Method for making surface antibiotic product using physical gaseous phase deposition technology

A physical vapor deposition, surface antibacterial technology, used in ion implantation plating, metal material coating process, coating and other directions, can solve the problem that the reaction gas cannot reach the surface of the plated workpiece, the concentration of argon gas becomes low, and the reflection is not comprehensive, etc. problem, to achieve the effect of beautiful appearance, simple and convenient process production, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

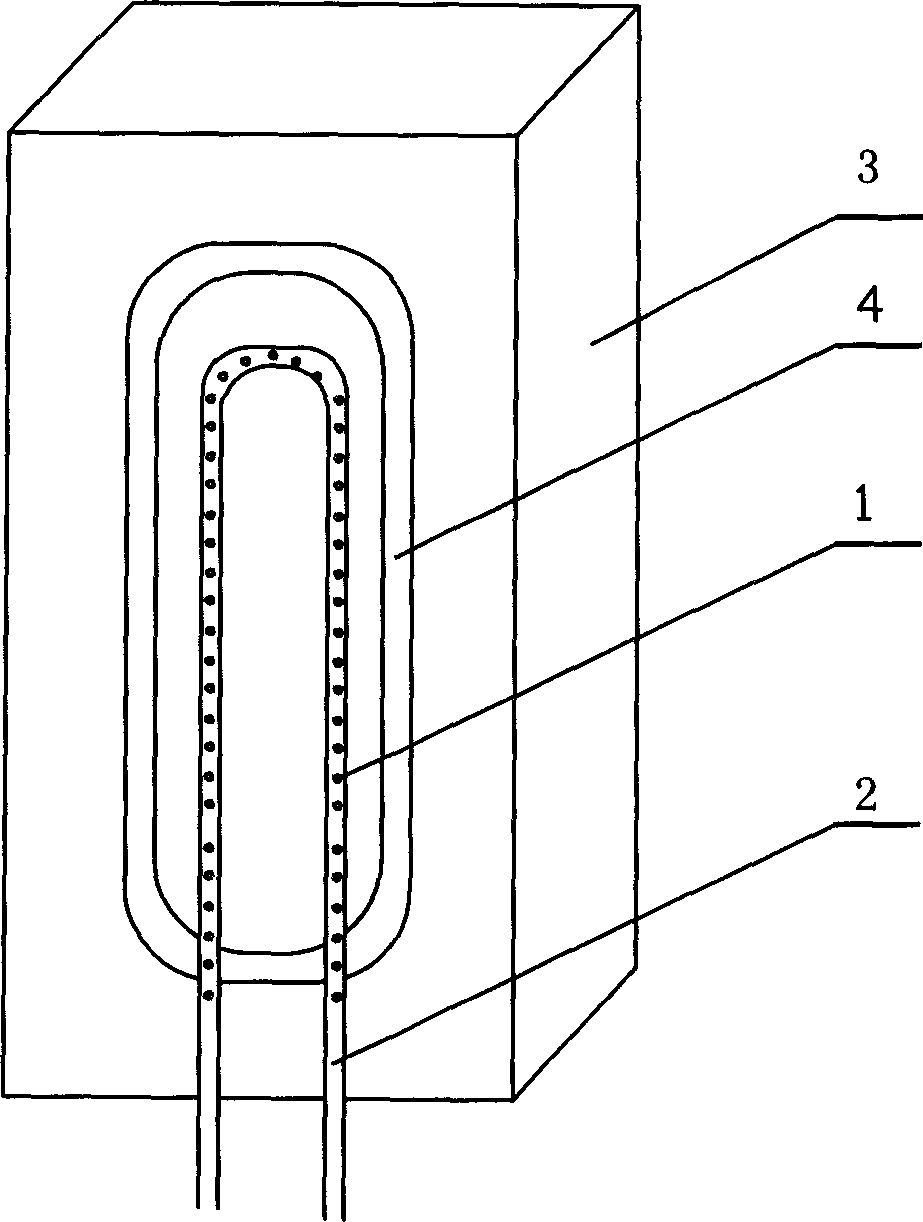

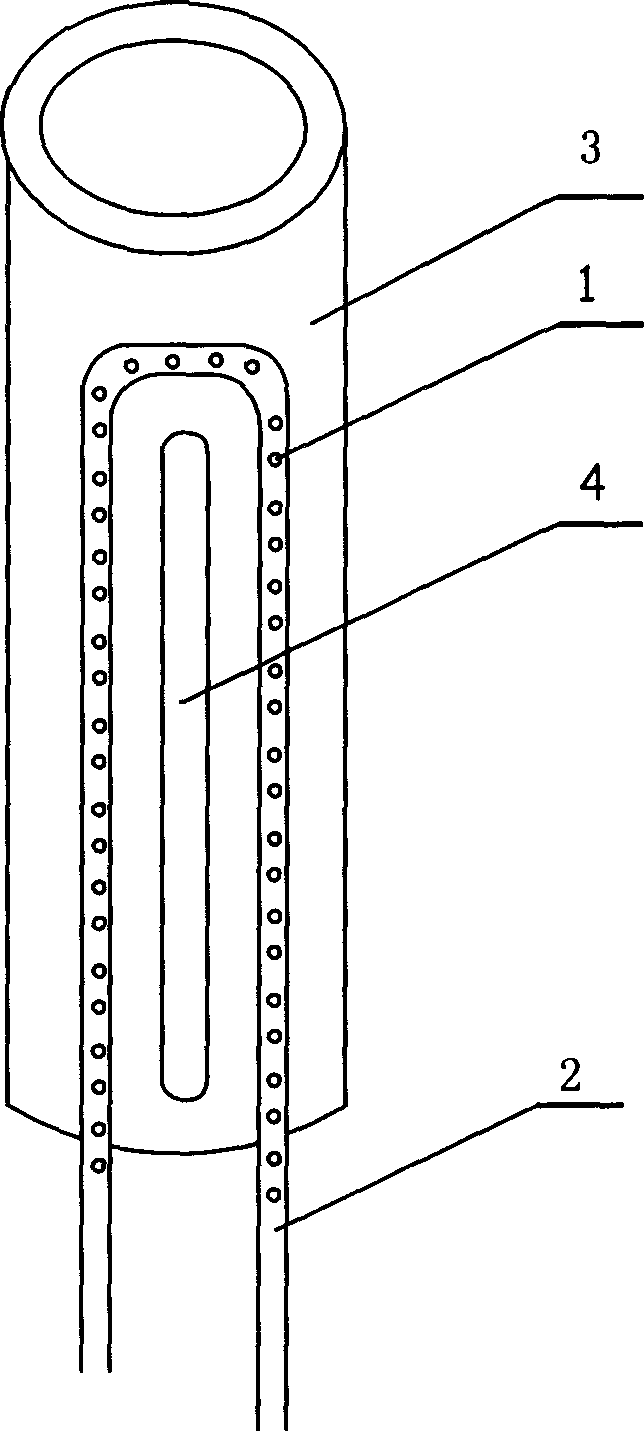

[0018] The invention is carried out in a physical vapor deposition coating furnace. The substrate to be coated is hung in the furnace. The substrate can be a metal material, a non-metal material, a fiber product, a polymer material, a dry implant material or a leather material. The antibacterial target material can be one or more of As, Sb, Se, Hg, Ag, Cu, Zn, Ce, Ca, Co, Ni, Al, Fe, S and its oxides and sulfides. The antibacterial target material The proportion in the film layer is 0.01% to 100%, and there can be other targets with special functions in the film layer, such as titanium, aluminum, zirconium, etc. with wear resistance.

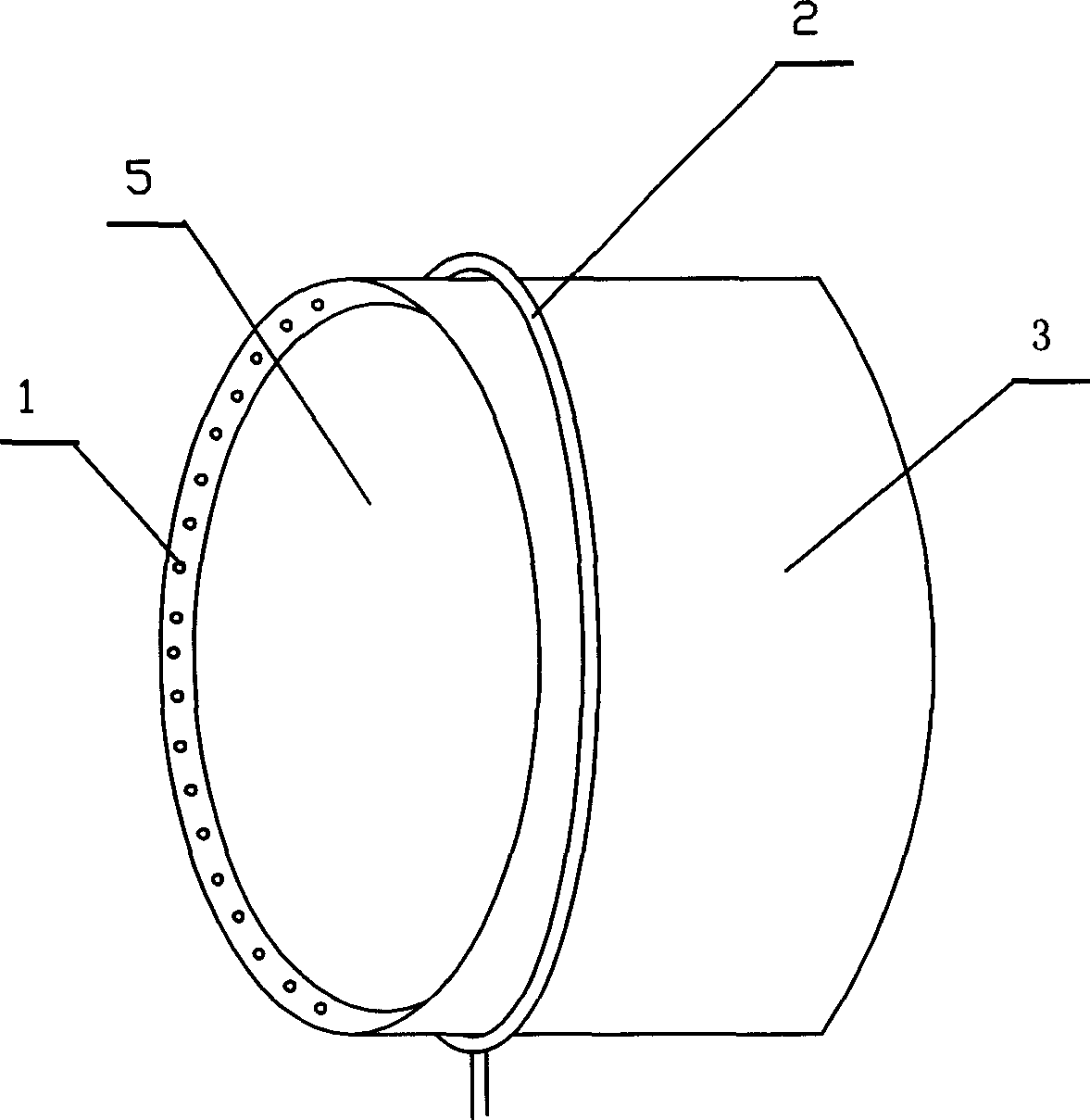

[0019] In the present invention, a number of tiny pores 1 are drilled on the surface of the antibacterial target 3, and the gas tube 2 is used to pass the reaction gas into the pores 1.

[0020] The target 3 can be a planar magnetron target or a cylindrical target. The cylindrical target in the cylindrical target is the first choice when plating pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com