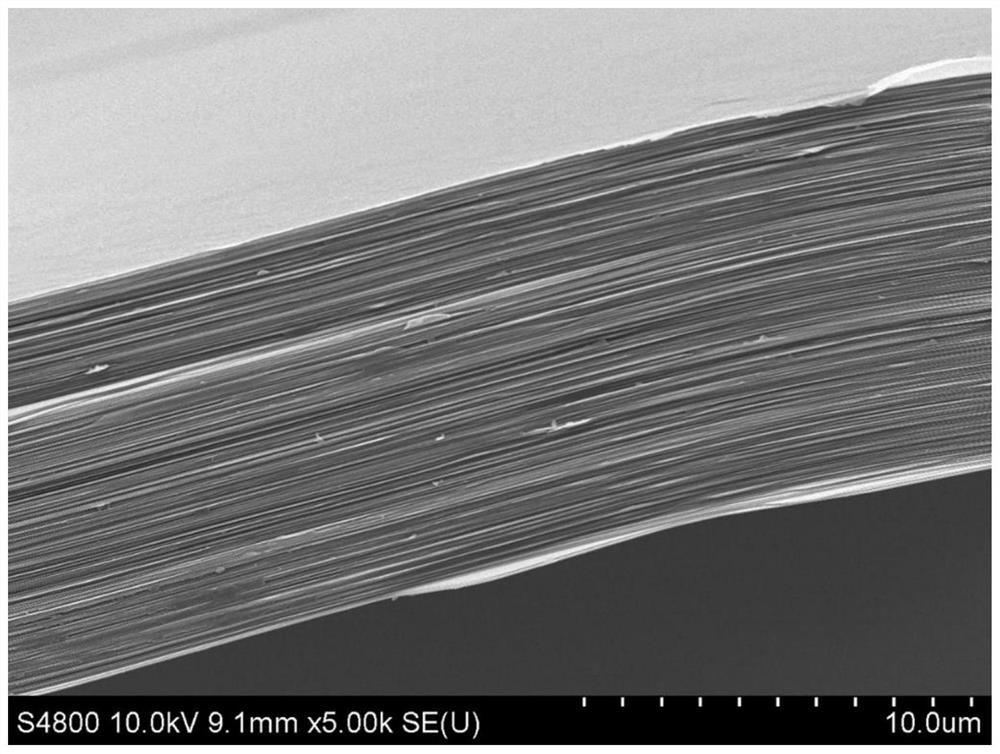

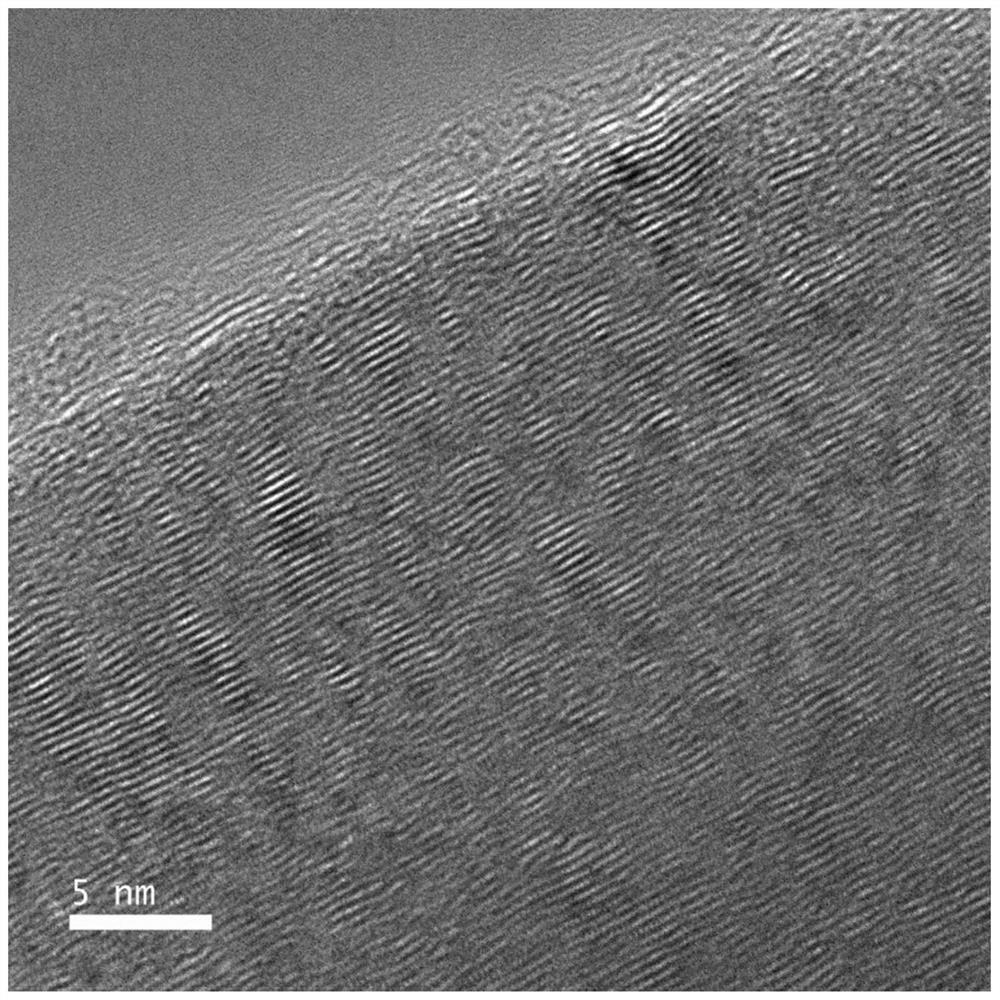

A technology of high graphite and graphite, which is applied in the field of high graphitized graphite thick film and its preparation, can solve the problems of uneven dispersion of filler matrix and incomplete graphitization of graphite film, achieve high degree of surface and internal graphitization, and solve internal The effect of incomplete graphitization and regular microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Preparation of graphite-phase carbon nitride-doped polyimide film:

[0052] Put 0.04g graphite phase carbon nitride in 10mL N-methylpyrrolidone, pressurize and ultrasonically disperse for 3h to obtain graphite phase carbon nitride dispersion; put 2.4g m-phenylenediamine in 100mL N-methylpyrrolidone, Magnetically stirred for 1 h to obtain a diamine solution.

[0053] Mix the graphite-phase carbon nitride dispersion and the diamine solution, and stir magnetically for 1 hour. Under the protection of nitrogen, add 11.6 g of bisphenol A dianhydride to the solution in batches, and react with mechanical stirring at a speed of 300 r / min for 7 hours. A polyamic acid solution was obtained, wherein the polyamic acid accounted for 14% by mass of the organic solvent, and the graphitic carbon nitride accounted for 0.29% by mass of the polyamic acid. Scrape-coat this solution on a glass plate with a thickness of 1000 μm, place the glass plate in a high-temperature oven at a tempe...

Embodiment 2

[0057] (1) Preparation of boron nitride-doped polyimide film:

[0058] Put 0.04g boron nitride in 10mL N-methylpyrrolidone, pressurize and ultrasonically disperse for 3h to obtain a boron nitride dispersion; put 5g polyimide film in 25.7mL N,N-dimethylformamide , adding the aforementioned boron nitride dispersion, and stirring evenly to obtain a polyimide glue solution containing boron nitride. Wherein polyimide accounts for 14% of the mass of the organic solvent, and boron nitride accounts for 0.29% of the mass of the polyimide. Scrape-coat this glue solution on a glass plate with a thickness of 2000 μm, place the glass plate in a high-temperature oven at a temperature of 100°C, and keep it for 1.5 hours to obtain a boron nitride-doped polyimide film with a film thickness of 108 μm .

[0059] (2) The boron nitride-doped polyimide film was placed in a carbonization furnace and carbonized at high temperature under an argon atmosphere. The end temperature of carbonization was ...

Embodiment 3

[0062] (1) Preparation of titanium carbide doped polyimide film:

[0063] Put 0.015g of titanium carbide in 10mL of N,N-dimethylformamide, pressurize and ultrasonically disperse for 2 hours to obtain a titanium carbide dispersion; mix 0.66g of p-phenylenediamine with 1.22g of 4,4'-diaminodiphenyl Ether was placed in 25.7mL N,N-dimethylformamide, and magnetically stirred for 1h to obtain a diamine solution.

[0064] Mix the titanium carbide dispersion and the diamine solution, stir magnetically for 2 hours, and under the protection of nitrogen, add 1.33g of pyromellitic dianhydride and 1.79g of biphenyltetracarboxylic dianhydride to the solution in batches at a speed of 500r / The reaction was carried out with mechanical stirring for 8 hours to obtain a polyamic acid solution, wherein the polyamic acid accounted for 14% of the mass of the organic solvent, and titanium carbide accounted for 0.3% of the mass of the polyamic acid. Squeegee-coat this solution on a glass plate with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com